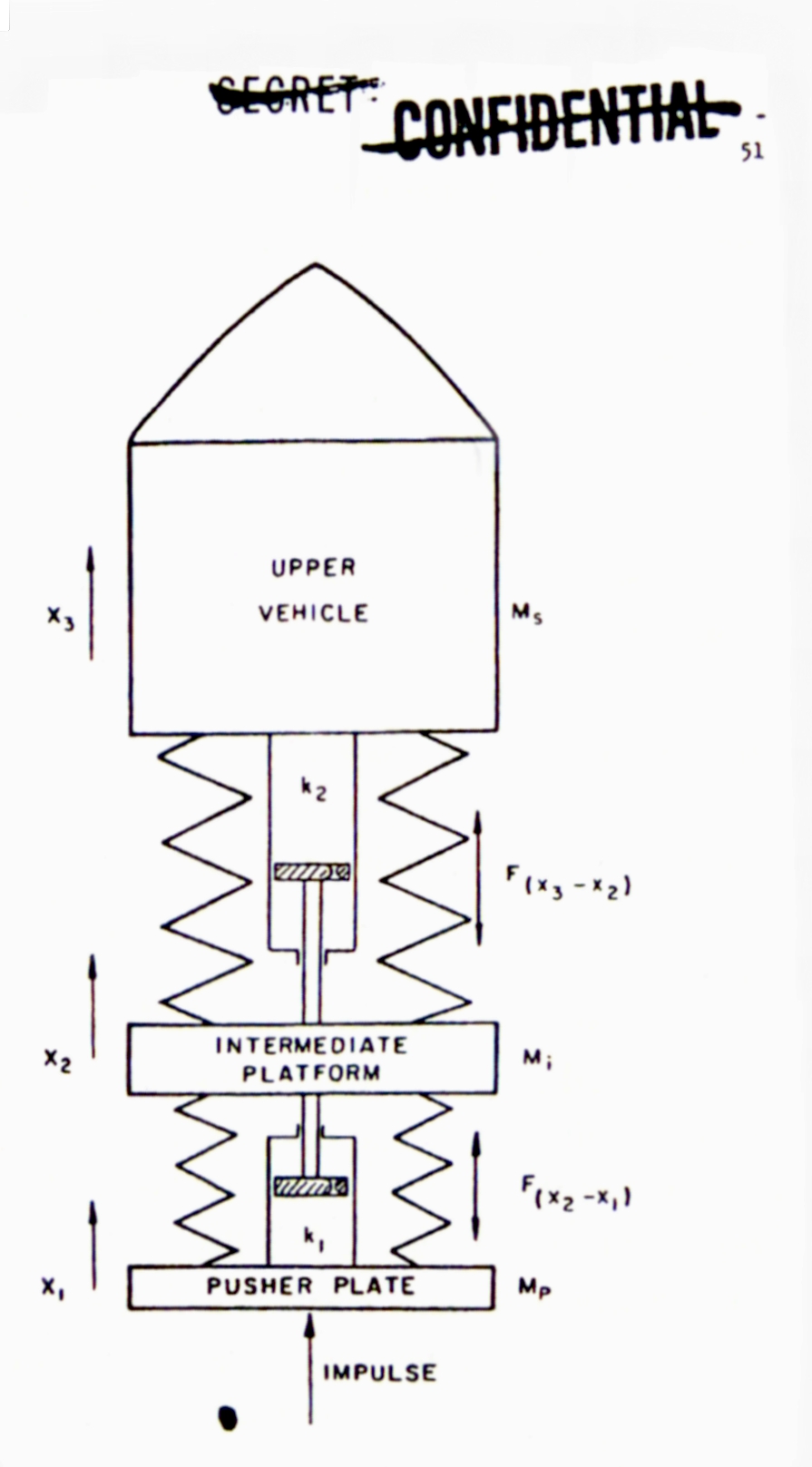

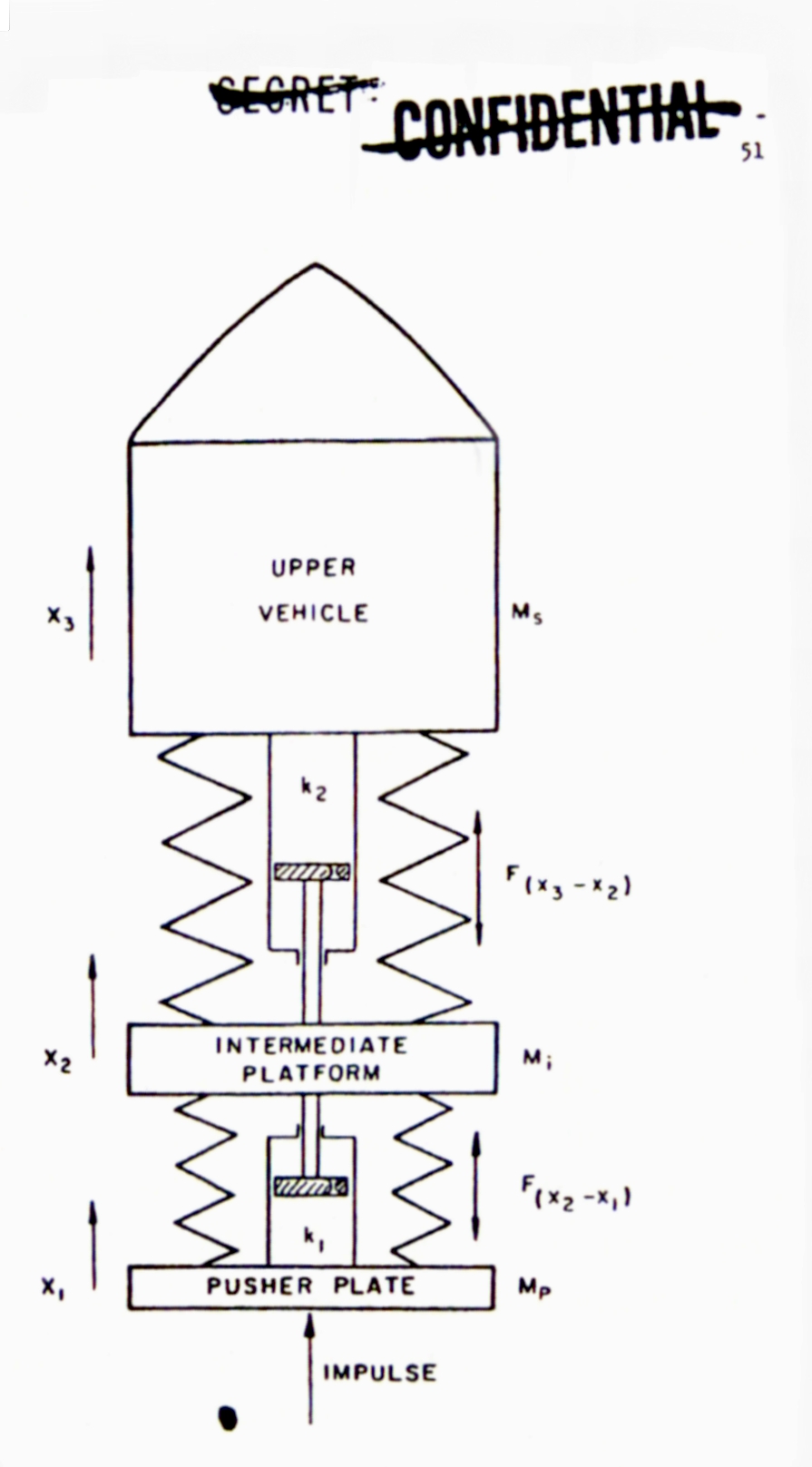

Orion vehicle as a three-mass, two-spring system. Relative mass, pulse frequency, and damping have to be carefully tuned.

"There was no school we could go to learn how to build these kind of ships. So we just started doing it," remembers Brian Dunne. Before political obstacles intervened, Orion's design was bounded by the laws of physics on the one hand and the laws of economics on the other. Orion's engineers worked in between.

Within a few weeks of Sputnik, Ted Taylor and Marshall Rosenbluth had settled on a ship with a takeoff weight of 4,000 tons. This remained the standard-size Orion until smaller, chemically boosted versions were added to the design repertoire in 1961. "Why was it 4,000 tons instead of 5,000 tons?" asks Ted. "I don't know. It just came out that way. What drove that was, arbitrarily, a thousand-ton payload, I think that's what did it. Just to throw it off scale from what people had been used to."

