CHAPTER 12

Fermentation

Any successful fermentation proceeds along a predictable course dictated by the composition of the wort and the characteristics of the yeast strain. The amount of extract, its dextrin/maltose ratio, the amount and complexity of the nitrogenous matter, the availability of yeast nutrients, the pH, and the oxygen saturation and biological purity of the wort are values that have been fixed by mashing particular malts and boiling, cooling, and aerating the wort.

The only significant influences upon the fermentation that can be manipulated by the brewer are those of the yeast — its character, purity, vitality, quantity, and its rousing — and the temperature and duration of the ferment. Changes in any one of these can affect the residual sugar, mouthfeel, clarity, aroma, and flavor of the beer.

Preparing for Pitching

The fermentation cycle should never be started with a weak yeast; such yeast will only be made weaker upon being diluted into the wort. The yeast to be pitched should have been cultured in a wort similar to that being brewed. Yeast that must undergo significant adaptation suffers a high rate of mortality, causing fermentation to start slowly and be relatively weak. The likelihood of contamination increases and decomposition of dead yeast cells mars the beer flavor.

Sugar solutions should not be used to culture yeast. When yeast is cultured in solutions lacking maltose, it loses its ability to absorb maltose, and suffers from unreasonably long periods of adaptation upon being diffused into the wort.

Approximately .5 to .6 fluid ounces (10 to 14 grams) of pasty, thick yeast is needed for each gallon of wort to be pitched to give 12 to 15 x 106 cells per milliliter of wort. Up to one fluid ounce (21 grams) of yeast is necessary for each gallon of wort when a very strong start is needed, or when the yeast is a weak fermenter. That much is also needed for worts of very low or high extract content. In the first case, more yeast ensure an adequate start in the nutrient-poor environment, and in the latter case are needed to ferment the greater amount of extract.

Pitching too much yeast, however, overtaxes the supplies of dissolved oxygen, simple sugars, and yeast nutrients and can result in yeast autolysis (self-digestion). The rapid fermentation and premature autolysis can result in fusely, estery and rubbery, yeasty and sulfurous flavors.

Less yeast than the amount recommended above should be pitched when the yeast strain has proven to be a very strong fermenter. A good culture should require only .4 fluid ounces (8.5 grams) of yeast slurry per gallon of wort. Conservative pitching rates (.8 to 1 x 106 cells/milliliters per each °Plato of the wort) of healthy yeast are the rule unless experience dictates otherwise.

Conservative pitching rates should not be confused with inadequate pitching rates. Pitching too few yeast results in long lag and reproductive phases, estery aromas, and increased risk of contamination. English ales are commonly pitched at far lower rates (.6 to .8 x 106 cells/milliliter per each °Plato of the wort) where esters are meant to be prominent in a beer’s aroma. In lager brewing, ester formation is repressed in part by limiting reproduction through higher pitching rates. Ale yeasts may grow to five to eight times the amount pitched, while lager yeasts generally increase three to five times.

The pitching yeast should be clear, white-to-tan, its sediment should be thick and rich, and its aroma pure and pleasant. If the culture is collected from the parent ferment at the height of kraeusen and repitched reasonably quickly, the sediment will be composed mainly of healthy yeast. Regular rousing of the culture produces more yeast and a richer sediment. Dusty yeast that remains suspended and does not form a rich sediment by the time it has thrown up a rocky foam cover is unsuitable for pitching.

The yeast culture can be the most significant source of microbial infection to the ferment. A culture that smells or tastes off will produce disastrous results if pitched. Yeast must be handled carefully, so that the brewing strain is cultured, not wild yeast or bacteria.

If a dry yeast absolutely must be pitched, then slurry two to four grams of granulated yeast per gallon of cooled wort into twice its volume of sterile 100 degrees F (38 degrees C) water to minimize shock excretion while the desiccated yeast resuscitates. Cover it and rest it for thirty minutes. It should be raising a frothy head before it is pitched.

(A note of caution: granulated dry yeast may be contaminated by significant quantities of bacteria. It is probably the least viable and most often contaminated source of brewing yeast. Subculturing from a slant, frozen, or liquid culture, or kraeusening from a healthy ferment is more likely to produce a satisfactory fermentation cycle.)

Before pitching, the yeast can be forcefully roused into the first clear runoff from the kettle (force-cooled to the pitching temperature and racked off of its sediment). The purpose is to aerate and evenly distribute the yeast, and allow it to adapt to the extract while the rest of the wort is being force-cooled and sedimented.

Cooled wort in excess of that to be fermented can be run off into the containers in which it will be stored until it is used for topping-up, priming, kraeusening, or for yeast culturing. The amount of wort removed should at least be equal to the requirements listed in table l4. Refrigerate the tightly capped containers until needed; they will keep for at least six months at 33 degrees F (1 degree C).

