—DON DRAPER, Mad Men

DON‘T GET ME WRONG: Jeff Gearhart is a lovely man.

I just never want to see him again.

This is what happens when you spend a day sitting beside somebody in a car parked in a hot room with the windows rolled up, inhaling toxic fumes.

Thankfully, the stuffy vehicle of which I speak stood 3 metres (more than 9 feet) high and 5.5 metres (17 feet) long and weighed in at a whopping 3,220 kilograms (7,100 pounds). The Chevy Tahoe LT was jet black and brand spanking new. It showed just 274 miles on the odometer, and the tag on the door told us it had been built about a month before Jeff rented it. All in all, it had everything we needed for our strange day: a huge interior we could stretch out in and, most important, an overpowering, nose-tingling “new car smell.”

Ahhh…the new car smell.

So intoxicating, yet so fleeting. Is your old beater getting you down? No problem! You now have the choice of a veritable smorgasbord of “new car smell”–scented air fresheners to give you that quick vehicular pick-me-up.1 But that day in Ann Arbor, the Tahoe’s acrid interior didn’t need the boost; it stank to high heaven all on its own.

We had a hypothesis: that the new car smell would result in measurable increases in chemicals in our body. We had an experimental design. And, very important, if anyone cares to replicate our results, we’ve provided enough detail that they can. Would wallowing in the SUV’s pungent embrace fill our bodies with pollutants? We were about to find out.

The cool factor of the Ecology Center’s stylish walk-up office—where Jeff is research director—is seriously undermined by the shop selling “discount ugly Christmas sweaters” down below. Fortunately, we didn’t linger. With his backpack stuffed full of food, we piled into Jeff’s rented Tahoe and hit the road for the forty-minute drive to the Space Station self-storage facility in Petersburg, Michigan, the closest place Jeff could find that had a unit big enough for our “new car smell” experiment.

“So what are you up to again?” asked Leanne, the proprietor, who took our payment for a day’s use of her large, heated garage.

“We’re measuring air quality in cars,” Jeff said. “We want to mimic the cabin temperature on a hot, sunny day, so don’t be surprised if you come into the garage and it’s a little bit warm.”

“Riiighht,” she said, looking us up and down, eyebrow raised, as she rang through Jeff’s credit card.

Jeff and I drove the Tahoe into the middle of Leanne’s garage, then cranked the thermostat on the wall to 86 degrees Fahrenheit (a common temperature on a summer’s day in the Ann Arbor area). We rolled up the windows, turned off the car, tuned the radio to NPR and sat there for the next eight hours, breathing in the pungent off-gassing from the vehicle’s newly minted upholstery.

Powerful memories can be triggered by smell. And I’ll admit that for me, the new car smell took me right back to wondrous family holidays in Bar Harbor, Maine: the sea air, sunlight reflecting off the pink granite mountains of Acadia National Park, and watching the world go by through the window of my dad’s new baby-blue 1972 Dodge Dart Swinger. On a molecular level, however, the new car smell is considerably less magical. It’s nothing more than nasty volatile organic compounds (VOCs) like formaldehyde, toluene and xylenes and other chemical goodies evaporating from the adhesives, sealants and plastic bits in the vehicle’s interior.

The structure of our experiment couldn’t have been simpler. Before we left Jeff’s office, we each banked a urine sample. And when we climbed out of the Tahoe in the early evening, we each took a second sample. We then sent the four little glass jars to EAG Life Sciences, a lab in Maryland Heights, Missouri, to measure whether the eight hours of breathing in the new car smell appreciably increased the levels of certain VOCs in our body.

If any of you have ever spent eight straight hours in a hot car with another person, you’ll realize that the conversation can pretty easily go off the figurative road, but Jeff and I did manage to chat at some length about his work at the Ecology Center and the reason why we were in the car in the first place. The Ecology Center’s work on cars and chemicals started at a grassroots level in the communities impacted by manufacturing plants in southeast Michigan. The center realized it could leverage broader public support by figuring in the “iconic product” of this manufacturing—the car—and tie it to their issues. So in the late 1990s they started doing report cards that examined and graded the car-manufacturing process. These reports assessed environmental factors and corporate management to determine which companies were doing better than others. Jeff told me that after a few years of preparing these report cards, they decided they had to make things more real for people. So in 2006 the center released a consumer guide to new vehicles at HealthyStuff.org—and there was so much interest that the website crashed on the first day.

The guide reviewed over two hundred of the most popular car models from that year, testing each of them for the toxic chemicals that off-gas from the interior parts. The Healthy Stuff vehicle guide focuses on chemicals such as flame retardants, plasticizers like phthalates, heavy metals and VOCs. To sample the vehicle interiors for these chemicals, Jeff and his team developed a method using a portable X-ray fluorescence (XRF) device, an impressive machine that slightly resembles a chunky phaser from Star Trek’s USS Enterprise. When you hold the XRF up to a piece of material, it identifies the elemental composition of the thing it’s aiming at in less than sixty seconds. Each car is then ranked according to the results of this material analysis, with the worst cars receiving high scores due to their high chemical content.

