CHAPTER I

MISCELLANEOUS CARRIAGE IRONS

The blacksmith is often called upon to repair carriages and wagons, or to iron some particular part of each on short notice, and unless experienced in carriage work much valuable time is lost in devising means of performing the work in a satisfactory manner. As a help to such the directions in this chapter for making a variety of irons will be found valuable.

As hammer signals are of interest we preface this chapter with a complete code.

Hammer Signals.

When the blacksmith gives the anvil quick, light blows it is a signal to the helper to use the sledge or to strike quicker.

The force of the blows given by the blacksmith’s hammer indicates the force of blow it is required to give the sledge.

The blacksmith’s helper is supposed to strike the work in the middle of the width of the anvil, and when this requires to be varied the blacksmith indicates where the sledge blows are to fall by touching the required spot with his hand hammer.

If the sledge is required to have a lateral motion while descending, the blacksmith indicates the same to the helper by delivering hand-hammer blows in which the hand hammer moves in the direction required for the sledge to move.

If the blacksmith delivers a heavy blow upon the work and an intermediate light blow on the anvil, it denotes that heavy sledge blows are required.

If there are two or more helpers the blacksmith strikes a blow between each helper’s sledge-hammer blow, the object being to merely denote where the sledge blows are to fall.

When the blacksmith desires the sledge blows to cease he lets the hand-hammer head fall upon the anvil and continue its rebound upon the same until it ceases.

Thus the movements of the hand hammer constitute signals to the helper, and what appear desultory blows to the common observer constitute the method of communication between the blacksmith and his helper.

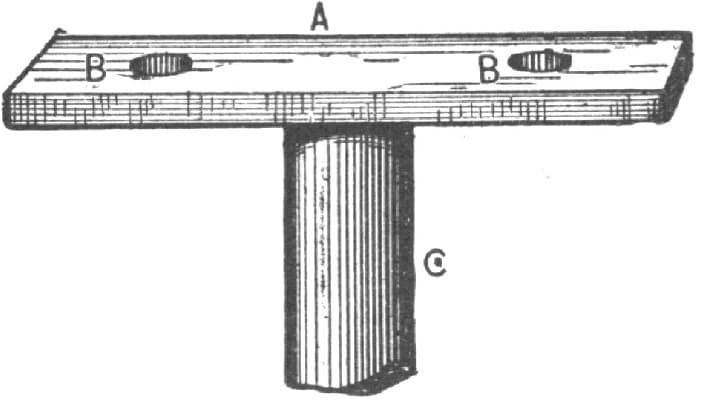

Making a Thill Coupling.

My way of making a thill coupling is as follows:

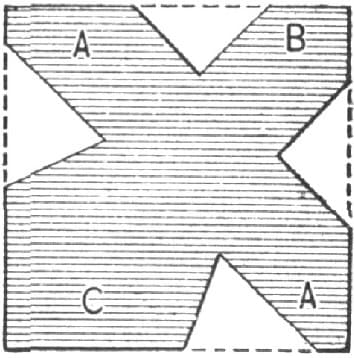

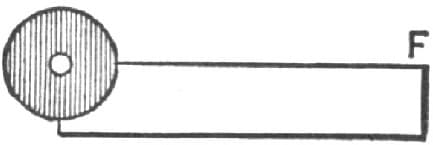

I take a piece of Norway iron, say, for a buggy, three-eighths of an inch by two and one-half inches, then cut off a square block and cut it in the way shown in Fig. 1 of the accompanying illustrations, and in which A A denote where the blot goes through. B is drawn down and rounded for the lower part of the front side, as shown in Fig. 2. C is drawn out to make the cuff which goes over the axle and down on the inside. I find this plan better than depending on welding the lugs A A to the other part.—By J. A. R.

Making a Thill Coupling. Fig. 1—Showing How the Piece of Iron is Cut

Fig. 2—Showing the Coupling Completed

Making a Thill Cuff.

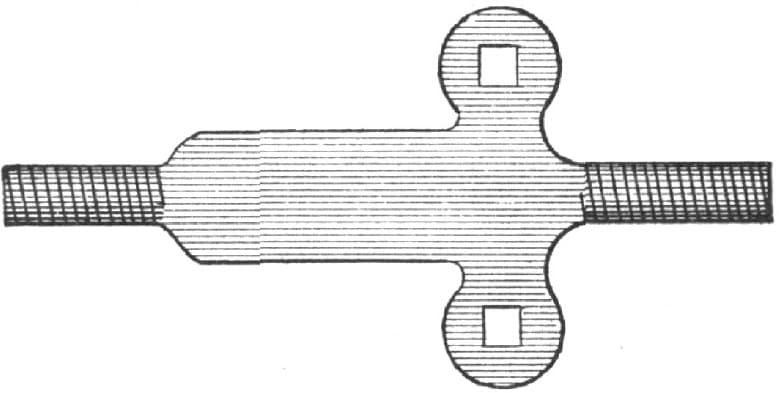

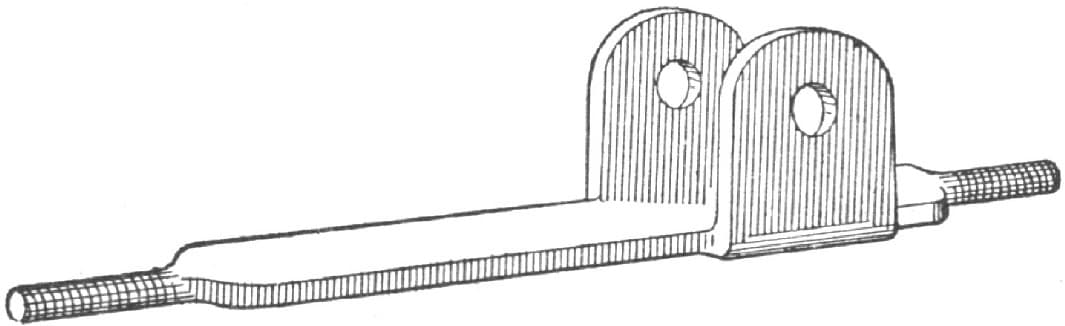

To make a thill cuff or shackle, take a piece of iron three inches wide and three inches long by five-sixteenths of an inch thick, and fuller it as shown in Fig. 3. I then bend up two corners to which the shaft end is to be fastened, and drill holes through for bolts, as in Fig. 4. One of the other ends is drawn out for the clip, with an end shaped for a nut. The other end is also threaded for a nut. The thill cuff is then finished, as shown in Fig. 5. It should be made of the best iron, either Norway or Sligo.—By E. W.

“E. W.’s” Method of Making a Thill Cuff. Fig. 3—Showing How the Iron is Fullered

Fig. 4—Showing How the Piece is Bent and Chilled

Fig. 5—Showing the Thill Cuff Completed

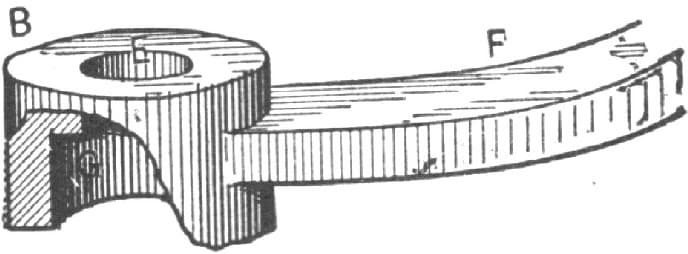

Making Spring and Axle Clips and Plates.

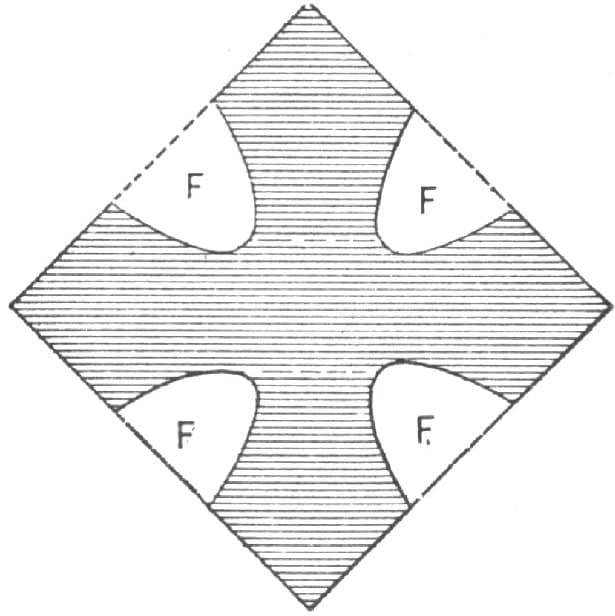

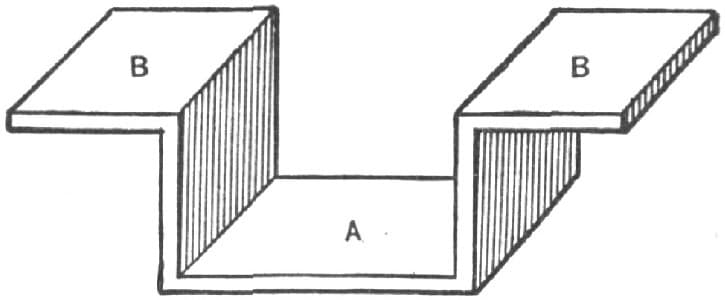

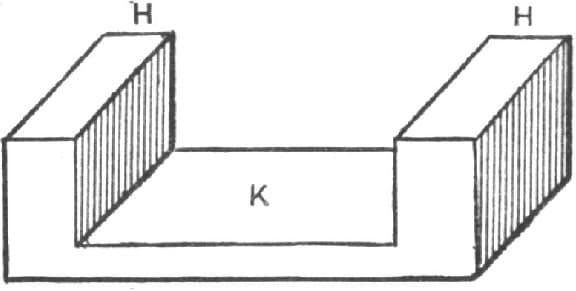

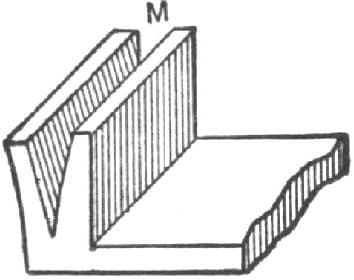

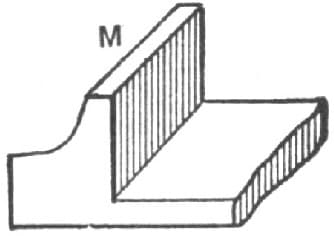

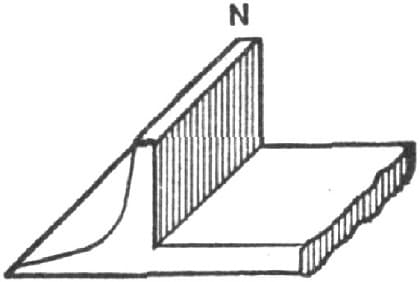

As most blacksmiths will be interested in learning a good method of making spring axle clips and plates, I will, with the aid of the accompanying engravings, endeavor to show how the job is performed in my shop. Fig. 6 represents the clip. A indicates where the axle sets, and B B are parts of the clip plate. Fig. 7 shows the finished clip plate. The part C sets on the spring. E is the space between the cars, D D, in which the clip shown in Fig. 6 fits. Fig. 8 represents the whole thing put together. A is the spring plate, F is the axle clip, C C are the spaces between the clip yokes. In making, first bend the ends at H H in Fig. 9, in which K indicates the plate, then split down as at M in Fig. 10, next fuller in with a small fuller as at M in Fig. 11, and then using a larger fuller bring to the shape shown in Fig. 12.

