Early RC system (1998–2001): One-piece chassis complete with four wheels, motor, steering, receiver with antenna, and battery box. Included a small remote with antenna. Incompatible with other systems. Sets: 5599, 5600 (re-release)

Early RC system (1998–2001): One-piece chassis complete with four wheels, motor, steering, receiver with antenna, and battery box. Included a small remote with antenna. Incompatible with other systems. Sets: 5599, 5600 (re-release)Despite being discontinued in 2003, the LEGO Radio Control (RC) system remains exceptional in many respects, most importantly in its motors’ high performance. Its strength makes it popular with builders who are not satisfied with the limitations of the Power Functions system. Constructions that rely on the RC system are still published on a regular basis, and the system’s components are still available on the second-hand market. Because no replacement for the RC system seems to be imminent, it’s worth learning about this valuable alternative to today’s PF system. This chapter helps you understand how the RC system works and what makes it unique.

The LEGO Group has been experimenting with RC systems since 1998, ultimately abandoning them for the infrared or IR-based PF system. Out of several RC systems, one system has retained its popularity ever since: We’ll call it the RC proper.

The RC proper system has two features that make it a builder favorite: You can combine it with regular LEGO pieces, and it can control any LEGO motor. This makes it unique in the RC family, which can be divided into four groups:

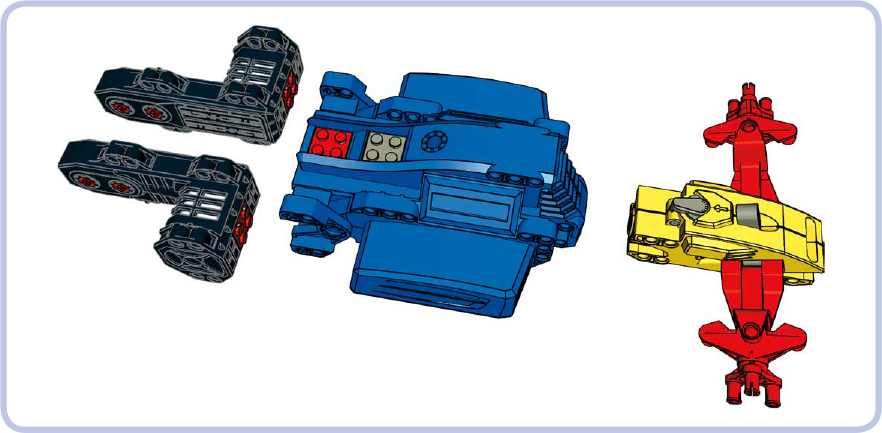

Early RC system (1998–2001): One-piece chassis complete with four wheels, motor, steering, receiver with antenna, and battery box. Included a small remote with antenna. Incompatible with other systems. Sets: 5599, 5600 (re-release)

Early RC system (1998–2001): One-piece chassis complete with four wheels, motor, steering, receiver with antenna, and battery box. Included a small remote with antenna. Incompatible with other systems. Sets: 5599, 5600 (re-release)

RC proper (2002–2003): Central control unit complete with steering, receiver with antenna, and battery box. Compatible with regular LEGO pieces, motors, and wheels. Included large remote with antenna. The 8366 and 8376 sets also included an extra pair of solid plastic wheels for drifting. As mentioned, this is the system this chapter focuses on. Sets: 8475, 8366, 8376

RC proper (2002–2003): Central control unit complete with steering, receiver with antenna, and battery box. Compatible with regular LEGO pieces, motors, and wheels. Included large remote with antenna. The 8366 and 8376 sets also included an extra pair of solid plastic wheels for drifting. As mentioned, this is the system this chapter focuses on. Sets: 8475, 8366, 8376

Mid-late RC system (2004–2006): Used a number of modules (one for steered axle, one for driven axle, and one for battery box/receiver with antenna) and the same remote as RC proper. Most elements, including body and wheels, were not compatible with standard LEGO pieces and were made exclusively for these sets. Equipped with a 7.2V battery pack and charger and a 9V battery for the remote. Sets: 8369 (originally with yellow body, re-released in 2006 with blue body), 8675

