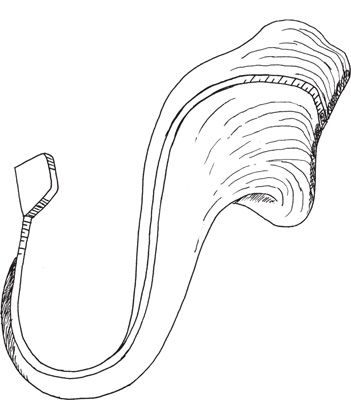

Musk ox are very unusual trophies in both appearance and the conditions under which they must be hunted. The horns of musk ox are quite unlike those of any other North American big game animal. They are very broad on the top of the head and the two horns almost touch along the middle of the skull. The horns grow downward from the top of the skull and then turn upward to the tip in a S-shaped fashion, somewhat resembling Cape buffalo horns in both shape and development of the bare, broad “boss” area of the horns where they emerge from the skull.

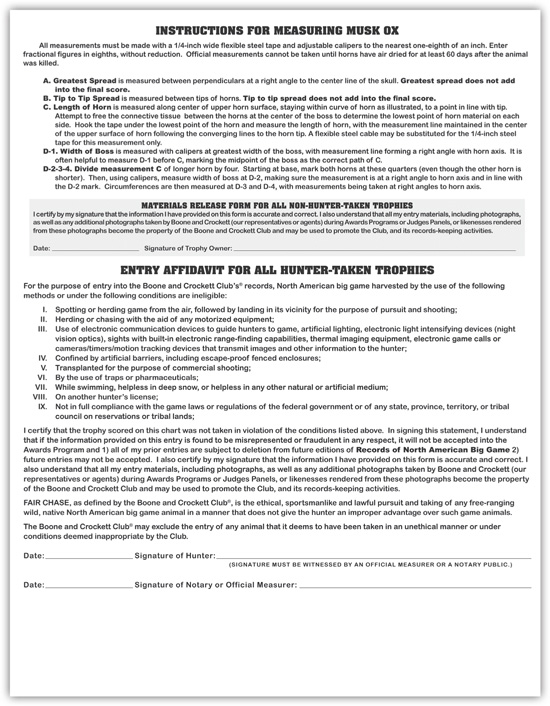

Prior to measurement, musk ox skulls should be cleaned by boiling and then removing all flesh and cartilage. It is important that all soft connective tissue be removed between the horns at the top of the skull. This is necessary so that, after the skull and horns have dried for 60 days after cleaning, the inside lower edge of the horn can be properly located to begin the horn length measurement.

As in all horn measurements, location and accuracy in measuring the lengths of the horns is vital to the subsequent measurements. The correct line of measurement is along the upper surface of the horn as it grows from the skull. As the curl reverses its direction, the measurement line remains in the same linear plane as begun, staying on the continuing upper surface that which may gradually turn upside down in the curling tip.

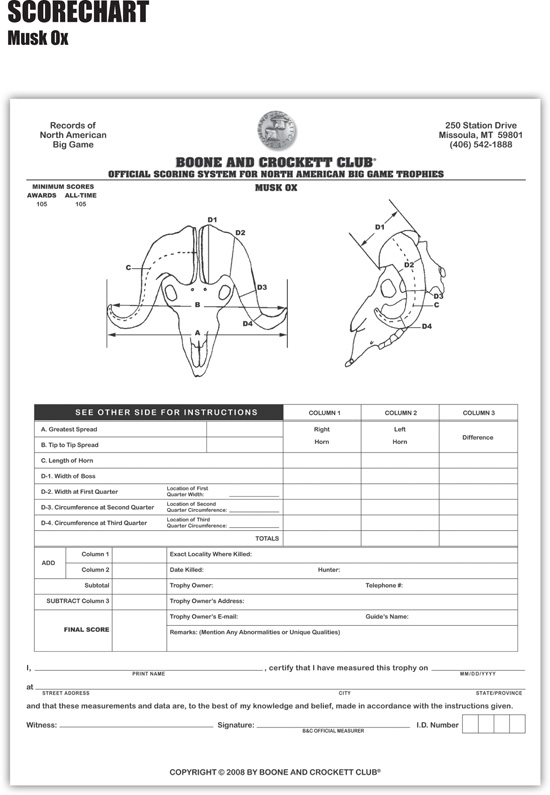

Prior to making the length of horn measurement, one must first locate the center point of each boss (the enlarged and flattened skull portion of horn), since the length measurements pass over these points. To locate the center of the boss, the width of boss is determined. Unlike other horned game, the D-1 (and D-2) measurements are not circumferences but rather the straight-line widths of the bosses.