Between 2006 and 2012, the Ecology Center released four of their ambitious consumer guides, which regularly turned up an alarming cocktail of toxic chemicals in automobile interiors. They have over one thousand cars in their database, and Jeff estimates they have data on about 90 percent of the 2006–12 vehicle models sold in North America. After years of releasing the results and naming the companies involved, the Ecology Centre drove (pun fully intended) some significant change: industry-wide, ratings started to improve, and the best vehicles eliminated some hazardous chemicals entirely. In 2012, for instance, 17 percent of new vehicles tested by the center had PVC–free interiors, and 60 percent were produced without brominated flame retardants. Jeff told me that car companies like Ford are now investing significant dollars to clean up their manufacturing act, and Honda was so delighted that its Civic was named the Ecology Center’s 2012 “Best Pick”—in recognition of the company’s work to make its vehicle cabins as non-toxic as possible—that it still regularly trumpets this accomplishment on social media.

When I interviewed Jeff for this tenth-anniversary edition of Slow Death, he told me the battle has shifted rather dramatically to global regulation of vehicle interior air quality. Interestingly, an explosion of public concern about air quality in China and south-east Asian countries has driven the creation of new regulation and caused Ford to create a crackerjack “golden nose” team to track down offending chemicals. The team’s mission? Nothing less than snuffing out the new car smell. The eighteen “golden noses” work out of the company’s research facility in Nanjing, China, smelling every component part of every Ford vehicle sold in every Asian country. If an armrest or air conditioning vent fails the smell test, parts are sent back to the manufacturer. And the nasal commanders take extreme precautions against infecting the parts themselves, according to Reuters, abstaining from smoking and even avoiding nail polish.

None of this good news applied to the Tahoe, unfortunately. In a report released around the time Jeff and I undertook our experiment, the center classified the car as of “medium concern” and found measurable levels of bromine, chlorine and other nasty chemicals in its interior.

I read this and much, much more about the Tahoe as I sat beside Jeff during the eight hours we were ensconced in its capacious interior. Some University of Michigan graduate students took air samples from the car’s interior, but they came and went in a flash, leaving Jeff and me alone, staring at the wall of the storage depot.

By hour 8 Jeff and I were hanging on to every minute as the dashboard clock clicked down to the end of the experiment. We wheeled out of the garage like bats out of hell, racing through the darkness back to Ann Arbor, courting a speeding ticket, so anxious were we to be free of our vehicular incarceration. The new car smell had gotten stale.

Yes, there have been a lot of studies of indoor air quality, and the reason, in this couch-potato age, is likely obvious: the average resident of an industrialized country spends more than 90 percent of his or her life in enclosed spaces. To be even more precise, Americans have been found to spend almost 87 percent of their time indoors and an incredible 5.5 percent of their lives in an enclosed vehicle. For those of you who aren’t fans of math, this leaves only about 8 percent of our lives for skiing, raking leaves in the autumn, sunbathing on docks, walking kids to school, golfing, enjoying picnics and all other outdoor pursuits combined (see figure 16).

Figure 16. Where Americans spend their lives.4

Scientists have increasingly turned their attention to indoor air pollution because, quite simply, this is where much of the world is spending their lives.

Indoor air pollutants are an incredibly varied lot, and virtually all Americans (and, it would be reasonable to assume, residents of other industrialized nations) have measurable levels of VOCs and other pollutants in their bodies.5 Not surprisingly, the presence or absence of tobacco smoke is a huge determinant of indoor air quality. So is your home’s attached garage, if it has one (because of the inevitable and smelly assortment of jerry cans, lawn mowers, broken-down cars and sundry abandoned painting supplies). And if you’ve recently been exposed to fossil fuel combustion (for example, if you’ve been sitting in traffic) or have worked with glues and solvents (doing home renovations, for instance), your body levels of VOCs will be through the roof.

Sometimes, though, it’s the innocuous activities that contribute to our toxic chemical load, like simply sitting in a car. Researchers have found that we are exposed to over 275 pollutants floating around inside the average automobile. More of these chemicals seem to be released from car interiors in the warmth of summer. Cars less than three years old and luxury automobiles (maybe because if you’ve paid a lot for a car, you want as much “new car smell” as possible) have above-average smelliness. Studies have underlined the fact that in many vehicles the interior air quality is significantly worse than is considered safe in indoor environments. However, it hasn’t been at all clear that these ambient levels result in measurable increases in the human body.6

Of all the chemicals we could have looked for, we zeroed in on those known to pose health concerns.7 We looked for the metabolites, or breakdown products, of hexane (2,5-hexanedione), heptane (2,5-heptanedione), benzene (phenyl mercapturic acid), toluene (benzyl mercapturic acid), and xylenes (methylbenzyl mercapturic acid). Hexane is one of the most common VOCs in many glues, and prolonged exposure to it can lead to neurological damage. Heptane is common in some paints and coatings and certain kinds of rubber cement. Benzene is a well-known human carcinogen, and exposure to toluene and xylene can cause changes in the central nervous system and other damaging neurological effects.