Mid-late RC system (2004–2006): Used a number of modules (one for steered axle, one for driven axle, and one for battery box/receiver with antenna) and the same remote as RC proper. Most elements, including body and wheels, were not compatible with standard LEGO pieces and were made exclusively for these sets. Equipped with a 7.2V battery pack and charger and a 9V battery for the remote. Sets: 8369 (originally with yellow body, re-released in 2006 with blue body), 8675

Late RC system (2004–2006): Used the same nonstandard body pieces and wheels as the mid-late system plus a new, smaller remote and one-piece chassis complete with motor, steering, receiver with antenna, and battery box. Sets: 8378, 8676

Late RC system (2004–2006): Used the same nonstandard body pieces and wheels as the mid-late system plus a new, smaller remote and one-piece chassis complete with motor, steering, receiver with antenna, and battery box. Sets: 8378, 8676

With the exception of the RC proper, the RC systems simply weren’t versatile enough to attract builders: They either relied on a one-piece ready-made chassis or on pieces that didn’t connect to regular LEGO pieces. It’s interesting to note that the LEGO Group tried the one-piece chassis solution again in the PF era with the 8183 and 8184 sets, both released in 2009. Both sets featured various bodies built on top of a chassis that combined the motor, steering, battery box, and IR receiver and could be controlled with a standard PF IR remote.

The RC proper system was designed as a combination of three elements: a control module, a steering attachment, and RC motors that were designed specifically for this system and were covered in Chapter 13. A typical set using this system would include two RC motors that were hard-coupled for propulsion, and the design and shape of all these elements made it easy to build a regular rear-wheel-drive (RWD) car around them, as shown in Figures 15-1 and 15-2.

Before we examine all these elements separately, it’s important to understand that the heart of the system is the control unit—all other elements are optional. The control unit can work with any LEGO motor, and its steering output can be used with a custom steering system. The remote is also a crucial part of the system, because it works in conjunction with the control unit.

Figure 15-1: The key elements of the LEGO RC proper system: RC motors (black), control module (blue, antenna not included), and steering attachment (yellow) with suspension arms (red). Note that in reality all these elements are black.

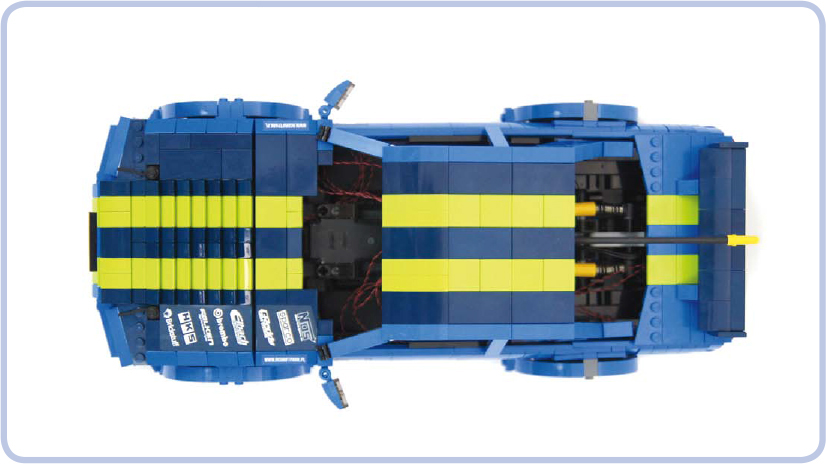

Figure 15-2: My F1 car model fits the RC elements within the slim body of the modern F1 racer. The control unit is located directly behind the driver’s seat, and two RC motors are hidden behind the side air intakes. A PF M motor, also connected to the RC control module, is used to remotely shift the car’s two-speed transmission built around the rear axle.

