CHAPTER 7

The Hidden Cost of Convenience

We are a 24/7 on-the-go society who wants convenience in our beverage choices.

—Kim E. Jeffery, CEO, Nestlé Waters North

America, May 21, 2008

There is no reason that the universe should be designed for our

convenience.

—John D. Barrow, English physicist and mathematician

Mr. McGuire: I want to say one word to you. Just one word.

Benjamin: Yes, sir.

Mr. McGuire: Are you listening?

Benjamin: Yes, I am.

Mr. McGuire: Plastics.

—From the film The Graduate (1967)

“WE , John Rex Whinfield, of Meyroyd, Hollins Lane, Accrington, in the County of Lancaster, and James Tennant Dickson, of 26, Ormingston Crescent, East Lothian, Scotland, both British Subjects, do hereby declare the nature of this invention to be as follows…”

These words announced the discovery and patenting of the material that would eventually become the key to the explosive growth of the sales of bottled water—the plastic throwaway bottle. If the only containers available for water were glass or aluminum cans, I believe that sales of bottled water would never have taken off.

In 1941, forty-year-old John Rex Whinfield was employed as a research chemist by the Calico Printer’s Association, a small English fabric company. Whinfield’s job focused on the chemistry of fabric dyeing and finishing for the war effort, but in his spare time, he studied the molecular makeup and properties of synthetic fibers. In March of that year, Whinfield and his 21-year-old assistant, James Dickson, discovered a method of condensing terephthalic acid and ethylene glycol to produce a magical new material that could be drawn into fibers with a high melting point and a strong resistance to biodegradation. This material became known as “polyethylene terephthalate” (PET or PETE), or polyester, or Dacron, and after World War II it rapidly became the most widely produced synthetic fiber in the world. It surpasses nylon in both toughness and resilience and it can be made into any number of forms, including fabrics, rugs, strapping material, films, recording tape, mylar, and especially, lots and lots of plastic bottles.

Portability has always been a problem for water. Simply put, water is remarkably heavy. One gallon weighs eight pounds. A cubic meter of water—imagine a cube about three feet by three feet by three feet—literally weighs a ton. The picturesque images we see of women in Africa carrying water on their heads from a village well or stream belie a backbreaking and grueling chore. Try it yourself: Fill a plastic container with four or five gallons of water and carry it around the block.

The earliest water containers were probably simple hollowed gourds or the bladders of large animals. Archeologists have also come upon early water containers made of earthenware, fired and glazed pottery, and stone. One of the most famous references to stone water containers appears in the Gospel of St. John:

And there were set there six waterpots of stone, after the manner of the purifying of the Jews, each containing two or three firkins apiece (John 2:6).

And Jesus saith unto them, Fill the water pots with water. And they filled them up to the brim (John 2:7).1

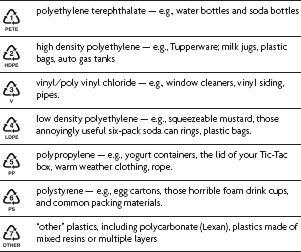

Recycling Codes for Plastics

There are many kinds of plastics and in 1988 the Society of the Plastics Industry introduced a classification scheme to help consumers identify different forms and to aid recycling efforts. This resulted in the triangular symbols that are embossed on most plastic items and increasingly familiar to consumers.

As the technology of containers improved, stone, clay, and ceramics gave way to wooden barrels and glass. In the nineteenth century, glass bottles were commercially produced and used for bottling mineral waters. Even today, many higher-end mineral waters come exclusively in glass bottles and collectors seek out old versions of water bottles at auctions and antique stores, and on eBay. But even for expensive bottled water, sales in glass are limited. Glass is heavy, which adds to the cost of producing and shipping it, and it breaks easily. After the Korean War, the widespread availability of aluminum led to the development of the aluminum can to replace individual steel and tin food containers, though all-aluminum cans were not used for carbonated soft drinks until the early 1960s. Aluminum cans then rapidly dominated the beverage market because of their convenience, light weight, and recyclability. Aluminum containers, however, are not commonly used for water because they impart a slight taste to their contents. When the contents are soft drinks or fruit juices, this taste is effectively undetectable. When the content is water, the taste is far more apparent.

Is Water from Plastic Bottles Safe?