Making Spring and Axle Clips and Plates, as Described by “Iron Doctor.” Fig. 6—Showing the Clip

Fig. 7—Showing the Finished Clip Plate

Fig. 8—Showing the Parts Put Together

Fig. 9—Showing the Method of Bending the Ends

Fig. 10—Showing the Manner of Splitting

Fig. 11—Showing How the Fullering is Done

Fig. 12—Showing the Fullering Process Completed

If the best iron is used the bending can be done with one heat, and another will be sufficient for the working out. If ordinary iron is employed more heats will be required. —By IRON DOCTOR.

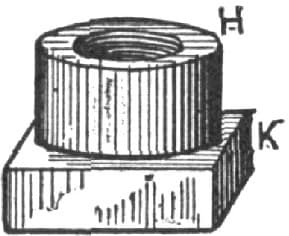

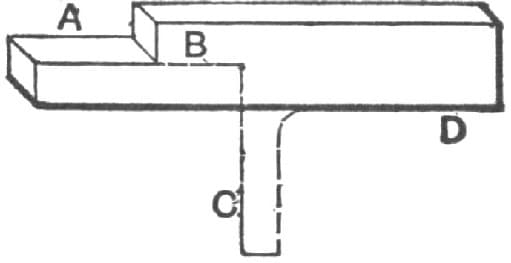

How to Prevent Working of King Bolt, and How to Make a King-bolt Stay.

All carriagemakers have had more or less bother with the head of the king bolt becoming loose in the head block, rattling, turning around and finally making a hole in the block. After some study and experimenting I have overcome the trouble. I have also managed to get up a first-rate king-bolt stay, which will wear a long time without rattling, and does not wear a hole in the king bolt or wear the thread off.

How to Prevent Working of King Bolt. Fig. 13—Showing How the King Bolt is Made

In Fig. 13 I show how I take care of the king bolt. A is the oblong or elongated head which is let in the head block, C is the king bolt or a section of the same. B B are holes in the head which I countersink from the upper side, and put in two five-sixteenths inch bolts which go all the way through the head block and head-block plate and fasten with nuts on the under side. Since making my king bolts this way I have had no more trouble.

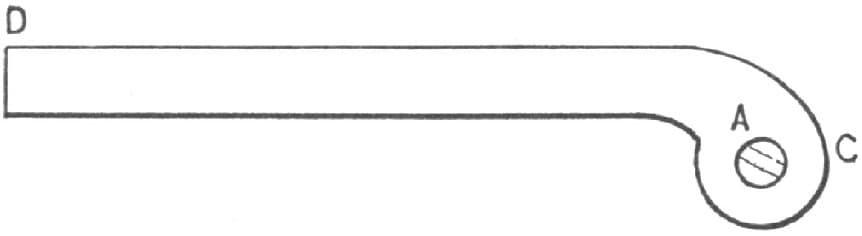

Fig. 14—Showing How the King-bolt Stay is Made

By Fig. 14 I show how I make the king-bolt stay. B is the head, with the hole E for the passage of the king bolt. F is the stay, which may be made flat, oval or round. I always make mine oval. By G I show a recess in the under side of the nut—done by counterboring—for the insertion of the king-bolt nut, which is so made as to fill the recess which I show by Fig. 15. K is the square part of the nut on which the wrench is placed. I sometimes make them six-cornered. H is a raised round section on the nut which fits in the recess in the stay head at G. The wear by this means comes on the nut and not on the king bolt. I make an ordinary nut and form the round part with a file. In conclusion, I think I have wrought out something good which all may use.—By IRON DOCTOR.

Fig. 15—Showing the King-bolt Nut

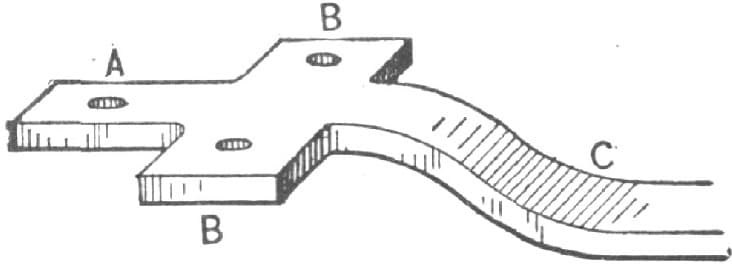

Fastening a King-bolt Stay.

It took me a good many years to learn that if I bolted iron to iron where there was much vibration the bolts would soon break. For years I bolted my king-bolt stays to the reach or reaches with, as I thought, bolts strong enough to hold. Well, they would hold a little while and then the nuts would get loose and drop off, sometimes the reach would split and refuse to hold a bolt. After putting up with the nonsense about long enough, I put on my thinking cap and turned out a pretty reliable stay, which I have been using ever since. It is a simple but effective stay. A, Fig. 16, is the back end, which extends under the reach enough to take one or two bolts. B B are ears on each side of the plate and form a good solid clip bar. C is a section of the stay neck. I make a wide clip (two inches wide), and secure the perch and stay with the same, and have no further trouble.—By IRON DOCTOR.

Fig. 16—Fastening a King-bolt Stay as Made by “Iron Doctor”

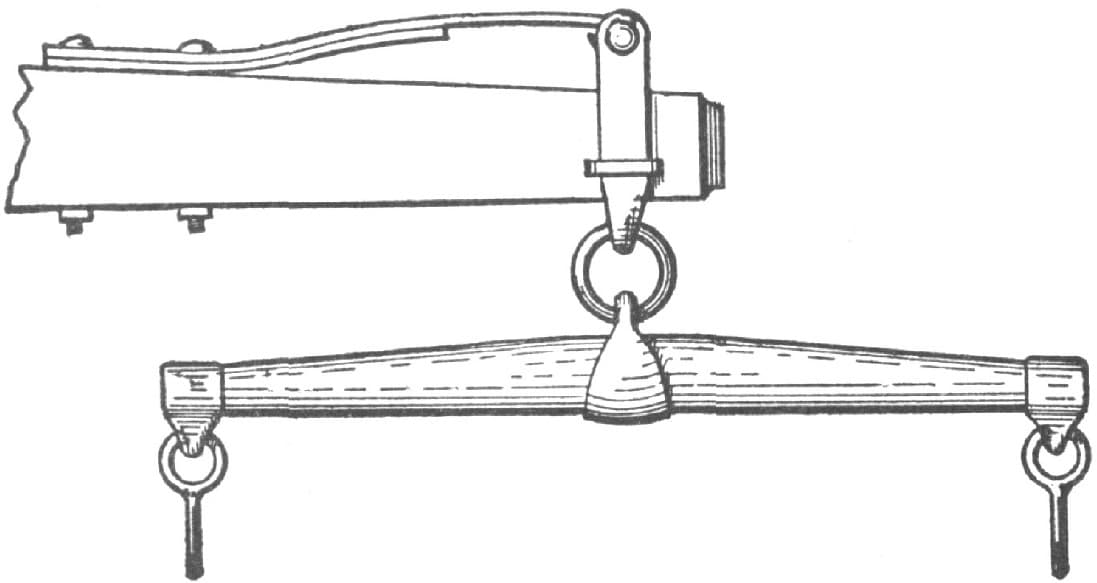

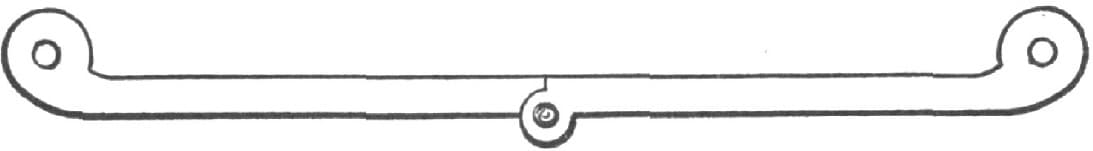

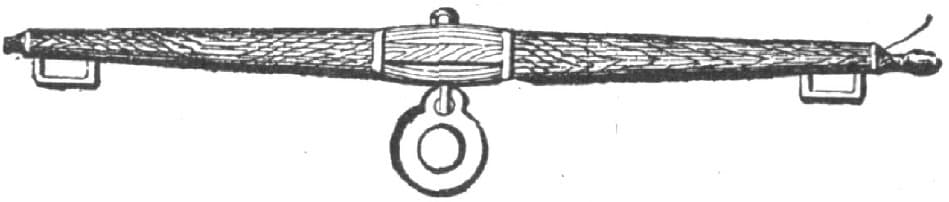

Fig. 17—Showing the Spring Doubletree Described by J. O. Hess

A Good Spring Doubletree.

I send you a spring doubletree (Fig. 17) which I think is much simpler than any other I have ever seen. Any blacksmith can make it. The spring is ten inches long by one and three-fourths inches wide, and made with two leaves. The spring stands off from the end of the doubletree two and one-half inches. Two bolts are sufficient to make secure.

This will do for ordinary farm work; for heavy work it should be made stronger.

One of these springs will pay for itself in less than a year in easing the wear and strain to horse, harness and wagon. —By J. O. HESS.

