CHAPTER NINE

BIG SALOON DEVELOPMENT

XJ40 to X-308

With the XJ name becoming so well established as a Jaguar luxury model, it was natural to retain it for subsequent models. The first entirely new car to bear it came in 1986 (code named XJ40*). Although this car would be short lived compared to its predecessor, it formed the basis of two other later XJs, coded the X-300* (1994 to 1997) and the X-308* (1997 to 2002). These three model ranges saw Jaguar develop new manufacturing techniques and technologies, including new engines, yet they retained many of the respected traditional elements that set Jaguar apart from other brands.

1986: The Birth of an Entirely New Car

Under British Leyland, the XJ40 went through a traumatic and elongated gestation period. It wasn’t until 1980 that Jaguar got the go-ahead from BL for the car. Over £70 million was invested and it became the most tried and tested car—covering over 5 million miles—that Jaguar had ever produced. The motivation for all this was to improve productivity, reliability, and quality; make the car more economical and technologically advanced; and retain the enviable position in the market place the XJ Series had gained over the years.

Under British Leyland, there was always the “threat” of Jaguar being told to abandon their own engines in favor of the Rover V-8. Because its own engines were so integral to the mystique, Jaguar’s designers cleverly ensured that the inner structure at the front end would not accommodate the wide V-8 engine. This move would bite back during later efforts to fit their own V-12 engine!

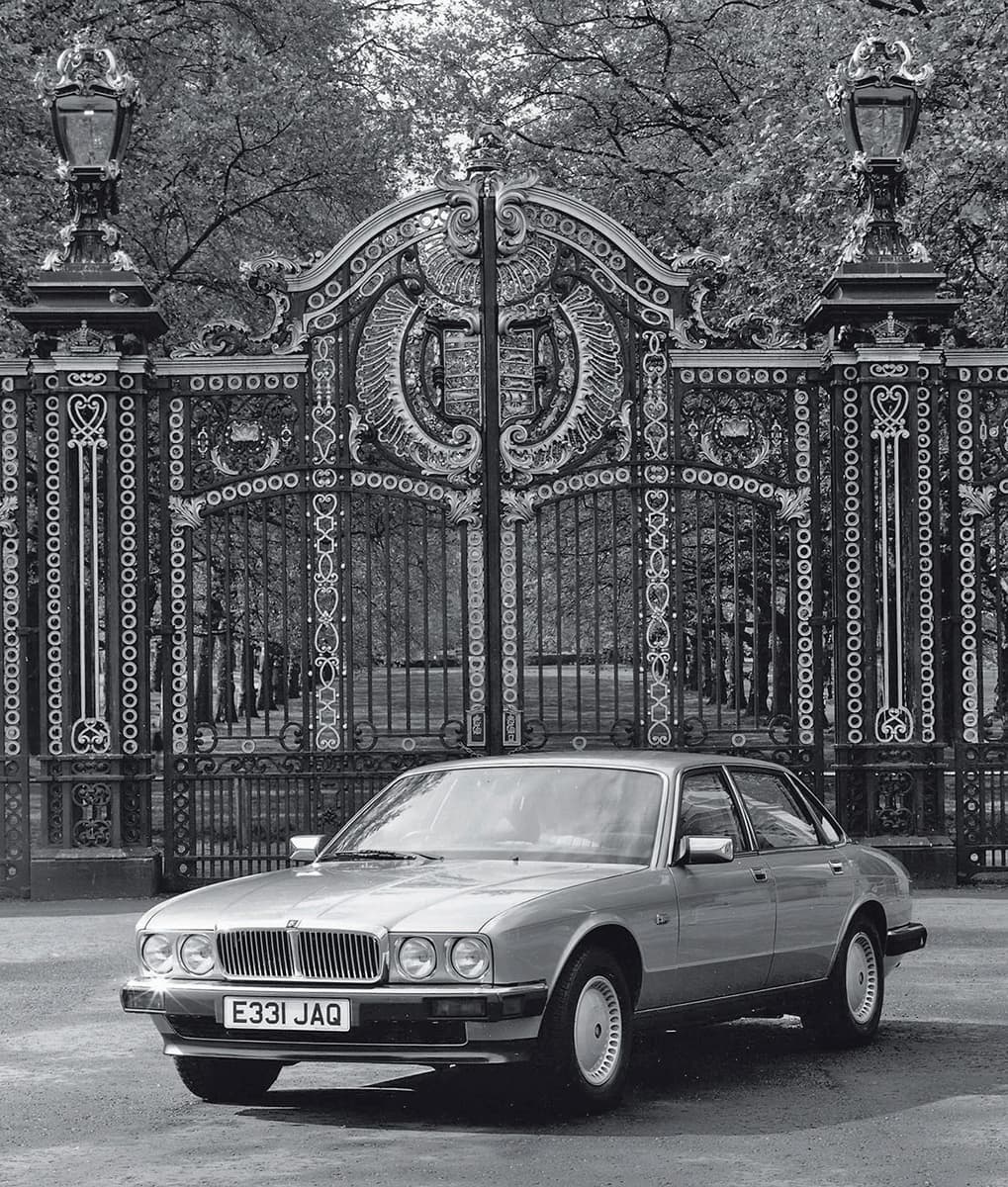

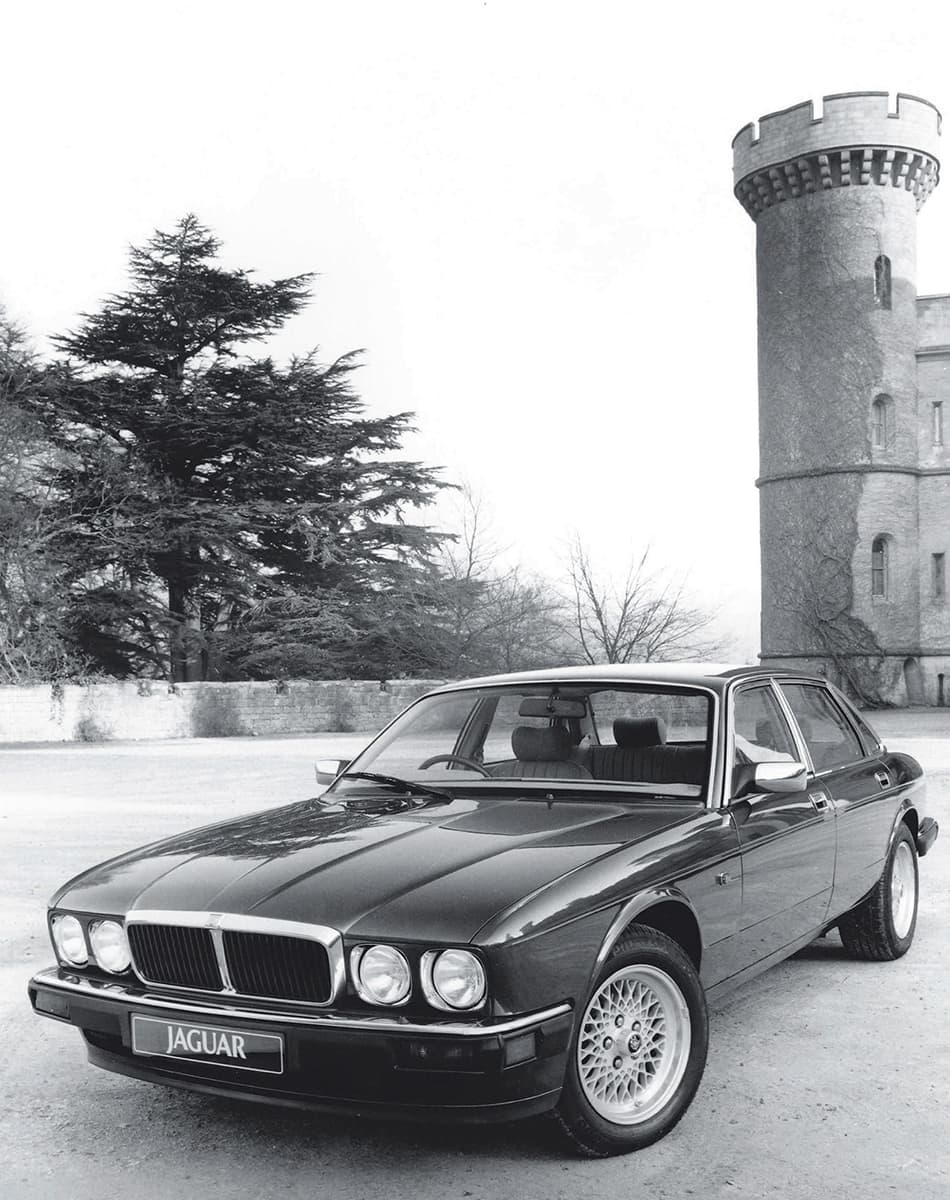

The XJ40 was a more angular shape following the fashion of the day. This was an early XJ6 model with conventional headlights and plastic wheel trim over steel wheels.