Part of the opposition to bottled water comes from concerns over the safety of the plastics used for packaging and whether these plastics leach dangerous chemicals into the product we drink. It should be no surprise that consumers are confused about the safety and environmental consequences of plastics and the chemicals used to make them. Who can blame us? Our society has shown a remarkable ability to create new weird chemical mixtures and combinations of materials. And industry has been able to get them into commercial production in massive quantities far faster than our scientists and regulatory agencies have been able to test them for their environmental and human health consequences.

History is rife with examples of smart things we did with magical new materials that turned out to be stupid. DDT—that wonderful pesticide that kills more than pests. MTBE—the gasoline additive that solves an air pollution problem while causing a far more serious water pollution problem. Dioxin—a byproduct of dozens of industrial activities and superb at causing cancer and reproductive failures. CFCs—stable chemicals that are effective for air conditioning and firefighting and, alas, also remarkably effective at destroying the Earth’s ozone layer. Perc (or perchloroethylene)—fantastic for dry cleaning and also for causing dizziness, fatigue, headaches, unconsciousness, irritation of skin, eyes, nose, and throat, liver and kidney damage, memory loss, confusion, and, oh yes, cancer.

We already know that some plastics should not be used for water or food. Polyvinyl chloride (PVC) leaches phthalates, a hormone disruptor, and dioxin, a carcinogen. Polystyrene can leach styrene, a possible human carcinogen. But what about the PET or polycarbonate commonly used for bottled water? PET is widely considered to be one of the safest forms of plastic for food packaging, and few credible studies have ever claimed to find a risk of leaching.

Not so for some other materials: some bottled water, especially bottled water sold in large sizes for office or home coolers, is packaged in polycarbonate (PC), which is stronger than PET for large volumes of water. Lexan water bottles are also made of polycarbonate. Under some extreme conditions, such as the cleaning of polycarbonate with abrasive materials, or long-term storage of water in PC containers, some PC appears to release bisphenol A (BPA), a potentially serious health hazard. A contentious and active debate in the health community is underway about both the extent of leaching and the human health implications of exposure to BPA. I have no doubt that we’ll learn more in the coming years as the science improves, and I urge more research on leaching risks and health consequences of all plastics used for water or food.

What should a wary consumer do in the meantime? I certainly wouldn’t drink water that has sat around in a hot car in any kind of plastic bottle for several days. Even if the plastic doesn’t leach, heat and light encourage bacterial growth. Cautious consumers can now find newer polycarbonate bottles made without BPA or buy lightweight stainless steel or enamel-lined aluminum bottles. And finally, tap water is so cheap that you can afford to empty your reusable bottle and refill it with clean fresh water as often as you like.

Enter plastics, specifically Whinfield and Dickson’s invention “polyethylene terephthalate” or PET. PET is easily recognized by the resin identification number 1, as illustrated on p. 89. This particular form of plastic has some wonderful characteristics of special interest to the food and beverage industry. It is resistant to heat, mineral oils, solvents, and acids. It is impermeable to carbonation. It is strong, light, impact resistant, naturally transparent, and completely recyclable. And it doesn’t impart a taste to its contents. As a result, PET is the most common plastic used for food packaging. The research available today also suggests that PET does not leach chemicals into the water, unlike many other types of plastic.

PET entered the commercial soft drink market in 1977, but bottled water in PET didn’t appear until 1990, when Nestlé introduced the plastic water bottle.2 “It revolutionized our industry,” said Kim Jeffrey, CEO of Nestlé Waters North America, “because now people could get bottled water in the same format they were getting soft drinks in.” Today the vast majority of bottled water sold in the United States—more than 95 percent—is packaged in PET containers.3 If you get your bottled water in large five- or six-gallon jugs that sit on top of a cooler, you are probably getting water packaged in polycarbonate (PC), not PET. Polycarbonate has greater strength in larger volumes, but research suggests it can leach bad chemicals into the water.

I love the TV show How It’s Made, produced in Quebec, Canada. I can sit happily for thirty minutes and watch how factories, smart machines, and skilled workers make baseball bats, kayaks, bicycle safety helmets, or gumball machines. And for bottled water, the process is equally fascinating. Almost all PET bottles are produced through stretch/blow molding. The first step involves making pure PET “resin” in the form of pellets resembling grains of rice. This resin is the raw material used to make a wide range of different PET products. In the United States in 2008, total PET resin consumption was about 4 million tons, with domestic production coming from seven main producers: Starpet, Eastman, Nan Ya Plastics, M&G Polymers, Dak Americas, Wellman, and Invista.4 Around a million tons of this product goes to the bottled water industry.