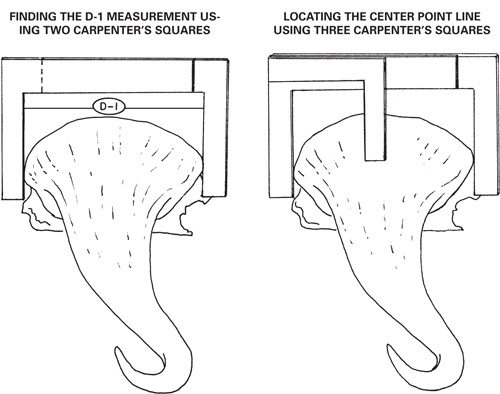

Calipers are often used to take these two measurements. Care must be taken to position the calipers properly at a right angle to the horn axis at the point of measurement. The caliper ends should be snug against the horn but not under tension. If the ends are under tension, the measurement line will “shrink” slightly when the calipers are removed and thus give an inaccurate measurement. When the calipers have been properly placed and closed correctly to reflect the greatest width of boss at the measurement point, they are carefully removed and placed against a folding carpenter’s ruler or steel tape to determine the length of the measured line. This value is recorded as D-1.

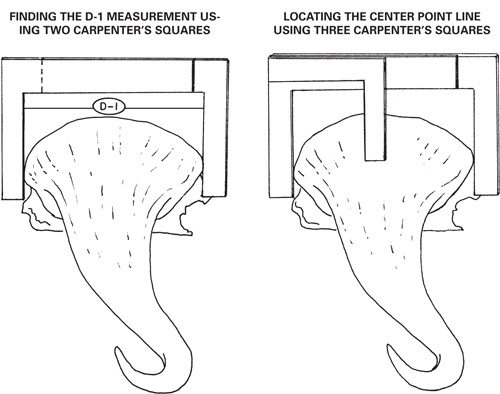

Two carpenter’s squares held together with small clamps can also be used. The arms of the two squares are held together and slowly moved inward until they contact the front and rear edges of the boss at its greatest width at right angles to horn axis.

The D-1 value is then divided by two and that value noted. The measurer then places a mark on the top of the boss corresponding to this half-width. One advantage of using the two carpenter’s squares is that a third square can be set perpendicular to the other two to drop the center point line from the squares onto the boss. If calipers are initially used, you will still need a carpenter’s square to find the actual center point. Due to the coloration of some horns, it may be easier to see this mark if a piece of masking tape is placed at the approximate center location and the mark placed on the tape. Figure 14-A illustrates the use of carpenter’s squares for finding D-1 and the center point mark. Since the boss widths may vary from side to side, each will need to be taken separately and separate center marks made on each boss.

The length of horn measurement is begun at the lowest point of horn material at the center of the horn. It may be necessary to free the connective tissue (if not properly cleaned) between the horns at the center of the boss to locate the starting point of this measurement. This location is down between the faces of the boss. If the connective tissue has not separated from the horn material, then the line of measurement begins at the juncture of the connective material and horn. On horns where there is considerable separation of the connective tissue, the horn material may extend deeper toward the skull from the separation. The point of beginning is directly below the center point mark on the top of the boss.

Once this starting point has been properly located, the measurement line then proceeds through the center of the boss, as noted above. Since the first two to three inches of the measurement are often between the faces of the two bosses, it is convenient to make a mark at the two (or three) inch location on tape placed on the boss and then continue measurement from that mark. As figure 14-B illustrates, the line of measurement is then maintained along the upper horn surface (even though “upper” may become the underside of the curve in the horn tip curl) to the point tip or to a point in line with the horn tip. If the horn tip should be broken or noticeably blunted, use a carpenter’s square (or a credit card) to determine the end of the measurement line by forming a perpendicular of the square and horn axis at that point.

Nearly always, the horn shows very visible “grain” in its material, which offers an excellent line to follow in making the length of horn measurement. Simply pick out the groove which best corresponds to the half-width mark on the top of the boss beginning the line as noted above, then follow this grain to the horn tip. It is an excellent idea to place masking tape where the length of horn measurement is to be taken so that the actual measurement line can be marked with a pencil before the length is measured. You can then concentrate on following the marked line you have established, making an accurate measurement.