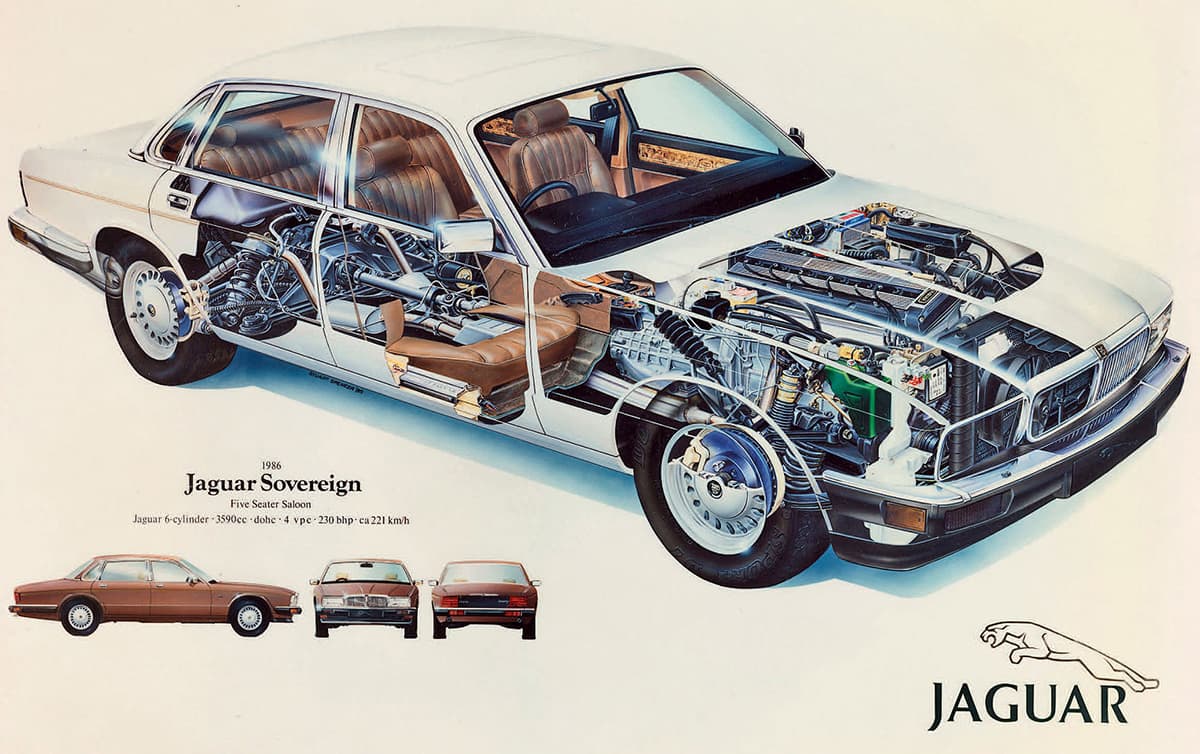

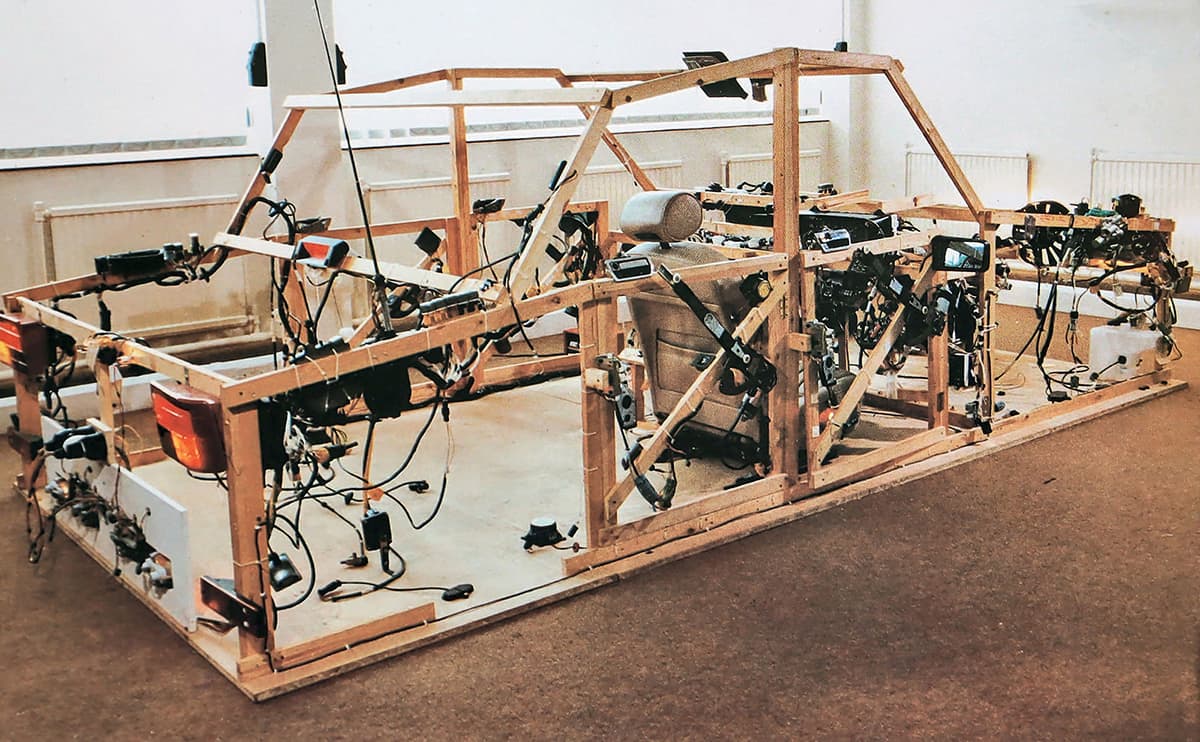

Virtually everything was new about the XJ40 from its bodyshell assembled from fewer panels, to trim, mechanicals, and electronics.

