Activity 32

Supplier management

Overview

The longer-term health and sustainability of any category solution are critical for the category team to establish before a category project is concluded. As most category solutions involve third-party suppliers, there should be a critical element within the category strategy that determines how the future solution is managed and resourced.

The category team must ensure that a detailed supplier relationship management (SRM) or contract management plan is worked through and established once the category has transitioned into its new operational environment. This will facilitate positive communication and understanding between the buying organisation and the category suppliers with regards to their roles, expectations and delivery requirements.

This needs to be done as part of the handover into the business and should consider the length, complexity and criticality of the contractual relationship, together with any ongoing issues that may arise over the term of the category solution. This will enable the most applicable form of supplier management to be put in place.

Elements

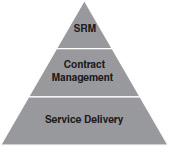

In terms of managing the supply solution once the category strategy has been implemented, it is commonly held that there are three main ways in which this might be undertaken, all of which might be applicable, or conversely just one may be adopted. Selection is dependent upon the relative importance of the supplier to the buying organisation:

- 1 Supplier relationship management (SRM) – SRM is regarded as a strategic approach to a buyer-supplier dyadic and is founded on principles such as trust, openness and continuous improvement. It centres on managing the relationship in order to gain additional value, usually from those in a so-called partnership arrangement. Not all agreements will necessitate the utilisation of this philosophy, but rather only those that are regarded as vital to the business.

- 2 Contract management – Contract management concentrates on ensuring that what was agreed by both parties is implemented and that no value is eroded, with the main driver being the contract management plan. Measurement techniques like service levels (SLs) and key performance indicators (KPIs) are instrumental to this process. There will be a far larger number of suppliers that will need to embrace this monitoring/management approach.

- 3 Service delivery – This is where implementation is carried out at ‘shop-floor’ level, that is between those using/consuming the product, and therefore this relies upon an operational working relationship between the individuals concerned. All contracts will have an element of service delivery, although those that are viewed as purely tactical arrangements may only have this form of supplier management in place.

So what?

A clear and concise plan that stipulates how any future supply-based solutions are to be managed is essential if maximum benefit is to be derived by the category team. In effect, implementing a supplier management approach helps make the benefits and any value added stick.

It should be remembered that supplier arrangements will vary in magnitude, and therefore an effort-versus-reward equation will need to be made so that optimum available resources may be deployed. Business participation in this decision-making process gains buy-in, which should make the adoption of any change (e.g. onboarding of a new supplier) less contentious and conflict bound.

Category management application

- Identifies who is responsible for ensuring ongoing contract compliance and delivery

- Helps manage future supply-base risks

- Provides an opportunity for stakeholders to buy in to the change

- Identifies contracts that may be strategically relevant in the long term

- Facilitates added value and continuous improvement developments

Limitations

There is confusion amongst the practitioner community when it comes to defining the activities of supplier management. There are many different terms in existence, and this creates a problem of consistency when it comes to applying the relevant tools and techniques.

This is a wonderful opportunity for consulting companies to offer you toolkits and methodologies, many of which are unnecessarily excessive. The ‘business case’ for supplier management is rarely driven from any incremental cost savings; rather it is far more likely to deliver risk assurance, which means it is harder to justify on financial grounds.

In addition, it is common for buying organisations to underestimate the level of manpower required to embed supplier management. It is especially important for the category team to gain business sponsorship for critical suppliers; otherwise, continuous improvement and value-added activities can be overlooked or given a low priority.

Template

The following template may be used to support supplier management activities:

- Template 32: Supplier management review