Kraeusening

Kraeusen is the German word used to describe the infusion of a strongly fermenting young beer into a larger volume of wort or beer that is past the stage of strong fermentation. Kraeusen beer introduces vigorous yeast in its own sugar-rich substratum. It is characterized by the active raising of a tightly knit or rocky foam head. Yeast colonies should visibly cloud the liquid below.

Kraeusen beer should be taken only from ferments that exhibit textbook characteristics. Although successive kraeusening may encourage the culturing of wild or dusty yeast, it still remains the best method by which fermentation may be induced in the cooled wort.

The culture must be strong, so that it is neither overwhelmed by the larger volume of wort nor unable to renew active fermentation in a well-aged, extract-depleted beer. Kraeusen is traditionally obtained from a strong primary fermentation, but it may be made from wort and a yeast culture (yeast starter). Sterile wort is pitched with a culture, and its volume is increased to at least 5 percent of the wort volume by doubling. (The starter volume is built by adding wort in up to a ten-to-one ratio each time vigorous fermentation becomes apparent.) It should be in full kraeusen when it is pitched.

When 10 percent new beer (just coming into high kraeusen) is used to induce fermentation in the cooled wort, the yeast lag-phase is virtually eliminated. The yeast, having adapted to the solution, require no respiratory phase to develop a cell membrane and enzymes appropriate to the given wort. Initial fermentation is stronger. Employing kraeusen beer to top up the secondary (lager) fermenter induces a strong temporary fermentation and reduces diacetyl and the risk of oxidation and contamination at racking.

When wood chips are used to clear the lager beer, aufkraeusening is absolutely necessary. There must be movement of the aged beer so that every part comes into contact with the latticework of chips. The introduction of kraeusen beer at a temperature 5 degrees F (3 degrees C) warmer than the aging beer and the subsequent fermentation create the necessary movement of the whole volume of beer. The chips alone would not otherwise clarify an aged beer.

Kraeusening also reduces lagering time by introducing vigorous fermentation, capable of more rapid metabolism of the small amount of fermentable sugar in the aging beer than the few yeast cells already in the solution.

Good sanitary procedures are an absolute necessity, and whether it is being mixed with wort or with aged beer, the new beer should be well roused in.

Pitching the Yeast

For lager beers, yeast is generally pitched into wort that is at or near the lower end of the intended fermentation temperature range. Although yeast will generally reproduce more quickly if pitched into relatively warmer wort, it will also produce more diacetyl, fusel alcohols, and esters.

Where practical, it is advisable to separate the chilled wort from the cold break in a settling tank. The yeast may be pitched in the settling tank up to twelve hours before the wort is transferred to a fermenter, or during the transfer. The wort temperature is generally allowed to rise to 39 to 43 degrees F (4 to 6 degrees C) before it is racked off the cold break into the fermenter along with the yeast starter, slurry, or kraeusen beer. Where a settling tank is not employed, the wort is generally pitched at 42 to 47 degrees F (6 to 8 degrees C).

The pitching yeast is commonly added at a temperature up to 5 degrees F (3 degrees C) warmer than the wort, and well roused into it in an aerating fashion. Because brewers’ yeast requires considerable dissolved oxygen (eight to twelve milligrams/liter) to synthesize fats to cell-wall consituents, a stream of air is often used to effect this mixture of yeast and wort. An aeration stone or other device that increases air-to-wort surface contact improves oxygenation. Gentle rousing should be continued throughout the transfer to achieve an intimate admixture and to dissolve oxygen into the wort.

Care should be taken that the wort’s trub sediment is not disturbed, especially as its draining nears completion. Good hot and cold breaks are meaningless if a significant amount of trub is carried into the ferment. Racking should cease as soon as the runoff shows the least bit cloudy; trub carried into the ferment taints the beer with objectionable flavors and aromas.

Proteinaceous precipitate from the hot and cold breaks forms the greatest part of the trub. Although amino acids are absolutely necessary for yeast metabolic functions, yeast react to an excess of simple protein by generating aromatic fusel alcohols. Even more of these volatile carbonyl compounds are excreted when the wort has been underoxygenated. Fusel alcohols are subject to esterization, which produces fruity and solventlike odors that are inappropriate in a lager beer, and to oxidation, forming “stale”-tasting aldehydes.

Trub also contains polyphenols, ketones, and sulfur compounds that may be absorbed into the ferment. Polyphenols give astringent-tasting, mouth-puckering flavors. Volatile sulfur compounds (H2S, DMS, thiois, and mercaptans) produce rotten-egg, skunky, onionlike, rubbery, and burnt-match flavors and odors.

