Cutaway view of 4,000-ton, 135-foot-diameter Orion Mark 2 vehicle, showing shock absorbers and storage of 1,400 bombs.

Jules Verne's lunar adventures, cushioned inside an explosive-driven projectile for their voyage in From the Earth to the Moon, had to withstand a single escape-velocity kick. Verne chose dissipative hydraulic shock absorbers, arranged in multiple layers much as the Orioneers envisioned stacking their non-dissipative pneumatic tubes. "This body of water was divided by horizontal partitions, which the shock of the departure would have to break in succession," he explained in 1865. "Then each sheet of the water, from the lowest to the highest, running off into escape tubes toward the top of the projectile, constituted a kind of spring. Undoubtedly the travelers would still have to encounter a violent recoil after the complete escapement of the water; but the first shock would be almost entirely destroyed by this powerful spring."[184]

"The real difficulty with shock absorbers is to get anything with a long enough stroke," Freeman Dyson elaborates. "The peak acceleration that you have to withstand if you are on top of a shock absorber is proportional to V2 divided by the stroke of the shock absorber, where V is the change in velocity at each explosion. If you want to get a decent kick from each explosion like 10 meters per second, and you want your peak acceleration to be not more than 2 g, the stroke of your shock absorber should be about 5 meters. That's awfully big. It s very hard to get a shock absorber with that kind of stroke, things have to be really whizzing back and forth. It has to be massive and it has to work 500 times with not enough time to cool off in between." The impulsive velocity given to the pusher plate is inversely proportional to its fraction of the total mass, so that if the velocity increment given to the 4,000-ton ship is 20 mph with each explosion, the impulse given to the 1,000-ton pusher is 80 mph at every kick. This difference in velocity, absorbed over 5 meters, is equivalent to driving down the freeway at 60 mph and having one car-length to come to a stop.

The governing principle of shock-absorber design—that acceleration is proportional to velocity squared divided by stroke—suggests three possible approaches: increase the stroke; fire less-powerful bombs at more frequent intervals; or accept a higher acceleration of the ship. In later versions of Orion, acceleration would reach a maximum of 4 g's only when an empty ship was firing its last few bombs in maneuvering into its return-to-Earth orbit after an interplanetary cruise. On a long voyage, weeks or months of zero-g coasting would be punctuated by a few minutes of intense acceleration or deceleration at the beginning and end of each segment of the trip. Most of the time would be spent with the ship spinning slowly, inducing mild artificial gravity so the crew could eat, drink, exercise, and stay in shape. Once in a while things would have to be put away to prepare for the bouncing acceleration of powered flight. Even the initial boost from the ground to 300-mile orbit would last only about 6 minutes, after which passengers could unbuckle their seat belts and move around the cabin as they wished. In 1958, the thinking was that brief periods of even higher acceleration might be tolerable, perhaps by providing Jules Verne-style acceleration couches for the crew.

"In order to get around some of the shock absorber problems they are considering a 10-g pulse lasting for a smaller fraction of the time," Mixson reported on August 1, 1958.[185] On August 13, Colonel Leonard A. Eddy, one of the Project Orion officers at AFSWC, wrote to the Air Force Aero-Medical Laboratory for information on "Multi-Gravity Tolerance of the Human Body." Explaining that "studies under way on a pulse-type propulsion system indicate that personnel may be subjected to as much as 10 g's for one-tenth of a second at one-quarter-second intervals over a period of about 10 minutes," Eddy requested "any available information on periodic g loading on the human body and on the use of acceleration couches and water immersion to mitigate the effects of g loading and allow personnel to remain alert and able to perform necessary duties."[186]

