How to sharpen and use this basic turning tool

Perhaps woodturners should sell naming rights. The field has never standardized the names of its tools (or measurements of their widths or how to describe their angles), so they’re often called different things. One tool stands out in this regard: Whether it’s called a detail gouge, spindle gouge, shallow-fluted gouge, fingernail gouge, contour gouge, forming gouge, long-and-strong gouge or just plain “gouge,” no other woodturning tool has as many names.

To avoid confusion in my classes, I call this essential tool a “detail/spindle gouge,” because those are its two most commonly used names. A detail gouge is said by some to be thicker under the flute than a spindle gouge, but essentially they’re the same tool.

This little gouge is used primarily for long-grain turning—when the stock is mounted so the grain runs parallel to the lathe’s bed. For this application, it’s hands-down the best choice for cutting coves (concave shapes). It’s also excellent for rolling beads (convex shapes) and shaping ogee curves, which combine concave and convex cuts.

The features that make a detail/spindle gouge perfect for these cuts, however, also make it a poor choice for roughing, shaping cylinders or making other straight-line cuts, such as tapers. In essence, this little gouge is great for cutting details in all types of turning—even on a face-grain bowl (when the blank is mounted with its face grain against the lathe’s faceplate). For this application, it’s a fine choice for working the bowl’s rims and the underside of its base—especially its feet.

A shallow flute distinguishes a detail/spindle gouge from bowl and spindle-roughing gouges, the other two types of gouges that woodturners commonly use.

Reshape the factory edge. An elliptical profile increases the cutting surface and allows cutting on both sides, which is much better for creating details with concave and convex shapes.

Grind the edge to an elliptical shape by swinging the gouge through an arc. Set the tool rest set at 90°.

Form the bevel and sharpen the elliptical edge one side at a time, using a push-and-twist motion. Rotate the gouge to follow the edge as you move it up the wheel; reverse the action as you move it back down.

Forming the bevel and sharpening an edge with a grinding jig is easy because it automatically sets the angle and makes a wide sweeping motion that follows the elliptical shape.

The detail/spindle gouge is distinctively different than the other two types of gouges that turners typically use, because it has a shallow flute (Photo 1). Although the flute’s radius and the metal’s thickness below it can vary, the overall design of this gouge remains shallow when compared to the other two types. Detail/spindle gouges typically range from 1⁄4" to 1" in width. For the scale in which I most commonly work, I prefer the 3⁄8" and 1⁄2" sizes see (Sources, page 22).

The bowl gouge is a heavy tool with a heavy round tang and a deep flute; it’s sometimes called a “deep-fluted gouge.” This gouge is the norm for turning bowls and vessels. It’s great for roughing out, shaping and finishing operations in such turnings.

The spindle-roughing gouge has a flat tang and a wide flute; it’s sometimes called a “half-circle gouge.” This gouge is used in long-grain turning to remove the corners from blanks and create cylinders, tapers and shallow concave and slightly domed convex shapes. It isn’t a detailing tool and it shouldn’t be used for turning bowls because its flat tang is weak and can break or bend.

In addition to a shallow flute, the other basic design element of the detail/spindle gouge is an elliptical cutting edge. As the tool’s factory edge is more likely to be straight, slightly domed or pointed like a spear, a new detail/spindle gouge typically requires reshaping (Photo 2).

An elliptical profile allows cutting with both sides of the tool, which is especially useful because it allows shaping coves and rolling beads in both directions. On each side of the ellipse, the more sharply-curved portion neatly cuts concave shapes, while the more broadly-curved portion easily cuts convex shapes. An elliptical profile also provides more cutting surface to work with and helps to reduce mishaps such as run-backs and dig-ins, because the edge trails away, rather than ending abruptly.

Sharpening consists of three separate operations: shaping, producing a sharp edge, and honing. Shaping includes two grinding actions: one to shape the elliptical edge (Photo 3) and another to create the bevel that supports the edge. If considerable material must be removed during these roughing operations, use a #46- or #60-grit wheel. Make sure there’s virtually no gap between the tool rest and the wheel and always wear eye protection and a dust mask when grinding.

How far back you grind the elliptical shape is a question of creating access for side-cutting operations. For the gouge shown here, bringing the sides back between 3⁄8" and 1⁄2" is usually more than adequate. For tight places, a longer, narrower ellipse might be better.

The bevel angle is usually between 25° and 35°. This is considerably lower than the bevel angles typically found on bowl gouges and spindle-roughing gouges—the edges on these tools require much more support. Producing a bevel with a sharp edge that follows the elliptical shape you’ve created is difficult. Most of these tools tend to be thick at the center, but very thin at the sides. This makes it easy to over-grind the sides and lose the shape. Creating a smooth bevel is another challenge. A bevel with multiple facets leaves an inconsistent edge that will be impossible to hone.

To form a sharp edge on almost any woodturning tool you usually have two choices: Do it freehand or use a grinding jig. To sharpen the edge freehand (Photo 4), slightly elevate the tool rest to make it comfortable to hold the tool at the bevel angle you choose. Visually divide the tool into three sections: the center, the left half and the right half, and plan to grind one side at a time. Begin by lightly resting the tool on the wheel (the home position). Then simultaneously push and turn the tool up and onto its side while holding it against the wheel at the same angle. Reverse the action to return to the home position. Then repeat the process on the other side. Repeat the process on both sides until the bevel is fully formed. Finish with one or two large sweeps that connect all three sections. When grinding a detail/spindle gouge, slow down and watch closely when the bevel is nearly complete. As soon as sparks start to consistently come over the top of the edge along its full length, it’s time to stop: The edge is sharp.

