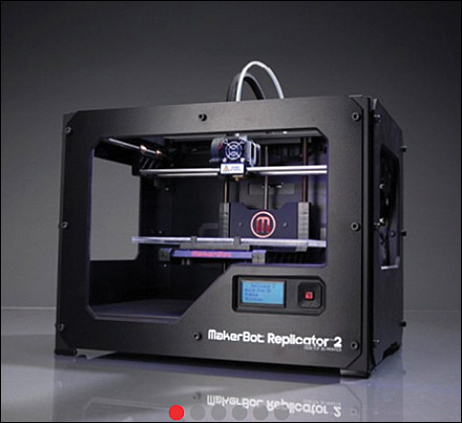

Figure 2.1 The Replicator 2 from MakerBot.

If you don’t yet own a 3D printer, this is the chapter for you. I give you some things to ponder when considering what type of 3D printer you might want to purchase. Believe it or not, you have hundreds of options compared to just three or four years ago. As in the previous chapter, my goal here isn’t to overwhelm you with a lot of technical talk. These days, when most people choose to purchase a computer, they don’t go to the store asking about memory cache amounts or hard drive transfer speeds (well, some do). Instead, they just want something that works and can run the software they need it to run. Today’s 3D printers are well on their way to being that easy to purchase and use (what computer companies used to advertise as plug-n-play). You can buy preassembled 3D printers, ready to go right out of the box. Just connect it to your printer, follow some simple instructions for installing the software, and you’re all set. (This is not completely true, because you’ve got to have something to print. More on that later in Chapter 5, “First Print with the Simple.”)

There are also 3D printer kits. These require you to assemble them, but today’s 3D printers have gotten much easier to figure out and put together compared to just a few years ago. Don’t believe me? I build a 3D printer and document much of the assembly in Chapter 3, “Assembly Assistance for the Printrbot Simple.” When you’re done with Chapter 3, I hope to have you convinced that a kit should not be intimidating if you choose that route.

So, let’s get started by taking a brief look at some of the options you have when purchasing a 3D printer. The goal for this chapter is to help you identify what you want to do with a 3D printer, how much you want to spend, and a few other factors. By chapter’s end, you should have a better idea of which 3D printers will meet your needs.

The practice of printing three-dimensional objects has been around for years. But it’s been only in the past five to six years that 3D printing has become a popular hobby and favored topic in the media, mainly due to costs dropping and component sizes shrinking. Today, 3D printing is available to anyone with a home computer and the interest to print out 3D objects.

The most popular type of 3D printing involves extruding melted plastic. You read about this in Chapter 1, “The Big Question—What Is a 3D Printer?” and that method of printing is the focus of this book. Melted plastic isn’t the only method for printing 3D objects; there are a number of techniques for creating 3D objects, but only the extruded plastic method can truly be considered the “affordable” solution at this time. But it’s not all about money, either.

The following list is by no means comprehensive, but it does represent the six factors that I believe someone new to 3D printing should consider when deciding on a 3D printer to purchase and use:

• Initial cost

• Ease of assembly and tech support

• Operating System compatibility

• Cost and type of filament

• Resolution/nozzle diameter

• Print bed size and leveling

Note

Another option that I don’t cover in this book is the availability of dual extruders. Dual extruders allow for users to load up two (or more) colors of plastic filament. Printing multi-colored objects becomes available with the proper software that can instruct the Extruder on which filament to feed into the hot-end. This topic is a bit beyond the beginner level set for this book, but if you find a reasonably priced 3D printer that you like that also offers an upgrade to a dual extruder, it’s worth considering as a beneficial add-on.

I’m going to go through each of these factors and explain why I believe they are key considerations for your future 3D printer purchase. For the purposes of this book, I’ll limit my discussion to the plastic-extruding type of hobbyist 3D printers. (If you want to learn about other methods of 3D printing, point your web browser to http://en.wikipedia.org/wiki/3d_printing and you’ll find details about half a dozen or more 3D printing techniques, such as selective laser sintering, an up and coming type of 3D printing that should become more affordable for hobbyists over the next 3–5 years.)