There were two good reasons, besides the impressive payload, for Orion to be so large. First: shielding from radiation. You want to have as much neutron and gamma-ray absorbing material as possible between you and the bombs. "The shielding problems get very rapidly worse when you make the thing smaller," Freeman Dyson explains. "The effectiveness of a shield goes exponentially with the thickness. If you have a couple of feet of shielding you are in good shape, but if you only have one foot it's terrible, it makes a huge difference." In a large Orion ship, the structural mass, spare bombs, propellant, and housekeeping supplies provide adequate shielding for the crew, whereas for smaller vehicles adding the requisite additional shielding carries a heavy payload cost.

Second: it is both difficult and wasteful to make low-yield atomic bombs. The smaller the amount of fissile material, the harder it is to compress it to a critical density and, when it does go critical, keep the resulting explosion from fizzling out. "Below a certain explosive yield of the order of a kiloton, nuclear weapons are grossly inefficient and extravagant," explained Freeman, remaining intentionally vague.[174] Despite Ted's genius for squeezing more bomb out of less uranium or plutonium, there is a point of diminishing returns past which die amount of fissionable material does not scale down. The cost of the implosion and detonating system remains the same or may even go up. You can produce a lower yield, but doing so wastes fuel and results in a dirtier bomb. "As for the bombs, they hope that with lots of high explosive they avoid use of plutonium and use all Oralloy, to avoid plutonium contamination problems," reported Don Mixson after a visit to General Atomic with Lew Allen at the end of the first month of the ARPA contract, in July 1958.[175] Oralloy (Oak Ridge Alloy) is highly enriched uranium (93 percent U-235).

If kiloton-yield bombs are exploded far enough away to be survivable but close enough to deliver significant energy within the angle subtended by the ship, a massive pusher plate is required to capture the impulse without accelerating to a velocity exceeding what the shock absorbers can withstand. It was the need for 1,000 tons of pusher plate, as much as the desire for a 1,000-ton payload, that set the 4,000-ton benchmark for Orion's initial design. "They have about a thousand tons for the ship and a thousand tons for the pusher," reported Mixson.[176] This left 1,000 tons for payload and 1,000 tons for bombs.

The 1959-model 4,000-ton Orion with a 135-foot-diameter pusher plate was designed to cruise on 5-kiloton bombs—low-octane regular given the state of the art in late 1958 and early 1959. Details of the various 4,000-ton vehicles remain classified, but it is possible to reconstruct the general parameters of their design. "At the time when I was on the project, when we were taking off from the ground, then it was just a big dome with a flat bottom and that was it," says Freeman. "It looked more or less like cutting off the front end of a submarine." A later version was 200 feet high and the propulsion system empty weight was 1,700 tons. The standoff distance was about 110 feet, which translates into an angle, subtended by the 135-foot pusher plate, of about 60 degrees. The bombs, initially estimated to weigh 3,000 pounds each, had already been scaled down to 1,870 pounds.

To design an Orion vehicle, you either tailor the bombs to suit the ship or you tailor the ship to suit the bombs. Which comes first, the chicken or the egg? When nuclear fuel is as scarce as it was in 1958, you start with the egg. Ted Taylor knew how to design the minimal bomb. You then configure the propellant to focus as much of the bomb's energy as possible, and tailor the ship to capture as much energy as possible from the propellant cloud. Bomb physics can tell you how tightly the jet of propellant can be focused, which roughly determines the diameter of the pusher plate at a given distance from the bomb. Weapons-effects physics allows you to estimate, given the temperature and density distribution of the propellant cloud, how much distance you need to keep between the pusher and the bomb, and how much impulse is given to the plate as a result.

Disregarding ablation this leaves three critical engineering problems concerning the ship: 1) How strong, how heavy, and what shape do you have to make the pusher plate to withstand the repeated kicks? 2) How do you absorb the resulting shock, and ensure a stable two-mass or three-mass system, so that the final acceleration is tolerable to the crew? 3) How do you store, select, eject, position, and detonate the bombs?