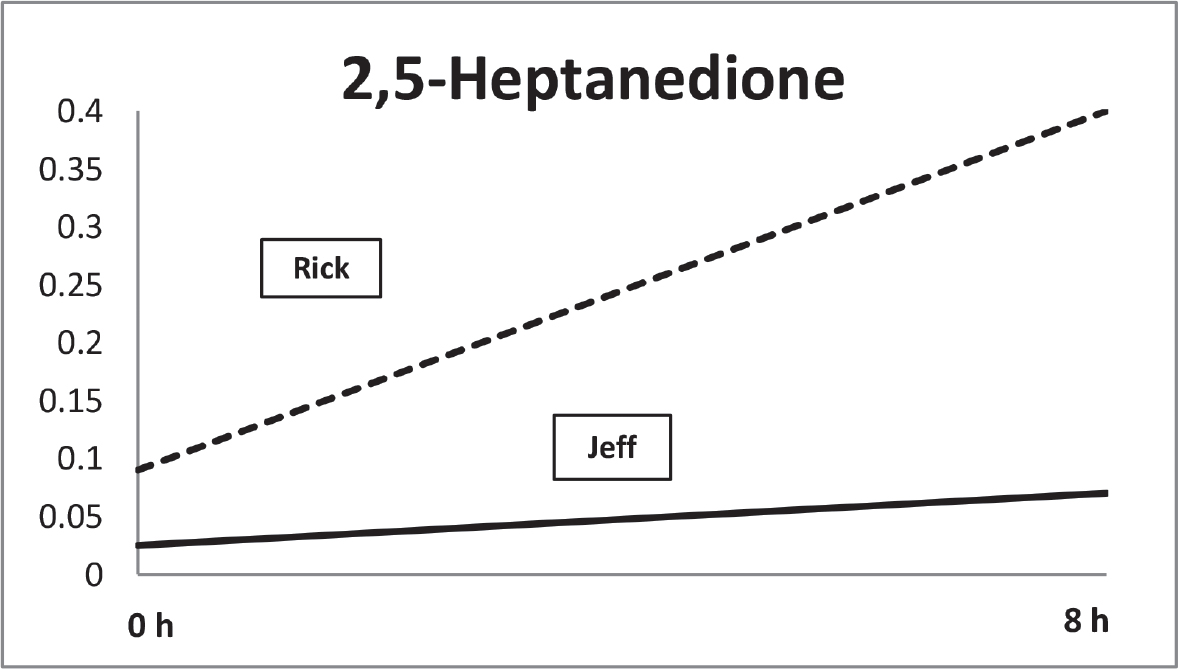

The results of our experiment were astonishing (see figure 17). For all the chemicals in question (including benzene and xylenes, not shown here), both Jeff and I saw significant increases in our bodies after eight hours of breathing the off-gassing. Look at the trends: in all cases our VOC levels rose—sometimes quadrupling. The implications of this are significant, since the average citizen in an industrialized country spends 5 percent of his or her life(!) in an enclosed vehicle. The Canadian government tells me that I, as an average Canadian guy, can expect to live until about eighty years of age: that’s four entire years of my life spent in a car. And for some of my fellow Torontonians who spend three hours a day commuting to and from work, I guarantee this number will be much higher. Granted, not every car will have the air-quality issues of a new Chevy Tahoe. But many will.

Figure 17. VOC increases in Jeff and Rick after eight hours in a warm, new car (all units mg/L).

Our experimental result, in a nutshell, was that with every breath they take, millions of people around the globe, every day, are slowly filling their bodies with benzene and other, unpronounceable toxic substances as they take a trip to the grocery store, pack the kids into the car to take them to soccer or head off for a summer vacation. We’ve included some specific conclusions regarding what to do about this in the last chapter of the book. Suffice it to say for the moment, if you have a new car, rolling the windows down and letting it air out is a good place to start!

One way to deduce how these sorts of pollutants impact us is to examine their effects on people who work with the stuff every day.

Though occupational exposure to chemicals and resulting health outcomes are poorly understood, one scientific study in particular is noteworthy for its connection to automobiles. A team of researchers led by University of Windsor professor Dr. Jim Brophy, through the support of the Canadian Breast Cancer Foundation (CBCF), decided to investigate whether certain types of work posed occupational risks for increased rates of breast cancer.8

Brophy and his team conducted a case-control study of over 2,000 women in Essex and Kent Counties in southwestern Ontario—an industrial expanse known for its flat landscape, automotive parts plants and plastic-manufacturing facilities. The case group of 1,005 women with breast cancer and the control group of 1,146 randomly selected members of the same communities were asked to provide detailed information about their occupational and reproductive histories. Here’s the simple but powerful result: industries characterized by high levels of occupational chemical exposure showed an increased risk for breast cancer.