A mounted specimen presents a problem in locating the start of the line of measurement. On a mounted trophy (or even a poorly cleaned, bare skull), the horn base may be covered with hair, cartilage, or mounting media. On such a specimen, it may not be possible to properly locate the beginning point of the measurement at the base of each horn. In such cases, begin the length of horn measurement at the lowest point of horn material that is visible, which means the measurement will be somewhat shorter than the trophy is entitled to have. Therefore, it is certainly advisable to measure a musk ox before it is mounted.

Once the proper horn lengths are established, locations of the quarters are determined by dividing the longer horn length measurement by four. The Quarter Locations for Circumference Chart in the back of this manual provides these values. Record the values of the three quarter locations in the space provided to the right of each circumference description on the score chart so they can be easily verified if there is any later question about the measurement. Mark the three locations (D-2, D-3, and D-4) carefully on the masking tape along the original line of horn length measurement of each horn with a soft pencil.

Be sure to establish these quarters by measuring from each horn base to the tip. This is essential to give proper matching of quarters on both horns. If the quarters were located by measuring from the tip toward the base, the quarter locations would be placed nearer the base on the shorter horn than on the longer. This would make an artificial difference between the quarter measurements. When marking the quarters on the horn, be sure to hold the tape or cable in place along the original line followed in measuring the length of horn.

The D-2 measurement is taken in a similar fashion to the taking of D-1 in that it too is a straight-line width measurement. Calipers (or carpenter squares) are generally used to take this measurement. Care must be taken to position the calipers properly at a right angle to the horn axis at the point of measurement. The calipers are held perpendicular to the horn surface at the first quarter mark and then closed to the edges of the main horn material (which usually overlays a portion of the boss). This measurement is of the horn width and does not include the flaring that may be present at the bottom of the horn edges.

The remaining two quarters (D-3 and D-4) are measured as circumferences in the usual manner for horned game. Measure each one by carefully arranging a ring-end measuring tape at a right angle to the horn axis at that point. At the zero point of the tape, the two ends should pass on opposite sides of the pencil mark, with the tape and the horn axis forming a right angle. Snug the tape around the horn before reading the result, again checking to be sure that the tape is correctly positioned on each side of the pencil mark. If you use a clip-end tape to measure circumferences, overlap the tape at a full 10 inch increment to simplify the procedure. Be sure to subtract the amount of overlap before recording the measurement. If it should happen that one horn is broken to the extent that the horn material is completely missing at the D-4 circumference location, simply enter a zero value in the appropriate column of the score chart to reflect this missing value.

The tip to tip measurement is simply from the center of the tip of one horn to the center of the tip of the other. The sweeping curves of the musk ox horns make it impossible on most specimens to take this measurement with a steel tape or carpenter’s folding ruler. A large pair of calipers, required for taking the widths of boss and first quarter, will usually serve to take the tip to tip spread measurement.

Greatest spread is best taken by use of two perpendiculars, such as carpenter’s levels held upright by large c-clamps or perfectly square-cut wooden blocks. The measurement is then taken by a folding carpenter’s rule between the perpendiculars. If perpendiculars are not available, a floor and wall can be used for one perpendicular, with the second being improvised from a carpenter’s level or a straight, square-cut board. In no case should the human eye be relied upon for establishment of the second perpendicular line.

