Adding soundproofing board and insulation are among the many simple ways you can reduce noise in your home.

In making homes quieter, building professionals add soundproofing elements to combat everything from the hum of appliances to the roar of airliners. Many of the techniques they use are simple improvements involving common products and materials. What will work best in your home depends upon a few factors, including the types of noises involved, your home’s construction and how much remodeling you have planned. For starters, it helps to know a little of the science behind sound control.

Sound is created by vibrations traveling through air. Consequently, the best ways to reduce sound transmission are by limiting airflow and blocking or absorbing vibrations. Effective soundproofing typically involves a combination of methods.

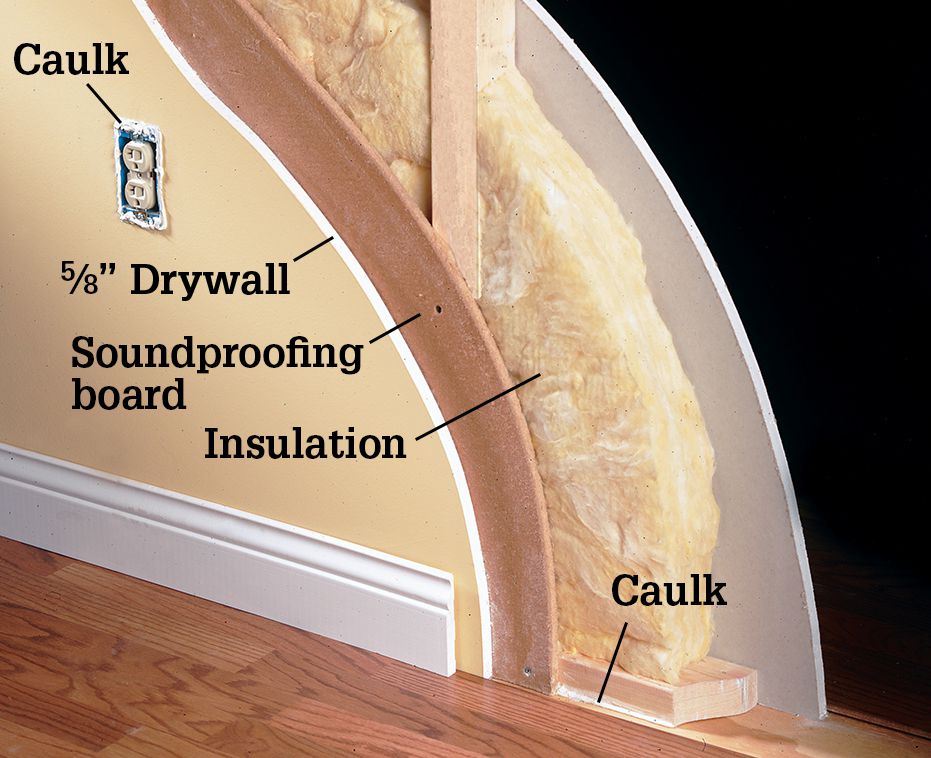

Stopping airflow—through walls, ceilings, floors, windows, and doors—is essential to any soundproofing effort. (Even a 2-foot-thick brick wall would not be very soundproof if it had cracks in the mortar.) It’s also the simplest way to make minor improvements. Because you’re dealing with air, this kind of soundproofing is a lot like weatherizing your home: add weatherstripping and door sweeps, seal air leaks with caulk, install storm doors and windows, etc. The same techniques that keep out the cold also block exterior noise and prevent sound from traveling between rooms.

After reducing airflow, the next level of soundproofing is to improve the sound-blocking qualities of your walls and ceilings. Engineers rate soundproofing performance of wall and ceiling assemblies using a system called Sound Transmission Class, or STC. The higher the STC rating, the more sound is blocked by the assembly. For example, if a wall is rated at 30 to 35 STC, loud speech can be understood through the wall. At 42 STC, loud speech is reduced to a murmur. At 50 STC, loud speech cannot be heard through the wall.