The results of Brophy’s study are especially worrisome for women who work in automotive plastics plants. The plastics industry is characterized by a very high concentration of female workers; in Canada, for example, 37 percent of the plastics workforce is female—a higher proportion than any other industry in the manufacturing sector.9 In Brophy’s geographic study area, Windsor–Essex County, where the majority of plastics products are produced for the automobile industry, women make up over half the plastics workforce.10 Similar proportions occur in plastics-related industries in the United States.

The plastic-manufacturing work done by the women in Brophy’s study involved mostly injection moulding, which can be described as follows. After a product is designed—any product really, but in the automotive case, let’s say a dashboard or the console between the seats with those handily designed cup holders—a mould is made to form the features of the plastic part. The injecting material for the part is fed into a heated cylinder, mixed around and forced into the mould cavity, where it cools and hardens.11

What does this mean in terms of the female workers’ exposure to chemicals? The molten mixtures that become the final product are made up of resins, multiple additives and sometimes lamination films. The heating process emits vapours and mists into the plant that can include plasticizers, UV protectors, pigments, dyes, flame retardants and unreacted resin components, among other things.12 Many plastics release estrogenic chemicals, and additives like phthalates and flame retardants in the molten mixture are known endocrine-disrupting chemicals. Furthermore, some of the ingredients present in the manufacturing of polymers (such as BPA and vinyl chloride) are carcinogenic.13 So it’s no surprise that Brophy and his team discovered that women in the plastics industry had double the risk of developing breast cancer as compared to the control group.

When I interviewed Brophy about the study, I was curious to know how these chemicals actually get into workers’ bodies. Are they inhaled, absorbed through the skin or what? “These people are getting exposed in just about every way imaginable,” he responded. “It’s very important to emphasize that they’re not just getting exposed to one toxic substance. They’re getting exposed to the most unbelievable mixture of substances, all of which are known to potentially pose a threat to their health. And we know that when you get exposed to these mixtures, it’s even more potent than if you get exposed to just one thing on its own.” He told me that, during interviews, his team repeatedly heard complaints of improper ventilation, and one of the women working with automotive plastics likened being in her workplace to being “in a toxic soup.”

Studies like Brophy’s show that the people who deal with high levels of these chemicals every day are at significant risk of truly terrible health outcomes. They are “canaries in the coal mine,” warning of possible effects on the rest of us even at much lower exposures. Their stories and their illnesses should also make us reflect on the tangible impact that our society’s consumption patterns have on the workers who sustain them—in southwestern Ontario and anywhere else where workers are exposed to toxic chemicals.

In this chapter we’ve focused on VOCs, but other chemicals cause big problems when it comes to indoor air pollution—the ones that can enter our bodies in ways other than inhalation. Flame retardants, common in a wide range of household products, building materials, electronics, furnishing, cars, airplanes, and upholstered products illustrate this very well.

Our friend Miriam Diamond, a super-dynamic professor and researcher in the University of Toronto’s Department of Chemistry, has done some impressive research on flame retardants in everyday environments. In 2004 she and her colleagues collected the grime from interior and exterior household windows throughout Toronto and surrounding areas to measure their relative levels of PBDEs. The results showed significantly higher levels of PBDEs on the interior films—especially in more urban environments.14 This finding prompted further investigation, after which Miriam and her team published a groundbreaking study: the first exposure assessment of PBDEs indicating that house dust was likely the main route of exposure for individuals with high levels of the chemical in their bodies.15 Miriam’s research earned her the Scientist of the Year award from Canadian Geographic as well as the honorific “Dust Doctor” from her students. I phoned up the good doctor to ask her a few further questions about flame retardants, dust and indoor air quality.

“If flame retardants are ingredients in seemingly inert items like the foam in seat cushions,” I asked, “how do they get into our bodies? Is it as straightforward as the fabrics and foams containing flame retardants breaking down over time and becoming dust that we inhale?” While this could be true of some older, ripped pieces of furniture, Miriam explained that it’s actually more complicated. She thinks there are two main ways flame retardants get into dust. She likened the first way to taking a hot shower and watching the water vaporize and condense on the cold window. “A product—like your computer or TV—heats up when you use it. As a result of heating, the flame retardants de-gas, or move from the plastic into the air. But flame retardants don’t want to stay in the air, because of the low vapour pressure and also because the air is colder than the electronic product. So then they partition into stuff, stuff like the greasy film on walls and floor and plant surfaces.”