It was incongruous to have high-priced nuclear physicists spending their time calculating bending stresses in steel plates, and it was dangerous to have them designing ejection mechanisms for nuclear bombs. Mechanical and aeronautical engineers were enlisted to help. By the end of 1959, says Ted, "the Air Force was getting nervous about a project in which everybody that was running everything were physicists, and not engineers." John M. Wild, cofounder of the Graduate School of Aeronautical Engineering at Cornell, and chief aerodynamics engineer at Northrop during the development of the P-61, B-35, and B-49, was brought in from the Air Research and Development Command's Mach 20 wind tunnel facility at Tullahoma, Tennessee, to direct the project at General Atomic. Despite the increasing number of engineers Orion remained dominated by physicists—partly because of Ted Taylor and Freddy de Hoffmann, and partly because the project was never granted the nuclear tests that might have given real engineering, as opposed to theorizing, the go ahead.

Orion

vehicle as a three-mass, two-spring system. Relative mass, pulse

frequency, and

damping have to be carefully tuned.

The design of Orion could be divided into two distinct regimes: what happens below the pusher plate and what happens above. Below the pusher plate is physics. Above the pusher plate is engineering. But when Orion's physicists reached the surface of the pusher plate, where things changed from physics to engineering, they did not stop. They kept going, roughing out much of the design of the ship in advance of the engineers. Orion's physicists tended to be young, both because of the head start many had received during the war and at Los Alamos and because younger physicists were more inclined to join as implausible an undertaking as Ted's. Experience and wisdom were favored when it came to engineers.

Among the first engineering jobs was the pusher plate—Feynman's "pie in the sky." Dennis W. ver Planck, fifty-two years old and a professor of mechanical engineering from Carnegie Institute of Technology, was the first engineer assigned to the project full-time. "In those days anyone over forty was old," remembers Freeman. "ver Planck had experience in the aerospace industry and tried to impose some bureaucratic order on the chaos of Orion. He was a good engineer." He began studies of a flat pusher in July of 1958. "As presently conceived the pusher will be a flat disk of steel 4 inches thick and 120 feet in diameter," Mixson reported in July of 1958. "The pressure pulse will be applied for about 1/3 millisecond. The pressure in the central region will be about 20% greater than at the rim and will produce stresses in the neighborhood of 50,000 psi. Pusher rim displacements will be on the order of a few feet which is rather small considering the size of the pusher."[177] The dimensions of the pusher were proportionately about those of an eighteen-inch cymbal with an average thickness of a little less than one-sixteenth of an inch. Considerable effort went into trying to predict how this 1,000-ton cymbal would resonate when hit. "They have been looking at the low frequency vibrational modes," noted Mixson. "Frequencies are around 1 second. Energy going into these is small."[178]

The physicists working on the ablation problem knew that after the cloud of plasma hits the pusher, the lateral pressure gradient across the surface of a flat plate would produce a flow of hot material toward the edge. To minimize lateral flow, and reduce the effects of turbulent ablation, the pusher should be curved—like a shallow hubcap or a saucepan lid. If you put a greasy plate and a greasy bowl under a hot shower, the plate gets cleaner first. A concave pusher, however, would have to withstand severe hoop stresses, complicating its design. The inflatable primary shock absorbers had to support the pusher evenly against this concentric stress.

