CHAPTER 4

SCIENCE AND INDUSTRY

“Is it a fact,” Clifford Pyncheon asks in Nathaniel Hawthorne’s 1851 novel The House of the Seven Gables, “or have I dreamt it—that, by means of electricity, the world of matter has become a great nerve, vibrating thousands of miles in a breathless point of time?”1 Fully fourteen years after Samuel F. B. Morse patented his first system, the telegraph still felt sufficiently revolutionary to be portrayed as well-nigh magical. A little over half a century after Hawthorne, however, the Irish playwright George Bernard Shaw expressed quite a different point of view in two epigrams from his Man and Superman: “Those who admire modern civilization usually identify it with the steam engine and the electric telegraph” and “Those who understand the steam engine and the electric telegraph spend their lives in trying to replace them with something better.”2

By 1876, the truth of the situation was this: The telegraph had been the last great electric invention before the Gilded Age and in 1851 it still seemed like a miracle. But at the very beginning of the Gilded Age, in that centennial year of 1876, Alexander Graham Bell patented “something better.”

Patented in 1837 by Samuel F. B. Morse, the telegraph rapidly evolved into a civilization-altering communications technology. During the Civil War, it revolutionized both strategic and tactical communications between higher headquarters and front-line field stations. Pictured here is a Union telegraph station in Virginia in 1864.

In what way was Bell’s telephone “better” than the telegraph? After all, telegraphy enabled virtually instantaneous communication, potentially in real time. True, there were delays created by the time it took to manually transcribe the electrical signals (the “dots” and “dashes” of Morse code) into more universally readable alphabetic language and numerals, and there was the time consumed in delivering messages from the telegraph office to the addressee. But in certain applications, communication was not only in real time but interactive, even conversational. A military commander at the front of a battle, for instance, could communicate telegraphically with higher headquarters in a rear echelon to report on conditions, ask for instructions, request reinforcements, or respond to orders. Indeed, during the Civil War, telegraph wire was run along the rope that tethered manned observation balloons to the ground, thereby allowing observers aloft to report in real time on enemy movements or the effect of artillery fire, so that commanders on the ground could adjust their tactics, and artillerists adjust their aim. Within years of its invention, the telegraph expanded into a vast network that one writer on the history of technology dubbed the “Victorian Internet.”3 Writers of the mid-nineteenth century were captivated by the notion of communicating via electricity, a force or phenomenon steeped in mystery and perceived to be so ineffably ethereal as to utterly defy physical reality. To be sure, using electricity, telegraphy actually did defy time and space, and when the “Victorian Internet” was vastly expanded from continent to continent via the submarine transatlantic cable, beginning in 1858, the degree of this defiance was almost beyond imagination.

“Within years of its invention, the telegraph expanded into a vast network that one writer on the history of technology dubbed the ‘Victorian Internet.’”

Morse Code, which Samuel F. B. Morse began developing in 1837, the year of his telegraph patent, could be called history’s first piece of software. Without it, the hardware of telegraphy would have been utterly useless. This 1877 diagram illustrates the Morse apparatus and key.

Yet the telegraph had a major failing as a civilization-transforming technology. It offered an interface between machine and human that was greatly flawed and a poor substitute for face-to-face verbal communication. First, unless you were very wealthy or were a corporate or government entity, you could not afford to install a telegraph set in your home or place of business. You had to go to a designated telegraph office to send a message or you had to summon a messenger to pick up a handwritten message from you to deliver to that office. As for receiving a message, you generally had to wait for a telegraph messenger to deliver a transcribed hard copy to you. Second, telegraph technology required a great deal of human intervention in the form of professional telegraphers skilled at transmitting and receiving Morse code.

These two interface flaws imply a third, which is even more profound than the first two. Telegraphy was a system that required a lot of tending. Until the development of multiplexing, which allowed multiple two-way transmissions over a single line, messages had to be carefully scheduled for transmission, something that involved human judgment for prioritization and sorting of transmissions and replies. Telegraph lines were subject to interference over long distances. Transmissions were often garbled along the line. In addition, encoding analog messages into binary dots and dashes for transmission—and then, at the other end of the wire, decoding those binaries back into an analog message—required operators with considerable mental agility. Mistakes were frequently made. Because of the high incidence of errors, telegraphers continually weighed workload against speed against error checking to decide how much to retransmit to ensure a reasonable degree of accuracy. Under the best of conditions, operating telegraph equipment was demanding and fatiguing. This was exacerbated by error and retransmission.