Another avenue for flame retardants entering household dust involves humans. Recent research by Miriam’s colleagues showed higher concentrations of flame retardants on the bottom of the hand versus the top, indicating that the chemicals are getting onto our palms when we touch them. “We know that bits of chemicals come off the surface of objects that contain them,” Miriam explained. “And we know that because all you have to do is touch something containing a flame retardant, like a computer, and you’re going to get it on your hand. A little bit of the plastic or fabric seems to come off just by microabrasion.” She went on, “Here’s another scenario: You’ve got dust on your couch, and when you sit down, some dust floats up and is resuspended in the air. While the dust was settled on the couch, it had the opportunity to pick up the flame retardant from the couch, and when it’s resuspended, it moves into the room.”

A study published in the spring of 2013 reminds us that it’s not only dust in the home that we should be worried about. Researchers at Duke University looked at a new-to-the-market flame retardant known as V6 and its concentrations in foam baby products and household and automobile dust.16 With the slow phase-out of PBDEs, V6 has been developed as an alternative, so it’s no surprise that the newer flame retardant was found in high concentrations in the baby products and dust that were examined. What’s more, the study found that concentrations of V6 were significantly higher in car dust than in house dust.17

When I think of dust, I tend to think of dust bunnies. But it seems that toxic dust, in your home or car is actually more likely to be distributed in places that you wouldn’t normally expect. “Dust bunnies are what we call the reservoir dust,” Miriam said. “It’s active dust, the stuff in the centre of the room that gets resuspended in the air, that’s the concern.” Think of dust bunnies as dust carcasses: dead creatures mouldering away on the ground that won’t bother anyone ever again. In contrast, the living dust, the really small and sneaky particles that we inhale and often eat (the motes visible in the sunlight as it streams through your kitchen window), actively move around.

In the same way that biologists track animals with radio receivers, Miriam Diamond tracks dust—and with equal zeal. Her work has revealed much about how these chemicals start out residing in the seat cushion under your butt and then go on to be an invasive pollutant in your bloodstream. And once flame retardants are in us, bad things start to happen. Miriam referred to a recent epidemiological study examining the effects of prenatal PBDE exposure on indicators of neurodevelopment in children one to six years of age.18 The study recruited 210 women in Manhattan who were pregnant during the 9/11 attacks and subsequently delivered at one of three downtown hospitals. Each baby’s umbilical blood was taken at birth and analyzed for the presence of toxic chemicals. At 12, 24, 36 and 72 months of age, various types of developmental tests were administered, and scores were compared to known developmental norms. The research team had hypothesized that prenatal exposure to toxins, particularly PBDEs, emitted from the World Trade Center buildings after the attack would affect neurodevelopment in children. They were right; the cohort study reported lower scores on mental and physical development and lower IQ in infants and toddlers, especially in children whose umbilical blood had the highest concentrations of PBDEs.

“It’s weird,” Miriam said. “As a mom, when I read the adverse effects, it just felt uncomfortably close to my circumstance. I thought of all those years working in front of a computer prior to and during pregnancy.” She has always sent her children outside to play, and thinks that maybe we should all play outside more.

Indoor air–quality researchers have also focused on another family of chemicals: our old friends the phthalates.

Not content to enter our bodies only through the personal-care products they infuse, phthalates also comprise a significant chunk of the dust in our homes. A particularly convincing series of studies has linked phthalate exposure to asthma and, perhaps surprisingly, the development of allergies.19 One of the key researchers in this area, Carl-Gustaf Bornehag, of Karlstad University in Sweden, told me that when he started his pioneering research, he didn’t have phthalates in mind at all. “In the 1990s in Sweden, we were collecting scientific data on environmental issues related to asthma and allergies, and we were focusing on moisture-related problems in buildings.” Bornehag had noticed that something was happening in damp buildings—resulting in higher rates of asthma and allergies in children—and he wanted to know why.

So he started one of the world’s biggest studies, called “Dampness in Buildings and Health.” It includes forty thousand kids and has tracked their lives and their health status in five-year increments since 2000. As Bornehag and his colleagues started to put together their mountain of data, they encountered a problem: no matter how hard they sifted, they couldn’t find a relationship between moisture-related exposures and asthma and allergies. For a while they were stumped. Clearly they were measuring the wrong things, so they kept analyzing and reanalyzing their air and dust samples, looking for some new trends. Finally, in 2004, they found the common thread: it was phthalates. The more phthalates in household dust, the higher the rates of asthma and eczema in kids. Given that a great deal of flooring in Sweden contains polyvinyl chloride (PVC), which is very rich in phthalates, the concentration of the chemical in household dust in many cases was through the roof. “We looked for something,” said Bornehag. “We couldn’t find it, but we did find something else.”