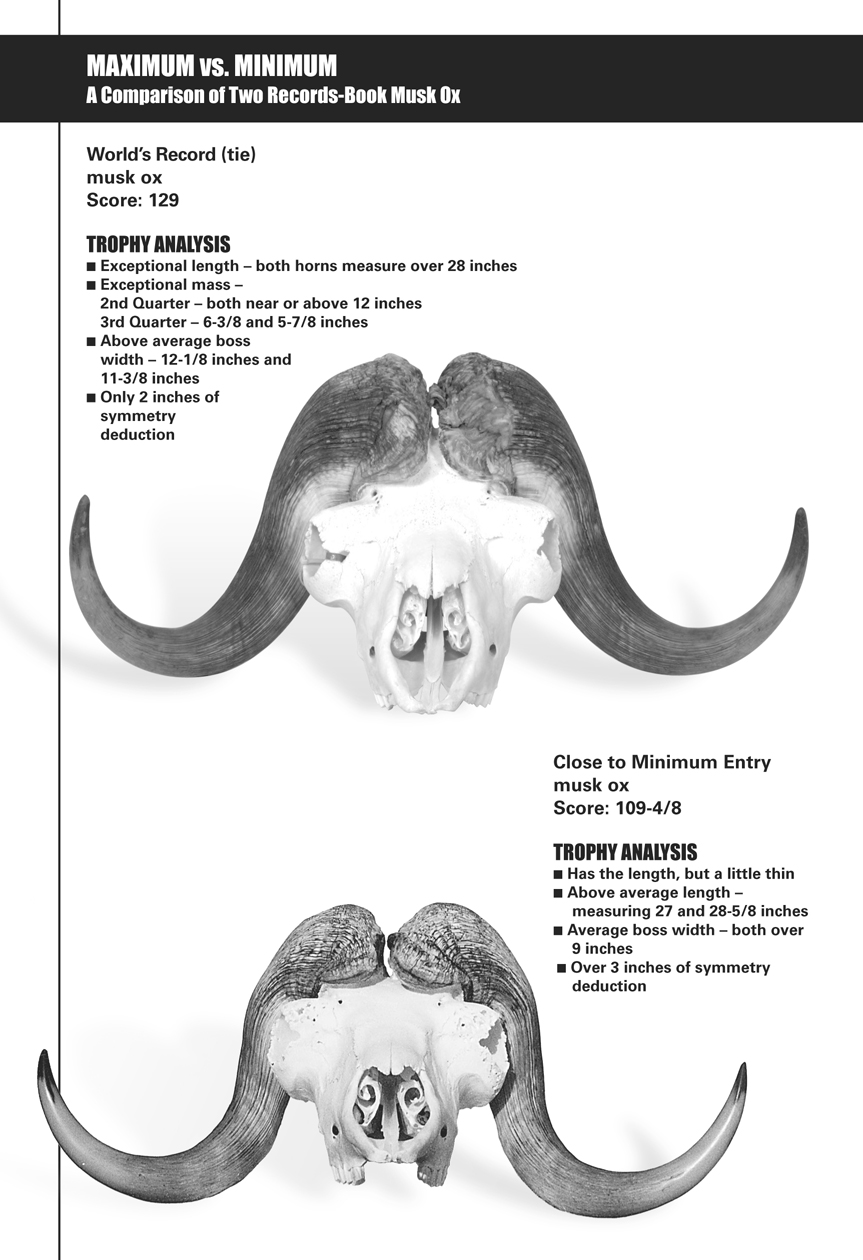

In musk ox, symmetry changes so much throughout the life of the animal that it is the number one consideration when evaluating them under field conditions. It takes about five years to produce a shootable musk ox bull. Such a bull will have the horn bosses “closed-up” and the tips of the horns will have made the full half-circle that they are going to make. Probably about the animal’s seventh or eighth year the maximum length of horn is attained. In Alaska musk ox, this normally means about 25 to 27 inches around the curve.

After the animal’s eighth year, the bosses, and the hairline going down the center of the bosses, begin to move and gravitate toward one side or the other (like a man parting his hair down the middle in his early years and then beginning to move the part left or right as he gets older). But, this can be very difficult to see at a distance. It is important, since a movement of the hairline of just a half-inch will add up to a one inch difference in horn length and a corresponding penalty. And, it will also make a difference in the quarter locations for width/circumference measurements, as well as a penalty for lack of symmetry between measurements.

You should also observe the general condition of the bosses. In the fifth, sixth, and seventh years, it will look like someone whitewashed the top of the bosses. The bosses are the widest, the hairline is in the middle, and the bull has achieved its maximum horn development about the seventh or eighth year. After that, there will be some loss of potential score. Before that time, some potential will not be realized because the edges of the boss are still soft, like a very rapidly growing sheep horn, and in the drying process will probably peel under, losing some material and therefore decreasing potential score.

As the animal grows, the horns grow with a wide flair, much like a cape buffalo. The horns drop down tighter and tighter against the head, until they begin to uncurl upward. As the horns drop down, the tips in effect are swung-out into the characteristic S-shaped curve of the mature horn.

In a good musk ox, the horns will come back up above the eye, and the tips will have a little bit of black on them, usually an inch plus on a records book size bull. A line drawn right through the middle of the eyeball should show about 55 percent of the horn below and 45 percent above it on a 27-inch animal. If the line shows 52 percent by 48 percent, you have about a 26-inch animal. ■