A load of 10 g is hard even on an exceptional test pilot, and plans for 10-g acceleration were soon abandoned. "The upper limit A = 8 g is imposed because the ship is supposed to carry people and scientific instruments," Freeman explained.[187] The remaining variable is how frequently to eject and detonate the bombs. "We would go back and forth between the charge propellant systems and the frequency," recalls Ted. "Fire twice as many of them with half the velocity change per charge for the same total change, which of course affected the overall acceleration." More bombs meant a smoother ride, like upgrading from a four-cylinder Ford to a Chevrolet V-8. "They are now thinking strongly of reducing the interval between bombs to 1/4 second and doubling the total," noted Mixson at the end of July 1958. "This would substantially ease the shock absorber problems as well as easing the loading on the pusher plate since the bomb output would be reduced by a factor of 2."[188] The problem was bomb ejection and economics: firing twice as often is more than twice as difficult, and bombs with half the yield cost more than half as much. "The time available for delivering the charges to the firing position is increased from 1/4 sec to 1/2 sec," it was reported in April 1959, going back the other way. "With the bomb yield unchanged, the average acceleration of the ship is decreased from 4 g to 2 g whereas the peak accelerations remain of the order of 6 g."[189]

These early 4,000-ton ground-launch versions of Orion specified the ejection of about 800 bombs—ranging in yield from .15 kilotons at sea level to 5 kilotons in space—to reach a 300-mile orbit around Earth. Smaller explosions are required at lower altitudes, because the air between the bomb and the pusher plate absorbs energy from the explosion, delivering a more powerful kick. The disadvantage, besides noise, fallout, immersion of the vehicle in the fireball, and a tendency for the surrounding atmosphere to side-scatter radiation at the crew, was that as you blast your way up through the lower atmosphere you had to incrementally increase the yield. "And that was a problem," explains Freeman, "because you would have to fine-tune the first hundred bombs."

Cutaway

view of 4,000-ton, 135-foot-diameter Orion Mark 2 vehicle, showing

shock

absorbers and storage of 1,400 bombs.

How do you store and eject all these bombs? "Each of them weighs half a ton and you have only half a second to get them down a hundred feet, so it's a major piece of engineering," says Freeman. "Roughly, there were two ways of doing that: either you shot them out of a gun straight down the middle, which meant you had to have an opening in the middle of the pusher plate, which was very troublesome, or else you had to go around the edge, which meant using a rocket with steering so it could zoom around and arrive in the right place. This rocket going around the edge was spectacular, you had to light the damn thing and within a quarter of a second or so it had to zoom out to the edge of the ship and then turn through 90 degrees and zoom back. That always seemed to me to be a very risky idea. I always said if you are serious you have to shoot straight down the middle. And then the trap door was a formidable problem. It has to open and close in a fraction of a second, under very rugged conditions with things going bang all the time. If the shutter jams shut then you're finished."

Launching from the periphery of the pusher is not quite as crazy as it sounds. Besides all the problems caused by having a hole in the center of the pusher plate, if you have only a single launcher its firing cycle has to be completed two to four times per second, and any serious mechanical problem is likely to be fatal to the entire ship. With multiple peripheral launchers, each individual subsystem has to fire only once every few seconds, and a failure is more likely to be survivable, the way a car can be kept running on 7 cylinders when one ignition wire goes bad.