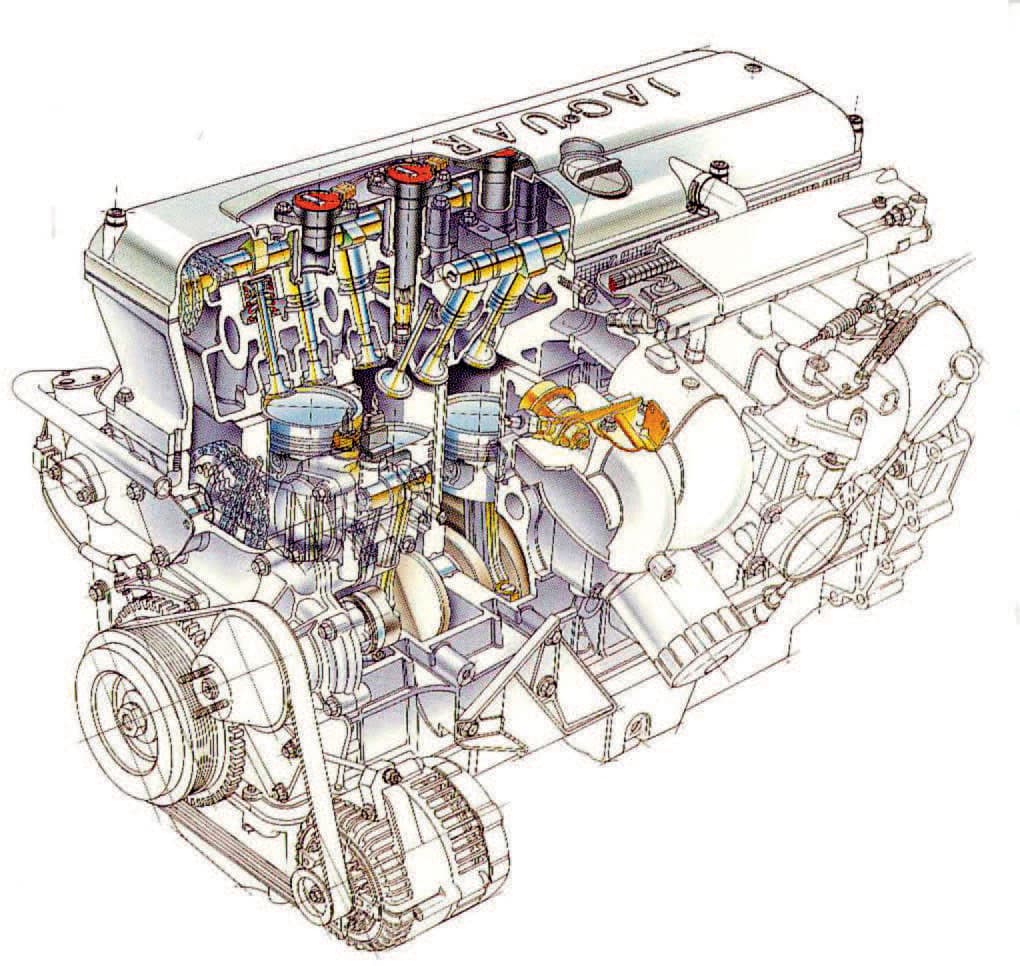

Two new six-cylinder engines featured in the XJ40 along with Jaguar’s “J-gate” transmission and a new suspension.

With some in-house confusion over whether to retain the four-headlamp treatment of previous XJs, a compromise was reached, with these and more modern rectangular singular integrated units used for the various models. New rubber bumpers were fitted with chromed top blades, now incorporating auxiliary lighting with reflectors to the sides. Under the bumper, a new air dam was designed to aid aerodynamics.

A rectangular radiator grille was retained, but it was more upright. The bonnet panel was very flat with a slightly raised central area but no chrome adornment, leading to an enlarged windscreen area, and for the first time in a Jaguar, a single centrally mounted windscreen wiper.

The relatively flat body sides incorporated a waist swage line (the Daimler model would feature full-length chrome trims), and a further horizontal line at a lower level extending the full length between wheel arches. Jaguar subtly retained the raised haunch over the rear wings. The large side window area was of conventional six-light style, without any quarterlights and retaining brightwork in various forms according to model.

Big changes in rear styling included a raised and flat boot lid which, to help aerodynamics, incorporated a very slight lip continued to the rear wings.

The whole effect of the new styling was much more angular in design, yet it retained many subtle features that made it an easily recognizable Jaguar. As to aerodynamics, the car’s drag figures were 0.762, compared to the Series 3 at 0.849.

In manufacturing the new bodyshell it was essential to cut costs and improve quality, hence the number of individual pressings was reduced by 25 percent. For example, the body side, which used 20 individual welded panels on the Series 3, was just 1 on the XJ40. The body was still of monocoque construction, but it now incorporated two crush tubes running the length of the engine bay, which dissipated energy rather than sending the crash force through the passenger compartment. Other changes to the bodywork ensured a much more rigid structure than the previous model.

The single-use 2.9-liter engine, derived from half a V-12, was fitted only to the XJ40 model and for a limited period.

The XJ40’s electronics were the most advanced of any production car when it was announced.

The interior of the early XJ40 with the unique dashboard instrument layout and J-gate transmission selector on the center console.

The interior of a base model 2.9-liter XJ6 with tweed upholstery and manual transmission. Note also the straight-grained woodwork.

Extensive use was made of zinc-coated steel, lead loading was eliminated, and a more durable, high-quality paint finish incorporated clear coat.

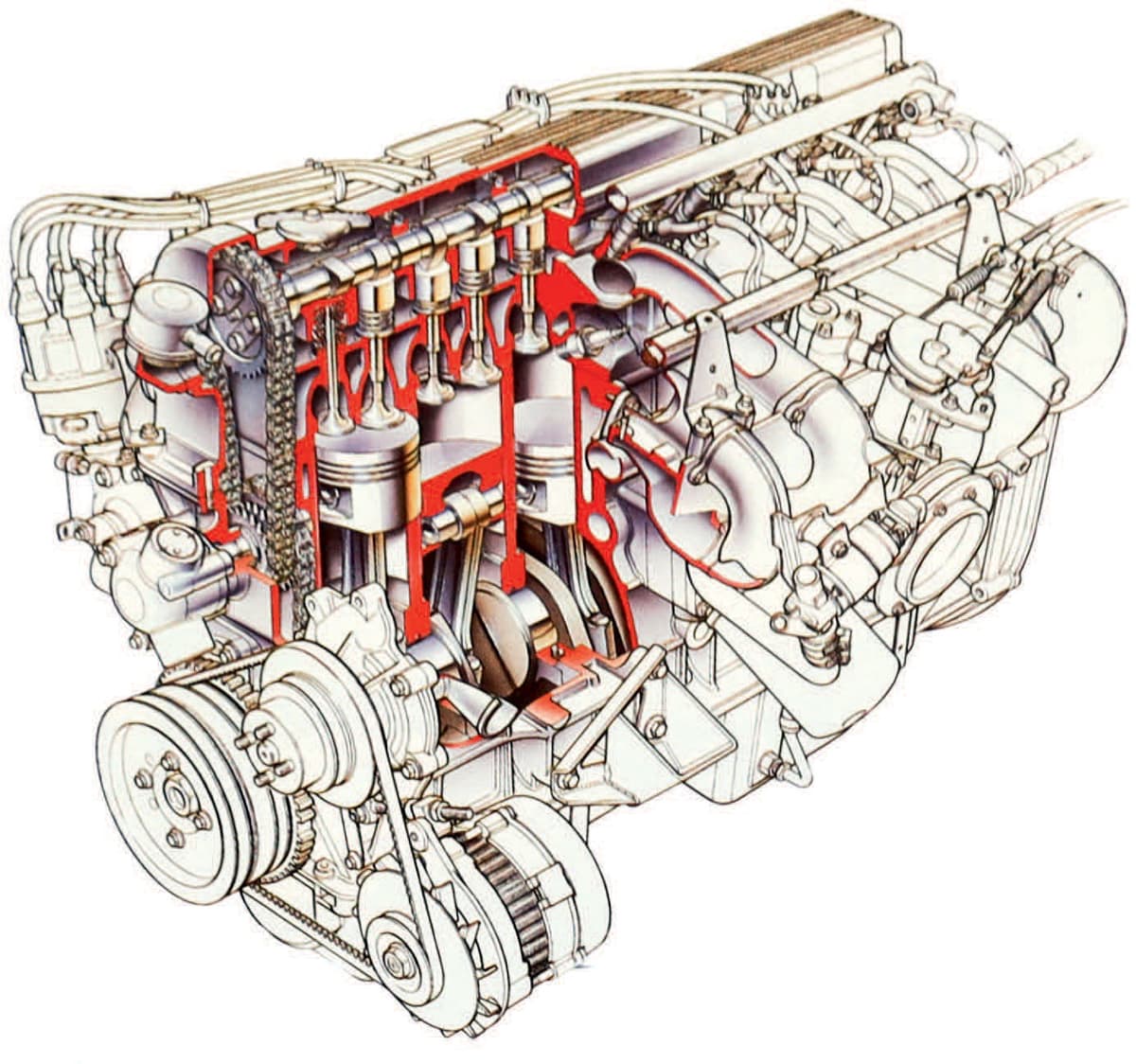

The AJ6 multivalve six-cylinder 3.6-liter engine first launched in the XJ-S in 1983 was available up front, with improvements including quieter valvetrain, modified cam profiles, lighter bucket tappets, new timing tensioners, and better overall engine balance.