Just a few years ago, the hobbyist 3D printer market (in contrast to the higher-end professional products used in specialty industries such as manufacturing and engineering) floated between $1,000 and $3,000. At that time, it was an amazing price for cutting edge technology that could be ordered, delivered, and assembled in your home. Still, the price was out of reach of most hobbyists, let alone any parents or teachers who might want to introduce a 3D printer to a child or a classroom.

But one amazing thing about technology (especially technology that gets a lot of media attention) is how fast the price can drop when demand goes up. Demand for 3D printers has grown, and this has resulted in hundreds of 3D printer options popping up, many almost overnight. Companies and individuals, big businesses and small businesses—the list of sellers of 3D printers is an impossible document to put together because it seems that a new 3D printer is announced almost daily. This is great news for anyone wanting to buy a 3D printer today.

The variety of 3D printers and the various options they offer have created a new market, where prices have dropped drastically. You can still find 3D printers in the high $1,000s, but these are the high-end printers that would have been out of reach of most hobbyists a few years back. And the entry-level 3D printers that floated around $800–$1,500 two or three years ago? Those can be had for under $500.

Today, you can expect to pay between $300 and $3,000 for a hobbyist level 3D printer. These are printers that are designed to be used in a home or small office, producing good to high-quality 3D objects.

But price isn’t just related to the print quality of the plastic object that is created. Price is often also related to whether the 3D printer is preassembled (also referred to as ready “out-of-the-box”) or comes in a kit for you to build yourself. Some 3D printers, such as the Replicator 2 from MakerBot (makerbot.com) shown in Figure 2.1, only come preassembled. The reason is that the assembly of a 3D printer often requires some fairly strict tolerances. If a screw isn’t tightened properly or two panels aren’t perfectly perpendicular to one another, a printed 3D object can come out a little lopsided or completely unusable.

Other 3D printers come in both preassembled and kit form. You can typically expect to pay around $100–$300 more for a preassembled version, maybe even higher. Keep in mind that a preassembled 3D printer typically incurs a higher shipping cost. The assembled 3D printer is bigger than an unassembled version; it is most likely a bit more fragile and must be packed better to keep anything from getting damaged during delivery. Take a look at the Ultimaker website (ultimaker.com), and you’ll see an example of a good mix of kit and preassembled 3D printers, such as in Figure 2.2.

If you’re feeling a bit of sticker shock at some of the prices you’ve seen, let me calm your nerves a bit. The 3D printer that I’ve chosen to use for this book won’t run you $2,000. It won’t even cost you $500. I use the Printrbot Simple in this book (and show you how to assemble it in Chapter 3). The Printrbot Simple comes in a kit for $300. You read that right—$300. It doesn’t have all the bells and whistles that some of the mid- to high-level 3D printers possess, but it does print out 3D objects in plastic and is a great way to introduce yourself to the hobby.

Note

Ready to buy? Point a web browser to printrbot.com and search for the Printrbot Simple. The website may change its appearance from time to time, but right now the Simple is advertised on the front page. As Printrbot introduces new products, you may find that you’ll need to look at the company’s complete listing of products to find it. And who knows? The price may have even dropped by the time you read this.

The Printrbot Simple is easy to assemble, as you’ll see in Chapter 3. I chose the Simple as the 3D printer to use for this book because of its low price and easy-to-understand assembly instructions that make it a great 3D printer for beginners. You can see the completed Printrbot Simple in Figure 2.3.

Be aware that the Printrbot Simple does have some limitations. For example, the Simple can’t print large objects. Imagine a cube that is four inches (4") square. That’s the print limit for the Simple. If you want to print anything that won’t fit inside a cube with 4" sides, you’ll need to consider a 3D printer with a larger print area. But if you’re wanting to experiment with the 3D printing hobby without spending a lot of money, the Simple will get you some hands-on time with both the hardware and software and let you test the waters before you consider upgrading to a more expensive and more feature-filled 3D printer.