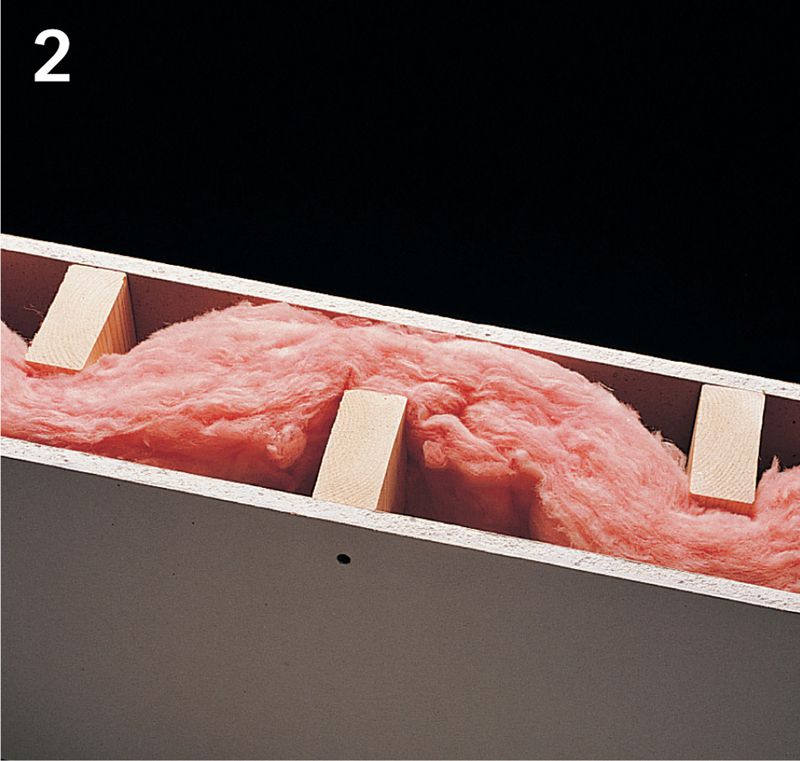

Adding soundproofing board and insulation are among the many simple ways you can reduce noise in your home.

Standard construction methods typically result in a 28 to 32 STC rating, while soundproofed walls and ceilings can carry ratings near 50. To give you an idea of how much soundproofing you need, a sleeping room at 40 to 50 STC is quiet enough for most people; a reading room is comfortable at 35 to 40 STC. For another gauge, consider the fact that increasing the STC rating of an assembly by 10 reduces the perceived sound levels by 50 percent. The chart above lists the STC ratings of several wall and ceiling assemblies.

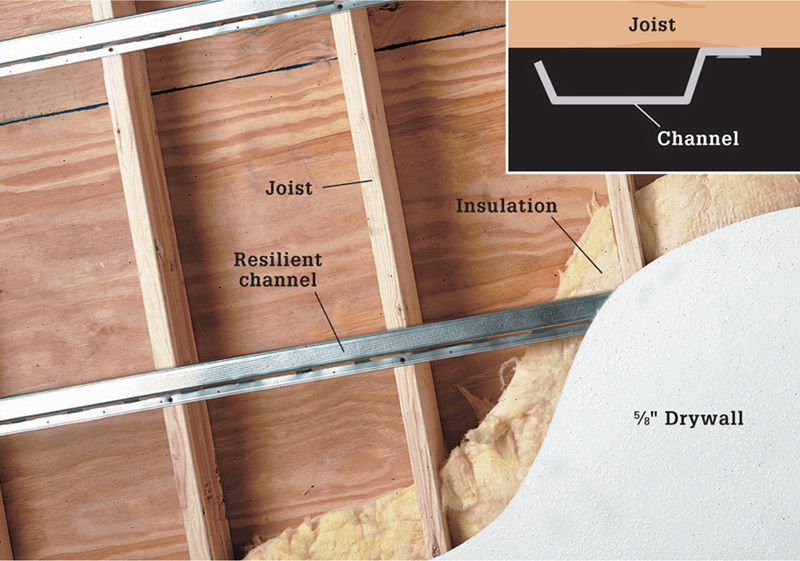

Improvements to walls and ceilings usually involve increasing the mass, absorbancy, or resiliency of the assembly; often, a combination is best. Adding layers of drywall increases mass, helping a wall resist the vibrational force of sound (5/8-inch fire-resistant drywall works best because of its greater weight and density). Insulation and soundproofing board absorb sound. Soundproofing board is available through drywall suppliers and manufacturers. Some board products are gypsum-based; others are lightweight fiberboard. Installing resilient steel channels over the framing or old surface and adding a new layer of drywall increases mass, while the channels allow the surface to move slightly and absorb vibrations. New walls built with staggered studs and insulation are highly effective at reducing vibration.

In addition to these permanent improvements, you can reduce noise by decorating with soft materials that absorb sound. Rugs and carpet, drapery, fabric wall hangings, and soft furniture help reduce atmospheric noise within a room. Acoustical ceiling tiles effectively absorb and help contain sound within a room but do little to prevent sound from entering the room.