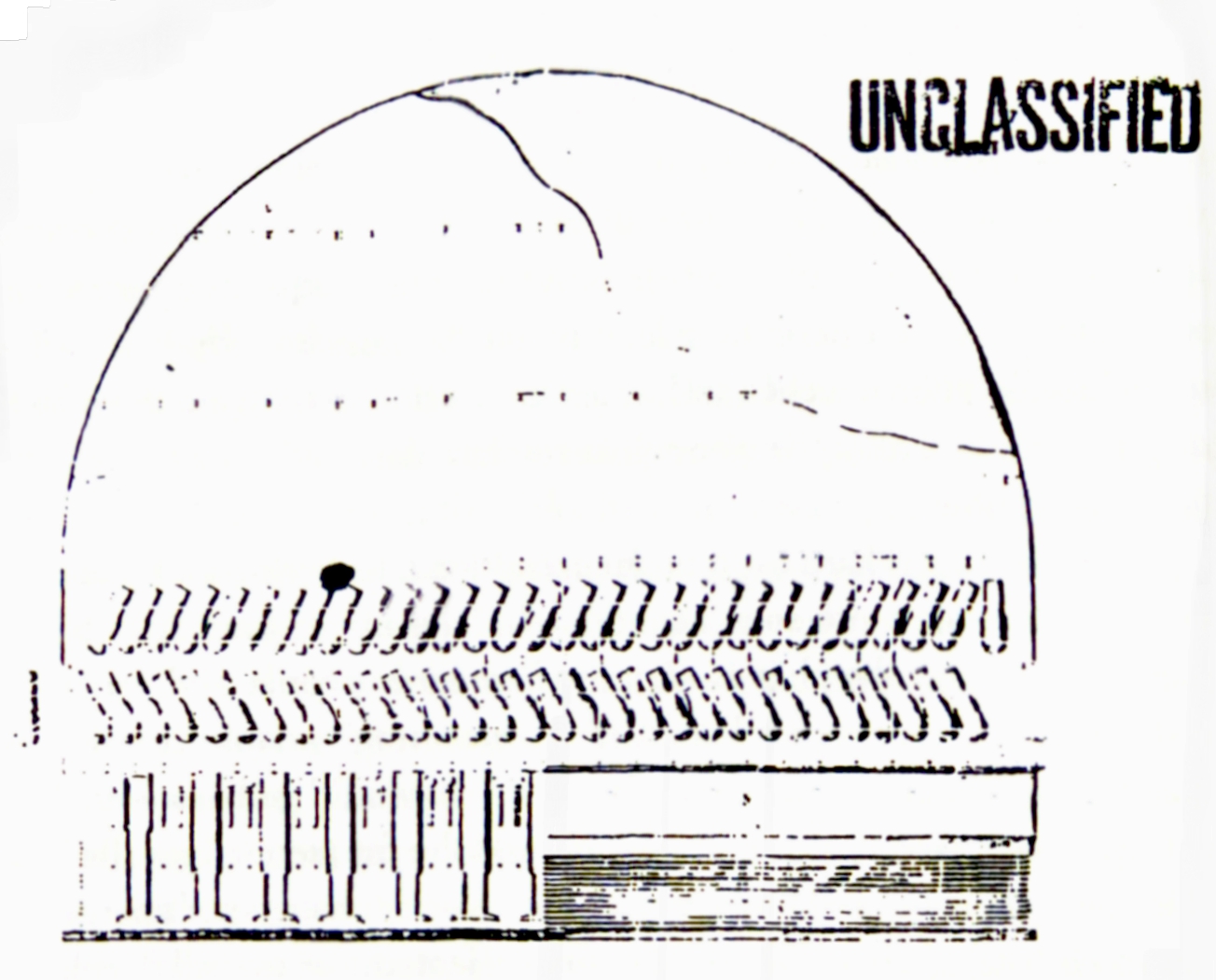

"For the delivery system they hope to avoid the hole in the pusher by using a gun or bazooka," reported Mixson at the end of July 1958. Mixson's notes describe "a gun a meter in diameter, walls about 1.5 centimeters, 10 meters long, weighing 2.5 tons to project a 1.5-ton projectile at 200 g's. Obviously this can't be reloaded every quarter of a second so you need maybe 10 of them. Can be a bazooka but the gun is easier, you need about a hundred kilograms of propellant per shot. This will probably wind up as a battery of Gatling gun-type gadgets."[190] One early series of sketches show the gun barrels supported on angled pylons around the circumference of the ship. When the shock absorbers are fully compressed, the muzzles extend just beyond the edge of the pusher, allowing unimpeded ejection of a bomb, and then the muzzles are safely protected by the pusher when the shock absorbers have reextended just before the bomb goes off. The pulse units are shunted into the launching tubes from loading bays around the edge of the ship. The scheme looks simple except in the event of a misfire, when an eccentric rocket is required to deliver a half-momentum charge around the edge of the pusher to get the pulse cycle going again.