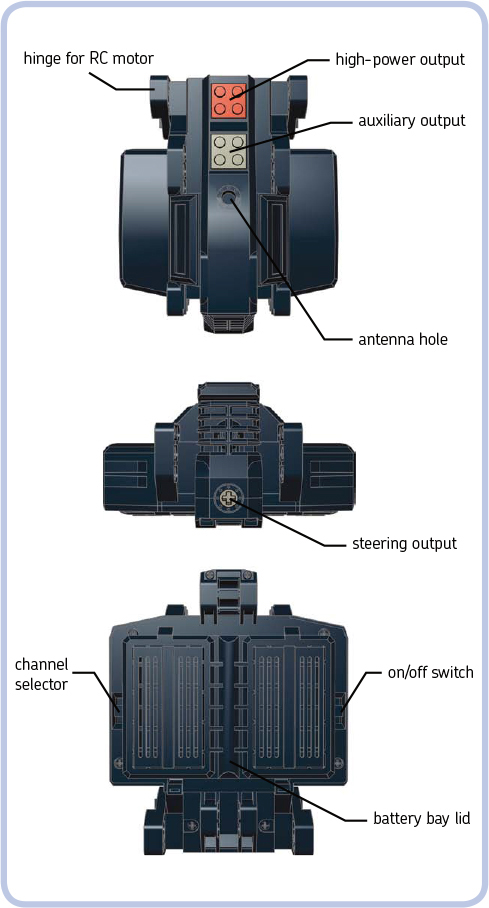

The RC control unit is commonly referred to as the RC unit. It combines a battery box (six AA batteries), an RC receiver, and a steering servo with return-to-center function. A metal antenna is screwed into a hole on its top. The unit can work without an antenna, but that reduces its receiving range to nearly zero versus roughly 10 m with an antenna. Also on the top are a high-power output (red) and auxiliary output (grey). A steering output is on the front; an on/off switch, a three-position channel selector, and a battery bay (closed by a push-in lid) are on the bottom. The outputs on top are simply contact areas for LEGO 9V plugs, whereas the steering output is just an axle hole that can rotate 90 degrees right or left and return to the center. Additionally, a hinge on each side of the module’s back is designed as an easy mounting point for one RC motor. With shock absorbers added, this can serve as a simple rear suspension.

NOTE A rare version of the control module with no auxiliary output exists. It was included in the 8376 set, and except for the missing output, it’s identical to the regular version.

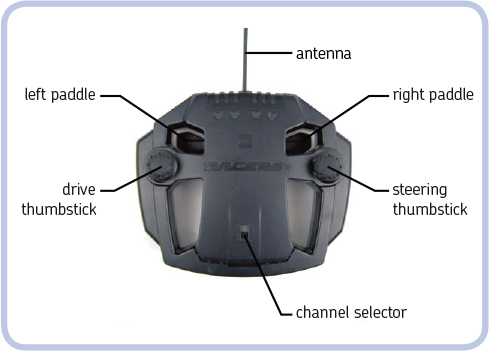

The remote comes with a screwed-in antenna on the top, which is identical to the one on the control module; two thumbsticks; a three-position channel selector on the front; two paddles; and a 9V battery bay on the back. The left thumbstick controls motors that generate the unit’s high-power output; the right thumbstick controls the motor’s steering output. Both thumbsticks allow limited proportional control: There are three motor speeds and three steering output positions, determined by how far you tilt the given thumbstick. Both thumbsticks return to a neutral position when you release them. The channel selector is identical to the one on the control unit, and a remote will only work with the control unit set on the same channel. The paddles control any elements connected to the control unit’s auxiliary output; for instance, if the element is a motor, one paddle makes it rotate right and the other makes it rotate left. Both paddles return to the off position when you release them. A single screw secures the battery bay lid.

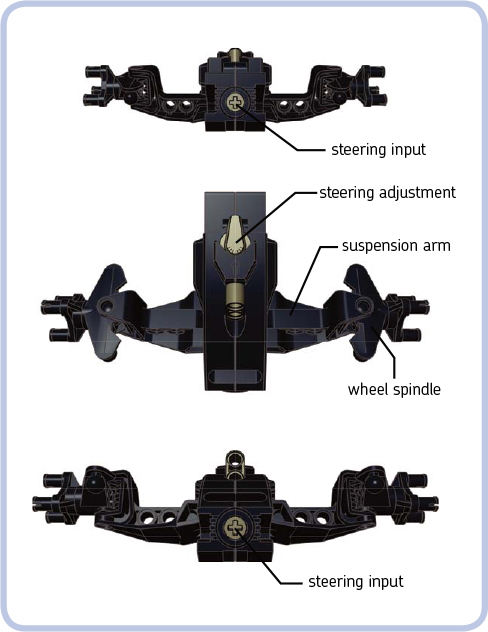

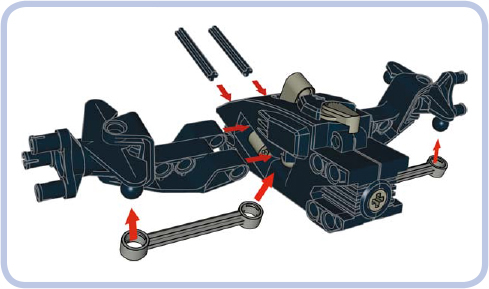

The steering attachment connects to the control unit’s steering output and combines several unique pieces in addition to regular LEGO pieces. The unique pieces are two suspension arms and two wheel spindles; two regular axles and two regular steering links are needed to connect them together, as shown in Figure 15-3. The attachment has a steering input in front and back, which are 1 stud deep and connected together. Also on top is an adjustment dial that can be used if the attachment bears to the left or right.