In short, while telegraphic technology served humankind by coming close to eliminating the obstacles of time and distance, it also demanded hard labor from human beings. Yes, the machine performed useful work, but that work also required skilled personnel to devote their time, attention, and training to serving the machine. Indeed, such service was also demanded from customers. Telegrams were not cheap. Charges were assessed by the word, with an allowed maximum of fifteen characters per word for a “plain-language” telegram and ten per word for telegrams written in code. Customers were therefore compelled to adapt their style of expression to the demands of the whole electromechanical system.

So the telephone definitely offered “something better.”

While the telegraph generated dots and dashes—mere electromechanical noise—the telephone carried nothing less amazing and expressive than the human voice. Why is this difference important? Unlike the fairly labor-intensive telegraph, the telephone put technology almost entirely at the service of human beings. Instead of people serving a machine, it was a machine serving people. Interpreting the human voice requires no special training, talent, or skill. You don’t even need to know how to read. Moreover, because no operator was required at the receiving end—no need for someone schooled and skilled in translating binary signals into analog language—the telephone was a technology easily adapted to any office, any home, any room, any place.

“Instead of people serving a machine, it was a machine serving people.”

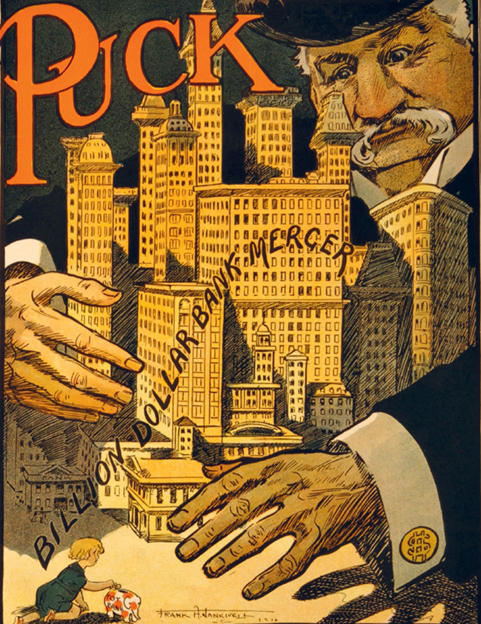

Human operators seated at telephone switchboards were originally required to make all call-to-call connections. The profession became an iconic and much-respected source of employment for women, mostly young and unmarried. Here, a Bell office in Hamburg, New York, c. 1905.

Think ahead for a moment, to August 12, 1981, when IBM released its model 5150 desktop computer. This was the machine they called the PC, the personal computer. Not long before, all computers were huge machines housed in dedicated, specially air-conditioned rooms that were staffed by technicians even more highly trained than telegraphers back in the nineteenth century. On August 12, 1981, however, computers became “personal,” in that anyone with an office desk or a kitchen table and an electrical outlet could own and operate one. What the IBM PC did for computing, Bell had done for telecommunications 105 years earlier. His master telephone patent no. 174465 (March 7, 1876)4 should be regarded as the first major, even iconic, invention of the Gilded Age because it made high technology accessible to ordinary people, and putting machines at the service of people would be the direction of science and industry in this era—provided that, by “people,” you meant customers, or consumers. To mass-produce these new machines as consumer products required workers who, in return for a paycheck, meekly subordinated themselves to an array of automated machines, the most consequential of which was the assembly line. This was one of the paradoxes of the Gilded Age. It was the first great era of American consumerism. It opened a vast consumer culture, an age in which marvelous machines served anyone who could afford to buy them. At the same time, consumerism created a tremendous demand for unskilled, low-paid labor to tend, in the capacity of wage slaves, the machines that produced the machines.