The AJ6 engine was the direct replacement for the aged XK unit, but there was a further new engine unique to the XJ40, which stayed in production only until 1991. Of 2.9 liters capacity, it employed the same cylinder block as the 3.6-liter unit (with the same bore); the rest of the engine was similar to Jaguar’s 5.3-liter V-12 design. A short stroke of 74.8 millimeters achieved a displacement of 2,919cc; a high-efficiency single overhead camshaft cylinder head allowed for a much higher compression ratio of 12.5:1. Despite its relatively small capacity, the 2.9 achieved 40 brake horsepower more than the old XK 3.4-liter six-cylinder engine. Produced extensively of aluminum, the new engines created large weight savings over the old XK unit: 25 percent for the 2.9 liter and 30 percent for the 3.6.

The strategy behind the 2.9-liter engine was to enable Jaguar to market a cheaper alternative and cater to countries where vehicle taxation was based on performance and engine size.

With the AJ6 engines, Jaguar offered the five-speed Getrag 265 manual gearbox as an option to an automatic. This option was available for the XJ40, albeit with a larger clutch master cylinder to provide more disengagement travel. The ZF 4HP 22 automatic transmission from the AJ6 equipped XJ-Ss was also used in the XJ40, but with an entirely new Jaguar-designed gear selection method that became known as the “J-Gate.” The gate formed a “J” with normal gear selection taking place on the righthand side. When in “drive,” the selector could be moved over to the left for selection of intermediary gears.

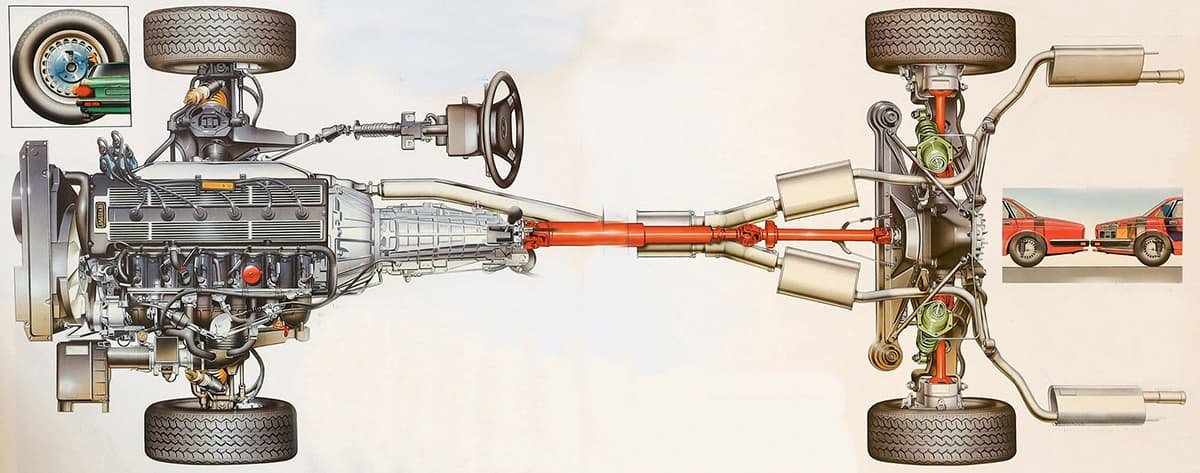

On the front suspension, double wishbones of unequal length and uprights in forged steel with pivoted angles provided anti-dive characteristics. The most significant difference was that the pitch control arms now faced rearwards, anchoring to a stiffer part of the body structure. An all-new subframe was fabricated from upper and lower pressings formed into a beam of simpler construction. It was filled with foam to reduce noise.

The fulcrums and mounting points were machined after assembly to ensure greater accuracy, eliminating the need for camber or steering rack height adjustment.

The engines were slanted over 15 degrees to reduce engine bay height and the engine mounts were placed so that the line between them passed through the minimum inertia axis of the engine, minimizing movement. A third engine mount connected directly to the body.

The rear suspension was also new and for the first time since Jaguar went “independent,” had outboard disc brakes. The suspension embodied a pendulum arrangement allowing fore and aft movement of the lower wishbone inner fulcrum but retained a high degree of lateral stiffness; its aim was to minimize road noise while maintaining accurate geometry for best handling.

A full depth tubular driveshaft and hook joints were used as the top link of each suspension and the lower wishbone was fabricated from two pressings. Because of the outboard discs, each wishbone would take brake torque as well as power and cornering reaction forces.

Another change from the old IRS was use of only a single coil spring and shock absorber per side, the latter containing the bump and rebound stops. The inner fulcrum of the lower wishbone was angled to give both anti-brake-dive and anti-acceleration squat characteristics. The rear subframe was mounted on two rubber bushings at the front and a pair of angled links at the rear.

Another new technology for Jaguar was a self-leveling device for the rear suspension (standard on some models). An engine-driven pump provided hydraulic power for both the self-leveling and the braking system. Using struts instead of conventional shock absorbers to avoid height correction when fitted, each contained a gas accumulator that implemented the height changes with hydraulic pressure in response to an electromechanical sensor connected to the righthand rear wishbone.

Apart from periodic greasing of the rear driveshaft joints, both front and rear suspension were maintenance free.

Steering followed conventional Jaguar practice via power-assisted rack and pinion. For the braking system, there were two major changes: a brake power boost system (instead of a conventional vacuum servo) and ABS.

The power boost system took its power from the engine-driven pump serving the self-leveling device where fitted. A pressure accumulator ensured that even if the engine quit, the system would store sufficient pressure to provide between 8 and 20 stops, more than with a conventional servo.