To make beverage bottles, resin is injected into heated forms that mold it into “preforms.” A preform looks like a thick-walled test tube with the same weight as the final bottle and with a finished neck and set of cap threads (or as several different industry salesmen told me at a trade show, “a very small hard condom with a screw cap”). Preforms are then heated, stretched, and blown into the final bottle shape in machines that can make literally hundreds of bottles a minute. Some major bottlers do the whole thing: take resin, make preforms, and blow, fill, and package their own bottles. Most smaller bottlers buy bottles that were blown somewhere else and then fill them in a bottling plant. When I toured the massive Nestlé Arrowhead plant in Cabazon, California, I was transfixed by the machines gobbling up tiny little round pellets of pure plastic resin and spitting out hundreds of bottles a minute, automatically testing them for flaws, rejecting bad ones, and sending good ones zipping off to the next set of machines to be filled with water, capped, labeled, and packaged. From start to finish, the entire process of turning raw plastic into a finished bottle of water ready to be shipped to a store takes only a few minutes. At a modern bottled water plant, millions of throwaway PET bottles can be produced each day.

This convenience comes at a cost. As we become increasingly savvy consumers and learn more about the implications of our purchases for natural resources and the environment, new and complicated questions arise. Were those inexpensive running shoes made by child labor in bad working conditions? Was the cotton in my blue jeans grown organically and with efficient irrigation? Are the Central American coffee growers who provided the beans for my morning cup being fairly compensated? What is the carbon footprint of my daily commute? And what are the true costs of my convenient plastic water bottle—the costs of making the plastic bottle and shipping it to me as well as the environmental costs of disposing of the plastic garbage when I’m done drinking?

Resources are required to make, package, transport, chill, use, and recycle bottled water and its packaging, including both energy and, ironically, water. Making the plastic for a liter bottle of water actually takes three or four more liters of water itself. The real problem, though, is the energy cost: PET itself is typically made from petroleum. Making a kilogram of PET, which is enough for around 30 one-liter plastic bottles, takes around 3 liters of petroleum. More energy is then required to turn that PET into bottles, to filter, ozonate, or otherwise purify the water, to run the bottling machines, and to chill the bottle before use.

And even more substantively, it takes a lot of energy—almost all in the form of fossil fuels—to move the finished product to the place where you buy it. The total transportation energy requirement depends on two major factors: the distance and the mode of transportation. Unlike purified water from municipal sources, which are typically bottled and sold locally, “spring” waters must be packaged at specific sources and transported, sometimes significant distances. As we’ve seen, Nestlé bottles water under the Arrowhead label at several plants in Southern California for distribution throughout their western markets, and the company bottles water under the Poland Spring label in Maine for distribution throughout the eastern United States. This water usually travels in trucks, which take more energy to move the same kilogram of stuff than do trains or cargo ships. Even more extreme examples include the specialty waters that travel overseas, like Fiji Natural Artesian water, which is packaged at its source in the South Pacific, or Evian water, which is packaged at its source in France, and then shipped to markets around the world.

The transportation energy cost thus varies significantly, depending on our choices as consumers. If you live in L.A. and buy Fiji Water, the energy cost of transporting the water to you is equal to the energy embodied in the plastic bottle itself. If you live in L.A. and can’t do without Evian from France, the transportation energy involved is even higher. If you can’t do without Fiji on your private jet, the most energy-intensive form of transport—well, you’re probably not thinking much about your energy costs anyway. Put all of these different pieces together—materials, production, and transportation—and the energy costs of bottled water can be the oil equivalent of a quarter or more of the volume of the bottle. And this energy cost is a thousand times larger than the energy required to procure, process, treat, and deliver tap water. A study I conducted with my colleague Heather Cooley and published in Environmental Research Letters in 2009 concluded that global production and use of bottled water required the equivalent of between 100 and 160 million barrels of oil in 2007, along with all of the concomitant environmental consequences of getting and using fossil fuels.5

What about the environmental consequences of the bottles when we’re done with them? How can we deal with the huge volumes of plastic waste that bottled water use generates? If bottled water isn’t going to disappear, what can we do to reduce the environmental consequences of this waste? Obviously, the first thought of many is simply to stop buying the bottles. But short of this solution, unlikely in the near term, there are five possibilities for our empty bottles: Throw them away, recycle them, reduce the amount of packaging used for each bottle, burn them for energy, or make the bottles out of something else entirely that may have less environmental impact.

