Create controlled curled shavings with a modified skew chisel

These trees come all the way from the Erzgebirge (’erts-ge-bir-ge). Actually, I made them in Wisconsin, but the unique curl-turning technique I used evolved in that mountainous region of eastern Germany, which borders on the Czech Republic. With an understanding of this technique and a bit of practice, you can have some real fun making trees in a variety of shapes and sizes as stand-alone decorations, parts of a scene or hanging ornaments. You can also make flowers.

What may look simple, however, is actually a bit tricky. Skills with a skew chisel—and a modified one at that, the right amount of pressure and depth of cut, the right feed rate and just the right wood are all factors in this style of turning. The key to success—being able to consistently turn attractive, lifelike trees—is practice.

Modify the short point of a skew chisel to create a hook, so you can roll shavings into curls. Round over all the sharp edges on the hook’s throat.

Use the modified skew to practice rolling shavings on a scrap block of green wood turned to a cylinder. Start by positioning the point of the hook at a low entry level.

Basswood is one of the most desirable woods for this method, due to its “stringy” quality. The best stock has straight grain (riven stock is preferred as a rule) and on the wet side—15 to 18 percent moisture content. Green basswood is an excellent choice. Pine, spruce and fir tend to give a coarser look than basswood, but are certainly worth experimenting with.

Plan to use 5" long blanks that are either 1-3⁄4" square or 1" square. If only air- or kiln-dried wood is available, soak the blanks in a bucket of water for a day or two, using rocks to keep them submerged.

The completed trees don’t require finishing, but they can be colored with spray paints or by dipping in water-based dye. Their exposed trunks and bases can then be hand-painted, for a more realistic appearance.

You’ll need to grind a hook on a 3⁄4" or 1" skew chisel to facilitate the process (Photo 1). While a “normal” skew will work to some extent, this modification definitely helps to roll the curls into position with more control and less breakage of the fibers. With a normal skew, even when leading with the short point in the wood, it’s far too easy to unintentionally cut off the curl.

Of course, this modification dedicates the tool to rolling curls, unless you want to grind away a lot of metal. So, plan to modify an inexpensive skew (or even a woodturning scraper) rather than your pride and joy (see Sources, page 173).

Starting at the bottom of the skew, grind the area behind and below the short point into a slight concave shape (the “hook”). Then soften all of the hook’s sharp edges. In German this type of turning is referred to as “sharp and soft turning,” because the hook’s sharp point and softened edges are both used to form and control the curl. So make sure that all of the hook’s edges are beveled back and the shape is as smooth and polished as you can make it. After grinding with the round stone, work the hook’s edges with a slipstone or round abrasive rod.

Sharpen the skew’s remaining edge in the normal fashion—angled approximately 70° from long point to short point, with the bevel’s width about 1-1⁄2 times the thickness of the steel. Be absolutely certain that the short point is razor-sharp.

Outfit your lathe with a scroll chuck with standard jaws for the 1-3⁄4" blanks or spigot jaws for the 1" blanks (see Sources). You’ll also need a few regular spindle turning tools: a roughing gouge, a 1⁄4" or 3⁄8" detail/spindle gouge, a 1⁄2" or larger “normal” skew and a parting tool.

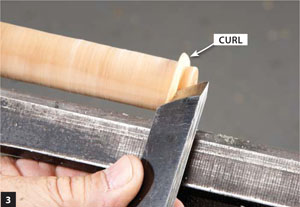

Make a planing cut using only the point, after hooking it into the wood. The hook’s curved throat helps to bend the shaving into a curl.

Practice extending the curl by continuing the cut for approximately 1". Experiment with shorter and deeper cuts as well as varying the angle of approach.

Pull another curl. The finished tree consists of multiple curls, so practice controlling the length of each curl while leaving even spacing in between.

Apply your newly learned skills to practice creating long curls on a tapered, cone-shaped blank. Now, you must work from smaller to larger diameter while drawing the tool toward you.

Start by practicing on 1" diameter round stock, held in the scroll chuck with small jaws. Understanding how to handle a skew chisel—and especially how to make the planing cut—will be essential for learning this process.

Hook the short point into the wood at a low entry level (Photo 2). Then make a planing cut to lightly raise or fluff up the wood into a curl (Photo 3). Experiment with the entry angle, depth of cut, feed rate and speed of the lathe. (I run the lathe between 1,500 and 2,000 rpm for this style of turning.) See how far you can roll the curl without breaking it or cutting it off (Photo 4). Roll some curls tight against the preceding ones; roll others leaving a gap of about 1⁄8" or so between curls (Photo 5). Periodically plane off the curls so you can roll new ones.

When you’re able to roll curls consistently, move on to the next step. Taper the blank down to a point at the tailstock end, using a roughing gouge or a regular skew chisel. Then, starting about 3" from the tapered point, roll a curl for approximately 1" (Photo 6).

During this exercise you’ll be doing the opposite of normal practice, which is to “follow the grain” by turning downhill, from a larger to a smaller diameter. In this case, you cut uphill, from a smaller to a larger diameter. Roll a second curl, stopping about 1⁄8" from the previous curl. Then roll additional progressively shorter curls until you have nothing but a small point.

Begin by making a small tree. Plan ahead for the overall height and the base section—either the curls will go all the way to the bottom, so the trunk doesn’t show, or the section below the bottom curl will be turned to form a trunk and base. Much of this will be a repeat of the practice sections, with tight curls that touch each other or looser curls that stand slightly apart. One subtle move is to vary how much you roll over the shape of an individual curl: more for the lower branches and steadily decreasing as you reach the top (Photo 7). As you approach the top of the tree you may need to re-turn the taper to maintain the desired shape (Photo 8).

If you’ve decided on an exposed trunk and base, turn it now, using a 1⁄4" or 3⁄8" detail/spindle gouge (Photo 9). Then use a regular or thin-kerf parting tool to cut the finished tree from the blank.

Create a series of evenly spaced curls to perfect your technique. Make each curl slightly shorter than the previous one to mimic a Christmas tree’s form and the shape of its branches.

Finish shaping the tree by using successively shorter curls to taper its top end to a point. This is tricky, because you have to leave enough material at the tip to create the last few curls.

Shape the trunk and create the base using the detail/spindle gouge. Then use a parting tool to separate the completed tree from the waste.

Turning dry wood creates a different look, because the curls roll under rather than flaring out. You can stack these tight curls right on top of each other or leave spaces between them.

Using dry stock creates an equally attractive but significantly different look because the curls lack the flared, open shape that you can achieve with wet stock (Photo 10). Generally speaking, dry stock produces tighter curls, so they must be shorter and more closely spaced.

SOURCES Oneway Manufacturing, oneway.ca, 800-565-7288, Talon Scroll Chuck with standard jaws, #2985, $232; Spigot Jaws, #3016, $40.95. Penn State Industries, pennstateind.com, 800-377-7297, Skew chisel, 1" wide, #LX020, $18.50.