The Fermentation Lock

Although the release of carbonic gas from the fermentation gives it some measure of protection against oxidation and contamination, covering the fermenter immediately after pitching and fitting it with a fermentation lock is advisable. The airlock allows the pressure created by the carbonic gas to push past the liquid in the lock without allowing air in. This prevents the reverse passage of airborne wild yeast and bacteria into the culture-yeast fermentation. Oxygen trapped within the fermenter by the lock is readily driven off by the rising blanket of heavier carbon dioxide produced by the ferment.

The liquid in the lock should be maintained at a constant level, but not so deep that it puts the fermenting beer under any appreciable pressure. During the primary fermentation, it is essential that virtually no carbon dioxide remain in solution, since it carries malt and hop debris into the head and sulphur compounds and esters out of the ferment.

The purpose of the fermentation lock is to prevent infection. It must be kept perfectly clean. The trap can be filled with an antiseptic solution in which microbes cannot exist, a practice that is advisable during later fermentation. Of course, this solution must not contact the ferment either by splashing caused by excess pressure or by careless handling.

Primary Fermentation

Five to twelve days may elapse from the time the yeast is pitched until vigorous fermentation abates; six or seven days is usual. Ales are fermented at higher temperatures over a relatively shorter period of time to develop characteristic esters and other fermentation flavors. Lagers are suited by lower temperatures, which retard fermentation times and ester development.

The duration of the primary fermentation is also subject to the strength and reducing characteristics of the pitched yeast strain. Nonselective strains that completely ferment the extract work very quickly but produce a thin, inferior-tasting beer. Temperamental strains such as Saaz yeasts incompletely convert the extract during a relatively long, weak ferment but produce a richer-tasting and fuller beer.

Normal primary fermentation is verified by its characteristic low, high, and post-kraeusen stages. Where deviations are encountered, the source of the irregularity should be investigated, identified, and corrected as soon as possible.

Temperature

The temperatures quoted here apply to dextrin-rich lager worts of 10 °Plato (SG 1040) or greater, producing full-bodied beer. If a high-maltose wort relatively free of haze-forming protein fractions is being fermented, or if a top-fermenting yeast strain is used, temperatures should be higher by 6 to 20 degrees F (3 to 10 degrees C). Fermentation times will be correspondingly foreshortened.

Do not exceed the recommended temperatures when fermenting a dextrinous wort with lager yeast. The yeast requires the longer fermentation time at the lower temperatures to break down and convert the less readily fermentable dextrinous sugars. Moreover, higher temperatures invariably cause an increase in esters, fusel alcohols, and solventlike flavors that are inappropriate in lagers.

Temperature Control

Fermentations generate heat. The temperature of any ferment must be monitored and the excessive heat drawn off by lowering the ambient temperature. In no case should the internal temperature of a lager ferment exceed 60 degrees F (15 degrees C), and it should be limited to a cumulative increase of 7 to 14 degrees F (4 to 7 degrees C) relative to the starting temperature.

Ideally, the maximum temperature should not rise above 47 to 52 degrees F (8 to 11 degrees C) when employing traditional lager strains. The maximum temperature may be maintained through high kraeusen until yeast nutrients are depleted, yeast activity slows, and heat generation ends, or even raised for “diacetyl” rest, but it is usually lowered soon after the maximum temperature is reached.

Controlling the temperature at the beginning of fermentation is more important than controlling the temperature near the end of fermentation, because esters and fusel alcohols are largely produced when the yeast is respiring, during the lag and reproductive phases of fermentation.

Temperature changes at any stage of the fermentation should not exceed 5 degrees F (3 degrees C) daily. Abrupt reduction in temperature will shock the yeast and may arrest fermentation completely. The sudden death of many yeast cells deleteriously affects flavor; moreover, yeast mutations tend to adapt to a sudden temperature change more readily than culture yeast. Temperature maintenance and modification must be handled carefully.

Convection currents within the ferment (formed by asymmetrical cooling of the fermentation vessel) improve temperature distribution and yeast performance, producing a more even fermentation.

Density and pH Monitoring

The acidity of the ferment increases as the yeast adapt and respire glucose to succinate and other organic acids. With top-fermenting yeast, the pH drop during respiration is dramatic; it falls .4 to .6 within twelve hours of pitching and to pH 4.0 within twenty-four hours, before it levels off as fermentation begins in earnest. With lager yeast, the pH drop is much less precipitous; for a wort of pH 5.3, a .5 drop requires forty-eight hours, and the pH only falls to 4.5 or so by the end of primary fermentation. One measure of consistent yeast performance is its effect on the pH of the extract solution. To this end, monitoring the pH is critical during the lag phase of a top-fermenting culture, and at the low, high, and post-kraeusen stages of a lager ferment.