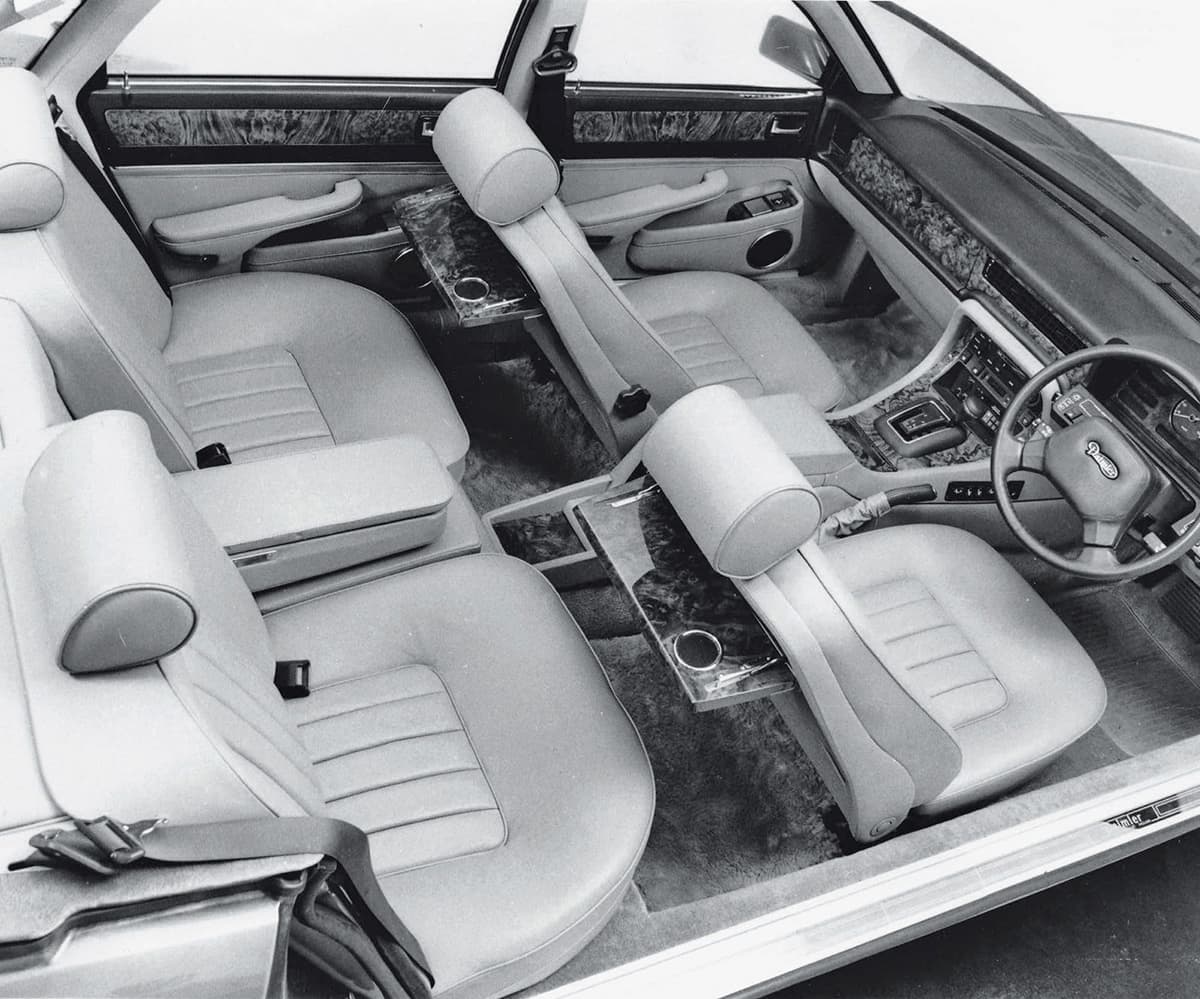

The luxurious interior of the Daimler model, also featured for some overseas markets as the Vanden Plas, featuring appointments such as individualized rear seating and occasional tables.

The ABS system was developed by Bosch. It incorporated a sensor on each wheel feeding information back to an anti-lock processor, which controlled the braking system via three channels—one for each front wheel and one for both the rear brakes. The system incorporated a yaw control to accommodate widely differing side-to-side braking requirements.

New metric TD-sized road wheels incorporated a bead groove for the specially developed Dunlop or Michelin 220/65 VR 390 tires. The system inhibited a punctured tire from coming off the rim and enabled the driver to carry on at low speed for a while, driving on a flat tire.

When launched, the XJ40 was heralded as the most electronically advanced car of its day. There was a wiring system with more reliable connectors, a significant increase in the number of onboard microprocessors, and an advanced diagnostic system. Jaguar adopted a low-current, high-duty earth line switching system carrying just 5 volts instead of the usual 12. No fewer than 90 electronic relays were fitted to the car and there were over 1,700 pieces of electrical wire, all of a higher quality than before. A new Jaguar Diagnostic System was designed for the car, operable from the dealerships via a new computer with connection points and probes for ease of fault finding.

For the interior, the parameters were less weight, better quality, modernity, and that unique Jaguar ambience. Wood and leather were retained wherever possible; otherwise it was all new.

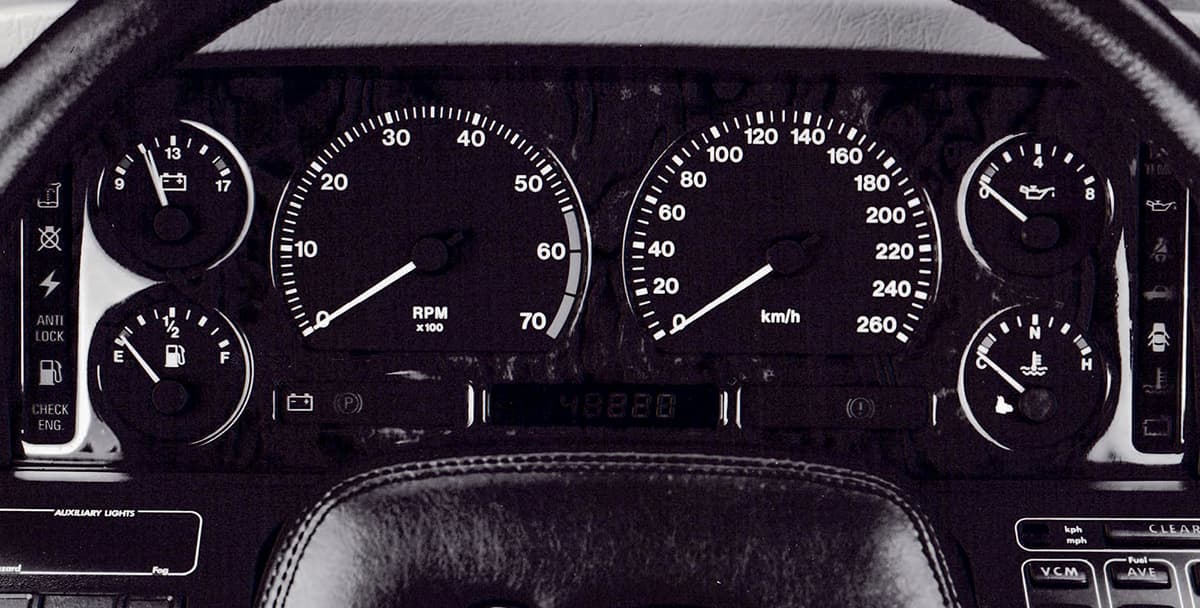

The instrument display in front of the driver was a mix of digital and analog. Traditional speedometer and rev counters were flanked on the left by vacuum fluorescent bar graph displays for fuel level, coolant temperature, oil pressure, and battery voltage, and on the right by a VCM (Vehicle Condition Monitor), a microprocessor driven unit presenting various diagnostic functions and visual and audible warnings. A total of 34 functions displayed through a dot-matrix screen. Before the instrument binnacle were controls for the onboard computer—providing information on speed and fuel consumption—and cruise control for certain models.

Most of the switchgear was new as were the steering wheel and stalks, and overall, regardless of model, equipment levels had improved. There was also a new sophisticated air conditioning system, optional on some models, offering not only temperature and air flow control but also humidity. A dashboard sensor allowed the system to react to external weather conditions.

Seats were all new, designed with the help of Loughborough University to maximize comfort. Cold-cure polyurethane foam was used in the seat cushions to provide consistent hardness and optimum support.

The all new center console incorporated the audio system and auxiliary controls. For the lesser equipped models, tweed upholstery was available instead of leather and straight grained woodwork instead of burr walnut.

The model line initially was quite small:

2.9-liter XJ6 (not sold in the States)

3.6-liter XJ6 (not sold in the States)

2.9-liter Sovereign (not sold in the States)

3.6-liter Sovereign (XJ6 in the States)

3.6-liter Daimler (Sovereign, later Vanden Plas in the States)

Service intervals had been dramatically reduced for the XJ40, even better than their German competition, and the starting price was a very competitive £16,495 for the 2.9-liter XJ6.

1987–1989: Inevitable Tweaks

With sales booming for the XJ40 in world markets, Jaguar continued to market the XJ12 Series models for the top-end buyers. Prices were increased by around 7 percent in 1987, justified supposedly by improved specification and high demand.

Prior to 1988, the audio systems in the XJ40 had been adapted from those fitted to other Jaguar models. From then forward, the top of the range models got a Clarion 926 HP unit.

Other trim and equipment changes involved heated door mirrors becoming standard on all cars; a rear sun blind and heated door locks became standard on Sovereign, Daimler, and Vanden Plas models; and 20-spoke alloy wheels became standard on Sovereign and VDPs.

In 1988, Jaguar sold 10,000 XJ40s in the UK alone (double the 1985 figure for Series 3 models). The model was voted The Boardroom Car of the Year.

Minor changes followed in 1989. Daimler and some early Sovereign models had displayed a matte-black rear panel to the boot, which was deleted in favor of normal body color paint. The door mirror design was slightly altered, and a new infrared remote door locking system was adopted.

Internally, Daimler and VDP models received boxwood inlays to the veneer, and Daimler rear compartment lighting was fitted to Sovereign models as well. Optional color piping was available for the interior leather trim. For the US and Canadian markets, the electrically operated metal sunroof (previously only standard on Daimlers/VDPs) was now fitted to the XJ6.