This plan was soon followed by one that delivered the charges to the edge of the pusher plate on a series of curved rails—a roller coaster that suddenly runs out of track. "Excellent progress has been made in the formulation of a bomb delivery system," Mixson reported at the end of August 1958. "The firing of about 2,600 bombs at the rate of 4 per second is a tremendous problem. This system consists essentially of a series of pairs of rails located around the periphery of the pusher and behind it. The bombs are launched from behind the pusher and, upon sliding down the last portion of the rails are ignited and given (by curved rails) just enough pitch motion that in flight they follow a curved path around the edge of the pusher to the point of desired detonation. This system lends itself nicely to storage of the bombs and the speed of launch desired for this application. How to detonate the bombs at the correct time and place is another question that has not been seriously considered yet."[191] The problem was similar to having to pitch curve balls for an entire season, without ever missing a throw. The plan was for intersecting radio or radar beams to detonate the bombs when they reached the correct position, but in 1958 few of the effects of radiation on electronics were understood. "The first plans were to have these pylons, and toss the bombs over the side," says Jerry Astl. "They would have been all over the space!"

One of Freeman's contributions was to investigate how critical it was whether the bombs ended up in exactly the right place or not. "Dyson has looked at stability," noted Mixson, "and found that for a wide class of delivery systems the ship is stable for random errors in positioning the bomb."[192] This was encouraging. "If you have a bomb that is slightly off-center and it starts to tip the thing over, then the next bomb may or may not make it worse, depending on how you throw it out," Freeman explains. "So what I did was to design the throwing system so that it would automatically correct itself, so if it was slightly off-center the next bomb would bring it back again, so it would become a more or less stable system. That worked quite nicely, it depends on the time of flight, and it turned out that the numbers came out right. It depends on the moment of inertia of the whole ship and the speed at which it is rotating and the interval between the bombs. You have to just do the algebra and either it is stable or it is unstable."

The details of the delivery system were left to the engineers. "Contrary to our original expectations, the ejector system stretched the state of the engineer's art more severely than did the shock absorbers," says Freeman.[193] Orion's specialist in bomb delivery was Michael Treshow, a Danish mechanical engineer who had been trained in shipbuilding in Copenhagen before visiting the United States in 1920 and becoming a permanent resident in 1929. During the construction of the Boulder (now Hoover) Dam between 1930 and 1936 he designed and supervised the installation of the equipment that pumped concrete—more than 8 million tons of it—from where it was mixed to the dam site. "Something over a mile as I recall," says his son, Ken.

Proposed

operating sequence, date unknown, showing

normal-mode charge delivery through peripheral launching guns, and

delivery by

eccentric rocket to restart the engine after a scheduled shutdown or in

the

event of a dud.

Treshow switched to nuclear reactor design and engineering after World War II. He received Q clearance in 1950, while working as a senior engineer at Argonne National Laboratory in Illinois, and held some twenty patents in several fields. "I am recognized as having an unusual talent for invention and development of new ideas and products," he wrote to Ed Creutz in November of 1956, seeking a position at General Atomic, "3-1/2 years from now at age 65 I will be compelled to retire from Argonne due to forced retirement rules. I feel this would be too early for me."[194] Treshow was hired by General Atomic in February 1958, at age sixty-four, taking a position as a senior design specialist, with Ed Creutz making special arrangements to bend the company's retirement policies so that he could keep working as long as he wished. He soon joined the Orion team, drawing upon his training as a marine engineer and naval architect to produce detailed plans for the various components and permutations of the Orion ship. "He drew beautiful pictures with loving care and was very meticulous," says Freeman. "He was an old-fashioned draftsman, and loved to make everything exact."

You can throw a curve ball in air but not in space, thus small rockets were required to guide the bombs into position beneath the ship. Treshow's Trajectories of a Rocket with Eccentric Thrust explains the problem and reveals certain dimensions that were highly classified in 1958. "The takeoff rails will essentially guide the natural movement for the first short distance. Air friction is disregarded.... The launching point is considered 21.6 meters from the centerline. Its height is 5.5 meters above the pusher surface and the target E is 33.5 meters below the pusher. The launchers are placed around the edge of the pusher. The rocket is guided during the initial burning and released when the right position has been reached. At this point the jet will be at full power. The mechanical launching system consists mainly of two guide arms... after discharging the rocket, the arms will immediately be moved back where they are essentially sheltered from the blast.... Details of this system are, of course, still to be worked out."[195] The Mark 1 version of the 4,000-ton vehicle, which Treshow was working on at that time, carried 2,200 charges, weighing 850 kg (1,870 pounds) each, or about the weight of a Volkswagen, in canisters about the size of two 50-gallon oil drums joined end-to-end. One end was the rocket, and the other end was the bomb, and the device had to perform a perfect somersault during its flight: "The charge will turn an angle of about 180 degrees to a position where the propellant is aimed straight upward at the time of the blast."[196] The pulse interval was 1/4 second, so with thirty-two peripheral launchers each individual launcher had 8 seconds between firings to reload. There were four separate levels of storage and delivery conveyors, with 550 charges on each floor.