The liquid pressure of the fermenting beer also makes its most dramatic drop during primary fermentation and should be regularly checked and logged to define yeast activity and pinpoint racking time.

Primary Fermentation: Lag Phase

After pitching, yeast take some time adapting to the conditions of their new environment. During this “lag” phase, there is little visual evidence of their activity. How successfully the yeast culture adapts to the wort depends upon the number and condition of the yeast cells and the nature of the wort itself. Temperature, density, glucose/maltose content, amino acid availability, and the level of dissolved oxygen all influence yeast behavior.

At pitching, yeast rely on free oxygen, wort fatty acids, and glycogen, an intracellular carbohydrate reserve, to provide energy for the synthesis of wort-specific enzymes and a permeable cell membrane. Glycogen is structurally similar to the amylopectin of malt starch, but with a greater number of shorter branches. Without adequate glycogen reserves, the pitched yeast cannot survive until they can develop the ability to absorb and metabolize wort sugars and nutrients.

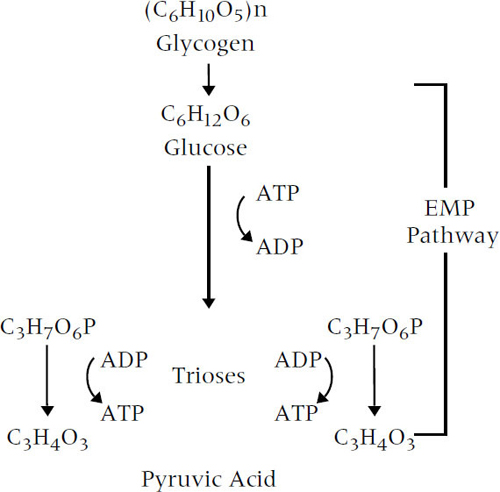

During the lag phase, yeast employ a complex enzyme system to hydrolyze the polymeric glycogen to glucose. The glucose molecule is phosphorylated and its carbon links broken (glycosis) to yield two triose phosphates. These simpler three-carbon compounds are oxidized to pyruvic acid (pyruvate, an important yeast oxo-acid) with the release of energy by formation of energy-rich ATP, adenosine triphosphate, from energy-depleted ADP.

An inadequate starch reserve may be characteristic of a particular yeast strain, but more often this is due to depletion of glycogen from storing a culture for too long or at too warm a temperature. A culture that survives glycogen deprivation produces abnormal levels of vicinal diketones (especially diacetyl), marring the beer flavor. Fermentation takes longer and is less vigorous, because there are fewer cells, and consequently, slower yeast growth.

Yeast cells also store simple acids, alcohols, nitrogen, and phosphates catabolized from compounds assimilated during culturing. At pitching, yeast employ other enzyme groups to combine these simple chains, synthesizing many of their complex structural and metabolic requirements. Pyruvic acid is reduced to oxaloacetate, from which amino acids and proteins may be synthesized, or to acetyl Co A, an acyl Co A, an acetic-acid-related sulfur compound that can be oxidized to a host of fatty acids, triglycerides, and lipids required for cell-membrane synthesis. Molecular oxygen is required for these reactions. The synthesis of a ten-fold increase of sterols in the yeast to make cell walls permeable requires oxygen. Unless there is sufficient dissolved oxygen in the wort, the formation of a cell wall able to react to and regulate uptake of the particular sugars and nutrients in that wort will cease. Unable to selectively absorb nutrients from solution, many yeast cells will autolyze, and surviving cells will not develop normally. Both scenarios produce off-flavors in beer.

Lacking dissolved oxygen, acetyl Co A esterifies alcohols, including fusel alcohols. These solventlike and harsh-tasting “higher” alcohols are intermediate products of amino-acid metabolism and are normally oxidized back to organic oxo-acids. When respiring yeast lack oxygen, fusel alcohols may be excreted or dehydrated by acetyl Co A to esters. The principle ester formed is ethyl acetate, which irreversibly flavors the beer with fruity/solventy aromatics.

Inadequate oxygenation also causes pyruvic acid, fatty acids, and amino acids to be decarboxylated to aldehydes. These too are normally metabolic intermediates, but without enough oxygen, brewers’ yeast must absorb trub to fuel sterol synthesis, and “staling” compounds are excreted. They may be reabsorbed by the yeast during fermentation, but they are just as likely to be further decarboxylated to fusel alcohols or remain after fermentation ceases. Acetaldehyde, the aldehyde of pyruvic acid, usually predominates, giving an odor like green apples.

As the yeast depletes its glycogen reserves, it starts to absorb glucose and fructose from solution and begins to manufacture the enzymes and permeases necessary to reduce other wort sugars. Only the monosaccharides and sucrose in wort can be absorbed by yeast that have not adapted to the wort into which they have been pitched.