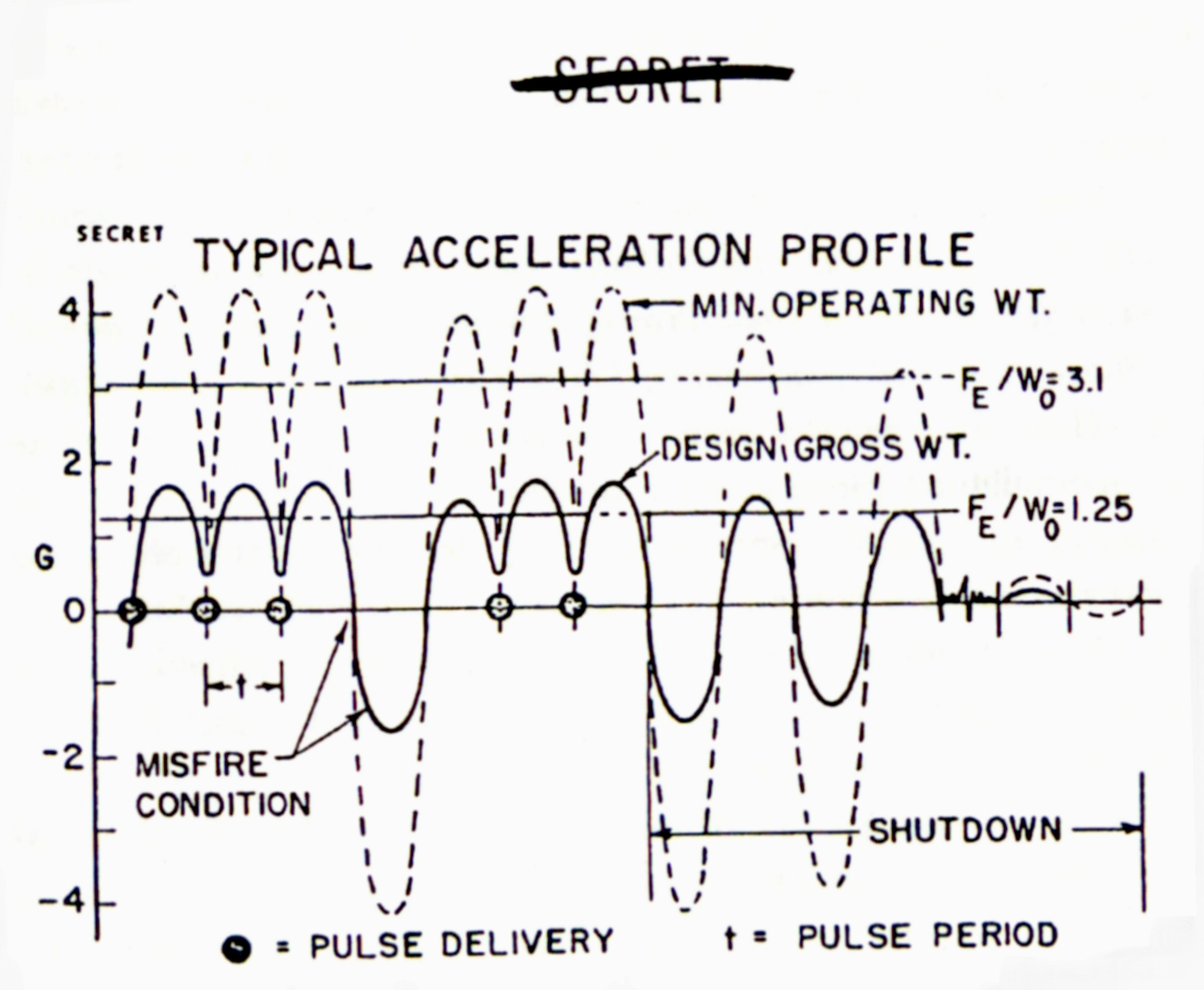

Crew

compartment acceleration: pulse interval is 0.86 seconds. Normal

acceleration

is below 2g, but rises to as much as 4g for an empty ship, and goes

negative in the event of a dud.

Half-momentum charges

are required to restart.

When the Orion crew increased from half a dozen to two dozen in 1959, engineer Carlo Riparbelli, forty-nine years old, was assigned the job of analyzing and optimizing the mechanical behavior of a 1,000-ton plate being given a 5-kiloton, twice-per-second kick. Riparbelli, whose mother was an obstetrician and whose father worked for the Italian Royal House, grew up in Rome where, as he says, "I had a very easy youth." Graduating with degrees in civil engineering in 1933 and aeronautical engineering in 1934 he went to work for the Caproni Aircraft Company, and became a second lieutenant in the Italian Air Force Engineers after serving in Libya during the early part of World War II. Later in the war he was appointed chief designer for Caproni, now supervised by the Germans, whom he remembers as "very efficient—not that turmoil that was the Italian organization." After the war he came to Cornell as an associate professor, moving west during a sabbatical to work for Convair. When he heard about Project Orion he interviewed with Ted, taking a job at General Atomic and giving up his position at Cornell. "We were all excited by this thing," he remembers. "I was also a little afraid to be in the middle of people so completely different. Because I am an engineer." His first appearance before the Orion physicists was a presentation on pusher-plate design. "I gave a talk, and Freeman Dyson liked it, and he encouraged me, and he said, you come and talk to me any time you like. So, I was less afraid after that." Carlo, who died in 1999, kept an espresso machine in his office available to the entire Orion crew. He remembers Project Orion as an orchestra, with all the players performing brilliantly, for the first two years, under the hand of their conductor, Ted.