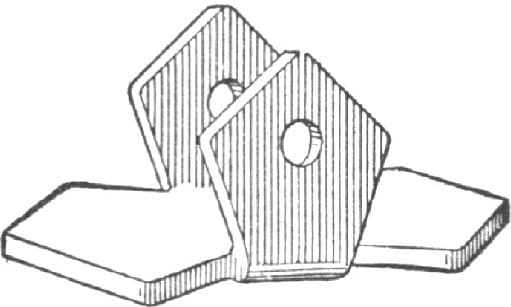

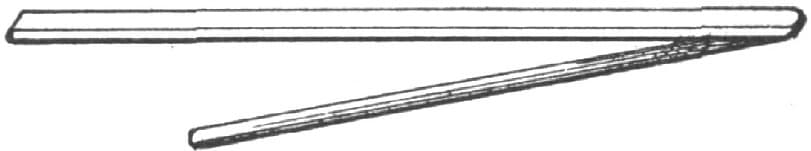

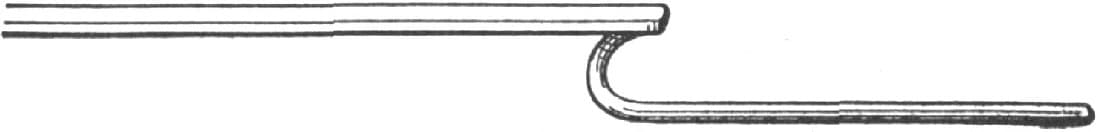

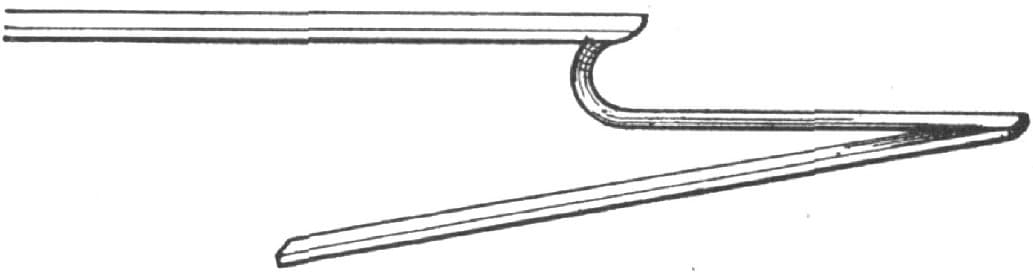

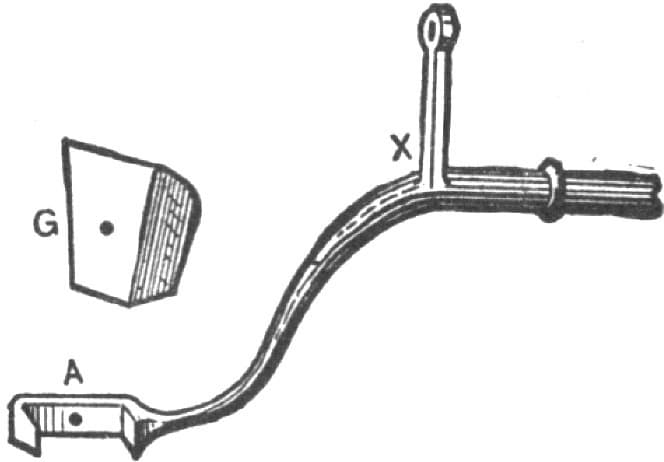

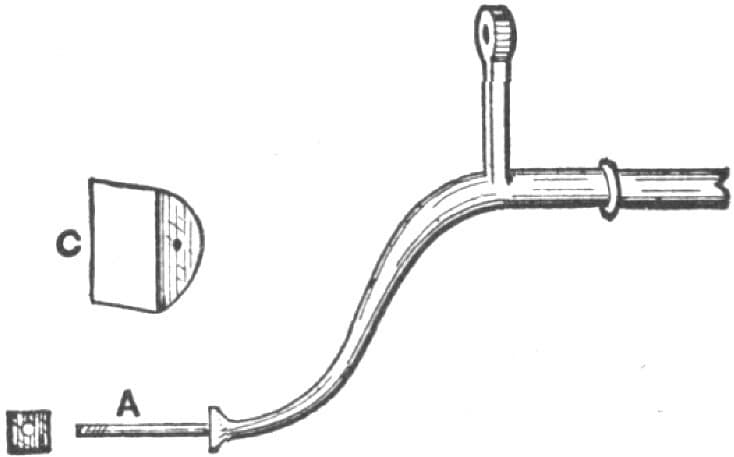

Making a Pole Cap or Tongue Iron.

To make a pole cap or tongue iron, take two pieces of band iron, fifteen inches long and one and one-fourth by three-sixteenths of an inch, and a piece of rod iron eleven inches long by five-eighths of an inch in diameter, and weld the rod to one of the flat pieces, as shown in Fig. 18 of the accompanying illustrations. Then shape them as shown in Fig. 19, weld on the other piece of band iron as in Fig. 20, and bend to shape as shown in Fig. 21. Then the bolt holes are drilled, and the job is completed.—By J. M. W.

Making a Pole Cap. Fig. 18—Showing the First Welding

Fig. 19—Showing How Bent after First Weld

Fig. 20—Ready for Second Bend

Fig. 21—Showing Pole Cap Completed

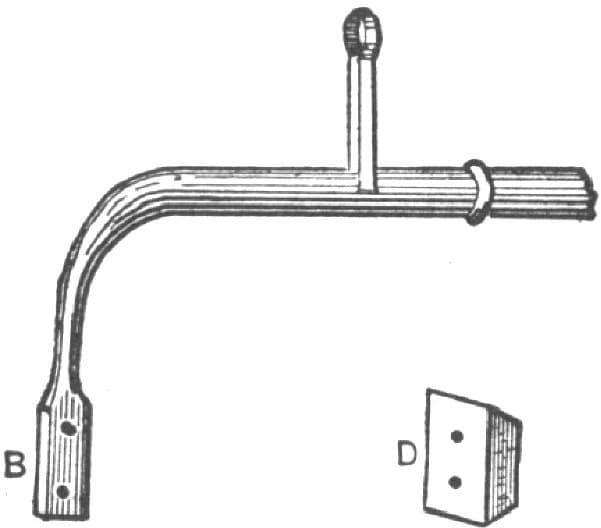

Making a Prop Brace for a Carriage.

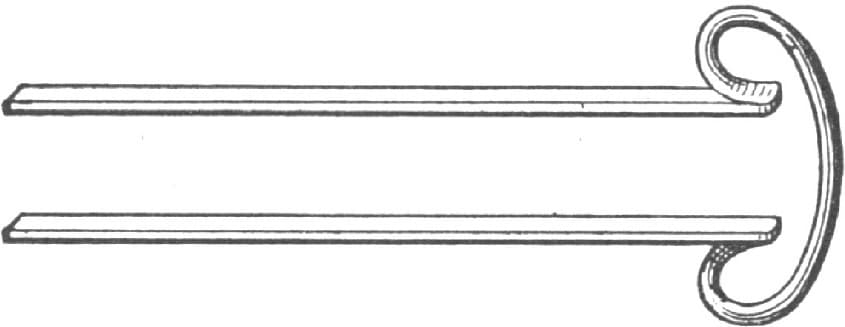

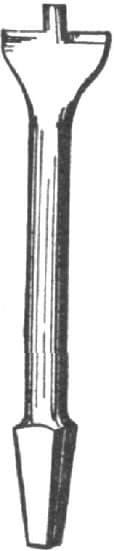

To replace a prop brace for a carriage I use oval iron of right size, upset the ends, and bend one end as shown in Fig. 22. I next take a key-hole punch and punch a hole as at A in Fig. 22. I then open up the hole with a small round punch. I next proceed to make an end or stock for a joint by forging a piece of iron so as to make it seven-sixteenths of an inch by eleven-sixteenths of an inch, and then bend the end as at C, Fig. 22. I then make a square-lipped drill with a centerpiece one-fourth of an inch round, as shown in Fig. 23, the lip being as broad as I want the joint to be. I next drill a hole three-fourths of an inch in diameter through the end, as shown in Fig. 24, and with the square-lipped drill make a hole half way through the end, as shown by the dotted lines in Fig. 24. I next file off the edges, all that the square-lipped drill had left. I file three-fourths of the way down, and file around, beginning at E and ending at B, Fig. 24, leaving the piece as shown in Fig. 25. I then weld the piece Fig. 25 to the part shown in Fig. 22, F being welded to D. I next make another piece just like the first I have described, put the two together with a large head-rivet, and this makes the job complete, as shown in Fig. 26. —By EARNEST.

“Earnest’s” Method of Making a Prop Brace. Fig. 22—Showing How the End of the Piece is Bent

Fig. 23—The Drill

Fig. 24—Showing the Position of the Hole when Drilled

Fig. 25—Showing the Piece Ready for Welding

Fig. 26—Showing the Brace Completed

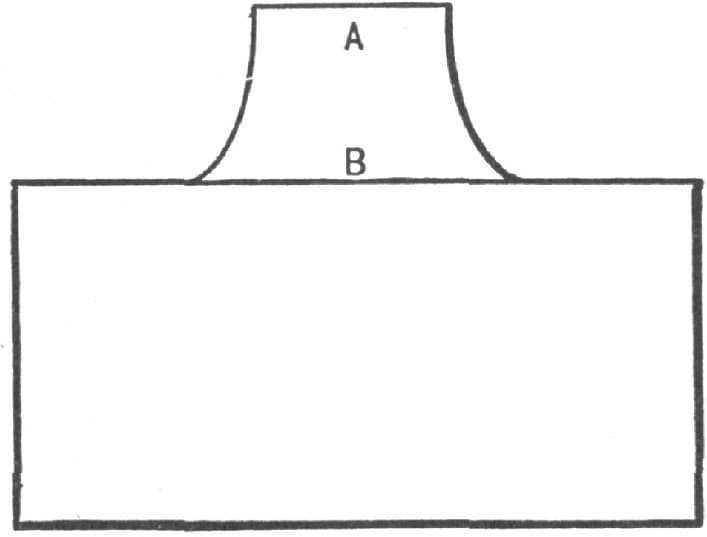

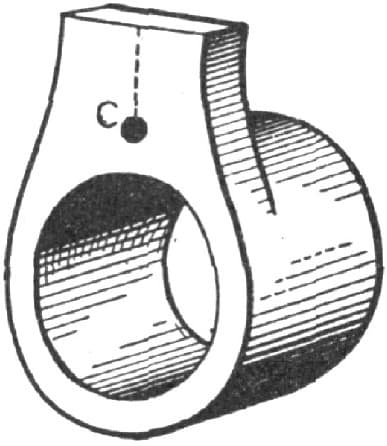

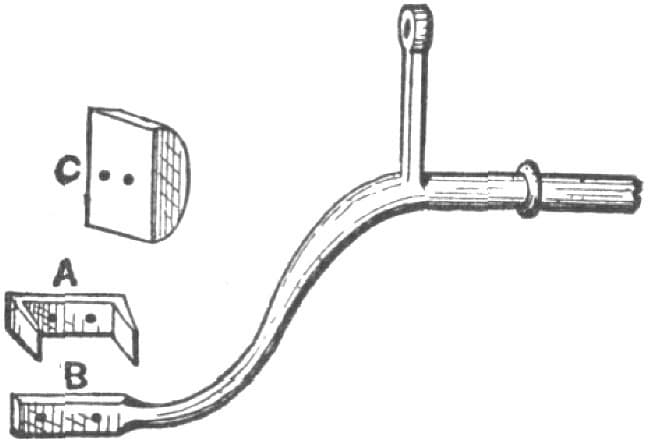

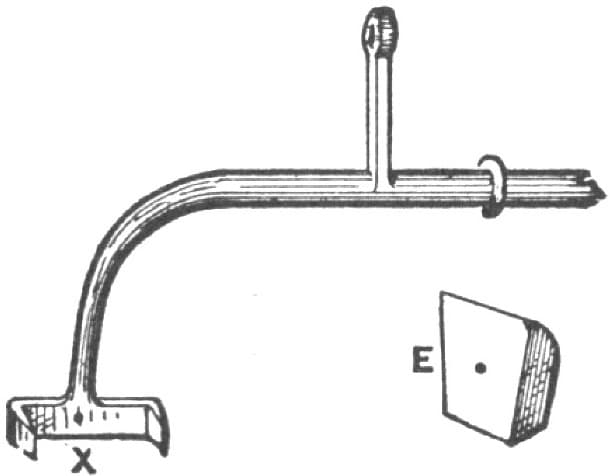

Making a Pole Socket.

I will describe my way of making a pole socket:

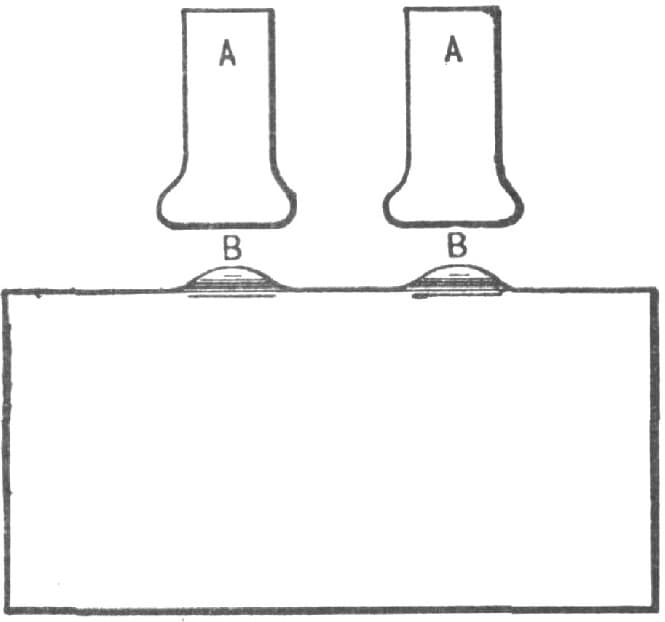

Take a piece of Norway iron at least three inches wide and three-eighths of an inch thick, cut it to the length of four inches, and mark it off with a pencil as shown in Fig. 27. Then mark the pencil lines with a cold chisel, heat the piece and cut it out. Next bend the part A down at B over the anvil and work the corner up square. Do not use the vise in bending, for it is a mistake to bend any sharp corner in a vise.