Permeases are enzymelike transports that carry specific compounds through the plasma membrane and into the yeast cell. The yeast must synthesize permeases to absorb maltose and maltotriose, and the enzyme a-glucosidase to hydrolyze them to glucose. Lager yeast (S. uvarum) synthesize and excrete melibiase to split and absorb the disaccharide melibiose. Other inducible enzymes are formed and secreted to the yeast’s outer cell-membrane surfaces after maltose and maltotriose are depleted. These sever glucose molecules from dextrins to fuel subdued metabolism.

The lag and respiratory phases are generally longer when yeast have not been cultured in a solution similar to the wort into which they will be pitched. Prolonged adaptation, common with granulated dry yeast, can lead to the increased formation of fusel alcohol and esters. Culturing in solutions that contain a high percentage of corn sugar or glucose inhibits the formation of maltose permeases. Worts high in corn sugar suffer prolonged lag phases; some yeast strains even lose the ability to ferment maltose in high glucose worts (catabolite repression, or the glucose effect).

The first evidence of yeast activity is usually the formation of wisps of lacy white foam on the surface of the beer eight to twenty-four hours after pitching. Gradually this foam forms a wreath at the rim of the fermenter, and the beer below becomes milky-white from the haze of suspended yeast colonies. Carbon dioxide production is prodigious, although attenuation of the wort is slight. Most of the CO2 is being released as a byproduct of pyruvic acid decarboxylation to acetyl Co A and oxo-acids; the carbon source for this reaction is glycogen, and only very little of the wort sugar is being metabolized.

If the yeast lag-phase extends beyond twenty-four hours, and the wort and yeast starter were originally well roused and oxygenated, then more yeast should be pitched. Rousing the quiet beer may cause the yeast to start fermenting, but as a rule, more yeast should be pitched. If the extended lag phase appears to be characteristic of the yeast strain, it should not be recultured; if it is due to prolonged storage of the culture before pitching, or to wort composition, the problem should be remedied.

As the yeast build cell walls and reserves up during the lag phase, they begin reproducing. As long as dissolved oxygen remains available in the wort, the yeast will utilize it to fuel anabolic reproduction. This respiratory period marks the period of greatest culture growth. Yeast growth, then, is most dramatic in a well-oxygenated wort.

Low Kraeusen

Although free molecular oxygen is not necessary for yeast growth, it does facilitate it. Yeast can utilize carbon as an energy source fourteen times more efficiently by respiring molecular oxygen than it can by fermenting it anaerobically. Yeast cells reproduce more rapidly in an oxygenated solution, but normally continue reproduction at least until maltose is depleted.

The yeast begin budding as the lag phase ends, and rapidly scavenge the free oxygen from the wort in the early part of the low-kraeusen stage. As long as readily assimilable nutrients remain, the yeast continues reproducing, albeit at a gradually slowing rate.

As they deplete the molecular oxygen, the yeast begin anaerobic wort metabolism. Within six to thirty-six hours of pitching, the foam wreath should begin to migrate toward the surface center, marking the commencement of the low kraeusen stage of primary fermentation. It characterizes the start of intense catabolism of maltose, the uptake of a wide range of wort amino acids, the gradual transition from respirations to anaerobic fermentation, and a period of exponential yeast growth.

Low Kraeusen

As the head rises to form low, rich mounds and curls of foam, it carries with it protein, hop residues, and degenerated yeast cells, which are visible as a brown scum that collects on the head and at the surface edge. In closed fermentations, the scum may be eliminated by being “blown off” along with some of the liquid supporting it, or allowed to drop. In open systems, it is eliminated from the fermenter by skimming. If oxidized scum is allowed to fall back into the ferment, it will impart harsh, bitter tastes to the beer and provide a nutrient source for bacterial contaminants. Care must be taken that the fermentation is not contaminated if it is exposed for skimming. A low humidity improves atmospheric purity, reducing the likelihood of contamination.

The ferment may be topped-up with sterile wort or liquor to compensate for evaporation and blowoff or skimming losses, although it is more practical to compensate for these losses by increasing initial wort volume.

At this point, the yeast have completely adapted to the conditions of the ferment and are rapidly multiplying. Extract reduction should be about .5 °Plato (SG 1002) during this brief low-kraeusen phase. The pH also declines as organic acids are released as by-products of the yeast metabolism of amino acids.

The major fermentation products are ethyl alcohol (ethanol) and carbon dioxide, but even during a normal fermentation cycle, other compounds are excreted by the yeast. The metabolism of the yeast is fueled primarily by the hydrolysis of carbohydrates, but amino acids and fatty acids from the wort also serve as energy sources.