Note

There’s a great way to print larger objects with a 3D printer like the Simple that doesn’t have the largest print area, and it involves breaking up your 3D models into smaller parts that can be connected with adhesives or methods, such as slots or even small screws. This can add to the complexity of designing an object, but you should be aware that a small print area doesn’t necessarily limit you to printing larger plastic objects...you’ve just got to be more creative in your solution.

What might you want to look for in more expensive 3D printers? Here are some things to consider before making a purchase:

• Multicolor support—Most hobbyist 3D printers can print using one feed of plastic filament. Because filament can come in colors, there are also printers that can be loaded with two to four colored filaments using dual extruders, allowing you to print 3D objects using a mix of colors. It’s a bit more advanced to print with multiple colors, but it is possible with some higher-end 3D printers. (Rumor has it that Printrbot is working on an upgrade to the Simple that will allow you to buy an upgrade for the single extruder that will turn it into a dual extruder, allowing you to print in two colors! It’s not available right now, but I suspect it could be available by the time you’re reading this book.)

• Customer support—Most 3D printer sellers are more than happy to answer technical questions from customers, but many of them push customers to an online forum or an email support system. Some sellers have customer support phone numbers and others do not. You’ll want to consider the level of support provided when purchasing a kit or a preassembled 3D printer. Kits seem to typically spur more questions from owners, so make certain if you buy a kit that you can get help from the seller should you have problems.

• Proprietary filament—Some 3D printer sellers require you to purchase their plastic filament. They can do this because they use some type of special spool or loader that fits inside the 3D printer. This can be a blessing or a curse, depending on your level of technical expertise. Filament can often be purchased on sale or at extremely low prices from specialty companies that cater to 3D printing hobbyists, so being locked into using a proprietary filament could be more expensive over time or at least prevent you from taking advantage of price breaks on filament.

• Hot-end options—Some hot ends/extruders require you to assemble them, involving some hands-on time with a soldering iron. This can be extremely intimidating, especially if you don’t even know what a soldering iron is or how it is used. Make certain that when you purchase a kit, the hot end and extruder are ready to go. You’ll also want to inquire about whether you can upgrade your hot end. A hot-end can have different nozzle diameters, allowing for different qualities of printing.

• Warranty—Most kits aren’t going to come with a warranty. But preassembled kits should have some sort of return policy if you find something is damaged or not working properly. Be certain to inquire about the return policy on any 3D printer you purchase, especially when buying a kit.

As you learn to use a 3D printer and the software tools needed to create 3D objects, you’ll begin to understand some of the benefits offered by higher-cost 3D printers, especially those with more advanced electronics. But if you’re just getting started, you’ll find that any sub-$700 3D printer will offer you a great experience.

If you end up purchasing a preassembled kit, you’ll skip this step. Yes, you may have some instructions on connecting it to your computer or inserting the plastic filament, but for all practical purposes, the preassembled 3D printer shouldn’t require much from you in terms of putting it together.

But a kit? A kit can be a bit overwhelming the first time you open it up and examine all the parts that come inside. Take a look at Figure 2.4 to see the parts used to build the Printrbot Simple.

Keep in mind that the Printrbot Simple is exactly that—simple. It has a limited number of parts required to build it (see Chapter 3). Now imagine a larger, more advanced 3D printer; it’s likely to have even more parts.

Some 3D printers come with instructions tucked into the box for assembly, whereas others have the build instructions available online. My personal preference is online building instructions. They typically come with full-color photographs; errors are typically corrected as soon as they are found, and corrections are posted immediately. However, you may have only a printed manual with your 3D kit, so be aware that assembly instructions vary from kit to kit. It never hurts to ask about what types of assembly instructions are available when ordering a kit!

Tech support is also a big deal. Find out if your 3D printer seller offers a forum where you can post questions. Most do, but not all. It’s great to be able to log in to a company’s online forum and post a quick question along with a photo or two if necessary. You’ll often find that fellow kit owners are fast to respond and offer help, often faster than the in-house technical support folks.

If you’re comfortable using a screwdriver or wrench, you should be okay putting your 3D printer together. Most 3D printer assemblies require few other tools, but it never hurts to ask. For example, be sure to ask if you need an Allen wrench. This is a cheap and easy tool to pick up at the hardware store, but you’d be surprised at how many people don’t own a set. See the Allen wrench set in Figure 2.5 if you’re not familiar with them.