At least three-quarters of our water bottles are thrown out and end up in one of the nation’s landfills—or lying in the gutter at the side of the road. Even if the bottled water consumer is responsible enough to throw the empty bottle in the garbage, rather than just on the ground, the path to the landfill is depressingly short and the consequences effectively permanent. PET doesn’t degrade or compost. I live in a small single-family house in Berkeley, California. If I fail to recycle and put a used plastic water bottle in my regular gray garbage can, it is picked up at my curb on Thursday morning by a local city garbage truck. When that truck is full, it heads off to the City of Berkeley transfer facility down near the highway, where it dumps its load. Very few cities around the world make any effort to recover recyclable materials from the general waste stream—it is hard to do and expensive, often requiring either poorly performing automated separation machines, or poorly paid hand labor. In Berkeley, as in cities all over the world, the day’s collected garbage is compacted without being sorted for recoverable materials and then loaded into larger trucks that take it out to one of two local landfills, where, by the end of the day, that plastic bottle will join tons of other waste for centuries to come. I have this recurring fantasy of some future archeologist digging through our landfills, finding a narrow band of dense plastic bottles that can be dated to the twenty-first century, and concluding that this was an early form of intentional carbon sequestration practiced when we learned that our carbon dioxide emissions were going to radically change the climate.

In any case, it is getting harder and more expensive to simply dump our garbage in landfills. The number of landfills in the United States has dropped since the late 1980s from nearly 8,000 to under 2,000 as landfills have filled up and closed in recent years. And as the costs of disposing of our garbage have risen, new efforts have been launched to try to reduce the volume of waste and, especially, to recycle and reclaim reusable materials such as aluminum, paper, organic matter, and a few kinds of plastic, including PET.

As criticism of bottled water has grown, we hear over and over from the bottled water industry that plastic PET bottles are fully recyclable. “The bottles our member companies produce are 100% recyclable,” blared a full-page ad taken out by the International Bottled Water Association in the New York Times and the San Francisco Chronicle in August 2007. “Our water bottles—as well as all of our product containers like aluminum cans and glass bottles—are 100 percent recyclable,” said Craig Stevens, spokesman for the American Beverage Association.6 “Our Eco-Shape bottle is 100% recyclable,” touts Nestlé on their Ozarka, Poland Springs, Deer Park, and Arrowhead websites.

Ah. Not to quibble, but “recyclable” is not the same as “recycled.” Water bottles are almost all recyclable, and yet most of them are never recycled. In 2007 the National Association for PET Container Resources (or NAPCOR) reported that over 5.6 billion pounds of PET bottles and jars were available for recycling, but only 1.4 billion pounds of PET were actually recycled—an overall recycling rate of under 25 percent. This is higher than recent years, but well below the rates of plastic recycling in the mid-1990s, when as many as 40 percent of PET bottles were recycled.7 According to the nonprofit Container Recycling Institute, recycling rates for PET water bottles are even lower than for other PET containers. The United States actually recycles far fewer plastic water bottles, and less plastic overall, than just about anything else in the waste stream we generate.

So what if I want to recycle my PET water bottle? Like a growing number of households, I have a number of options: I can return it to a nearby recycling center at a grocery store; I can take it to Berkeley’s central recycling plant; or my son can do his chores and put it out on our curb in a separate blue bin late on Wednesday night with our other recycling materials. Thursday morning, that plastic bottle, along with the rest of my recycling, is picked up by a truck operated by Berkeley’s nonprofit recycling program—the Ecology Center. The Ecology Center has a contract with the city to collect and recycle all paper, cardboard, aluminum, glass, and two kinds of plastic bottles, PET and HDPE (the ones with the number 1 and number 2 plastics logos on them). All the paper goes into one container on the Ecology Center trucks and all the other materials go into another, to be sorted at the recycling center. Some recycling programs will accept all plastics, which greatly increases the volume of plastic that is collected but reduces the value, since the recycler can often get more money for clean streams of PET or HDPE than for streams of mixed plastics. In particular, recyclers have nicknamed polyvinyl chloride (number 3) “Satan’s Resin” because of its toxic properties and completely unrecyclable nature, and they try hard to avoid having it contaminate recyclable materials.