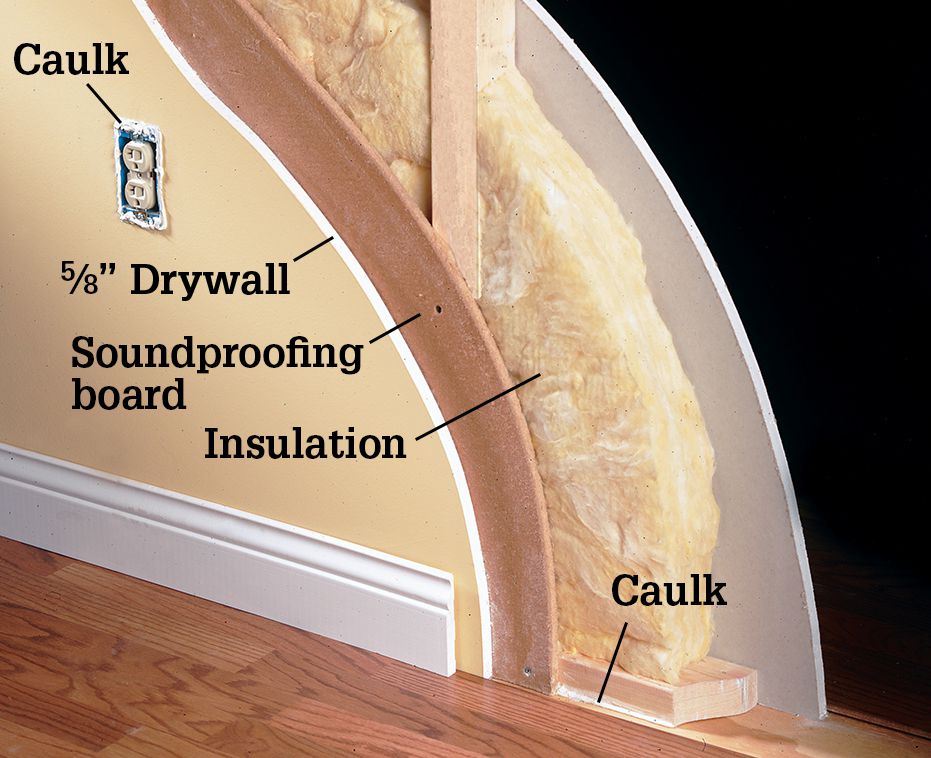

INSTALLING RESILIENT STEEL CHANNELS

INSTALLING RESILIENT STEEL CHANNELS

On ceilings, install channels perpendicular to the joists, spaced 24" on-center. Fasten at each joist with 1 1/4" Type W drywall screws, driven through the channel flange. Stop the channels 1" short of all walls. Join pieces on long runs by overlapping the ends and fastening through both pieces. Insulate the joist bays with unfaced fiberglass or other insulation and install 5/8" fire-resistant drywall, perpendicular to the channels. For double-layer application, install the second layer of drywall perpendicular to the first.

On walls, use the same installation techniques as with the ceiling application, installing the channels horizontally. Position the bottom channel 2" from the floor and the top channel within 6" of the ceiling. Insulate the stud cavities and install the drywall vertically.

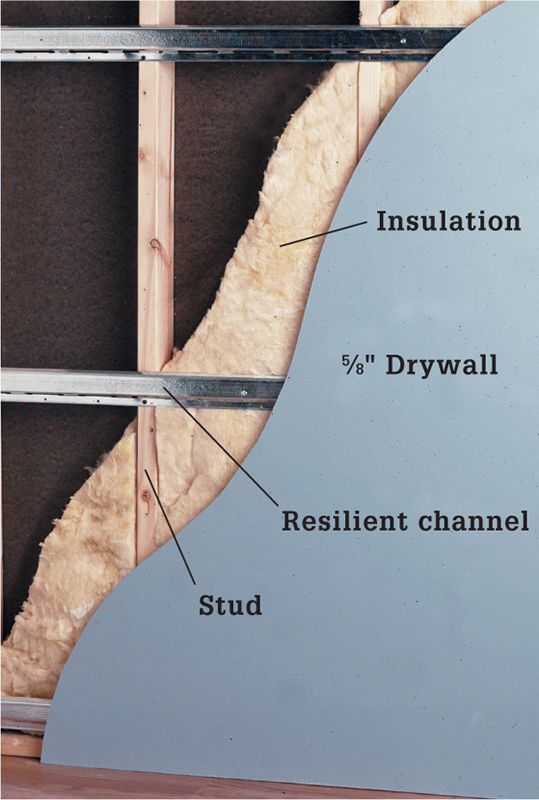

HOW TO BUILD STAGGERED-STUD PARTITION WALLS

HOW TO BUILD STAGGERED-STUD PARTITION WALLS

Frame new partition walls using 2 × 6 plates. Space the studs 12" apart, staggering them so alternate studs are aligned with opposite sides of the plates. Seal under and above the plates with acoustic sealant.

Weave R-11 unfaced fiberglass blanket insulation horizontally between the studs. Cover each side with one or more layers of 5/8" fire-resistant drywall.