Making a Pole Socket. Fig. 27—Showing How the Iron is Marked

Fig. 28—Showing the Piece After the Rounding and Welding Operations

Then draw out the part B, leaving it one-half inch or two inches wide and three-sixths of an inch thick. Next bend it round to a diameter of one and one-half inches, then weld, finishing and rounding it upon a mandrel, and it will then be of the shape shown in Fig. 28. Next punch a very small hole at C, split it upward as shown by the dotted line, and bend and form each half as in Fig. 29. My boss had another way of making a socket. He took a piece 13/4 × 5/16, and welded on the two ears shown in Fig. 30, A A being the ears and B B the scarf ends to weld on. When the welding was done as shown in Fig. 31, he did the bending and other work in the same way that I do.—By T. J. B.

Fig. 29—Showing How the Piece is Split, Bent and Formed

Fig. 30—Showing How the Ears are Welded in Another Way of Making a Pole Socket

Fig. 31—Showing the Ears as Welded On

Making a Staple and Ring for a Neck Yoke.

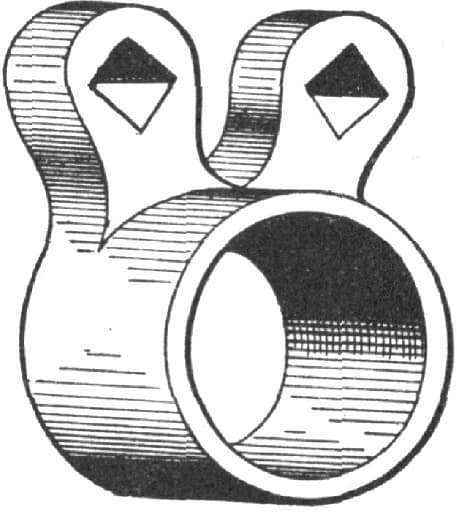

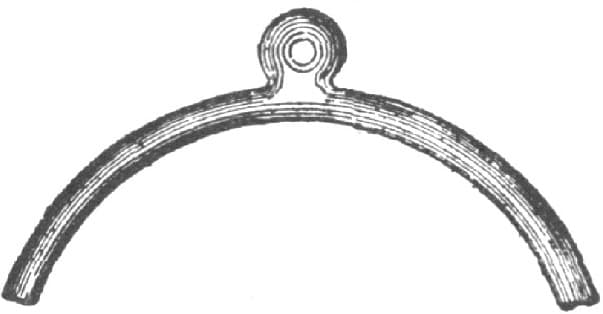

Many years ago, when I worked as a journeyman in a carriage and wagon shop, I often thought when ironing neck yokes, that I could devise a middle ring for a neck yoke that would be much easier on the horses’ necks than anything I had ever seen. So when I went into business for myself, I put on the first neck yoke I ironed a staple and ring like the one shown by Fig. 32.

Making a Staple and Ring for a Neck Yoke by the Method of “M. D. D.” Fig. 32—The Finished Ring

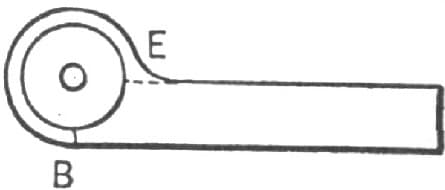

All the other rings I know anything about are rigid, or nearly so; not one of them will work like this. It is over ten years since I ironed that neck yoke, and it is still in use and has never been repaired. For a spring wagon this ring will outwear half a dozen leather ones. I have two ways of making it, but think that Figs. 33 and 34 illustrate the best way.

Fig. 33—The Piece Punched and Split

I get a piece of good Norway iron, of a size to correspond with that of the ring wanted, put in the fulling hammer and work the eye round; then punch a small hole and split it down from the hole to the end, as shown in Fig. 33. I then bend back the arms nearly but not quite horizontally, work them round, punch and work out the eye, as in Fig. 34. It is then ready for turning round and welding, after which I get a piece of round iron, which also ought to be good, form the eye bolt or staple, then open it a little and slip it into the eye, take a weld and draw it down tapering. I then make two plates for the neck yoke, making the holes for the eye bolt to fit snug; if for a farm wagon the plates must be longer, and fastened with two rivets; but for a spring wagon all that is needed is two wood screws for each plate. After boring the hole I burn it with the eye bolt, being careful not to get the hole too large, for the eye bolt ought always to fit tight at first. For a spring wagon I put on a six-sided nut, for a farm wagon a ferule, and rivet the end of the eye bolt red hot. To make the ring as shown in Fig. 35, such good iron is not needed. In that case I put in the fulling hammer at A A, draw down the arms to B, turn them round and weld them, then work out the eye; but if I have good iron would much rather make them the other way. Fig. 36 shows the ring in position. There is no patent on this ring; at all events, I have taken none out; and I believe I am the original inventor.—By M. D. D.

Fig. 34—Showing the Piece Ready for Rounding and Welding

Fig. 35—Showing Another Method of Making the Ring

Fig. 36—The Ring in Position

Making Wagon Irons.

I will give you my way of making iron toe calks that will wear almost forever and outlast two steel ones. Simply heat the calk nearly to a welding heat, dust it with cast-iron and cool in cold water. If done right the surface will be of a light gray color. A great deal of iron about very heavy wagons, whiffletree irons most especially, if treated this way would last much longer, and the cost would be small if it were done at the time of ironing.—By H. A. S.

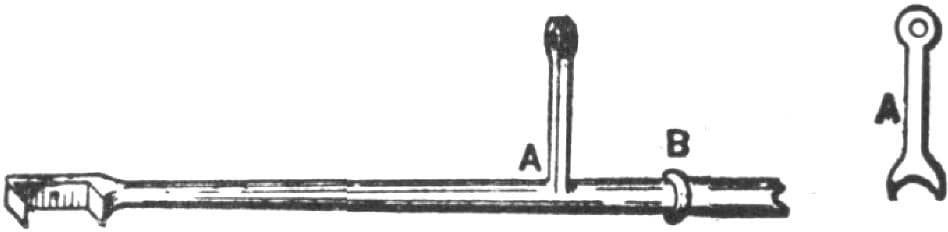

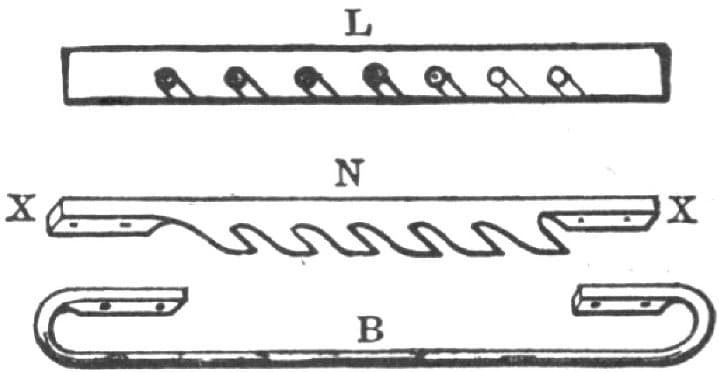

Making Shifting Rail Prop Irons.

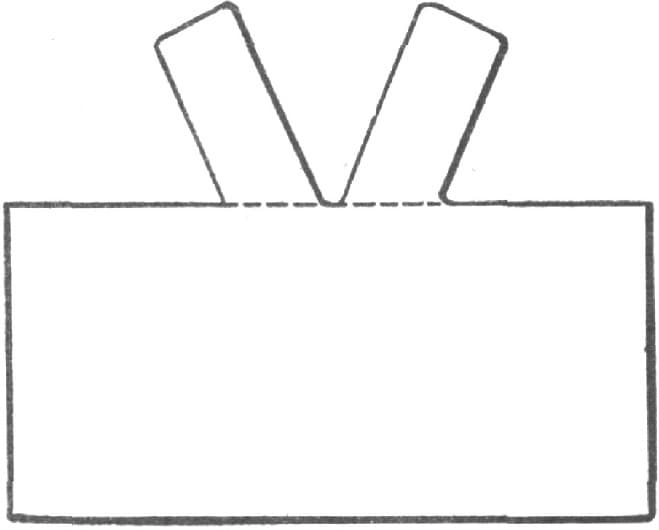

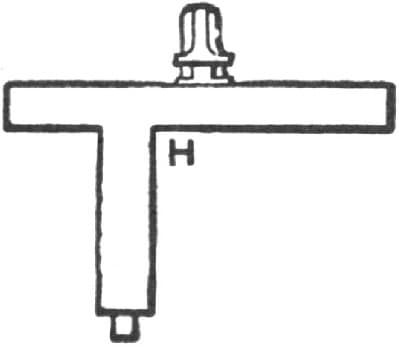

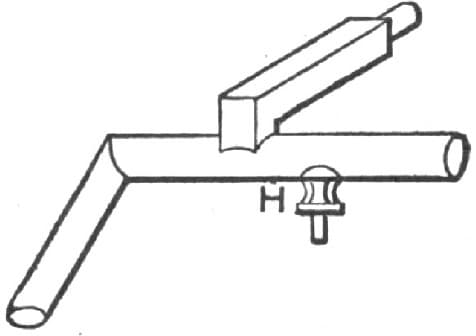

I will explain my method of making a shifting rail prop iron. I take a bar of Norway iron one and one-eighth by one-half inch, and draw out or cut it out half the breadth two inches long, as at A in Fig. 37; then cut into the dotted line B, and bend the end down to the dotted lines C. This leaves B and D at different heights, so I put the end C in the square hole of the anvil and drive B down even with D, as in Fig. 38. Then I draw out the end in the dotted lines E, and split at F and bend up F as at G, and swage to the size of iron needed for the rail. I make the upturned end one-half inch round and make the collar and prop piece. Then I have a swage one-half an inch wide to fit between the collar and prop piece, as at H in Figs. 39 and 40. I like the collar to be close to the prop piece, as this makes a stronger rail—one that cannot bend. Most of the railings I see have a space or length two inches where I only make one-half inch or five-eighths. The next thing in order is to raise the prop part, which gives the top a nicer appearance when lying down. The top rests or blocks are usually too low, and the bows are lower in the rear than where they part. I do not pretend that this is the quickest or easiest way of making a prop iron, but in my opinion it makes a firm and neat-looking railing.—By H. N. S.