Consider your own comfort level, too. Not everyone enjoys taking a bag of 50 or even 100+ parts and putting it all together. I’ve put together three 3D printers over the past few years, and I’m comfortable reading instructions, asking questions, and “figuring it all out.” But if that’s not your idea of fun, a kit may not be for you. (I do believe that putting something together, like a 3D printer, is one of the best ways to understand how something works and how to repair it later.)

Some 3D printers work with the Apple OS X operating system (OS), and some 3D printers play well only with Microsoft Windows. Let’s not forget that the Linux operating system is enjoyed by many people around the globe, but unfortunately not every 3D printer can be connected to a computer running this particular OS.

Whatever your choice of operating system, make certain that your new 3D printer can be connected to your computer. Without a compatible computer (and OS), you won’t be able to print your 3D objects. The question to always ask (or look for on product pages) is “what operating systems support this 3D printer?”

By all means, dig deep and make certain that the version of your OS is supported. If you’ve got an older computer running Windows XP and that new 3D printer you purchased supports only Windows Vista or newer, you’re going to have to upgrade your OS (if you even can) or find a new computer to connect it to.

Note

Be aware that it’s not just the 3D printer’s compatibility with your OS that you should be concerned with. You also want to make certain that whatever 3D design software you want to use will run on your OS. Software is discussed later in the book, but for now know that some 3D printing software runs only on Windows, for example. Other 3D printing software might work with only the Mac OS. (And poor Linux has even fewer options.)

Because this book is focused on plastic 3D printing, you’ll typically be purchasing your plastic filament in one of a half-dozen varieties. There are two types of filament, however, that you’ll find most used in the hobbyist 3D printing world—PLA and ABS.

PLA is Polyactic Acid and ABS is Acrylonitrile Butadiene Styrene. I’m not a chemist, but I can tell you that these two types of plastic do have slightly different characteristics, and you need to ask which type of plastic is recommended for use with your 3D printer.

PLA has a lower melting temperature than ABS (but the hot end will still be too hot to touch), it’s biodegradable and the smell is not nearly as offensive as ABS. ABS, however, produces a much harder 3D object and can sometimes be found on sale at a lower cost than PLA. PLA and ABS come in a variety of colors, as well.

Both are typically sold by the kilogram. My first 3D printer used PLA, so I’m a bit fond of it. It smells better when melted, and I like the fact that it’s better for the environment.

Pricing varies from site to site, so it pays to shop around. To give you an idea of pricing, printrbot.com is currently selling one kilogram of natural color PLA or ABS at $30, but MakerBot is selling it for $43.

Keep in mind that 3D printing technology changes constantly, so you’ll also want to be looking into what level of resolution a 3D printer can provide. Currently there are two popular filament sizes (in terms of diameter) you can purchase. These two diameters are 1.75mm and 3mm.

I mentioned in Chapter 1 that the hot end is responsible for heating, melting, and extruding the molten plastic onto the print bed (surface). You always need to check to see what size of filament is used by your 3D printer so you can purchase the right diameter.

But the nozzle diameter is also its own consideration. The Simple extruders use a 0.4mm diameter bead of plastic and provides smoother surfaces (generally speaking) than a nozzle with a larger diameter. Think about it in terms of a fine-point pen versus the wider point of a highlighter. With the finer point, the output on paper is a finer line and sharper details. With the wider point, the output is a wider line and less detail on things like curves. When your 3D printer lays down lines of plastic on the print bed and builds up layer after layer, that 0.4mm nozzle gives smoother transitions between layers. Figure 2.6 shows the difference in surface smoothness between two nozzles of different resolution.