Riparbelli produced dozens of reports concerning pusher-plate design, among them: Propagation of a Strain-Wave in a Bar across a Section Change; Deformation Analysis of a Plate-like Structure Represented as a Grid of Beams; Mass and Stiffness Distribution of the Pusher for the 800-Ton Vehicle; Strain Wave Propagation across the Pusher Plate and the Shock Absorber Attachments; Large Deflections of a Lens-shaped Disc. His engineering studies were based on dividing the pusher plate into an equilateral grid of uniform structural elements and mass nodes, presaging the finite-element analysis now used in computer-optimized structural design. According to Carlo, when he first arrived from Convair "General Atomic did not have a computer. And I noticed that we would have used one, certainly, and I told Taylor, and so they bought a computer and they put Charles Loomis in charge."

The key to the design of the pusher was to shape the mass distribution of the plate so that it matched the momentum directed at it by the bomb. This was the only way to keep the plate from accelerating unevenly and disintegrating under the resulting stress. A misaligned charge could be catastrophic. "We wound up with something like three times the thickness in the middle as at the edge," says Ted. "That raised the question: suppose the explosion was tilted, and it hit the thin part of the pusher plate with the wrong stuff?" Another question was what happened at the edge. "We used to argue quite a lot about that, whether you wanted to have a flange at the edge to confine the flow, or not," says Freeman. "One day we thought it would be good to have a flange and the next day we thought it would be better not. The advantage of a flange is that you keep the pressure up toward the edge, you get more momentum from the same amount of gas. The disadvantage is that it is hard to calculate the erosion of the edge; if the edge erodes irregularly it may be a disaster, so it's a risky thing to do. Whatever you do in the way of an edge is where you are likely to have trouble. So probably in the end we wouldn't have one. But that was the kind of thing we could argue about all day."

Once the pusher plate is accelerated—at thousands of g's—what happens next? Anything rigidly attached to the other side is liable to be smashed as if hit by a sledgehammer driven by an atomic bomb. In some of the tests of pusher-plate sections subjected to high-explosive charges, heavy steel eyebolts attached to the back side of the plates were catastrophically deformed simply by being unable to keep up with the acceleration of the plate. This is where the gas-bag shock-absorbing doughnuts came in, as a primary cushion between the pusher plate and the intermediate platform to which the secondary, piston-type shock absorbers could be rigidly attached.

The initial idea was to rely on gas bags alone, but it soon became apparent that even if the gas bags could take the shock, there was no reasonable way to restrain the pusher from rebounding off into space (or back toward the Nevada desert) in the event that the next bomb in the sequence was a dud. "The latest method devised for the shock absorbing system is to use a large number of low-pressure gas bags placed between the pusher and the floor of the spaceship," Captain Mixson reported at the end of August 1958. "This is apparently a very good and simple system except when a bomb misfires." Mixson then described an improbable solution that "as presently envisioned consists of a rather complicated arrangement of steel cables, pistons, and magnetic clutches. The total weight of this arrangement including misfire stopper and gas bags is estimated at about 500 tons."[179] Orion went back to the drawing board, where the dual-stage shock-absorber configuration quickly evolved.