In early 2009 I went down to the Ecology Center facility in Berkeley to see where my plastic goes. The day I visited the Center, they were paying individuals a healthy 96 cents a pound for PET bottles and 54 cents a pound for HDPE bottles, which helps explains why all the high-quality plastics are often scavenged from my curbside recycled bins in the middle of the night before the Center’s trucks can collect them. All together the Center collects around 8,000 tons of recycling a year from over 35,000 households and thousands of businesses, around one-fifth of which consists of drink containers.

The recycling system in place in Berkeley is relatively simple, using real people and straightforward technology to sort the recycling into a few basic categories. “Separation is key,” Andrew Schneider, Berkeley’s recycling specialist, told me. “Berkeley has a reputation for producing clean streams,” which are vital for getting good contracts with material resellers who don’t want to buy mixed or contaminated materials. In Berkeley, a magnet pulls out tin-plated steel cans and other iron-based materials. Aluminum cans are grabbed by hand and tossed down another chute. Plastics are separated into three streams: PET, HDPE, and other plastics. Glass is sorted by color into brown, green, and clear streams.

The separated PET is crushed, perforated, baled into cubes roughly a meter on a side, and loaded into a shipping container. Berkeley has a contract with a few plastic exporters or domestic reprocessors, and every day or so a container full of PET bales gets placed on a truck and shipped to a plastic exporter, who in turn sends it to be recycled where it is either cleaned, chopped, or shredded into little “flakes” and turned back into new feedstock for PET, or crushed, shredded, and made into a wide range of polyester products, including carpet, clothing, automotive parts, strapping material, and plastic toys. In all, Berkeley sends around six tons of PET a week to plastics recyclers—much of it used water bottles.

Berkeley’s recycling system is called “single stream,” since residents don’t have to separate out glass, plastic, and aluminum into different containers. Some cities require that the homeowner or business carefully sort materials before they are picked up, but this requires trucks with five, or six, or even seven separate containers, and even then, the central facility has to have a way to deal with blended materials from lazy recyclers. In some cities, the separation of recyclable materials from garbage is increasingly being done by machines in a “materials recovery facility” or MRF (“merf”). The technology for MRFs is rapidly improving and sophisticated systems can do more sophisticated sorting. New machines that automatically sort PET from other plastics dramatically increase plastic recovery rates while reducing labor costs. Smart MRFs, for example, can even differentiate among different colors of PET, HDPE milk jugs and water containers, mixed colored HDPE containers, such as detergent containers, or shampoo bottles, and they can separate out plastics numbers 3 through 7 to be sold separately or as a mix.

There are dozens of businesses that buy recycled plastic and repackage it for sale to domestic recyclers or for export. Of all PET collected for recycling in the United States, half went to the fourteen reclamation plants operated in the U.S. by domestic recyclers. The other half is exported. Demand is especially intense in China. In an example of the bizarre economics that define the modern world, most of our recycled bottles end up in giant bundles stuffed onto container ships heading for Asia. The Chinese find it cheaper to buy our plastic garbage, ship it across the entire Pacific Ocean, and use it to make stuff to ship back here, than to make virgin PET from petroleum. And they can’t get enough of our plastic garbage. At times, Chinese recyclers have found themselves in bidding wars in the ports of Long Beach and Oakland, California, competing for bundles of plastic garbage coming from all over the country.

The economics of recycling are complicated and variable, affected by oil and energy prices, demand for materials, and even the overall state of the economy, as well as whether a state has a bottle bill that supports recycling programs. A high price for oil raises transportation costs and makes it more expensive to ship recycled materials over seas, yet it also raises the cost of virgin PET, making recycled materials more attractive. Some countries require that PET bottles contain at least some recycled materials in order to encourage markets for recycled plastic, while other countries ban the use of recycled materials for food containers because of fear of contamination. At times recyclers, who are often required by law to collect plastics, have actually had to pay exporters to take mixed bags of plastic when the market for recycling weakened, as happened in the economic collapse in late 2008. The once red-hot global demand for recycled plastic plunged and containers of plastic scrap began piling up at Chinese ports as importers failed to claim the goods. Demand for plastic resin also plummeted as demand for toys and clothes made from PET dried up.