Making Shifting Rail Prop Irons by the Method of “H. N. S.” Fig. 37—Showing How the Bar is Drawn Out and Bent

Fig. 38—Showing Further Operations in Drawing and Bending

Fig. 39—Showing How the Swage Fits Between the Collar and Prop Piece

Fig. 40—Showing the Collar and Prop Piece in Position

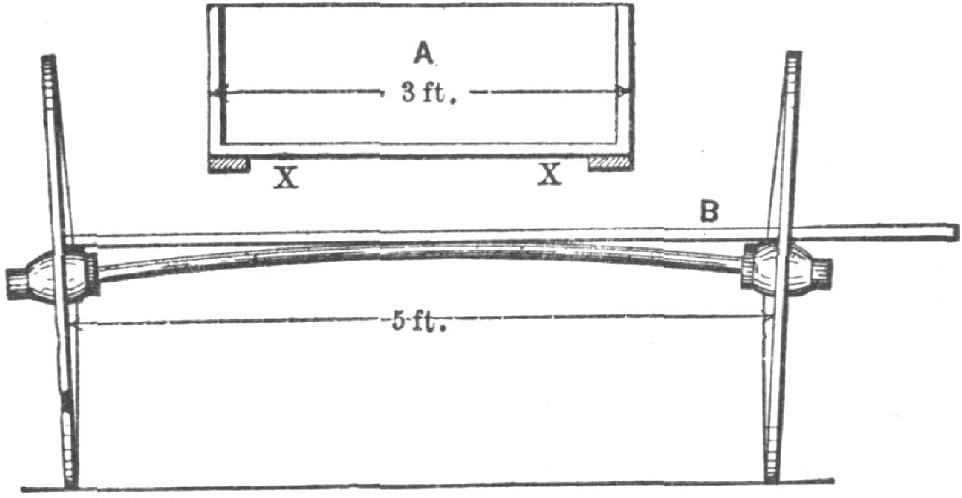

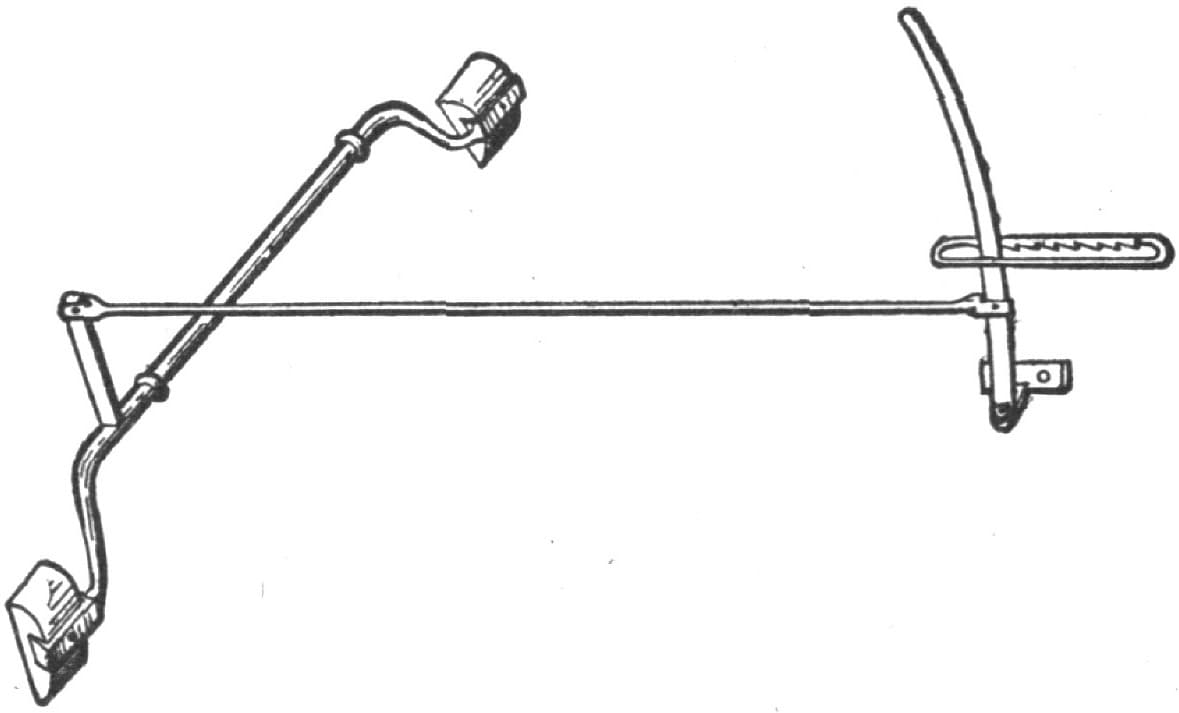

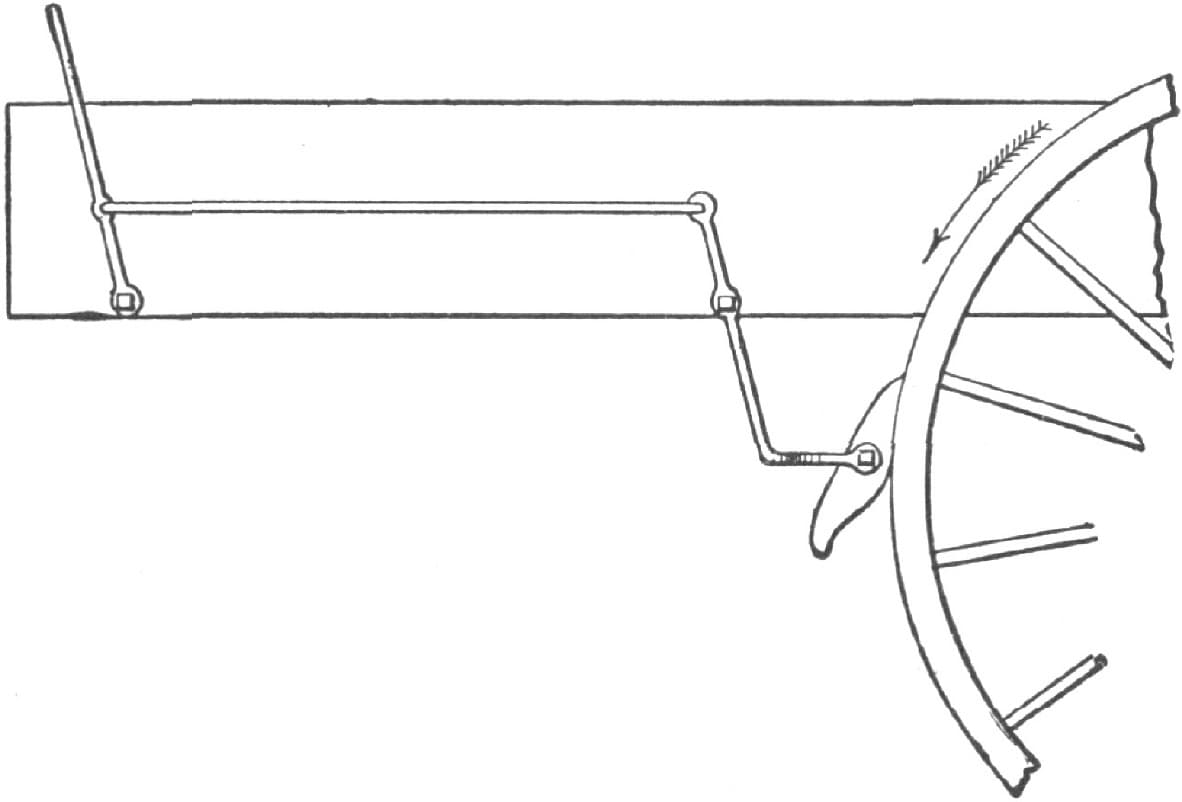

Bending a Phaeton Rocker Plate.

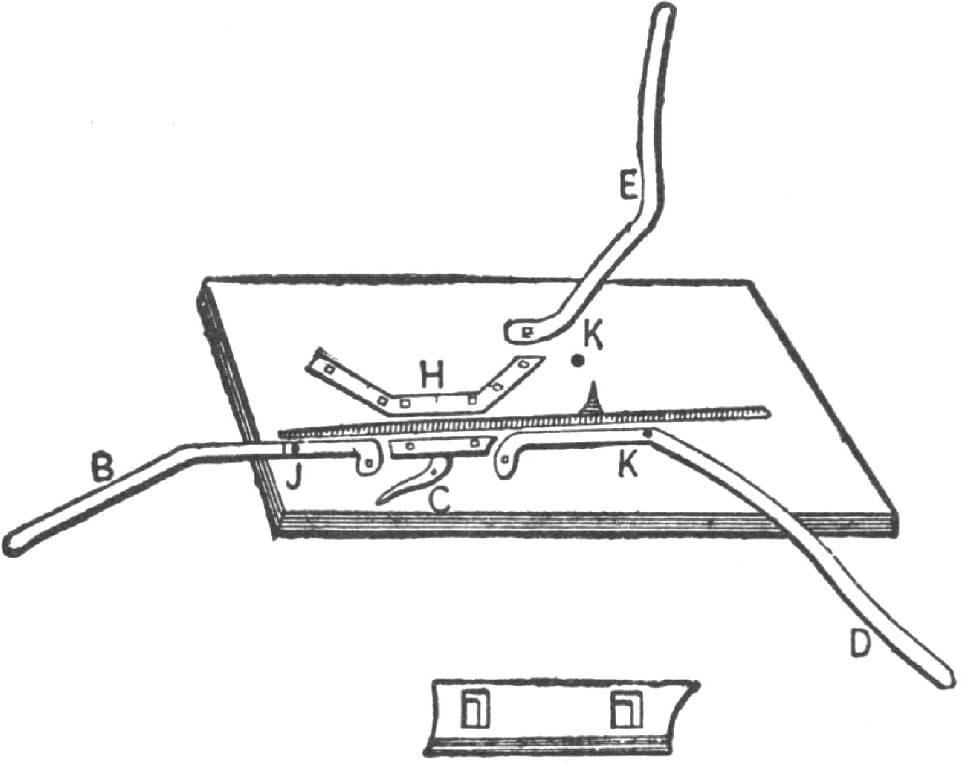

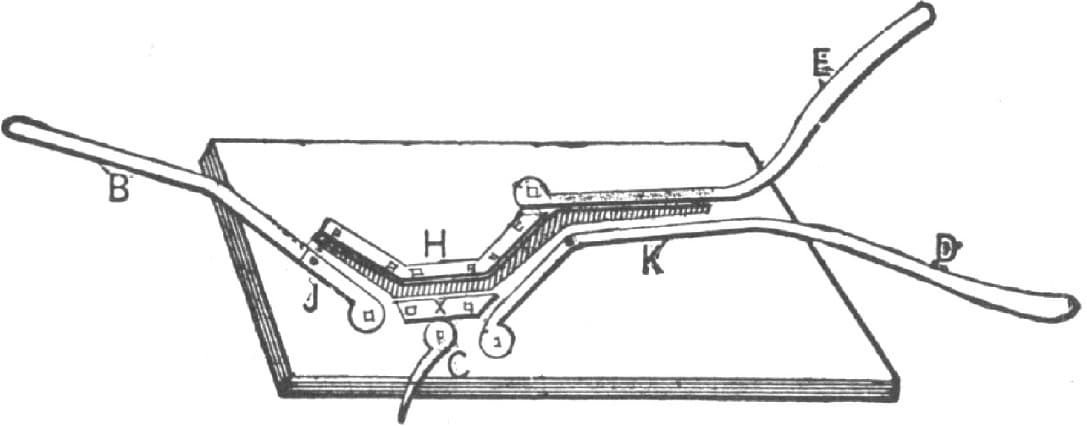

The following is the method of making phaeton rocker plates in large factories where they make from one to five thousand pairs a year. These plates are all bent with one heat, and come from the form after they are bent, ready for use. In Fig. 41 I show a straight piece of steel one and one-fourth by five-sixteenths of an inch, drawn at both ends, and ready to be bent.