Normal carbohydrate metabolism follows the EMP pathway to pyruvic acid so that ATP may be regenerated to fuel, continuing biosynthesis of the yeasts’ metabolic requirements. The ADP-ATP cycle, however, cannot continue if pyruvic acid buildup is left to block it. Pyruvic acid in excess of that required for acetyl Co A and oxaloacetate synthesis is metabolized to CO2 and acetaldehyde by the yeast enzyme pyruvate decarboxylase. The CO2 is excreted. Acetaldehyde is hydrated to ethyl alcohol by the enzyme alcohol dehydrogenase so that hydrogen buildup blocking the ADP-ATP synthesis can also be eliminated.

Nitrogen metabolism is closely related to glucose hydrolysis. The yeast enzymatically split amino acids in the wort and separately absorb the nitrogenous amino groups (NH2) and oxo-acid skeletons. These can be reassembled as amino acids, or as proteins, appropriate to the yeasts’ requirements. Oxo-acids necessary for amino acid synthesis may also come from carbohydrate metabolism, and similarly there are several other ways in which oxo-acids are used with consequences affecting beer flavor. They may be decarboxylated to aldehydes, and the aldehydes hydrated by the enzyme alcohol dehydrogenase to form fusel alcohols. Lack of dextrinous sugars, trub in the yeast cake, and elevated temperatures all contribute to the formation of piquant, solventlike, and highly aromatic harsh fusel alcohols.

Oxo-acids may be metabolized to acetohydroxy acids, which are not metabolized by the yeast and are therefore expelled by them. During low kraeusen, this provides for the elimination of oxo-acids (primarily from pyruvic acid), which carbohydrate metabolism is producing in excess.

Excreted into solution, acetohydroxy acids can be oxidized to vicinal diketones, principally diacetyl (dimethyl diketone, C4H6O2). Diacetyl has a perceptible buttery flavor, which is objectionable in amounts above .15 ppm; during low kraeusen it may be as high as .35 ppm. That there is some oxygen in the ferment during low kraeusen and that the temperature is not unreasonably depressed in later fermentation are both important to diacetyl control, because after yeast growth has slowed, healthy cells reabsorb vicinal diketones and metabolize them to harmless diols. When the acetohydroxy acid is not oxidized to vicinal diketones during vigorous early fermentation, later diacetyl formation may irreversibly mar beer flavor. The presence of dissolved oxygen later in fermentation also increases the likelihood of oxidation of acetohydroxy acids to diacetyl; vigorous anaerobic fermentation after the low kraeusen stage is essential to diacetyl control.

High Kraeusen

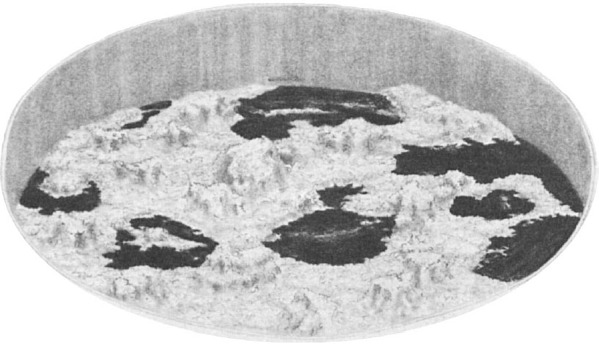

With top-fermenting yeast, a thick head of clumped yeast covers the beer soon after intense fermentation becomes apparent. At their normal operating temperatures, top-fermenting yeast have largely metabolized the sugars in solution at a time when lager yeast are still undergoing growth. Not until eighteen to seventy-two hours after the mounds of foam begin to form (two to four days after pitching) do the lager yeast weave a tightly knit cover over the surface of the beer. This cover rises further and finally breaks into cream-colored, less dense, “rocky heads.”

In a lager fermentation, extract reduction approximates l °Plato (SG 1004) daily over the two to five days of high kraeusen, while the yeast may still be reproducing logarithmically. The temperature must be exactly controlled.

Although 60 degrees F (16 degrees C) is given as the maximum allowable temperature, with most lager yeast strains every effort should be made to hold it to 47 to 52 degrees F (8 to 11 degrees C). When this temperature is reached within the ferment, the ambient temperature can begin to be lowered if diacetyl levels in the beer are not a problem. The temperature should not be lowered more than 5 degrees F (3 degrees C) daily and should be reduced to 38 to 40 degrees F (3 to 4 degrees C) over several days. The temperature at the conclusion of a traditional kraeusen fermentation is usually about 45 degrees F (7 degrees C).

The continued release of organic acids during high kraeusen reduces the pH, depending on the yeast strain and wort characteristics, to 4.0 to 4.5. If the pH drops too rapidly, the yeast will settle out of suspension prematurely; if the pH drops too slowly, it may prevent the beer from clearing properly.