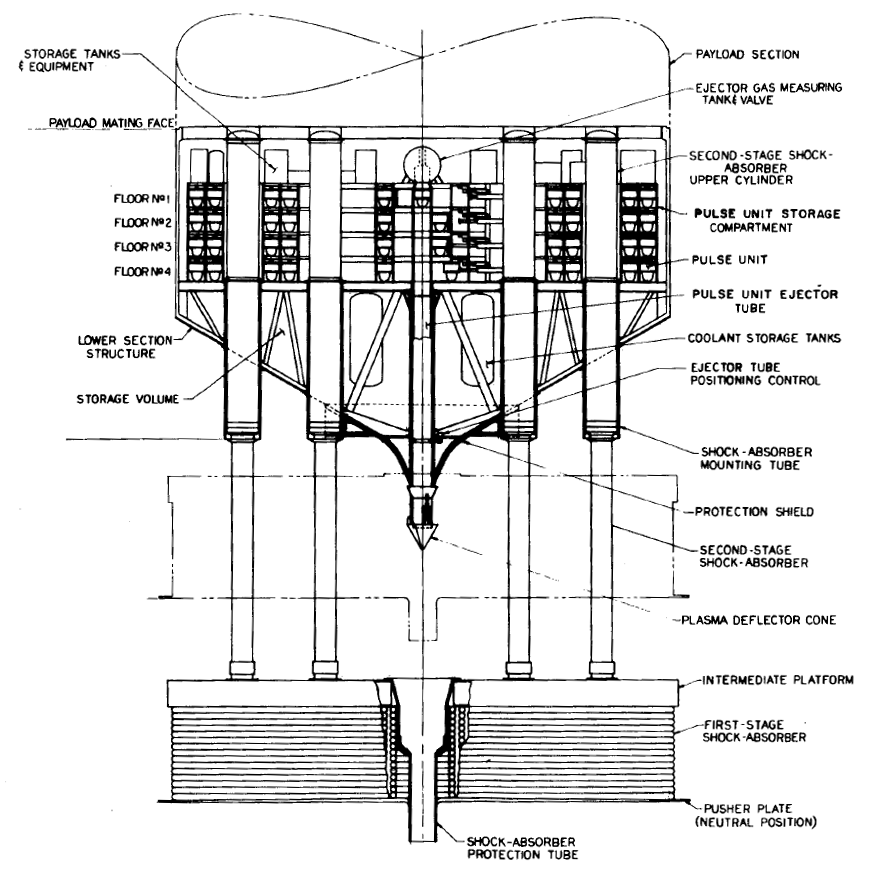

In the Mark 2 design, developed in early 1959, the storage and delivery system was reduced to two levels, with 700 charges on each floor. "This allows 1,400 charges in live storage," Treshow explained. "An additional 600 charges are expected to be stock-piled outside the conveyors for use in case of interplanetary travel."[197] There were twenty-eight individual conveyors, terminating in two groups of fourteen launchers distributed around the circumference of the vehicle. The pulse interval was 1/2 second, giving each launcher a little more than 12 seconds to reload. "In order to save space, no passageways are provided between adjacent conveyors," says Treshow. "Checking the charges before takeoff can be carried out by persons sliding in on roller pads above and below the charges. Such roller pads can move on light rails at right angles to the conveyor rails."[198] Someone like Carroll Walsh would have been squeezed in among those 2,000 bombs for one last inspection before launch.