Bending a Phaeton Rocker Plate, as Described by “H. R. H.” Fig. 41—Showing the Steel before Bending, and also the Part Marked × in Fig. 42

First, they cut off any desired number of pairs of plates with power shears to the exact length required. Then the ends are drawn out under power hammers. The plates are next thrown into a large furnace and heated to the proper heat. From twenty to thirty pieces are heated at once. After they are hot they are placed on the cast plate between the formers as shown in Fig. 41. Then the eccentric C, Figs. 41 and 42, is pulled around so as to press the small plate X against the rocker plate and the part H of the form. The lever B is now pulled into its place and a pin is placed in the hole J, which will keep the lever in position, The lever D is next pulled in its place, and pins are put in the holes K K; then the lever E is pulled around in its place. Then, with a hammer, the rocker plate is levelled and straightened while it is in the former; next the two pins J and K are taken out, the lever is pulled back, and the rocker plate is taken from the former finished.

Fig. 42—Showing the Plate Bent Between the Levers

In Fig. 42 I show a sketch of the former as it is when the rocker plate is bent between the levers. It does not take much work to make a former of this kind. Have a cast-iron plate the proper length and width, and one and one-half or two inches thick, and plane it level on one side. The levers and other pieces of the form should be made of steel the same thickness as the rocker-plate, and from two to two and one-half inches wide. The levers E, B and D are bolted to the plate with five-eighths inch steel bolts. The part ×, where the eccentric presses the plate, has two slotted holes five-eighths of an inch wide and one inch long, as is shown in Fig. 42. The part H is bolted solid to the plate. The levers B, E and D should have jaw-nuts on the bolts so as to have the levers work easy. The eccentric C is fastened the same as the other levers, and with a five-eighths inch steel bolt. On the lever B will be seen a mark which is the gauge for the proper length of the front end of the rocker plate. Besides its use in forming, this plate can also be employed as an ordinary straightening plate.—By H. R. H.

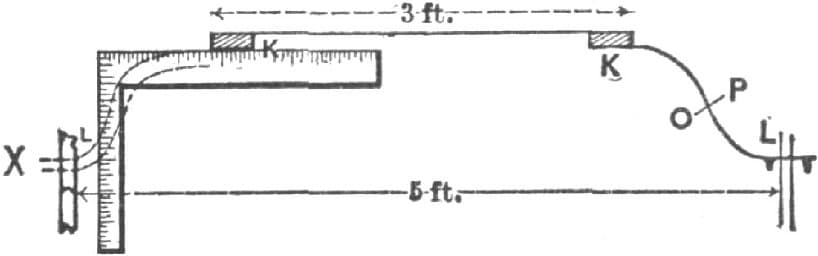

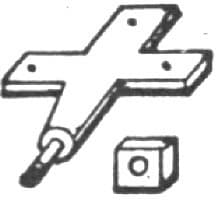

Shifting Bar for a Cutter.

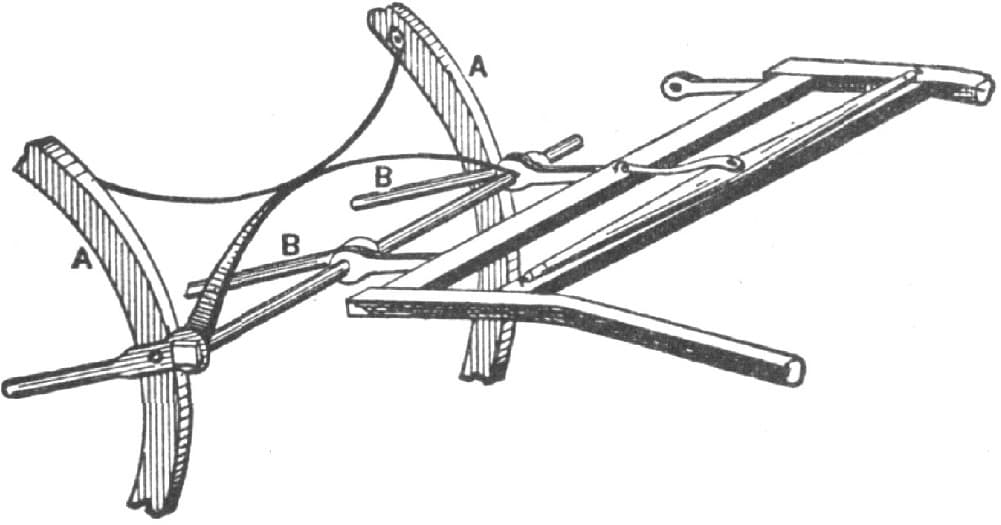

The shifting bar for a cutter illustrated herewith I have used for some time, and it has been pronounced by competent judges one of the most complete devices for the purpose that has ever come before their notice. Fig. 43 shows the device arranged for side draft, and Fig. 44 for center draft. A A represent the runners of the cutter. B B show some double acting springs which hold the shaft in place. The draw-bar is made of nine-sixteenths inch round iron, with a center stay running back to the beams. The cross-bar is provided with three eyes. When the shafts are brought to the center the third eye catches the end of the draw-bar and holds the shafts firmly to the runners. The draw-bar is rounded down to one and one-half inches, and the thread is cut back of that for screwing into the draw-iron.—By L. P.

Shifting Bar for a Cutter. Fig. 43—Arranged for Side Draft

Fig. 44—Arranged for Center Draft

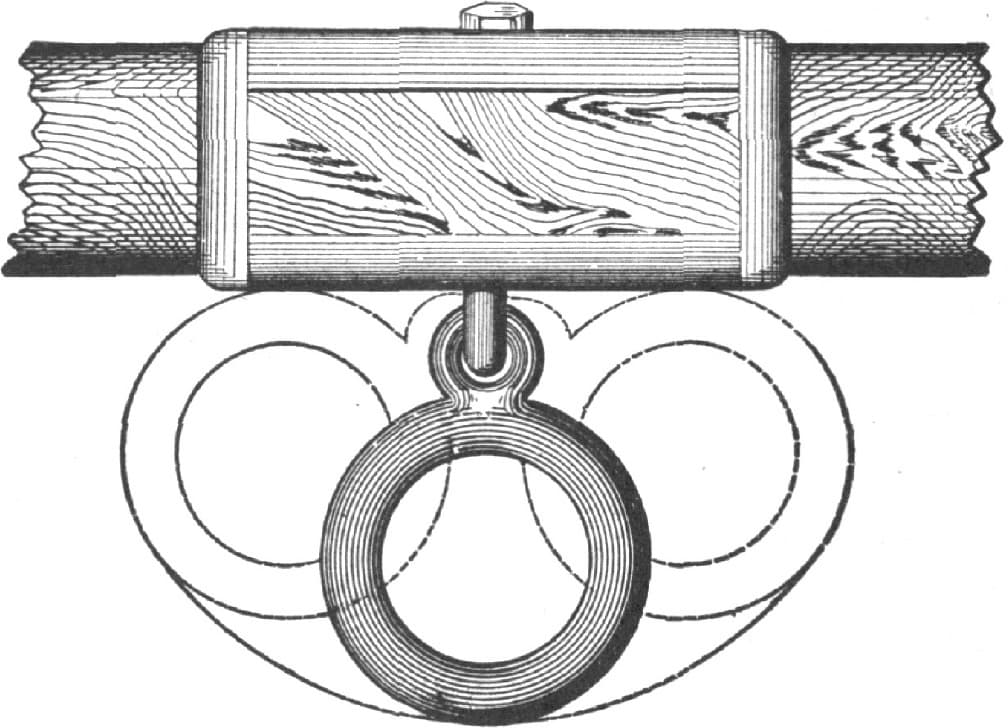

A Crane for a Dump Cart.

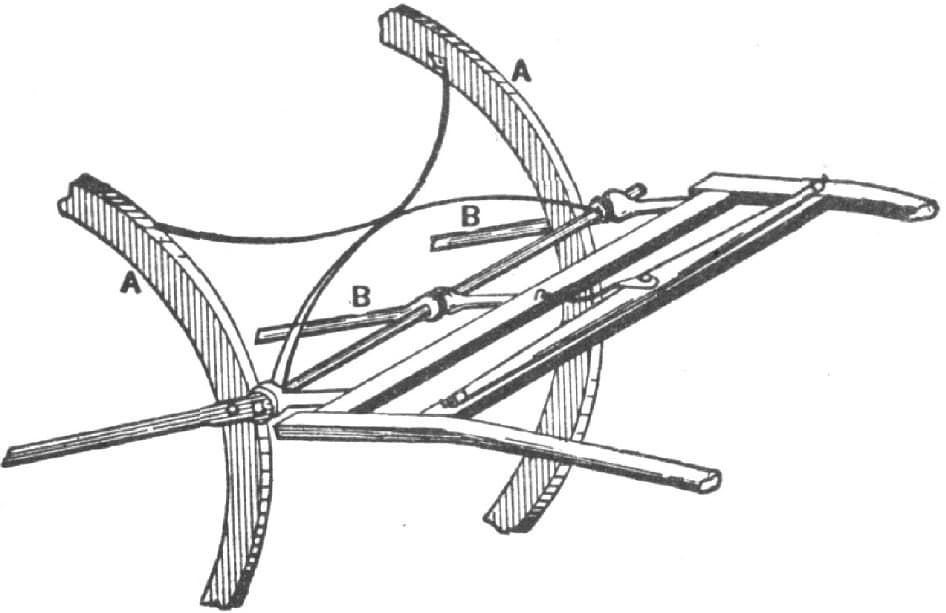

I have been using what I call a crane for holding up the pole of a dump cart, and I think the device as shown by Fig. 45 may be of use to some; it will prevent sore necks on horses, and this should be a sufficient object for many people to utilize it. Any smith can make it by proceeding as follows:

Fig. 45—Crane for a Dump Cart, as Made by “A. H. S.”

Take a piece of flat iron the width of the tongue, make an eye in one end and put a hook on it; now bolt the pieces on the tongue, one on the top and the other on the bottom; make a hole for transom bolt and another for the crane; in punching the hole for the transom bolt make it oblong. Put your crane in between the two plates and put a pin in; bolt a piece of chain to the cross-bar, raise the pole up and hook the chain to the crane. With this device you can turn the cart around just as easily as if it was not there, and it can be removed in a moment. A indicates a side plan of the hooked piece.—By A. H. S.