Note that the steering attachment has its own return-to-center function, which works just like the one in the control unit and allows the two units to work in unison. But whereas the control unit relies on an internal servo, the attachment’s function is spring-loaded. It works very feebly in most used attachments due to prolonged wear.

Also note that regular pin holes connect suspension arms to the attachment, making it possible to build custom suspension arms and use them instead. Any suspension arms, custom or not, are kept at an angle to the attachment, producing a caster angle for the wheels; whether the angle is positive or negative depends on whether the attachment is facing front or back.

Figure 15-3: Exploded view of the RC steering attachment showing how two steering links and two axles connect steering arms and wheel spindles to the actual attachment.

Although you can connect the RC proper system to any motor, it was designed specifically to work with the RC motors and to let them run at full power (see “RC Motor” on page 191).

The 8475 set’s building instructions (available online) are the best reference material for the RC proper system’s elements. They demonstrate how to use hinges on the control module and how to add a working suspension to the steering attachment. Although you can enjoy the advantages of this system using nothing more than the control module and remote, it’s useful to have all the pieces. You can experiment to make the elements of this system better suit your constructions, as shown in Figure 15-4. For example, you can bend the control unit’s antenna or hide it entirely inside a model’s body (neither seems to have any significant impact on the RC system’s range).

Figure 15-4: At 45 studs long and 18 studs wide, my Nissan Skyline GT-R model was probably one of the smallest cars ever built using the RC proper system. The body had a number of thin panels covering the control unit, and the steering system was entirely custom-built to make it small enough to fit. Additionally, the antenna was bent at a right angle to make it come out the rear windshield.

The RC system and PF system are strikingly different despite being released just a few years apart, and not just because of the different control medium (RC versus IR). The RC system is more specialized and was designed for high performance and ease of use with simple cars that could be built quickly and played with outdoors. The PF system, on the other hand, sacrifices performance for versatility and introduces a whole array of parts that are much less specialized and thus much more flexible: LEGO explicitly states that this system is not intended for outdoor use.

Perhaps the most important feature for the RC system’s popularity is the famously powerful RC motor designed to work with it. The RC unit is the only original LEGO power supply designed to cope with the enormous power consumption of two of these motors at a time. Although it’s entirely possible to operate RC motors using a PF battery, some of their power will go unused. The PF system comes with safety measures that limit the current drawn from a power supply to prevent electrical elements from overheating. The PF motors were built to work under these restrictions; the RC motors were not and are limited as a result.

Let’s look at the pros and cons of the RC system compared to the PF system. The RC system has some considerable advantages, including the following:

Superior range up to roughly 10 m, both indoors and outdoors.

Superior range up to roughly 10 m, both indoors and outdoors.

No interference from sunlight, and no need to maintain a clear line of sight between the remote and the receiver.

No interference from sunlight, and no need to maintain a clear line of sight between the remote and the receiver.

Limited proportional control—the RC system has only three motor speeds (the PF system has seven). Although this seems like a drawback, it comes with the benefit of working immediately without the lag inherent in the PF system.

Limited proportional control—the RC system has only three motor speeds (the PF system has seven). Although this seems like a drawback, it comes with the benefit of working immediately without the lag inherent in the PF system.

More power, meaning better performance.

More power, meaning better performance.

A larger, more comfortable remote that is also more intuitive to use.

A larger, more comfortable remote that is also more intuitive to use.

A control unit that comes with integrated steering output that acts very much like the PF servo motor. The unit also comes with a robust attachment that makes adding a positive-caster steered axle easy.

A control unit that comes with integrated steering output that acts very much like the PF servo motor. The unit also comes with a robust attachment that makes adding a positive-caster steered axle easy.

Batteries that can be replaced without removing the entire control unit.