Bornehag expanded his study to another eight countries around the world and a whopping hundred thousand children. It’s slow going, but similar results linking phthalates to respiratory and skin problems as well as allergic reactions in children are popping up with growing frequency.20

Bornehag ended our conversation with an intriguing observation: “There’s no question that there has been a significant increase in allergies in people during the last five or six decades. And if you take not only phthalates but a number of these endocrine-disrupting chemicals, they have all been introduced during exactly the same time period.” One attempt to get at this casual connection occurred at the Boston Children’s Hospital.

Doctors there realized they were seeing an unusually high number of asthma patients from certain low-income neighbourhoods.21 They knew that asthma attacks can be set off by things like dust, mould, polluted air and other environmental aggravations common in low-income neighbourhoods, and they wondered if they could do something about it. The Community Asthma Initiative was born.

The programme identifies children who make frequent visits to the hospital’s emergency ward suffering from asthma attacks. Willing parents of these kids are then visited by a community health worker, who helps identify and educate the families about problem conditions and products in the indoor environment that can trigger attacks.22 Visits from the community health worker mean going through a checklist of asthma triggers and indicators of problem environments—things like mould, cockroaches and mice.

The programme has been a success. A report noted “a 56 percent reduction in patients with any emergency room visits, and an 80 percent reduction in patients with any hospitalizations.”23 All this has been done through simple and low-cost changes such as dusting and vacuuming more often, avoiding chemical-heavy cleaners and minimizing the use of fragranced products like room fresheners, which can all aggravate asthma. Who knew that a simple spring cleaning could have such tangible detox benefits?

I had ploughed my way through a tonne of papers on hundreds of different indoor air pollutants, and my head was hurting. I needed someone to give me the bottom line. For an overview of what’s been getting better and what’s been getting worse when it comes to indoor air quality, I turned to one of Bornehag’s occasional co-authors: Dr. Charles Weschler, a researcher at the Rutgers Environmental and Occupational Health Sciences Institute. Weschler had penned a refreshingly clear “everything you wanted to know but were afraid to ask” treatise titled “Changes in Indoor Pollutants Since the 1950s.”24

“In terms of many known or suspected carcinogens, at least in the U.S. and Canada, things have improved significantly,” Weschler explained. For benzene, formaldehyde, asbestos and radon, the levels in typical homes and offices today are much lower than they were in the 1960s and ‘70s. He cited two large surveys of VOCs in the indoor air of U.S. homes, one conducted between 1981 and 1984 and another between 1999 and 2001. “The average level of benzene went down from about 14 micrograms per cubic metre to about 2 micrograms per cubic metre. And we saw similar declines for other aromatic solvents: toluene, xylenes and ethylbenzene. So that’s good news.”

Weschler’s assessment of “classic toxic gases” like carbon monoxide (CO), sulphur dioxide (SO2) and nitrogen oxides (NOx) is similarly upbeat. “Fewer people are dying of carbon monoxide poisoning today, per capita, than were dying forty or fifty years ago,” he said. “We have CO detectors in homes, but more importantly, CO emissions from a lot of combustion appliances are just much lower than they used to be.” He adds cars as another household item whose CO emissions have been vastly reduced. Similarly, levels of sulphur dioxide are down because of reduced use of sulphur-containing fuel and coal. And nitrogen oxides indoors are way down, a result of the most innocuous of changes. “Do gas ranges in Canada still have pilot lights?” he asked. Not many, I told him. “Right!” he continued. “So pilot lights were this continuous source of nitrogen oxide that could actually reach elevated levels in a tightly sealed home. No more.”

Heavy metals are another good story. “Lead, mercury, cadmium—they’re all much lower in homes today. You collect dust samples today and compare the levels to what you would have found twenty or thirty years ago and again you see orders-of-magnitude reduction. Lead and mercury used to be used in paints to prevent mould and mildew—same with cadmium. And as you know, that’s no longer permitted for indoor paints. So that’s good news.” The last rosy update Weschler underlined was the change in pesticides and the fact that many of the most toxic ones have been curtailed. “You no longer see DDT or chlordane or chlorpyrifos or Mirex used indoors.”

Weschler is also interested in focusing specifically on the extent to which our bodies’ chemical burden is a result of the indoor environment and exposure through the dermal pathway (that is, our skin). In his 2012 journal article “SVOC Exposure Indoors: Fresh Look at Dermal Pathways,” Weschler examined the concentration of several semi-volatile organic compounds (SVOCs)—a category that includes common chemicals like BPA, phthalates, pesticides and flame retardants—in indoor air and on indoor surfaces. Using these levels, he then developed equations to estimate the levels of SVOCs that got through the skin of experiment participants.25 What he found was that air-to-skin transdermal uptake can be comparable to, or larger than, inhalation intake for many SVOCs of current or potential interest indoors.26 His results indicate that exposure to these indoor chemicals through the skin has previously been underestimated and that this pathway should be given more weight by exposure scientists and health officials when examining exposure to indoor SVOCs.