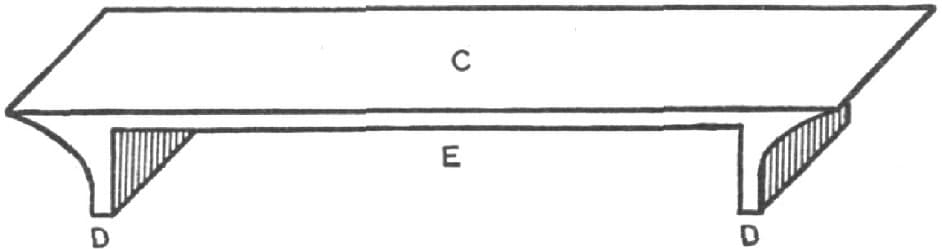

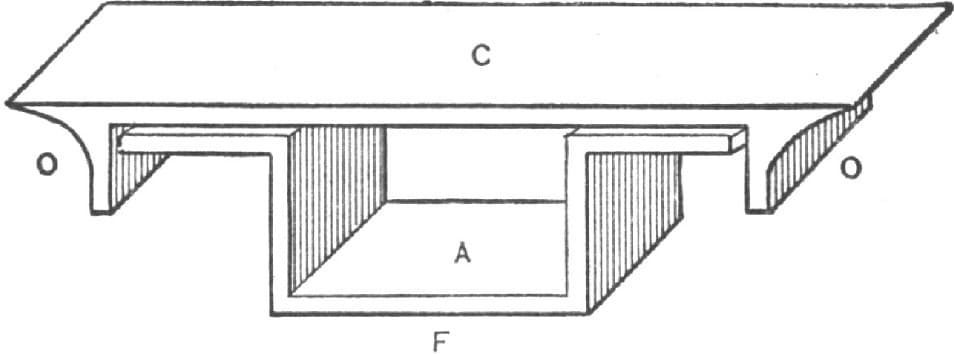

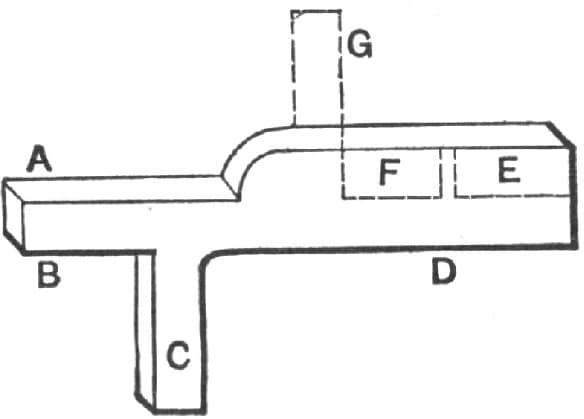

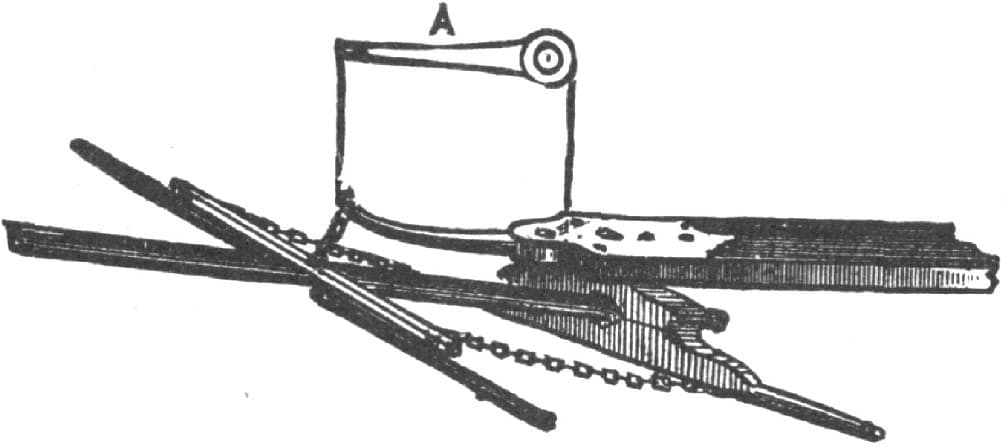

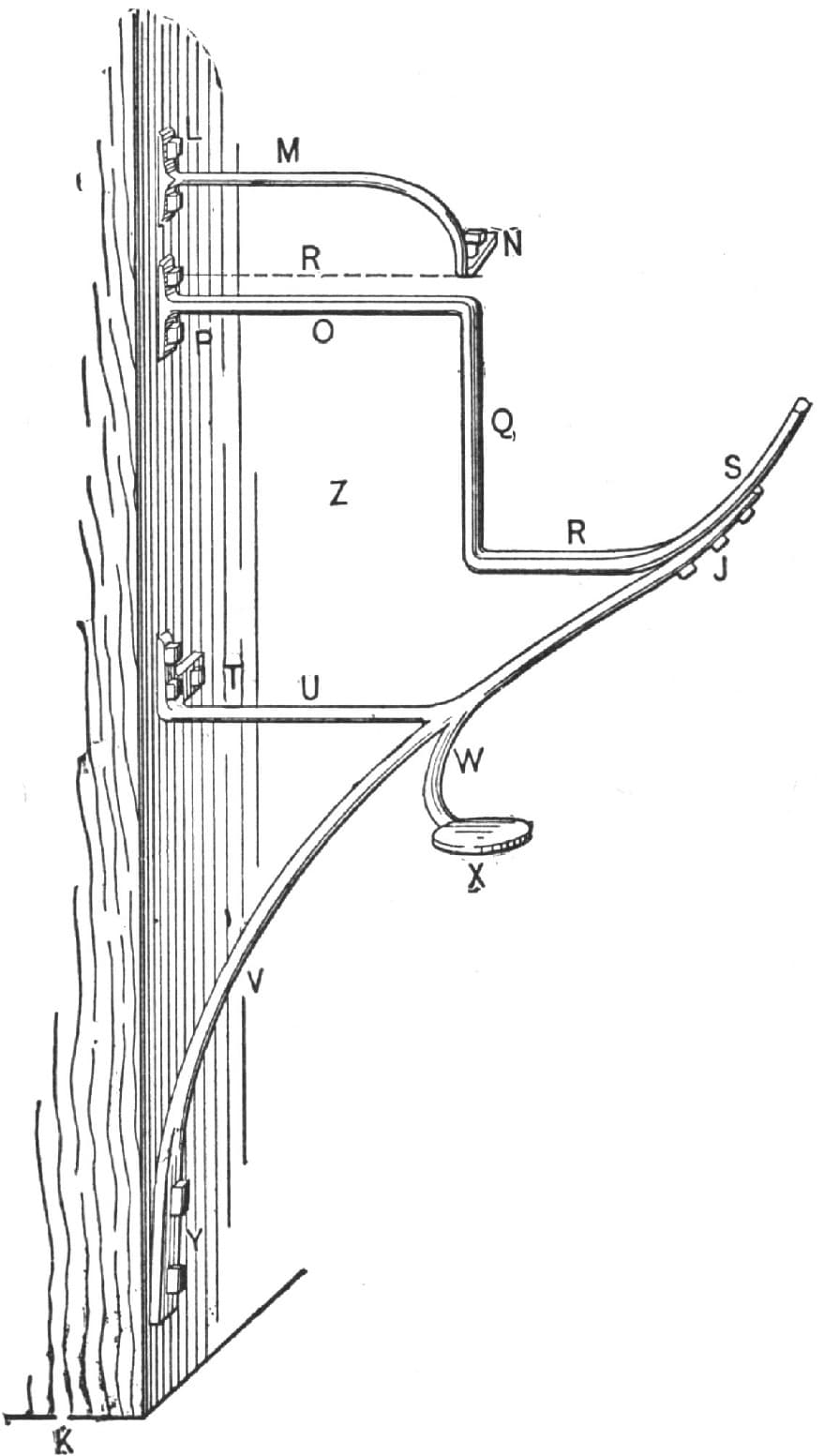

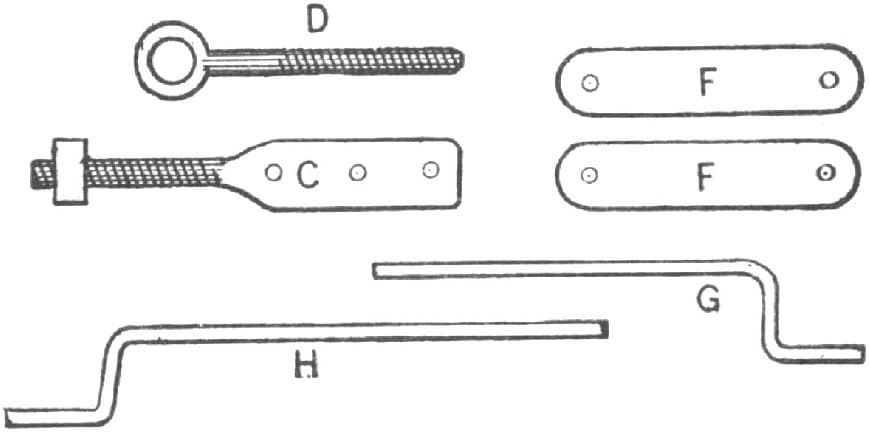

To Iron Front Seat of a Moving Van.

The primary points to be kept in view when ironing the front seat of a moving van, a lookout for general ease, convenience, comfort and security for the driver and his associates on the seat; I also plan to give strength throughout, and see that the fastening of the work to the body frame is such as to hold it firm and prevent it from working loose.

In Fig. 46, A is the outside line of body in front, B the base line. C C, where the handle is secured to the body frame. D is the hand piece of the handle. Make D of one-half inch round iron and cover with harness leather, which will insure a safer grip than iron alone. Make C C one inch wide and one-half inch thick at the first hole, and taper in thickness to three-eighths of an inch, four inches long, and fasten with three-eighths inch bolts. E, F and G represent the step, E where it is secured to the body, F the shank, and G the tread. Make E six inches long, one and one-half inches wide, seven-eighths of an inch thick at lowest hole, and taper to top to one-half inch thick. Fasten with seven-sixteenths inch bolt top, one-half inch bolt bottom. Make the shank F seven-eighths of an inch in diameter at the body, and taper to three-quarters of an inch at the tread, and between the body and tread six inches long. Make the tread, G, an oval six inches by five and three-sixteenths of an inch thick; round over the top edges to prevent cutting.

To Iron Front Seat of a Moving Van. Fig. 46—Showing How the Handle and Step Should be Secured

In Fig. 47, K is the base line of body, M the seat rail, L where it is secured to the body, and N the foot which secures it to the seat board. The dotted line R is the space occupied by the seat bottom. P is where the seat iron secures to the body, O the horizontal foot of the seat iron, Q the vertical part, R the horizontal part of the foot board, and S the bracket or toe piece. U is a safety stay from the stay V to the body, where it is secured to the body. V is the main stay, Y where it secures to the body, W the central step shank, and X the tread. Z is the space in which to set the blanket box, with a gate at each end.

Fig. 47—Showing How the Seat Should be Ironed

Fig. 48—Showing How T of Fig. 47 Should be Made

Make M of nine-sixteenths inch round iron, and fasten to body and seat with three-eighths inch bolts; O, Q, R and S of 2 × 3/4 inch half oval iron. V and U of 11/2 × 7/8 inch oval iron. Step shank W and tread X same as F and G. Fasten at P, T and Y with one-half inch bolts. Make O, Q, R and S in one piece; also, U, V, W and X in one piece, and bolt all together with three seven-sixteenths inch bolts at J. Make T the same as Fig. 48, A and B to bolt on the body to prevent racking. P and Y may be made the same when additional security is desired. —By IRON DOCTOR.