Michael Treshow devoted his attention to everything from shock absorbers to parametric design studies that laid out the broad range of possible vehicles, from 200 to 10,000 tons. His drawings, few of which have been declassified, are remembered as exquisitely detailed. "The ship was about 120 feet high so it was big, like a ten-story building," says Freeman, describing the earliest version. "It was just a big flat dome, it wasn't particularly aerodynamic. It was so heavy it did not matter. The bottom 20 feet or so were mostly shock absorbers and then above that you had machinery borrowed from the Coca-Cola Company for the handling of the bombs, like a Coke machine where you put in a quarter and get out a Coke bottle. The bombs are arranged in racks and are shunted along; as each one was used the next one would move in. They came in a regular sequence and then they would get snapped into the catapult that launched them down the middle. So that occupied the next 30 feet or so. And then above that you had the dining room and sleeping quarters for the crew."

Propulsion-module

cross section, ca. 1962, showing four levels of pulse-unit storage,

plasma

deflector cone, meteoroid protection shields, coolant storage, and

two-stage

shock absorbers.

A successful Orion launch would depend upon being able to select exactly the right flavor of bomb at exactly the right time. Although the link to Coca-Cola may have become exaggerated, bottle-handling equipment was definitely involved. "Oh yes, the Coca-Cola people did come," confirms Freeman. "We had interesting conversations with a lot of people, and many of them had to be in an unclassified context," says Ted. "One major source of information was the Coca-Cola Company, where we got detailed descriptions of how they set up mass production systems for Coke bottles and all kinds of mechanical stuff." Jerry Astl remembers reviewing the ejection system with Michael Treshow. "I saw the drawings and we discussed it. I agreed with him one hundred percent. He didn't design that, he said, why should I bother? Vending machines already have something like that, and it works and is well proven. All we need is to make a few changes to make it sturdier, and what he had was pretty damn good-looking.

"When it comes to the charges you will need several, maybe, ten different levels of yield," explains Astl. "You will have to load them into a revolving Gatling gun so you can grab the proper yield because you don't know when you need that special yield. To have instant access to it you simply have a rotating drum and when it comes around you yank it out into the chamber. You have an advantage—you are not going at any fantastic speed. At the beginning, Ted was hoping that maybe we can fire four times per second. That's a little scary. When you get it down to say one per second it might be realistic."

In the later 4,000-ton versions of Orion, the shock absorber stroke was extended to 33 feet (10m) and the pulse frequency to 1.1 seconds. Average acceleration during propulsion periods was 1.25 g, tolerable to all but the most delicate of crew. In attempting to sell Orion, for post-Apollo missions (including a 400-passenger lunar ferry), to NASA, the General Atomic project team pointed out that "both the pulse frequency and the acceleration profile are reasonably well simulated by a child's backyard swing operating through an arc some 65° each way from vertical."[199]

All the later Orion designs ejected the bombs through the center of the pusher plate, and relied on massive cylinder-and-piston shock absorbers that were non-dissipative but actively cooled. The vaporized shock absorber coolant (water or ammonia) was recycled as propellant to eject the charges, and there were direct linkages between the shock absorbers and the pumps that sprayed anti-ablation oil at the pusher, at the top of each cycle, through a series of nozzles fitted to the central launching tube. There have be four externally visible events in each pulse cycle: the ejection of the charge, signified by a puff of steam; a brief spray of anti-ablation oil to coat the pusher and the "plasma deflector" that protected the muzzle of the ejection tube; the explosion of the bomb; and the flash of plasma against the plate.

On the bridge of an Orion ship on active maneuvers, the primary control would be the regulator for pulse-detonation timing—equivalent to the spark advance lever by which the driver could manually advance or retard the ignition timing on a Model T. Down below, past the layers of charge storage magazines, the engine room would be filled with steam lines, coolant reservoirs, and tanks of anti-ablation oil, and permeated by huge pistons reciprocating back and forth between the compressed gas within the shock absorbers and the impact of the bomb-driven plasma out in space. The crew would be watching oil levels, steam pressure gauges, and critical voltages, but as the bombs descended with a hiss of vapor once per second, they would have little indication that they were aboard a spaceship from the age of nuclear energy rather than a storm-tossed vessel from the age of steam. Jules Verne, born in 1828, or Michael Treshow, born in 1894, would have been equally at home aboard Orion. Below decks, the engine room would appear as familiar to a steam engineer from the nineteenth century as to a rocket technician from the twenty-first.