A new model, the XJR, was added to the range in 1989. Only fitted with the 3.6-liter engine, this car was clearly aimed at a younger market (see Chapter 9). Offered through a limited number of UK dealerships only, this sportier car boasted external body kits, Speedline 16-inch alloy wheels with Pirelli P600 tires, uprated suspension, and steering and interior trim changes.

At the British Motor Show in 1989, Jaguar debuted another new model, the 4.0 liter.

1990–1991: New Models

A major change took place for the 1990 model year with the introduction of the 4.0-liter AJ6 engine. The fundamental objective was to increase low-speed torque and enhance the feeling of effortless performance and refinement.

Capacity was raised to 3,980cc by increasing the stroke from 92 to 102 millimeters. In non-catalyst set-up, peak torque was increased from 249 pounds at 4,000 rpm to 250 pounds at 3,750 rpm. Revised camshaft profiles, tappets, valve timing, redesigned pistons, and a crankshaft in forged steel instead of cast iron, all enhanced refinement.

The analog instrument pack fitted to all XJ40s from 1990 and carried forward to the later X-300 models.

The limited XJR model, which sought to create a younger and more sporting market for the XJ. Here in 3.6-liter form, it was later upgraded with the 4.0-liter engine and more changes.

A new more powerful engine-management system better regulated fuel and ignition and the new engine was set up to run on unleaded fuel.

The 4.0-liter engine used a new automatic transmission, the ZF 4HPE unit, featuring electronic controls linked to the engine-management system, and two programmable modes, “Normal” and “Sport.” The manual Getrag gearbox was replaced by the 290 series with a repositioned gear lever. Internally, a three-plane gate pattern made reverse easier to engage. A larger diameter clutch and twin-mass flywheel came with the new gearbox.

With the 4.0 liter a new Teves anti-lock braking system was fitted, bringing the XJ40 in line with other Jaguar models.

To distinguish the new 4.0-liter XJ, more chrome trim was added to the rear area, with a wider range of paint finishes, and for the US market there were new headlights.

Resistance to the instrument binnacle prompted a new conventional analog instrument layout and ISO symbol warning lights instead of the Vehicle Condition Monitor. Some of the switchgear was also modified as was the sound-deadening insulation.

With the 4.0-liter engine came a revised XJR model from JaguarSport, with an extra 16 brake horsepower.

Model changes took place specifically for the US market as well. The XJ6 (Sovereign in the UK) got matte-black painted window frames, while the Vanden Plas got the same single headlamps as the UK cars. Specifically for the US market, cars would now be equipped with a unique front seat passive-restraint system that required significant engineering to install. Using a rail system above the front doors, the seat belts would automatically move and lock in position upon closing the doors.

A limited-edition model was the Majestic, only available in a single Regency Red Mica paint, fitted with diamond turned alloy wheels with individual spokes faceted in red; the brakes were fitted with protective, color-coded shields. The car was trimmed in Autolux high-quality leather in magnolia, with contrasting Mulberry Red piping, red carpeting, and red overrugs. Mirror finished best burr walnut featured boxwood inlays and the car was equipped with everything as standard! This included a one-touch integrated security system that closed windows at the same time as locking the doors. The car was badged as a Vanden Plas Majestic with appropriate gold badging and cost $5,000 more than the best-equipped other model.

Midterm in the production of the XJ40, for the US market, passive seat belts were added, at considerable extra development cost.

Also new for 1990 was an optional Sports handling pack, which provided stiffer springing, a larger diameter anti-roll bar, revised damper settings, lowered ride height, 16-inch wheels, a limited slip differential, and more direct steering, all of which improved the overall handling of the cars.

For 1991, there was another model change. Due to poor sales, the 2.9-liter car was deleted in favor of a new 3.2-liter model. Based on the 4.0-liter unit with the stroke reduced to 83 from 102 millimeters and the same bore, the capacity dropped to 3,293cc. Jaguar’s first engine to be available only in a catalyst form, it produced a healthy performance increase to 200 brake horsepower, comparing favorably with the 3.6-liter engine.

External differences between the last of the 2.9s and the 3.2s came down to rear badging. Greater changes were made to all XJ40 models at this time. The original metric-sized wheels and tires were abandoned (apart from special order), replaced with conventional 7×15-inch wheels with 225/65 VR15 tires. The bottom-end models still retained steel wheels with plastic hubcaps, while the Daimler got a new style of wheel called Roulette. A fingertip lip to the fuel filler eliminated the need to push the filler to open it, and now the driver could operate all door locks from the driver’s door.

By the end of 1991, over 158,000 XJ40s had been sold, marking the continued success of the XJ line.

1992: Mid-Life Crisis

More model changes followed, initially for the US market only. That special edition Majestic was offered in Black Cherry mica-metallic paint, sporting a chromed strip down the bonnet panel and chrome/rubbing strips along the sides of the car; they also received the Roulette alloy wheels from the UK Daimler model. Internally, the previous red support trim was now cream.

In mid-1992, at a time of growing competition from Lexus, Jaguar improved their new car warranty period to three years on all models.

Engine upgrades during this period included twin cooling fans and revised camshafts and allied components to improve efficiency and decrease noise levels. The ZF gearboxes were recalibrated to improve shifts. A first gear inhibitor was incorporated allowing the engagement of first gear momentarily before engaging second gear; this helped traction in difficult conditions. A gearshift interlock required the driver to apply the brake before selecting park, and to have the car in park before the ignition key could be removed.

To help with increased electrical loads a more powerful battery was fitted, now situated in the boot. Catalytic converters were standardized on all cars.

Minor changes took place to the interior with better, more supportive seat foams, and different electric seat controls. Even the base XJ6 got power height-adjustable front seats. Door panels were redesigned with better storage, and there were revised switches.

1993: The V-12 is Dead, Long Live the V-12

Jaguar became the first British quality car manufacturer to fit air bags, with a redesigned steering wheel in the XJ40 in 1993. This was a standard fit for most markets including the US. Another safety feature involved revised front seat belts with web lock devices to prevent excessive tightening of the reels. At the rear, the seat belt buckle mountings were incorporated into the seating.

The air conditioning system was totally revised with more logical controls and a recirculating feature. Another new feature was an optional heated front screen.

New, fully integrated vehicle security and better hi-fi audio systems were fitted.

Finally, in 1993, the XJ40 body was redesigned to take the V-12 engine. Here, seen in Jaguar XJ12 form, it used the four-headlight treatment normally applied to lower specification models. Unique features at the time included the black radiator grille vanes and gold badge.

Midterm US range of XJ40s from the Sovereign in the foreground to the Majestic at the rear. Note the different alloy wheel and window surround treatment, according to model.

Despite all the changes up to this time, the old Series 3 V-12 cars had still been selling. Bringing production to an end left Jaguar with no direct replacement. Because the XJ40 had been designed not to accept Rover’s V-8, wedging in a V-12 meant significant modifications. Over £35 million was spent redesigning the XJ40 to accept Jaguar’s V-12, but part of that figure was offset by the need, afterward, for only one production line.

Accepting the V-12 meant 44 percent of the total XJ40 paneling had to be changed or modified. Sixty changes were attributable to the front end of the car alone. To support the larger engine, a new subframe of a different open form was designed—which in future years would prove to be longer lasting than that used on the six-cylinder models. Springs and dampers were uprated to handle the extra weight.

The V-12 engine, now at 6.0 liters (see Chapter 9), was mated to a GM 4L80E automatic transmission and never received a manual gearbox. The 6.0-liter XJ40 outperformed the departing Series 3 V-12s.

Two variants were offered, the Jaguar XJ12 (fitted out to Sovereign specification except for four headlights) and the Daimler Double Six/Vanden Plas.

1994: More New Models, But the End Is Near

Announced for the 1994 model year, the 3.2-liter S (for Sports) offered sportier handling at a competitive price with a more youthful exterior and interior finish.