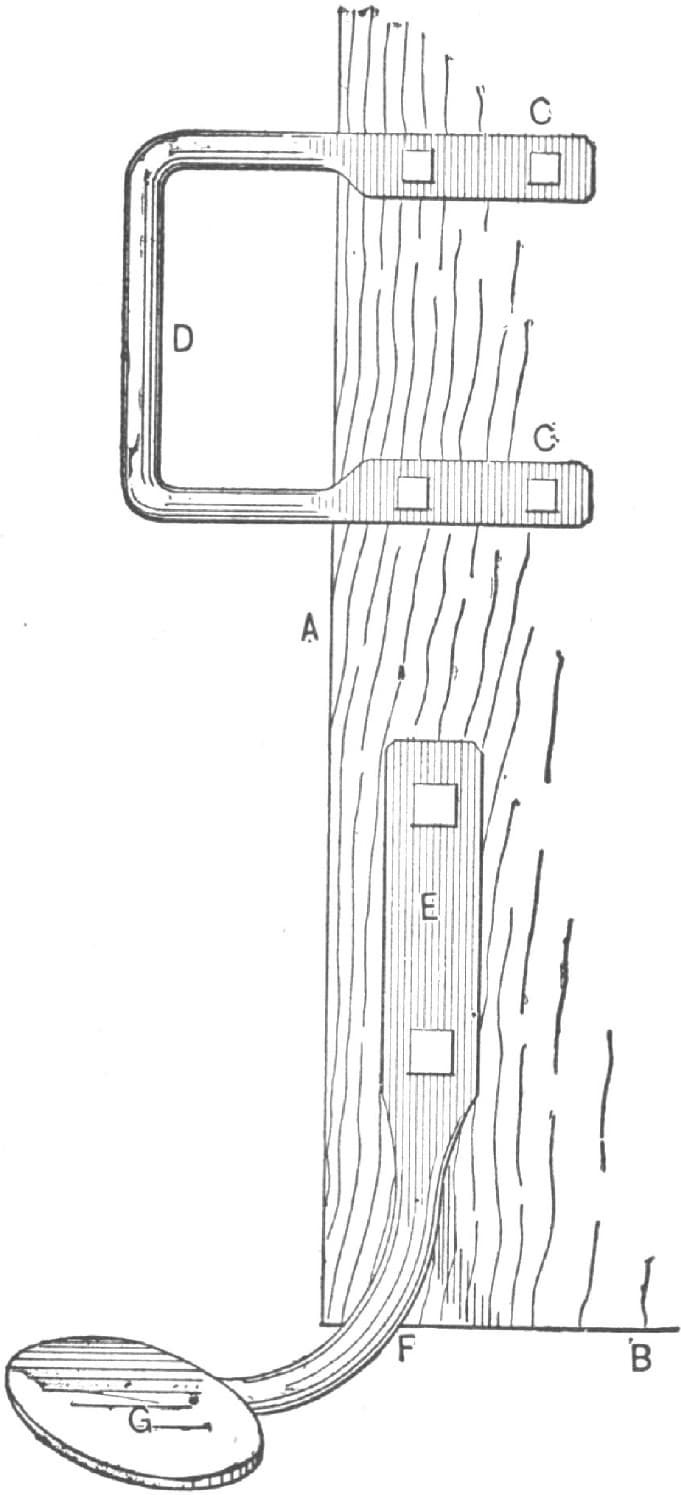

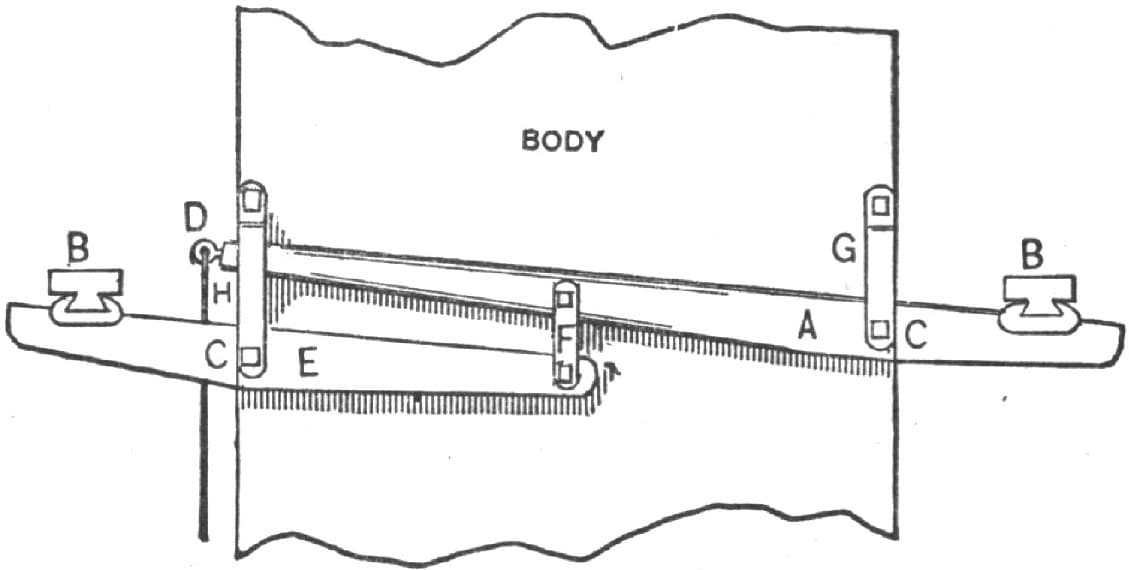

Wagon Brake.

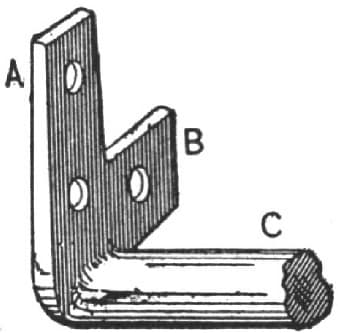

For a brake suitable for a light wagon to carry from four hundred to six hundred pounds I should recommend three-eighths-inch round iron. For a wagon that is to carry from seven hundred to one thousand two hundred pounds, one-inch round iron. For a wagon that is intended to carry from two hundred to one thousand five hundred pounds, one and one-eighth inch round iron, and for one that is to carry from one thousand five hundred to two thousand four hundred pounds, one and one-fourth inch round iron. The special feature that recommends the brake made by me is its simplicity. It is also the easiest for the smith to make of any with which I am acquainted.

In order to explain the brake intelligently, let it be supposed that a brake is to be made in order to fit a given wagon. The first thing I would do would be to get the width of the body, which may be assumed to be three feet from out to out, as indicated by A in Fig. 49, a section of the body of the wagon. Next I get the width between the sills of the wagon, then I get the distance from center to center of the wheels, or, what is the same, from in to out of the wheels at the place where the brake blocks are to come. This is also indicated in Fig. 49. I then take a piece of board of proper length and width, and mark upon it, first, the width of the body. Then I would mark the distance between the sills of the body as shown by K K in Fig. 50. Now, as the width of body is three feet, and the width from center to center of the brake blocks is five feet, there will be left the space of one foot on each side of the body between it and the wheel. Take the square and place it on the board as indicated at K X in Fig. 50, and measure one foot out on each side of the body. At X will be the center of the block. With a piece of chalk make a double sweep, as shown from K to L, in Fig. 50. This sweep should be the same in its two halves; that is, the curve from K to the cross line marked O should be the same as from L to the same cross line. Next get the length of the iron from this board, and shape the brake over the draft thus constructed. Cut the iron so that each piece will make one-half of the brake, and make the last weld in the center.

Fig. 49

Fig. 50

Fig. 51

Fig. 52

Fig. 53

Figs. 54 and 55

In making the brake a choice must be made as to the fastening to be employed for the block. For the sake of illustration we will choose that indicated by A, in Fig. 51. To make this fastening proceed as follows: Heat the iron and split it, as shown at F in Fig. 52. Then forge out the end marked X, as shown at A in Fig. 53. Next place the iron back in the fire, and getting a good welding heat, use a fuller and thus turn back a part for the lip, and swage the iron a trifle thinner back of the lip, as shown at X in Fig. 53. Should the iron by this operation be made too light at the flat part of the lip, indicated by O in Fig. 53, heat it again and upset it until the proper shape is obtained. This iron might be forged out of a solid piece, or of a large piece of iron, and then welded out to the round iron. This, however, I think useless, as the plan I have described is fully as good a way of making it, and has the advantage of being accomplished in one-third the time required for the other. After the iron has been finished as is shown in Fig. 53, turn the other lip as indicated by X, in Fig. 54. This part is then finished. Weld on the lever for the rod as shown by A in Fig. 54. Fig. 55 illustrates how this lever is prepared, ready for welding. Then weld on the collar as shown at B in Fig. 54. This collar, B, must be welded on so that when the iron is bent, as shown in Fig. 51, it will come even with the inside of the sill of the body, as indicated by X X, in Fig. 49. The object of these collars is to keep the brake in its place. In shaping the lips A of Fig. 51, they should be made wider on the top than on the bottom, so that they will receive a block, as indicated by G. This block is made dovetail, so that it will not give trouble by slipping through the iron when the brake is applied to the wheel. The opposite side of the brake is made in the same manner, save that it does not need the lever X shown in Fig. 51. The rod operating the lever is placed only on one side of the body. It is generally placed on the right-hand side.

Fig. 56

Fig. 57

Fig. 58

Fig. 59

In Fig. 56 the brake is shown as it would appear when applied to the body. The body itself is omitted because it would conceal the irons, which it is desirable to show. In Fig. 57 two forms of hanging irons are shown for hanging the brake to the body. The iron A is generally used on very light work, while the iron B is desirable for heavy work, such as platform, mail or express wagons. If the iron B is used, it must be put on the brake before the collars are welded in place. In Fig. 58 another method of fastening the block in place is shown. The iron is flattened out wide and two holes are punched in it, as indicated at B. Then an iron is made of the shape shown at A. The block C is fitted to the iron A, and block and iron are together bolted to B. In Fig. 59, at A, a collar is shown that is swaged round. A thread is cut on the end of the iron, and the block, made of the shape shown at C, is slipped over it and held in place by the nut. This kind of fastening for brake blocks is in general use on heavy work. Still another form for fastening the brake blocks is shown in Fig. 60. B is flattened as indicated in the sketch, and the block D is bolted on to it by means of two bolts. Fig. 61 shows the use of the block of the general shape shown at E, which is very nearly like that shown in Fig. 51. In making this iron, weld on a piece in the same manner as employed in welding a T or shaft iron. Then turn up the ends for the block. In Fig. 62 is shown a detail of the iron used where the lever is fastened.

Fig. 60

Fig. 61

Fig. 62

In making a brake ratchet I proceed as follows: Take a piece of steel one by one-fourth inch, or one and one-fourth by one-fourth inch, according to the size of the wagon. Drill as many holes in it as there are teeth required. Then cut them out, as is shown at L in Fig. 62. Finish as indicated by N in Fig. 63. After the teeth are in proper shape, twist the flat part at each end, as indicated by X X, Fig. 63, so that it can be bolted with the wide side against the body. B shows the shape of the guard for the lever. This is bolted on to the ratchet with the same bolts that hold the ratchet to the body.—By H. R. H.

Fig. 63

An Improved Wagon Brake.

Having, as I believe, an improvement on that antiquated instrument, the wagon brake, I give it for the benefit of the trade.

The improvement consists in using a cam in such a manner as to hold the wheel tighter than the ordinary brake will, while the exertion of force on the part of the driver is much less than in using the common style of brake. The device is shown by Fig. 64.

Fig. 64—Improved Wagon Brake Made by “E. L. H.”

The friction of the wheel turns the cam, this springs the brake into the ratchet plate, and it tightens in revolving until the shoe proper rubs on the tire. The shoe is made double so that when the wheel revolves backward it can be locked by the same process. The lower shoe should be made heavier than the upper one, otherwise it would not fall into the proper position on loosening the brake.—By E. L. H.

How to Make a Two-Bar Brake.

My method of making a two-bar brake:

Fig. 65 shows the brake as applied to the wagon body. A is the lever which goes across the body, and by the moving of the rod H the blocks B B are applied to the wheels.

Fig. 66 shows some of the iron work required to make the brake. F F, Fig. 66, are two iron plates one and one-half by one-half inch and six inches long One goes above and the other below at F, Fig. 65. D, Fig. 66, is an eye bolt which goes in D, Fig. 65, and to which the rod H, Fig. 65, is attached. Any kind of a ratchet may be used. G and H, Fig. 66, are iron straps used at C C, Fig. 65.

How to Make a Two-Bar Brake. Fig. 65—Brake as Applied to the Wagon Body

This brake is a very common one in the West, and for a box brake is quite as cheap and as good as any in use.

Fig. 66—Iron Work for Brake

There are single bar, two-bar and three-bar brakes, and we also have single bar brakes for hounds, which can be used with or without the wagon box.—By G. W. P.