Right now, we can’t recycle all of our PET water bottles. Traditional recycling programs were not designed with plastics in mind, but were focused instead on getting consumers to bring back empty containers made from aluminum and glass. The very first bottle bill was passed in Oregon in 1971 with the simple idea that you pay a nickel deposit on a glass or aluminum container when you buy it and you get your nickel back when you return it. The idea of putting a price on garbage was radical, and yet it was an undisputed success. The year after it was implemented, recycling rates for glass and aluminum in Oregon went from 25 percent to more than 90 percent. In states with bottle bills, recycling rates range from 65 to 95 percent, substantially higher than in the states without deposit laws. Yet despite this record, the powerful beverage industry and grocery lobbies have successfully fought the expansion of bottle bill laws. Only eleven of the fifty states have bottle bills: California, Connecticut, Delaware, Hawaii, Maine, Massachusetts, Michigan, New York, Iowa, Oregon, and Vermont.

Moreover, none of the existing bottle bills include adjustments for inflation, and a nickel in 1971 is worth about a penny today. As a result, recycling rates are falling, even in states with bottle bills. And how many of us actually get our nickel back? We typically pay the deposit when we buy the container, but if we throw it away or put it out at the curb for recycling, the beverage industry often gets to keep the money—hundreds of millions of dollars a year. Even worse, almost no bottle bills include deposits for bottled water, which barely existed when the first bills were passed in 1971, and recent efforts to close this loophole and expand the definitions in existing laws to include bottled water have been regularly defeated. In 2009, years of effort by New York State to make its bottle bill apply to water bottles finally succeeded, making it only the sixth state to include a deposit on water bottles. As a result, U. S. water bottle recycling rates are far below those of other beverage cans and bottles.

Some countries do much better. Comprehensive container deposit regulations are in place in countries like Australia, Canada, Denmark, Germany, Norway, and Sweden. In some of these countries, plastic bottle recycling rates can approach 90 percent. In Switzerland, there are bottle bins at every supermarket with separate slots for clear, green, and brown glass and for plastic bottles. As a result, 80 percent of plastic PET bottles are recycled there, far higher than the overall European average of 40 percent.8 Some countries are implementing “take-back” programs that require companies to either reduce waste volumes or accept packaging waste from their products for recycling or disposal. In June 2003 the Pollution Control Board of West Bengal, India, told bottle producers that they were now responsible for collecting and recycling used bottles.9

Another way to boost recycling rates is to require that plastic bottles contain more recycled content. Existing markets are capable of using far more recycled PET if regulators require it or manufacturers voluntary commit to using recycled PET. Small actions can have big effects. In 2004 the use of recycled PET in non-food containers tripled in the United States, solely as a result of California enforcing a law (the “Rigid Plastics Packaging Container Law”) that requires the use of 25 percent post-consumer resin content in non-food packaging products.10

The major water bottlers could, in theory, use recycled PET to make all their bottles. They’ve made noises about this over the years: In 1990 both Coca-Cola and Pepsi Co made voluntary commitments to use up to 25 percent recycled PET in their beverage bottles, but quickly abandoned those commitments. In 2000 Coca-Cola announced their intention to reach a target of 10 percent recycled PET use in beverage containers and Pepsi Co followed suit in 2002. Both companies claim to have temporarily reached that target by 2005, before again backing off their efforts. In 2008 Coca-Cola again announced their intention, this time by 2010, to boost the recycled PET content of their bottles to 10 percent. To help meet their goals, in 2009 Coca-Cola opened the world’s largest plastic “bottle-to-bottle” recycling plant in Spartanburg, South Carolina. This plant will eventually be capable of producing around 100 million pounds of recycled PET plastic for use in new bottles each year,11 though the company continues to oppose new state container deposit bills (or “Forced Deposit Bills,” as the company characterizes them).12 In Great Britain in 2007, two beverage makers, Innocent Drinks and Ribena, both announced their intention to use 100 percent recycled PET for their drink containers.13 Until these efforts lead to higher recycling rates, the number of PET water bottles that end up in our landfills is likely to remain high.

If it is hard to boost recycling rates, perhaps the amount of plastic used to produce each bottle can be reduced. This is the main approach taken by the bottled water industry in its efforts to counter criticism of the high environmental and energy costs of producing PET. The concept is called “lightweighting” by the packaging industry (in a particularly striking example of verbifying a noun or adjective). Lightweighting reduces the cost of production, the energy required for shipping, and the mass of plastic in landfills. Beverage manufacturers have achieved some remarkable success with this in other areas: the food industry has reduced the weight of aluminum cans by 26 percent between 1975 and 2005. Steel cans now weigh 40 percent of what they did in 1970. Glass containers are half the weight they were in 1990.14