Post Kraeusen

The extract is largely metabolized by the yeast during high kraeusen. As the yeast activity slows, carbonic gas production slows, and consequently the agglutinated yeast colonies sink out of suspension and the foam head is no longer formed.

Late Kraeusen

At this point, all of the head can be floated, siphoned, or skimmed off, even as more is forming, so that it does not fall back through the beer. An exception to this procedure is made when a low-extract, quickly maturing beer is being brewed. Such a beer requires the peptides and amino acids from clean foam for yeast nutrients and for body. The increase in the alcohol content of the beer induces the reabsorption of the albuminous matter into solution. Only a clean head should be allowed to fall back through the ferment. Residual scum gives the beer a harshly bitter background flavor. The stability of the beer is invariably less than if the head is removed or the beer is quickly separated from its trub after the head falls.

Generally, four to six days after high kraeusen begins (six to ten days after pitching), the formation of the foam cover ceases. As the availability of fermentable extract drops during the post-kraeusen stage, the yeast adapt to changing conditions by accelerating their secretion of extracellular enzymes capable of splitting off glucose from dextrins in solution. Reasonable levels of diacetyl and the related diketone 2,3-pentane dione are also absorbed and metabolized by the yeast. It is important that the fermentation temperature not be prematurely lowered and that the beer not be racked off its yeast sediment until the diacetyl has been reabsorbed. With a clean fermentation, it is usual for the beer to be held in the primary fermenter for two or three days after the kraeusen head has fallen, with the temperature being lowered from 45 degrees F (7 degrees C) to 38 to 40 degrees F (3 to 4 degrees C). The extract drop over the final twenty-four-hour period of primary fermentation should be about .5 °Plato (SG 1002), and the density should be about one-third what the wort density (OG) was.

An entirely different approach is relatively common in modern fermentation cycles. When the density drops to about 1.5 °Plato (SG 1006) above the target terminal gravity, the brewer raises the temperature of the post-kraeusen beer to 52 degrees F (11 degrees C) or higher, and holds that temperature for two to seven days for a diacetyl rest to reinvigorate the yeast culture so that it will metabolize diacetyl, removing it from solution.

Because fermentable extract is rapidly consumed at the higher temperatures of the diacetyl rest, subsequent conditioning can be foreshortened. Secondary fermentation will be both subdued and brief, and lagering may require only fourteen to twenty-one days to achieve the same clarity and flavor stability (but not the same flavor development) that would be expected with the usual five-to-seven-week secondary fermentation and lagering.

Real and Apparent Attenuation

Normal primary fermentation ends when head formation ceases; this may take as few as five days when the wort is below 10 °Plato (SG 1040), or eight to ten days for a very rich and dextrinous wort. Roughly 50 to 65 percent of the extract will have been converted to alcohol and carbon dioxide, although the hydrometer may show a 65 to 80 percent reduction in density (“one-third gravity”). The difference between the real attenuation of the beer and the apparent attenuation as gauged by the hydrometer is usually about 15 percent. This phenomenon occurs because the hydrometer measures liquid pressure, and does not reflect the fact that this pressure has been reduced by the formation of alcohol as well as by the reduction of the fermentable extract. Because alcohol is far lighter than water (the liquid pressure of pure water is SG 1000; of alcohol, 798), the hydrometer sinks further into a solution in which alcohol is present, and the hydrometer reading is lower than the extract loss alone can account for.

The real attenuation can be determined. First, a volume of beer is measured at the temperature the brewer’s hydrometer is calibrated to, usually 60 or 68 degrees F (15.56 or 20 degrees C), and is decarbonated, usually by membrane filtration. This volume of beer is raised to a temperature of 173 degrees F (78 degrees C) or slightly higher and roused for thirty to sixty minutes to drive off the alcohol. The sample is cooled to 60 degrees F and topped-up to its original volume with distilled water. The volume of water required to replace the lost volume of beer, divided by original volume, is equal to the percent alcohol by volume of the beer. The hydrometer reading of the dealcoholized sample, after topping-up, accurately reflects the real extract content of the beer. The real attenuation is measured by subtracting this reading from the original °Plato (OG) of the wort.

Racking

The beer is carefully racked off its settlement when its density is one-third or less of the wort density (OG) and its drop over the preceding twenty-four hours is .5 °Plato (SG 1002) or less. A reducing-sugar analysis usually shows less than 5 percent. The beer should be free of any foam cover. The transfer to a closed secondary fermenter should be made under antiseptic conditions, and all equipment should be sanitized before use.