External changes were subtle with color-coordinating grille vanes, headlight surrounds, front valance and door mirrors. At the side a “3.2 S” badge adorned the lower front wings and along with the conventional swage coachline, there were two more coachlines at a lower level. New 7×16-inch five-spoke alloy wheels finished in eggshell or silver were fitted with 225/60 ZR 16 tires. At the rear red or gray neutral density lighting was used along with a plastic in-fill panel to the boot lid. The 3.2 S was offered in a limited range of colors.

The sporty 3.2-liter S (later also in 4.0-liter form) was produced to entice a younger audience to Jaguar.

The XJ6 Gold, a limited edition last-of-the-line model to create an attractive luxury entry model to the range.

Internally, walnut veneer was replaced by rosewood stained maple with dashboard top roll and door tops finished to match the seat trim. The seat facings were unique with horizontal pleating and mulberry red stitching.

Mechanically the car was standard except for the Sports pack. Priced for the UK market only, the 3.2 S cost just £2,000 more than a standard 3.2-liter XJ6.

A few months later, the 4.0 S was announced, and apart from the larger engine and new badging, was exactly the same as the 3.2 S.

Release of these two models was paired with deletion of the base model 4.0-liter XJ6, as was the 3.2-liter Sovereign. The remaining models received a broad range of changes from new wheels to myriad trim updates.

All XJ40s from 1994 were fitted with a passenger side airbag, which meant the deletion of the glove box in all cars.

With improved production methods and quality control, Jaguar was able to offer extended 10,000-mile service intervals.

It wasn’t over yet for the XJ40, as yet another new model came into being in 1994, the Gold, to boost the entry level range, which now offered three models in the under-£30,000 price bracket.

Aimed at a limited-edition market, the Gold represented excellent value for money at £28,950. It was based on the 3.2-liter engine car with leather trim, burr walnut veneer, uniquely fluted seating, and color matched gearshift and handbrake surround.

Outside, 16-inch Kiwi alloy wheels, gold on black wheel centers, gold radiator grille badge, twin gold coachlines, and rear badging completed the look. Offered in a limited range of colors, the model was a challenge to the Mercedes E280 and BMW 730i.

The XJ40 did well for Jaguar and its Ford owners. A total of 208,706 XJ40s had been produced and sold in just 8 years.

1994–1995: A New Series

Over £50 million was spent modernizing the assembly facility at the Browns Lane Plant in Coventry in readiness for a new model, the first new car produced under Ford ownership. The XJ saloon had been Jaguar’s biggest money earner, so the vehicle code named X-300 was introduced at the 1994 UK motor show as the “New Series XJ.”

Stylistically the aim was to bring back curvature, capitalizing on the heritage of the earlier XJs, while retaining and improving the quality and enhancement achieved with the XJ40. Underpinnings of the body derived from the XJ40, but significant new paneling was in store for the X-300.

At the front, the classic four headlight treatment served all models, now with new surface reflectors giving 15 percent more light output. Auxiliary lights were now standard on all models and the indicators were incorporated in the polyurethane injection molded bumper styled with chrome finishers. A traditional Jaguar radiator grille was neatly blended into the more rounded front of the car, finished differently dependent on model. The hood was sculpted around the headlights with a pronounced hump in the middle.

From the side view, it was very much XJ40 although substantially repaneled with, for example, the rear wing being a single panel including the E pillar to eliminate the need for a finisher. Window surrounds and other detail trim were also altered according to model, but all bodies featured not only coachlines but below-level rubbing strips finished to body color.

The X-300 XJ6 and XJ12 range covering base models with a 3.2-liter engine, through to the top-of-the-range 6.0-liter, brought a return to a more curvaceous style.

The new curvaceous styling of the X-300 was well received and took Jaguar back to a period of styling success in the 1960s and 1970s.

Jaguar’s first production supercharged car, the XJR, was one of the fastest saloons in the world, aimed at the BMW M market. This was the first model to feature the mesh radiator grille, which has been used ever since for many Jaguar models.

The newly appointed X-300 interior was adapted in various forms to suit the different models and their probable owners. This is a Sport with a large degree of black finish and, in this case, half leather trim.

The new AJ16 multivalve, coil-on-plug engine in 3.2-liter and 4.0-liter form for the X-300 models, also available in a supercharged version.

The new rear wings and boot panel followed the “curvature” approach with new lighting, registration panel treatment, and a polyurethane bumper as at the front. Unusually, for the US market, a revised boot pressing was used to accommodate American style registration plates.

Overall the X-300 required 11 percent fewer body panels and sub-assemblies. Fit and finish were drastically improved on all panels, and even the door gaps were 25 percent reduced compared to the XJ40. The rear doors incorporated a “jiggle” on the leading edge, so the front doors overlapped the rear doors on closure. All glass areas were semiflush glazed, so the torsional rigidity of the glazed body was improved by 18 percent. All exposed body panels were double-sided zinc coated to offset corrosion.

With the X-300 Jaguar was the first manufacturer to offer total electrical short circuit protection with no fewer than 90 fuses, gold plated connectors, shielded leads, and more robust installation.

Internally, most was new. There were new seats and frames, door panels, carpeting, woodwork, and other trim, all of improved quality. While the main instrument pack was unchanged, accompanying switchgear and trim was altered.

Mechanically the new cars were also vastly improved. Jaguar installed the AJ16 six-cylinder engines, also used in the later XJS models. Instantly recognizable by the silver finished cam cover and concealed wiring, the new engine was available in both 3.2-liter and 4.0-liter capacities, plus for the first time a supercharged 4.0-liter version for a new model, the XJR.

The AJ6 units were improved with over 100 newly tooled engine and ancillary components. There was a new cylinder head and reworked block, camshaft profiles, on-plug coils, a higher compression ratio, new pistons, sequential fuel injection timing, knock sensing, and new valve gear. Also debuted were a new throttle system, induction manifold and exhaust, plus a highly sophisticated engine-management system designed to comply with the latest American onboard diagnostics legislation. All these changes brought between an 8 and 10 percent increase in performance over the AJ6 units.

The supercharged 4.0-liter engine developed 326 brake horsepower and 378 pounds-feet of torque at 5,000 rpm. A Roots-type Eaton M90 mechanically driven supercharger provided immediate throttle response. A seven-rib poly-vee belt drove the supercharger off the engine at 2.5 times crankshaft speed for low speed torque. Valve timing was changed to suit the lower compression ratio. The inlet system was unique to the supercharged engine with a heat exchanger of the intercooler system incorporated into the manifold.

The 6.0-liter V-12 was still available on selected models, now taking advantage of the same new engine management system.

To improve off-line performance and decrease weight, the existing four-speed automatic transmission was reengineered with a reduced-size torque converter. The five-speed manual remained an option for six-cylinder models.

A new brake actuating system provided improved pedal effort. Rear brakes were now ventilated, with larger calipers. There was also a new traction control system and ABS was standard across all models. A new electronically controlled ZF rack-and-pinion steering system was employed.

The suspension was basically carried forward from the XJ40 models, but in line with the policy for the “New Series,” each model would be differentiated by not only trim, but also ride. With no fewer than five suspension packages according to model, each was designed to match the characteristics for each car.

1996–1997: The Long and the Short of It

For 1996, Jaguar reengineered the front passenger area to incorporate a new glove box below the air bag area and even produced a kit for existing owners to convert their early X-300s.

They also introduced a 4.0-liter version of the base model XJ6, responding to customer demand. More significant were longer-wheelbase bodies made available for Sovereign, Daimler, and Vanden Plas models, providing an extra 6 inches of space in the rear compartment.

In 1996, Jaguar recognized the centenary of Daimler, which it purchased in 1960, with two special Daimler Century models. Limited to 100 Daimler Six Century (six cylinder) and 100 Daimler Double Six Century (V-12) models, the cars were equipped with every conceivable extra and on the long-wheelbase body, becoming the most expensive production cars the company had ever produced.

Yet another new model appeared later in the year, the Executive, aimed at a younger businessman. Based on the standard 3.2-liter XJ6, it featured sports leather trim, half wood/leather steering wheel, the wider Sport wheels and tires, plus air conditioning.

Throughout the later production period, the longer wheelbase could be specified for other X-300 models.