Why is this particular type of transmission of SVOCs such a concern? Because the nature of the dermal pathway means that the dose of chemical entering the body is potentially much higher than for a comparable amount of chemical that is inhaled or ingested. Whereas inhaled or ingested SVOCs have to pass through various systems (respiratory and digestive) where their appearance can trigger defence mechanisms, SVOCs passing through the skin can go directly to the blood and organ tissue. So it’s no wonder that human exposure to these chemicals indoors is a serious concern. Weschler makes the case for improved biomonitoring for these indoor pollutants—that is, ongoing measurement of levels of these chemicals in the human body. This will certainly help illustrate the dimensions of the off-gassing problem, but as always, we also need to make our homes and other indoor environments healthier through our own efforts.

I can still remember what my hard-bitten Newfoundland grandmother used to say about latex paint. “Pah!” (dismissive wave of the hand). “That stuff never lasts, b’y. Oil is what you need!” But what she might have thought in the 1980s isn’t the case today. In fact, as Carl Minchew, director of environment, health and safety at Benjamin Moore Paints, told me, you’ll be hard pressed to find anything other than latex paints now. And this is a good thing.

Those older oil paints, Minchew said, were really solvent paints: 50 percent of the volume of the paint in the can was a solvent mixture that evaporated as the paint dried. Given that latex paints dry more quickly, don’t make your eyes burn and can be cleaned off your hands with soap and water rather than paint thinner, it’s no surprise that latex has enjoyed a rapidly increasing market share. The difference between VOC levels in my grandmother’s standby oil paint and modern zero-VOC paints like Benjamin Moore’s Natura brand “is almost infinite,” according to Minchew. The early latex paints contained about 10 percent of the VOCs contained in oil paints, and with improving paint technology, this proportion is now down to virtually zero. Natura, according to Minchew, is simply “a better-performing paint. It goes on better, dries better, hides better and is more durable under use.” And it doesn’t fill your house with noxious pollutants. What’s not to like?

The market’s transition from oil to latex paints is just one example of the ongoing revolution in the way that building materials are made. Whether your house paint is smelly or not is a fairly tangible and obvious thing, but many recent advances are far subtler, though no less important.

In North America the introduction of the LEED (Leadership in Energy and Environmental Design) certification system marked the turn toward better building materials. LEED is a third-party certification programme for the design, construction and operation of high-performance green buildings.27 It provides building owners and operators with a specific framework that allows them to identify and meet practical and measurable green building design, construction, operations and maintenance solutions that will help contribute to a healthier overall environment.

I spoke to Thomas Mueller, president of the Canada Green Building Council, the group dedicated to promoting LEED in Canada, about the extent to which LEED is now paying attention to indoor air quality. He explained to me that within the leed system, there are five main credit categories, and one of these is called Indoor Environmental Quality. The core of this category is related specifically to the products that are being used in a building. “These are usually what we call finishing materials,” Mueller told me, meaning things like paints, varnishes and sealants, “and they tend to off-gas harmful pollutants during their life in the building.”

Mueller said it was the 2000 version of LEED (the second version in the United States, the first in Canada) that really broke into the marketplace and became popular. “The 2000 version focused on and addressed in a more consistent way the idea that some of these products and chemicals needed to be avoided, to enhance the health of building occupants,” he explained. Mueller noted the impact LEED has had by way of the paint example. “When paint first came up in leed, there was a certain threshold for VOCs in paint. If you want these points [the Indoor Environmental Quality points] in LEED, you cannot use paints that have a threshold above so many milligrams of VOCs per litre of paint.” These leed standards introduced the idea of low-VOC paint to the wider marketplace for the first time, and since then low-VOC paints have increased in quality and availability in the building sector. Now carpeting can also be rated according to Indoor Environmental Quality points, and Mueller explained that this point system is being extended to other product categories as well.

Mueller was quick to point out that improvements in building materials can’t all be attributed to LEED but noted that the power of the rating system allowed it to become a market mechanism. “The interesting thing is that these products—paint, carpet—are marketed commercially, and they’re sold at a price point to be competitive in the marketplace with other products. All the paint manufacturers, all the carpet tile manufacturers, they all have to have these low-VOC products. And that gets rid of the premium. People just say, ‘I’m not using this old stuff anymore,’ and they don’t buy it.”

Since its inception in 1998 and relaunch in 2002, LEED‘s impact has grown exponentially. According to the U.S. Green Building Council, the total floor area of LEED-certified buildings now expands by over 2.2 million square feet a day.28 Moreover, roughly 92,000 new projects adopt the LEED rating system on a daily basis in over 165 countries and territories around the world.29 In the United States alone, LEED-certified and -registered projects now represent over 10.5 billion square feet of total building space.30 The LEED certification program for existing buildings has also experienced explosive growth since its launch in 2004. Indeed, in 2011 the square footage of LEED-certified existing buildings surpassed that of new construction by 15 million square feet.31 Through such initiatives, we now have the chance to right some of our previous wrongs and ensure that future buildings are safer and more environmentally sustainable than ever before.

