When you design a piece, one of the first decisions you’ll make is what kind of metal to use. The color, tone, and temper of the metal will all impact the final look. Sheet metal and wire come in a multitude of materials, giving you the flexibility of working within your price range. The projects in this book use four different metals, all of which are easy to find and easy to work with.

Copper and brass are base metals, which are inexpensive and common. Base metals can be alloys or mixtures of metals. They all corrode and tarnish easily when exposed to air or moisture, so you can expect them to change in color if left untreated. You can protect these metals using sealants (see Chapter 8).

Sterling is a precious metal, which is, by definition, relatively scarce and therefore expensive. In jewelry making, precious metals usually refer to gold, silver, and platinum. They’re quite corrosion resistant. And because they’re a traded commodity, prices fluctuate constantly.

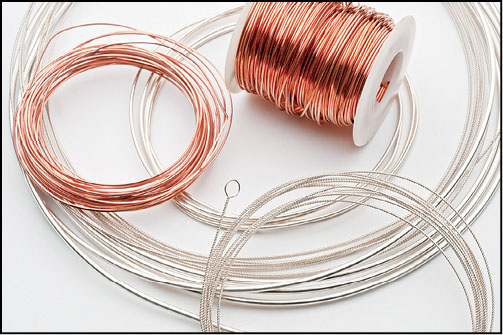

Left: copper and brass; right: sterling

Aluminum is a nonferrous metal, which means it does not contain iron. It resists corrosion and is soft and easy to cut and form.

Aluminum (colored)

Each wire type has specific properties; some are soft and malleable, and others are harder to manipulate. Knowing the properties of your wire is important before you begin working on a piece.

Bezel wire is a thin-gauge wire strip sold in different widths and used primarily for bezeling stones. Because it is precut into thin strips, it is also useful for easy metalsmithing techniques such as stamping, connecting, and riveting.

Bezel wire

This material comes in a variety of prefabricated designs that can be oxidized to enhance the patterns. They are used to create rings, bracelets, dangles, and more.

Patterned wire

Plain sheet comes in a variety of gauges and types. You can usually buy it in small quantities or larger sizes, depending on what your project requires. In order to use shears to cut the sheet, stick to 24-gauge and thinner. For heavier gauges, you will need to cut it using a saw.

Plain sheet

Jewelry suppliers sell sheet metal already imprinted with a texture that can be cut and is ready to use. Depending upon the hardness of the metal, it can also be used as a texture sheet to imprint softer metals.

Pre-textured sheet

Tin cans are readily available and easy to cut with shears. They’re quite thin, so they are very sharp; always use gloves to handle tin cans.

Tin cans

The thickness of metal sheet and metal wire is known as the gauge. In the United States, the standard is Brown & Sharpe (B&S), also known as American Wire Gauge (AWG). The thickness of sheet in inches or millimeters is translated into a numeral from 0 to 34; the higher the number, the thinner the sheet.

Wire gauges

Silver, copper, and twisted wire in different gauges

Temper defines the hardness of metal. There are several methods you can use to change the temper of metal; you can soften, or anneal, metal by heating it (see Annealing). This makes it easier to manipulate as you are working. You also can work-harden, or stiffen, metal by hammering or tumbling it. Work-hardening happens naturally as you are working with your metal, so you may need to periodically anneal it so you can manipulate it easily. Also, you usually want your finished piece to be work-hardened so that it holds its shape.

When metal is referred to as dead-soft, it is fully annealed when you receive it. It’s the easiest to work with and easiest on your tools, such as disc cutters and hole punches. It’s also quite easy to texture, taking impressions nicely from hammers and punches.

Half-hard metal has some spring-back, or stiffness, to it. If you’re not intending to work too long on a piece or texture it much, half-hard will hold its shape better and be less likely to bend during wear.

Hard, or full-hard, metal is the most difficult to manipulate and hold its shape. It’s best for making bangles, chokers, cuffs, and any design where stiffness is an advantage.