The same trend is underway in the plastics industry. The weight of PET bottles has fallen by 25 percent since 1977, and new efforts are underway to make them even lighter. In the course of work I’ve done evaluating the energy implications of plastics production, I surveyed the weight of PET water bottles. The average weight of 45 different bottles was 44 grams per liter of volume. But nearly a dozen newer bottles now weigh less than 25 grams per liter. Nestlé’s is particularly proud of their efforts in this area. In 2007 they introduced the “Eco-shape®” half-liter bottle weighing 12.5 grams, and the French packaging company Sidel has developed a half-liter “NoBottle™” that weighs in at 9.9 grams. While the trend toward light-weighting will continue, there are structural limits to how light and thin a PET water bottle can be made. In the end lightweighting does nothing to increase recycling rates or reduce the actual volume and numbers of bottles ending up in landfills.

In addition to recycling and lightweighting, the volume of plastics going to landfills can be reduced through incineration. More countries and municipalities are burning solid wastes that cannot be, or haven’t been, recycled or composted. Incinerators can reduce municipal solid waste volumes substantially—by as much as 70 to 90 percent according to some estimates—while simultaneously generating electricity and heat. Modern incinerators can produce energy with very low emissions of pollutants, unlike early waste incinerators that spewed all sorts of nasty things into the air over nearby populations. In 2007 the United States had 87 waste-to-energy plants capable of producing 2,700 megawatts of power and handling about 13 percent of our trash. The Japanese have also moved strongly in this area, actually reducing efforts to recycle plastics because they find that they get far more energy burning the plastic than would be saved by recycling it. A trade-off of this approach, however, is that burning plastic creates carbon dioxide—the principal gas responsible for global warming—and other air pollutants, converting a solid waste problem into an air pollution problem.

Then why not create “green,” environmentally friendly bottles made of a biodegradable material as a way of reducing the problem of billions of plastic bottles that will last forever in our landfills? Part of the challenge is producing a food-grade container with all of the strengths and advantages of PET without the liabilities. A few possible materials have been tried, and entrepreneurial bottlers are beginning to sell bottled water in them, though with little success. One such alternative to PET is polylactic acid (PLA), or polylactide. PLA can be made from almost any starchy vegetable, including potatoes, beets, and corn. The largest producer of PLA is NatureWorks, a joint venture between giant corn producer Cargill and Teijin Ltd. of China. Cargill’s NatureWorks unit then sells PLA to a variety of food packagers, including Walmart, Wild Oats Markets, Del Monte, and Newman’s Own.

Unfortunately, PLA has some serious liabilities of its own. First of all, the stuff is not really very biodegradable. Cargill claims that PLA will degrade rapidly in certain environments into carbon dioxide, water, and organic material. Those conditions, however, are high heat, high moisture, and the presence of certain micro-organisms—conditions not commonly found in landfills. NatureWorks has acknowledged that PLA dumped in a landfill will probably last as long as a PET bottle.15 No advantage there.

Even worse, recyclers are afraid that the presence of PLA bottles in PET recycling streams will contaminate them. Separating PLA from PET is hard to do. While pure PET has a relatively high value, recyclers consider it contaminated—and the market value drops considerably—if more than around 1 percent of the bottles are not PET. This can worsen the already marginal economics of recycling centers, where PET often makes up an important part of the revenue stream. Other questions about PLA arise. How should it be labeled? Should PLA be made from corn or is corn too valuable as a food product—a worry made even more serious by the recent push for corn-based ethanol and growing global food shortages.

Because of these problems, a coalition of recycling organizations and local recyclers asked NatureWorks in October 2006 for a moratorium on any expansion of using PLA for bottles until the bio-resin’s recyclability has been demonstrated. The members of the coalition include a mix of recycling and community waste-management groups, such as the Plastic Redesign Project, Eco-Cycle, Eureka Recycling, the Ecology Center in California, the Institute for Local Self-Reliance, the Center for a Competitive Waste Industry, and the GrassRoots Recycling Network. Eric Lombardi, president of the Grassroots Recycling Network, said that if NatureWorks doesn’t cooperate, “We will educate the public to avoid products bottled in PLA.”16