More and more 3D printers are coming that use the 1.75mm filament and the 0.4mm (or even smaller) diameter nozzle, and the benefits are definitely worthwhile: faster feed rate (the filament can be fed into the extruder and then into the hot end at a faster speed), more detailed designs can be printed, and the motor has to apply less power (torque) to feed the filament into the hot end. Still, the 3mm filament shouldn’t be discounted. A lot of prototypers and hobbyists like a larger nozzle because it puts down more plastic in a single pass, and it takes less time to print large objects (fewer layers). Keep all this in mind as you do your shopping, but remember that filament in either diameter is just about the same price. Buy a 3D printer based on what your printing needs are. If you’re designing small trinkets that might be used to create molds for jewelry, you’ll probably appreciate a smaller diameter nozzle and the detail it can provide. But if you’re printing out large gears for testing in your handmade robots, for example, a larger diameter nozzle will get you those gears faster.

All 3D printers lay down the bead of melted plastic on the print bed. This print bed is a flat surface that helps to ensure that each layer is parallel to the floor and that the hot end isn’t printing out a lopsided object. Most 3D printers come with a method for leveling the print bed, but not all. It’s definitely helpful to be able to level the bed (and the printer itself), especially if you get in the practice of toting your 3D printer with you to various places. You never know where you’ll be setting the printer, so being able to make certain the printer and the print bed are level to the ground is a nice benefit.

Note

If your 3D printer doesn’t come with small feet for leveling, you can easily add them. Just purchase a set from any hardware store, but be sure to buy the kind that you can turn with your fingers to raise and lower. Investing in a tiny level can also be helpful when fine-tuning the printer.

Another consideration when it comes to the print bed is the bed size print area. The Printrbot Simple, for example, is a smaller 3D printer, and it can print out only objects that would fit inside a 4" square cube—or 64 cubic inches. This might not be a problem for someone wanting to print out custom game pieces for Monopoly, for example, but if you’re thinking you want to print out a 6” tall robot body, you’ll want to find a 3D printer that can handle the printing of larger objects or resort to breaking that robot up into individual parts (arm, body, head) and assembling them after printing. For example, the MakerBot Replicator 2 can print objects as large as 410 cubic inches—that’s about 11” long × 6” wide × 6” tall.

You’ll find printers that can print extremely tall objects but are limited to length and width. Likewise, you’ll find printers that can print extremely wide and long objects but don’t offer much in terms of Z-axis movement (height). Again, think about exactly what kinds of objects you want to print. If you’re not sure, look for a happy medium or just go with the inexpensive Simple to see what you can do. By the time you find that the 4" cube printing area isn’t big enough, you’ll have a better idea of what you want to create with your next 3D printer purchase. (You’ll quickly find, as many 3D printer owners have, that one 3D printer is never enough. It’s an addictive hobby; I own three 3D printers myself.)

I would place researching and purchasing a 3D printer somewhere between the purchase of a toaster and a car. You’ve definitely got a number of factors to consider, but don’t let them overwhelm you. Your first 3D printer doesn’t have to be the one with the most bells and whistles, and truth be told, unless you’re extremely comfortable with technology and troubleshooting, you’ll likely find yourself getting frustrated and overwhelmed with the most advanced 3D printers out there.

Instead, start as small and as uncomplicated as you can get. There’s a very good reason I’ve chosen the Printrbot Simple for this book—actually, there’s a number of good reasons:

• Its low cost—At $300, it’s a perfect way to discover whether the 3D printing hobby is for you.

• It’s easy to assemble—Compared to my first 3D printer that took me almost an entire weekend to assemble, the Simple took somewhere between two and three hours. (I took plenty of breaks and worked slowly to avoid mistakes.)

• It doesn’t use a proprietary filament cartridge.

• It comes standard with the finer 0.4mm hot end that also uses the 1.75mm filament.

• The Printrbot crew has proven to me that they have outstanding customer service. (This is my second 3D printer from printrbot.com.)

The Simple comes with an excellent set of assembly instructions, and in the next chapter I provide commentary and photos on building it.

But should you purchase another brand of 3D printer, you’ll still find the rest of the book useful. The 3D printer is the hardware, but there is still a software element that you’ll need to understand, and my goal with this book is to make this technology as easy to understand as possible.

So, let’s continue to Chapter 3, where I use the assembly of the Printrbot Simple to explain more concepts related to printing 3D objects.