"We always made the analogy of a car in which the first stage of the shock absorbers were the tires and the second stage were shock absorbers tied to a rigid chassis," says Ted. "So going along a very bumpy road a lot of what happened was evened out by the tires and big jolts that involved a big displacement were taken up by the shocks." For the 4,000-ton design, with a velocity increment of 10 m/sec (20 mph) per shot, this is an automobile that is hitting 15-foot speed bumps at half-second intervals—800 times in a row. As a 1963 reference to a 34-meter (111-foot) diameter version of the 4,000-ton design explains: "The first-stage shock absorber system, a series of concentric gas-filled tori, serves to reduce the initial pusher acceleration to approximately 100 g's. An intermediate platform couples the first-stage shock absorbers to the second-stage, piston-cylinder shock absorbers, which in turn reduce the accelerations felt by the upper structure of the engine to a few g's or less."[180]

Orion then becomes a two-spring, three-mass dynamic system, exhibiting complex behavior depending on the mass distribution, the pulse period, and how much damping is introduced into the system and where. Carlo Riparbelli produced one of the classic Orion reports. Parameter Study—Cylinder with Piston, which analyses the simplest-case, one-spring, two-mass Orion ship and assigns some parametric numbers to the results. "The mechanical system considered here consists of a cylinder and a piston, free in space," Riparbelli explains. "The given initial velocity of the piston relative to the cylinder can be visualized as caused by a sudden impulse imposed on the piston's lower (external) face. The piston is decelerated by the gas pressure while the cylinder is accelerated. The study of the relative motion is the subject of the present report."[181] A short Fortran program is included as an appendix. To imagine an Orion ship in operation requires visualizing not only a series of explosions, but the rhythmic, undulating movement of the ship as it bounds through space.

Orion's dynamic behavior received repeated study for seven years, most intensely by Constant David, a French engineer who joined the project in late 1958. "When a shock is transmitted to a flexible structural system, a pressure wave is generated and travels back and forth throughout that system until it is eventually damped out," he explains in Minimum Energy Loss in a Two-mass Spring System. "It is sometimes of interest to evaluate the amount of energy dumped into the system during the damping process, especially if the shock is repeated at short intervals... when a momentum increment is imparted to such a system by hitting one of the two masses for a very short time, so that the impulse is all delivered before any appreciable displacement of the hit mass takes place."[182] The harmonics of later designs were tuned so that the secondary shock absorbers oscillated one-half cycle between explosions, while the primary shock absorbers oscillated 4 1/2 cycles. Timing was critical. "An explosion timing tolerance of 10 m/sec is allowable (compared to 4 m/sec for a previous study). This is of significant importance," Constant David concluded in December 1964.[183] When Project Orion was shut down in 1965, he was still conducting tests of scaled-down gas-bag shock-absorber assemblies in a bunker at General Atomic's Green Farm high-explosive test facility, and was still simulating the resonant behavior of full-sized Orion vehicles using the enormous analog computer banks at Convair.

There were four main questions concerning shock absorbers: how to achieve a long enough stroke; whether to make them dissipative or non-dissipative; how to tune the resonance; and what to do about duds. As late as December 1964 the Fortran IBM-7044 codes for modeling shock-absorber behavior were still evolving in two separate versions: SAND (Shock Absorber Non-Dissipative) and SAD (Shock Absorber Dissipative). "We were never really settled on whether to drive the shock-absorber system at resonance or not," says Ted. "You could pick up a lot in performance if you did it in resonance in the sense that the pusher plate would be moving down, bouncing off the ship through the shock absorbers, moving down at high speed, and that's when we'd fire. Question: suppose an explosion doesn't work—then it would keep going and so we had to arrange things so that under those conditions the pusher would nondestructively overshoot by a factor of two in distance and then go back and damp out or lock and say, 'OK, we missed one.' I think most people favored locking. It would come down, go back up, and say, 'OK, start me again.' So we had to have a supply of half-momentum charges that would not stop the pusher when it was moving down but start it moving up."

What about a misfire during the initial Earth-to-orbit launch? "It was the rule that we imposed on ourselves that it must not be fatal," explains Freeman. "It was unacceptable that a single dud bomb would put you out of business. And that was one of the major problems. The shock absorber had to be designed so that if a bomb failed to go off you had some way of stopping the plate from running away into space. There had to be some way of catching the pusher plate and bringing it back, which meant the shock absorber became much more difficult to design."

"My technical questions about whether Orion would work the way we said it would were almost entirely tied up, not with what we called the big problem of ablation—I think that can be solved—but with complicated machinery," says Ted. "Things like unspecified types of car trouble, if the car is too complicated."

"We really were a bit insane," admits Freeman, "thinking that all these things would work."