Despite the opposition to PLA, NatureWorks is continuing its aggressive expansion efforts. A growing number of water bottlers have adopted PLA for packaging water. In 2006 a company called Biota offered what they claimed was “the World’s First bottled water/beverage packaged in a Planet Friendly bottle,” and they continue to sell water in PLA bottles. In 2008 Primo Water Corporation of Winston-Salem, North Carolina, started offering water in 16.9-ounce bottles made from NatureWork’s PLA.17 The industry has also launched a conference to push the use of PLA in bottles. The first one, held in Hamburg, Germany, in September 2007, drew 100 industry participants from 25 countries and led to a major “world congress” on PLA in the fall of 2008 in Munich.18

There are other alternatives to PET under development. In May 2009 Coca-Cola announced that they were going to test a new “PlantBottle™” that is a mix of plastic, sugar cane, and molasses, calling it more “environmentally friendly.” Beginning in late 2009 they will test the bottle with Dasani bottled water and some of their carbonated brands. This material appears to be PET, but with some of the petroleum-based components of PET replaced with more natural biomass materials. This composition can still be recycled using traditional PET recycling methods without contaminating the waste stream, but it may not degrade any faster in our landfills.

In the meantime, while we invest enormous sums of money in new materials for bottled water, our investment in convenient public water is going to waste. Most public fountains in London and Paris and our other cities and towns are gone or disconnected. New public buildings, like the University of Central Florida’s new stadium, are increasingly built without them. And existing fountains are not adequately cleaned or maintained. A survey of university campuses in Canada reveals the extent of this trend. A third of survey respondents noticed a drop in the number of water fountains on campus, while nearly half said they noticed delays in repairing broken fountains. One respondent from Brock University in Ontario, Canada, said, “In new buildings on campus, there are no water fountains, only Pepsi machines, and the water fountains that do exist are sparse and in inaccessible places.” At Carleton University in Ottawa, the Physical Plant department issued a directive saying that fountains that could not easily be repaired would not be replaced.19 In June 2008, the associate vice president of land and building services at the University of British Columbia was quoted as saying that because drinking water fountains are not required under B.C. building codes there is no obligation to install them.20 A similar national poll of a thousand Australians found the same problem. Nine out of ten people said they didn’t know where to find a local water fountain (which Australians call “bubblers”). Eighty-five percent said they worried about the cleanliness and safety of drinking from fountains. And 80 percent said there weren’t enough fountains in their city. “As far as the public are concerned, public water bubblers have disappeared off the map,” said Jon Dee, an organizer of the Bottled Water Alliance, which commissioned the poll. “The lack of uniform signage for bubblers and the concerns that people have about the upkeep and quality of public bubblers are significant—they’re two of the reasons why Australians are spending half a billion dollars on bottled water every year.”21

In August 2005 Andrew Ferguson wrote a scathing report on the state of the Washington, D.C., mall. Among other things, he noted the complete lack of water: “If you want a vision of hell, look here: the national mall in Washington, D.C., at noon on a summer’s day…hey, where are the water fountains?”22 In New York’s Central Park, even today, there are still 150 drinking fountains, but many no longer function, or they are dirty and ignored. The Park’s public watchdog group regularly gives the fountains a failing grade, describing them as “plagued by maintenance, safety, and structural challenges. Even when drinking fountains provide water with sufficient pressure, users frequently find trash, mold, and severe leaks.”23 In schools around the country, water fountains are scorned or turned off because of fears of contamination. Instead, children arrive at school with expensive single-serve plastic “Aquapods” tucked in their lunches and backpacks—little throwaway water bottles marketed by Nestlé to parents as a convenient and healthy alternative to the soda and juice containers that have also replaced milk cartons in our children’s school lunches. Or students buy bottled water from the vending machines aggressively promoted to school districts by beverage companies.

We’ve become more reluctant to drink from public water fountains, and the convenient availability of bottled water has further reduced public demands for fountains. Who hasn’t seen trucks driving around our streets delivering bottled water to homes or schools or businesses, or hand carts stacked high with bottled water being delivered to outlets in our airports, malls, or convenience stores? If any movement away from bottled water is going to succeed, there must be good, safe, and conveniently available alternatives.

The irony is that the more bottled water we buy, the more invested in it we become and the more susceptible we become to industry efforts to convince consumers that bottled water is not a luxury, but a necessity. Part of that effort is their campaign to vilify tap water, but another part is their use of the classic tools of advertising and marketing to make bottled water attractive—tools that have proven so successful in our commercial, product-driven society. If you’re peddling something that looks, tastes, and smells the same as your competitors, you have to find other ways to make your product stand out and to convince consumers to spend their money on what you’re selling.