In April 1997, Jaguar ended V-12 production after just 3,492 X-300 V-12s were produced.

The rest of the X-300 range only stayed in production until late 1997 as a stop-gap measure until Jaguar released its new AJ-V-8 engine, for which this car was destined. Despite the short production period, a total of over 92,000 X-300 XJs were produced.

The range topper limited-edition Daimler Century, one of just 200 produced to commemorate the centenary of the Daimler Motor Company. All examples used the long-wheelbase bodyshell and were finished with every conceivable extra and some unique badging and trim.

The sumptuous interior of a Daimler Century model.

1997–2002: Into V Formation

Late in 1997, Jaguar announced their new saloon car range, coded X-308, and known as XJ8. These incorporated the new AJ-V-8 engines, first seen a year before in the XK8 sports (see Chapter 11), now available in 3.2 liter, 4.0 liter, and 4.0-liter supercharged form. All engines were matched to a ZF five-speed electronically controlled automatic transmission and, due to a general falloff in demand over the years, no manual gearbox versions would be available.

The V-12’s run ended in 1997. Here, the very last X-300 XJ12 is set against other Jaguar models that used a V-12 engine. From left to right: the prototype sports/racing XJ13, E-Type Series 3 roadster, one of the very first XJ12s (Series 1), European Touring Car Championship winning XJ-S, and Le Mans–winning XJR.

Most of the chassis development technology came from the XK8 sports. The new saloons featured a front suspension system of spring to beam, twin wishbone design, and for braking, the latest version of the Teves system. Stability and traction control, variable ratio speed-proportional power steering, drive-by-wire throttle management, and retuned rear suspension all made for better performance, handling, and comfort. Allied to this a new on-centerline differential and two-piece propshaft helped reduce noise and vibration.

Electronically the X-308 models incorporated multiplex harnessing to inter-communicate and share information and a controller area network for all drivetrain functions.

Environmental issues were also addressed. Waterborne paint systems were used, cutting down solvent emissions by 85 percent and over 80 percent of the car was now recyclable.

Body changes from the X-300 were subtle with more rounded bumpers and new lighting, while the interior came in for a major revamp, including an entirely new dashboard with the wood veneer attached to light aluminum substrates, new instrumentation and switchgear, much of it from the XK8 sports, a new center console, steering wheel with many controls mounted around it, and better quality single-piece door cards.

The passenger-side glove box had been improved in size, the seat travel extended by 20 millimeters for better legroom, and there was another improved audio system.

Comparisons between the X-300 and X-308 models. Subtle changes included a new bumper bar with split chrome blades, new lighting, and a less angular radiator grille.

One of the AJ-V-8 engines, a 3.2-liter version as fitted to many XJ8s at this time.

An entirely new interior for the X-308 XJs with wood veneer set onto an aluminum substrate for lightness and better fit, new instrumentation (taken from the XK8 sports car), new seating, and other trim.

Interiors for the XJ8 varied according to model, with different wood treatments, degree of black trim, and even seat design.

The XJ8 3.2-liter Sport model with Dimple alloy wheels, marginally reduced ride height, and a sportier interior.

The special Jaguar XJR 100, all of which were produced in black and commemorated the centenary of Sir William Lyons, the founder of the Jaguar (previously Swallow).

The model range upon introduction was XJ8 3.2, XJ8 4.0, XJ8 3.2 Sport, XJ8 4.0 Sovereign, XJR, Daimler Eight, and Daimler Super V-8 (Vanden Plas in the States). Short- and long-wheelbase policy followed the same practice as the earlier model.

There were various minor changes to the specification and model range throughout the relatively short production period of the X-308, including replacement of the base model with the Executive, and the Sovereign becoming the SE (Special Equipment).

A total of 126,000 X-308s were produced and although it outsold the X-300 for only one year, overall it sold steadily and was a well-respected and refined Jaguar saloon. But it was time for something entirely new.

SPECIFICATIONS

MODEL |

2.9-liter XJ40 |

3.2-liter XJ40 |

3.6-liter XJ40 |

ENGINE SIZE |

2,919cc |

3,239cc |

3,590cc |

CARBURETION |

Fuel Injection |

Fuel Injection |

Fuel Injection |

MAXIMUM BHP |

165@5,600 |

200@5,250 |

221@5,000 |

MAXIMUM TORQUE |

176@4,000 |

220@4,000 |

249@4,000 |

GEARBOX |

5-speed |

5-speed |

5-speed |

AUTOMATIC |

4-speed |

4-speed |

4-speed |

0 TO 60 MPH |

9.6 sec. |

8.5 sec. |

8.8 sec. |

STANDING 1/4 MILE |

n/a |

n/a |

18.9 sec. |

TOP SPEED |

118 mph |

118 mph |

135 mph |

AVERAGE FUEL CONSUMPTION |

19.8 mpg |

19.8 mpg |

18.7 mpg |

MODEL |

4.0-liter XJ40 |

6.0-liter XJ40 |

ENGINE SIZE |

3,980cc |

5,993cc |

CARBURETION |

Fuel Injection |

Fuel Injection |

MAXIMUM BHP |

235@4,750 |

318@5,400 |

MAXIMUM TORQUE |

285@3,750 |

342@3,750 |

GEARBOX |

5-speed |

n/a |

AUTOMATIC |

4-speed |

4-speed |

0 TO 60 MPH |

7.6 sec. |

6.9 sec. |

STANDING 1/4 MILE |

n/a |

n/a |

TOP SPEED |

138 mph |

155 mph |

AVERAGE FUEL CONSUMPTION |

19 mpg |

15 mpg |

MODEL |

3.2-liter X-300 |

4.0-liter X-300 |

ENGINE SIZE |

3,239cc |

3,980cc |

CARBURETION |

Fuel Injection |

Fuel Injection |

MAXIMUM BHP |

219@5,100 |

249@4,800 |

MAXIMUM TORQUE |

232@4,500 |

289@4,000 |

GEARBOX |

5-speed |

5-speed |

AUTOMATIC |

4-speed |

4-speed |

0 TO 60 MPH |

8.9 sec. |

7.8 sec. |

STANDING 1/4 MILE |

n/a |

n/a |

TOP SPEED |

139 mph |

144 mph |

AVERAGE FUEL CONSUMPTION |

26.9 mpg |

26.8 mpg |

MODEL |

4.0-liter S/C X-300 |

6.0-liter X-300 |

ENGINE SIZE |

3,980cc |

5,993cc |

CARBURETION |

Fuel Injection |

Fuel Injection |

MAXIMUM BHP |

326@5,000 |

318@5,350 |

MAXIMUM TORQUE |

378@3,050 |

353@2,850 |

GEARBOX |

5-speed |

n/a |

AUTOMATIC |

4-speed |

4-speed |

0 TO 60 MPH |

6.6 sec. |

6.8 sec. |

STANDING 1/4 MILE |

14.9 sec. |

n/a |

TOP SPEED |

155 mph |

155 mph |

AVERAGE FUEL CONSUMPTION |

23.4 mpg |

18.4 mpg |

SPECIFICATIONS

MODEL |

3.2-liter X-308 |

4.0-liter X-308 |

4.0-liter S/C X-308 |

ENGINE SIZE |

3,248cc |

3,996cc |

3,996cc |

CARBURETION |

Fuel Injection |

Fuel Injection |

Fuel Injection |

MAXIMUM BHP |

240@6,350 |

290@6,100 |

370@6,150 |

MAXIMUM TORQUE |

233@4,350 |

290@4,250 |

387@3,600 |

GEARBOX |

n/a |

n/a |

n/a |

AUTOMATIC |

5-speed |

5-speed |

5-speed |

0 TO 60 MPH |

8.1 sec. |

6.9 sec. |

5.3 sec. |

STANDING 1/4 MILE |

n/a |

14.8 sec. |

13.5 sec. |

TOP SPEED |

140 mph |

150 mph |

155 mph |

AVERAGE FUEL CONSUMPTION |

23.5 mpg |

23.7 mpg |

21.6 mpg |

* To avoid confusion between models bearing the same XJ name, the Jaguar codes will be used to identify the different cars.