If sharpening freehand seems too daunting, use a grinding jig (Photo 5); (see Sources). Many are available and they all work well. With either method, be careful not to ruin the elliptical shape by over-grinding (Photo 6).

Avoid creating a spear-pointed edge, caused by overgrinding the sides of the tool’s elliptical edge. Also avoid a faceted bevel, caused by changing the angle as you rotate the tool.

Create a cove by cutting mirror-image concave profiles. First, cut a groove to establish the depth at the center. Then make a shallow knife cut at one edge (left), just deep enough to create a shoulder that supports the tool. Push in the gouge (center) while riding its bevel against the shoulder and gradually turning it face-up (right). Complete the shape by cutting a series of incrementally deeper and wider concave profiles on both sides of the groove.

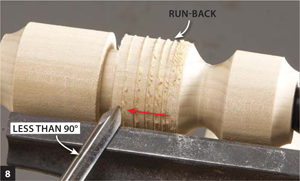

Avoid run-back. If you make the initial knife cut at less than 90°, the gouge will skate back. Instead, push the back end of the handle toward the cove until the gouge cuts in at more than 90°.

The process of refining and maintaining a sharp edge requires a flat hone for the outside bevel and a rounded hone to “slip” the inside edge. For modern high-speed steel tools, diamond or boron honing tools work best (see Sources). To hone the outside bevel, hold the gouge securely and move the hone up and down all along the cutting edge—concentrate on touching the back of the bevel to just below the edge.

To hone the inside, hold the curved hone flat in the flute and follow the edge all the way around, again with an up-and-down motion.

A detail/spindle gouge is most adept at cutting coves and other concave shapes (Photo 7). When cutting a cove, the goal is to cut a pair of mirror-image concave curves that meet in the center. This requires a sharp tool, good technique and close observation of the shape as it’s being formed—done by watching the horizon (the top edge of the blank) as you cut.

These tools work best when they can “move into air,” so practice cutting concave shapes on the ends of a cylinder or by working from both sides into a groove that you’ve cut with a parting tool. Always work from large to small diameters. Position the gouge at a right angle to the blank, with its flute facing the direction of the cut, and score the wood to create a small recess that will support the tool’s bevel. Then begin a light and slow twisting cut with the gouge, while keeping the bevel against the wood.

The greatest obstacle when cutting a cove is overcoming the tendency of the tool to skate across the wood (or “run back”) when you start the cut (Photo 8). The underlying cause is the tool’s sharp edge engaging the wood at the wrong angle, so there’s no support for the bevel. This immediately pushes the tool backwards across the surface.

Create a bead by cutting mirror-image convex profiles. Rest the gouge on the blank while holding its flute face-up (left). Lift and roll the handle so the gouge “rides the bevel” until its edge starts cutting (center). Continue the rolling action while gently advancing the gouge until it rolls completely onto its side (right). Refine the shape incrementally, by making shallow cuts on each side.

A flat “V” shape results, rather than a nicely rounded curve, if your advancing and rolling motions aren’t well coordinated.

Practice cutting coves (and beads) of different widths and depths to master the nuances of this extraordinary tool.

To create a bead, you cut a pair of mirror-image convex shapes (Photo 9). Here the challenge is to produce fully rounded surfaces with no flats. Begin with the flute upright, the bevel resting on the wood and the back of the handle held low. Gently lift the gouge until it begins to cut. Then, working from large to small diameters, turn the flute in the direction of the cut and gradually roll over the gouge as you continue to advance it. Aim to have the flute fully on its side at the bottom of the cut. A twisting motion that smoothly combines advancing and rolling is critical for good results (Photo 10).

Mastering this tool requires practice, so use a spindle roughing gouge to create a bunch of 1-3⁄4" dia. x 7" long cylinders made from softer woods such as poplar, pine or alder. Then practice cutting concave shapes that curve smoothly and continuously from top to bottom (Photo 11). You’ll probably find that it’s easier to cut smooth curves from one direction than the other. If so, devote an entire cylinder to cutting curves from the more difficult direction. As you practice, the initial knife cuts and turning/rolling moves will start to make sense.

It’s a good idea to practice cutting coves of different sizes. Lay out a series of coves that gradually get smaller, (or more shallow, or both) on one or more of the cylinders. Start with a 1-1⁄4" wide cove and reduce the width by 1⁄8" until you reach a cove that’s only 1⁄4" wide. Then strive to cut fully rounded, mirror-image concave shapes on every cove. You’ll discover the size and shape of the gouge determines how narrow a cove can become.

To practice cutting convex shapes, prepare 10" long practice cylinders and use a parting tool to lay out beads from 1-1⁄4" wide down to 1⁄4" wide. Then practice as for concave shapes. Parting down to different depths dramatically changes the look of the bead. Learning how to handle the gouge accordingly is part of the exercise.

SOURCES Packard Woodworks, packardwoodworks.com, 800-683-8876, Packard 3⁄8" Detail Gouge, #100108, $38.50; Packard 1⁄2" Detail Gouge, #100109, $44.95; Oneway Vari-Grind 2 Attachment, #142614-2, $74.95 (requires Oneway Wolverine Grinding System, #142611, $89.95); Sharp Fast Grinding System, #140909, $99.95; Credit Card Hone, #145105, $11.95; Honing Cone, #145110, $30.95. Alan Lacer, alanlacer.com, Diamond Slipstone, $88.