Batteries that can be replaced without removing the entire control unit.

A whole system that is well suited for fast, simple cars, and whose components easily come together in a durable, off-road capable chassis.

A whole system that is well suited for fast, simple cars, and whose components easily come together in a durable, off-road capable chassis.

But the RC system also has a few downsides:

Overall, the RC system is much less versatile, and it’s difficult (but possible: see Figure 15-5) to use for anything other than a RWD car.

Overall, the RC system is much less versatile, and it’s difficult (but possible: see Figure 15-5) to use for anything other than a RWD car.

The control unit is bulky, heavy, and difficult to integrate into many constructions, and its antenna is especially tricky to work around.

The control unit is bulky, heavy, and difficult to integrate into many constructions, and its antenna is especially tricky to work around.

The higher power consumption means shorter battery life.

The higher power consumption means shorter battery life.

Powerful motors create high stress on drivetrain pieces along with the risk of permanent damage.

Powerful motors create high stress on drivetrain pieces along with the risk of permanent damage.

The remote has no room for modifications and doesn’t have an indicator to show whether it’s working.

The remote has no room for modifications and doesn’t have an indicator to show whether it’s working.

The remote only lets you control two motors independently per one power supply because the power supply is also the receiver (a problem that doesn’t exist for the PF system thanks to separate power supplies and receivers).

The remote only lets you control two motors independently per one power supply because the power supply is also the receiver (a problem that doesn’t exist for the PF system thanks to separate power supplies and receivers).

The control unit’s on/off switch is difficult to use.

The control unit’s on/off switch is difficult to use.

Replacing batteries requires access to almost the entire bottom of the control unit.

Replacing batteries requires access to almost the entire bottom of the control unit.

The steering attachment has a fixed track of wheels (but this limitation can be circumvented by adding custom-built suspension arms to the attachment).

The steering attachment has a fixed track of wheels (but this limitation can be circumvented by adding custom-built suspension arms to the attachment).

The system has been out of production for more than a decade, and all its elements are rare, expensive, and often in deteriorating technical condition. The control units in particular are known for breaking down, so buyer beware.

The system has been out of production for more than a decade, and all its elements are rare, expensive, and often in deteriorating technical condition. The control units in particular are known for breaking down, so buyer beware.

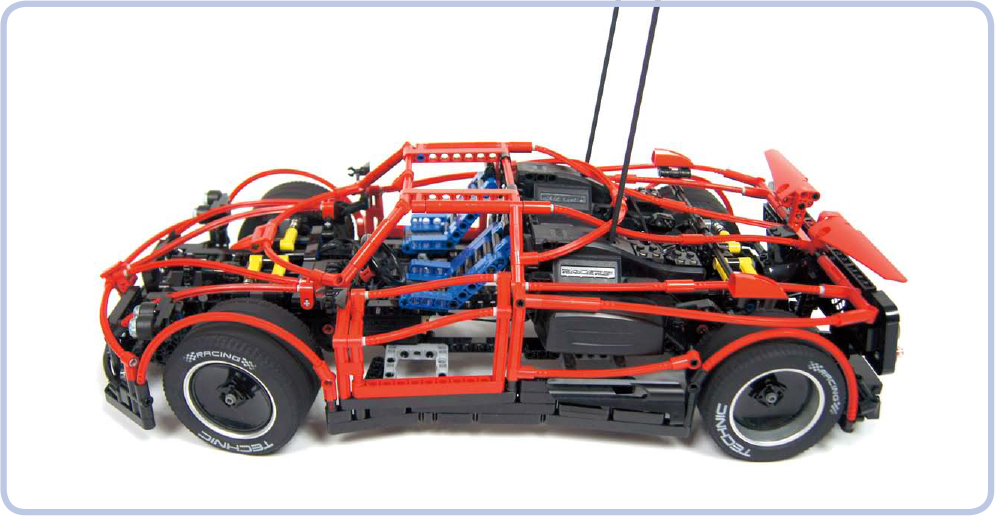

Figure 15-5: My Pagani Zonda model combined a lightweight skeletal body with two RC control units that powered four RC motors. Both units were set on the same channel so I could control them with a single remote, and one unit’s auxiliary output was used to allow steering with a PF M motor. The car needed 12 AA batteries but reached speeds over 15 km/h, despite weighing 2 kg.