At its inception, LEED was considered to be “aspirational” in terms of greening the building industry, but today it’s considered to be a reasonable benchmark. A newer certification system, the Living Building Challenge (LBC), is looking to further transform the building industry with the idea of “nutrition labels” for building materials and increased transparency around what’s in the products we use. I spoke to Jason McLennan, the author of the Living Building Challenge codification system and CEO of the International Living Future Institute (ILFI), a non-governmental organization that focuses on creating a world that is socially just, culturally rich and ecologically restorative.32

Jason is considered one of the most influential figures in the green building movement today, and he was the recipient in 2012 of the prestigious Buckminster Fuller Prize. But his humble beginnings in Sudbury—an Ontario mining city known for both its toxic and its regreening experiences—are what really started him on his path. “I was inspired by my community and its environmental legacy,” he told me, “and also its legacy of trying to heal the landscape and regenerate what we had so degraded. I was a participant as a young child in the regreening process and was connected to the environmental changes that occurred. When I went into architecture, I went into it explicitly wanting to make this my focus.”

The philosophy of the Living Building Challenge arose out of Jason’s graduate research and his work with “green” architects throughout the United States and Europe in the 1990s, but the actual LBC rating system wasn’t launched until 2006. Much like leed, it is a certification programme that addresses development at all scales. It consists of seven “performance areas”: site, water, energy, health, materials, equity and beauty. These are subdivided into a total of twenty “imperatives,” each of which focuses on a specific goal.33 An important aspect of the LBC is the idea of transparency and toxicity prevention within the building industry. Through the LBC, Jason and his colleagues have developed a “Red List” of materials and chemicals forbidden to use in any project seeking Living Building Challenge certification. The Red List also itemizes materials that should be phased out of production because of health concerns and known toxicity issues.

The Living Building Challenge is still in its infancy in terms of its scale and impact on manufacturers, but Jason believes the building industry is starting to take notice. In May 2011, Google announced that it would abide by the Challenge’s Red List and drop any and all of the cited suppliers. Considering that the company is expanding into roughly 40,000 square feet of office space a week (and that a recent acquisition was over 300,000 square feet34), Google’s decision is a powerful market signal.35 Other organizations have committed themselves as “communities” to the LBC. The prestigious Williams College in Massachusetts, for instance, obtained LBC status for its environmental centre in 2016 and has since then committed to acquiring similar designations for as many campus buildings as possible.36

When I asked Jason to describe his preferred green building universe, he wasn’t shy about suggesting that the system he’s developed is where we need to go. “All buildings should be Living Buildings: net zero energy, net zero waste, net zero water, carbon neutral and free of toxins. We have to have a completely renewable energy–powered world without pumping more carbon.” Jason’s basic point is that we shouldn’t have to think so hard about these things. It should be easy to do good, rather than easy to do bad. “Everything I’ve said sounds crazy,” he acknowledged. “But it’s all doable now. The only reason it sounds crazy is because we live in a paradigm that thinks the way we design and build now is ‘normal.’ And it’s not.”

Much of this chapter was written while I was sitting on my living-room couch, listening to the banging and drilling of renovations beneath my feet. Our house in east-end Toronto is one hundred years old, and our basement was showing its age: mould appearing on the 1970s faux-wood wall panelling, water bubbling up through the concrete pad. The Toronto Star newspaper we found in the wall was dated November 29, 1941 (with the headline “Sink Nazis in Arctic”).

As I was writing about indoor air quality, we were making related choices about new windows, carpeting, paint and furniture. Most of our decisions involved trade-offs of one sort or another. In order to secure windows with fibreglass rather than vinyl framing, we delayed construction an extra month. Instead of going with bare floors, as recommended by the dust-averse Miriam Diamond, we decided to carpet the cold (now waterproof) concrete pad. We did, however, use Interface Flor carpet tiles made from recycled materials and free of VOCs, as well as natural wool carpeting on the stairs. We were careful to use low-VOC paint and carpet underlay, and despite some recent traces of problematic things in ikea sofas, I chose to believe their renewed corporate commitment to ban any harmful flame retardants from their products.37 (According to a 2017 online statement, ikea strives to “totally refrain” from use of “chemical flame retardants” except where required by law.38) The Månstad sofa bed in a lovely Gobo blue grey fits in just fine.

In the real world, such trade-offs are the rule. But as a result of the “new car smell” experiment that Jeff and I undertook, I will never again take for granted the quality of the air in the places where I spend 90 percent of my life. In the summer, when the slush and sleet disappear from Toronto’s streets, we plan to have the basement windows and the new energy-efficient back door open as much as possible.

Bruce likes to say that detox isn’t a one-shot deal but a philosophy and a lifestyle—a statement that is entirely apt when it comes to managing the quality of the air itself.