The purpose of racking is to separate the beer from decaying yeast cells and flavor-impairing precipitates. Care should be taken that no yeast sediment or trub is carried along into the secondary fermentation. Siphoning or decanting must be terminated just as soon as the runoff becomes the least bit cloudy.

Employing up to 5 percent strongly fermenting kraeusen beer at racking produces a stronger start of secondary fermentation and a better overall fermentation. This absolutely must be done when yeast performance during primary fermentation has been poor, as it replenishes the degraded culture.

Racking must be done without rousing or splashing to prevent oxygen from entering the solution. Oxygen in beer past early kraeusen poses serious consequences to the beer flavor: oxidation of acetohydroxy acids in the secondary fermenter produces diacetyl that the yeast may not reabsorb; alcohols may be oxidized to aldehydes; amino acids may be oxidized to fusel alcohols; acids may oxidize alcohols to esters; and phenolic material may polymerize and become haze fractions. It is also advisable that the secondary fermenter be topped-up with kraeusen beer or wort so that only enough airspace remains to allow for very mild foaming. Cone-bottomed “unitank” fermenters preclude the necessity for racking to a secondary fermenter/lagering tank. Trub is discharged from the bottom outlet throughout the course of the primary fermentation, and yeast is collected as it sediments.

Gauging Yeast Performance

A sample of the beer at racking should show very clear and bright. It should demonstrate a good break. When held up to the light, it should show clear. When agitated, distinctly visible suspended yeast colonies may float about, but upon resting, should settle out rapidly and firmly. Such a yeast is satisfactory for collecting to be repitched and for employment in a long secondary and lager fermentation.

Only “break,” or Bruchhefen, sedimentary yeast form colonies as the yeast nutrients in the beer diminish. Powdery or dusty Staubhefen yeast do not sediment in so clean a break and are likely to remain as a foam cover on the beer surface even after measurable attenuation falls off.

Dusty yeast ferment more of the extract than do break yeast, and do so more quickly. Beer brewed with dusty yeast is unsuitable for long secondary fermentation and lagering, because the yeast have largely eliminated the less readily fermentable extract necessary to support aging. Lagering must be conducted at lower temperatures (as low as 30 degrees F [-l degree C]) to increase sedimentation and retard fermentation. The beer should be racked into the secondary/lagering fermenter before the density has dropped much below one-third that of the wort (OG).

The appearance of dusty yeast in a ferment is usually due to the propagation of an inferior strain and/or harvesting late in the fermentation cycle. It should not be used for repitching.

Yeast Collection

Fermentations displaying normal characteristics and desirable flavors are the best sources of yeast suitable for culturing. If the yeast have deteriorated (the beer is tainted with burnt-rubber or sulfury flavors, or fermentation is sluggish), are unable to reabsorb diacetyl (buttery taste and aroma), or are contaminated by wild yeast (cloudy beer after kraeusen, medicinal flavors) or bacteria (abnormal, sour, vegetal, or rancid-butter taste and aroma), the culture is not suited for repitching or culturing.

Seed yeast for subsequent brewings, culturing, and bottle priming should be collected only from the middle layer of the primary-fermentation sediment. The sediment should be relatively clean; an undisturbed sediment is composed of three distinct layers. The very thin, dark upper layer and the bottom layer of dead, inferior cells and trub sandwich between them the active, healthy, white yeast, or barm. Barm has the best fermenting qualities — strong cells that agglutinate well and settle out properly. Where an open fermenter is used, after the beer is transferred from the primary fermenter, all of the top layer is scraped aside before the middle layer is gathered up into a sterile container. When a closed fermenter that has no yeast-collection system at its base is used, the entire sediment is washed out and the barm separated from the trub by several rinsings, which float off the dead cells and organic residues. With cone-bottomed fermenters, collection begins when the sediment begins to run clean, and ceases when it becomes discolored again by settling trub.

Yeast collected for repitching can be covered with very cold, biologically clean water and agitated into suspension. When most of the yeast has settled, the water is decanted off, taking with it dead cells and trub. The rinsing is repeated. A subsequent acid wash with phosphoric acid or ammonium persulfate solution destroys bacteria, but the yeast culture may need to be recultured to restore its normal fermentation characteristics.

Depending upon the strain, yeast covered with sterile wort in a container fitted with a fermentation lock can be stored at 32 to 40 degrees F (0 to 4 degrees C) for from seven to twenty-one days without significant deterioration. If the seed yeast will not be pitched within that time, it must be fed again, or drained, pressed, and frozen.

Again depending upon the strain and the sterility of the conditions, lager yeast may be subcultured through as many as twenty successive brewings if they are repitched within twenty-four hours of collection. If the period between repitching is longer, or the strain is prone to mutation, it may be usable for only four or five intermittent brewings. As a general rule, the greater the frequency of use, the more times a strain may be directly subcultured.