ALEXANDER GRAHAM BELL’S “HISTORIC SHOUT”

Histories describe Alexander Graham Bell as an inventor, scientist, and engineer. Both by education and vocation, however, he was none of these. Born in Edinburgh, Scotland, in 1847, he was the son and grandson of pioneers in the field of elocution, with emphasis on working with what were then called “deaf-mutes,” people with severe hearing and speech impairment. Bell, whose mother was deaf, followed in the family profession, becoming an elocutionist and a teacher of the deaf and speech-impaired as well as a student of both the physiology of speech and of acoustical physics. While studying the physiology and acoustics of speech, he experimented with the use of tuning forks to convert sound into electrical signals. He pursued this work with the thought that the musical tones of tuning forks were similar to the vowel sounds of speech. He reasoned that if he could convert tones to electrical signals, he could convert vowel sounds as well. If he could produce vowel sounds electrically, why not consonants? And if both vowels and consonants could be produced electrically, they could be transmitted electrically.

While Bell experimented, he supported himself as an elocutionist and as a tutor to hearing- and speech-impaired clients in London, where his family had moved. When he was twenty-three, he moved from the UK to Canada, where he used a system of “visible speech” (developed by his father) to transcribe the previously unwritten language of the Mohawks. In 1871, he moved to Boston, Massachusetts, to introduce visible speech to instructors and students at the Boston School for Deaf Mutes. But Bell never abandoned his tuning-fork experiments, which he now struggled to transform into a practical invention he called the “harmonic telegraph.” The device was intended to allow the transmission of multiple telegraph messages over a single wire by tuning each message to a different pitch. While pursuing this work, he opened his own School of Vocal Physiology and Mechanics of Speech in Boston, which drew many deaf students, including the young Helen Keller.

Self-educated as a scientist and engineer, Alexander Graham Bell was by training and profession a teacher of elocution who specialized in helping the hearing-disabled communicate. Bell (the dark-bearded man in the center of the back row) poses with the students and teachers of the Scott Circle School for deaf children, Washington, DC, 1883.

In 1873, Bell was appointed professor of vocal physiology and elocution at Boston University, yet even as his academic and clinical stature rose, he became increasingly consumed by his experiments in the electrical transmission of sound and harmonic telegraphy. He gave up what had become a lucrative teaching career, retaining just two private students: a profoundly deaf boy who could not speak and Mabel Hubbard, a young deaf woman he would later marry and whose father, Gardiner Greene Hubbard, a lawyer and financier, would become one of the founders of the Bell Telephone Company. This was the pattern of Bell’s early career, which combined work with people in need, science, and invention.

Learning that Western Union was intensely interested in the development of a multiplexing telegraphy system capable of sending multiple messages over a single wire, Gardiner Hubbard and another backer, Thomas Sanders, agreed to finance Bell’s work and to fund the hiring of an assistant, Thomas A. Watson, who was a skilled electrical technician. Bell’s latest version of the harmonic telegraph used tuned reeds, one of which, on June 2, 1875, Watson accidentally plucked while working on the transmitter. Bell, stationed at the receiver in the next room, distinctly heard the reed’s overtones through the device. What flashed through his mind was that the electrical transmission of speech was neither more nor less than the electrical transmission of overtones. At the moment, he had a viable harmonic telegraph, which he now called an “acoustic telegraph,” and immediately filed a patent application. At the same time, he moved ahead on a patent for what he described as a “method of, and apparatus for, transmitting vocal or other sounds telegraphically.” This patent was issued on March 7, 1876, and three days later, he refined his device by using not a vibrating metal diaphragm to transmit speech, but a more sensitive liquid transmitter. “I then shouted into M [the mouthpiece] the following sentence,” Bell recorded in his notebook on March 10:

“Mr. Watson, come here—I want to see you.” To my delight he came and declared that he had heard and understood what I said.

I asked him to repeat the words. He answered, “You said ‘Mr. Watson—come here—I want to see you.’” We then changed places and I listened at S [the speaker] while Mr. Watson read a few passages from a book into the mouthpiece M. It was certainly the case that articulate sounds proceeded from S. The effect was loud but indistinct and muffled.5

Watson recalled the wording somewhat differently—“Mr. Watson come here I want you”6—and a fuller context for the first telephone message was reported in his 1934 New York Times obituary:

In an interview here several years ago Mr. Watson described how an accident, involving spilled acid, resulted in the first actual reception of a human voice over a wire on March 10, 1876.

Professor Bell and Mr. Watson had arranged wires leading from a room on the top floor of a Boston boarding house to a room on the floor below. The apparatus was arranged for transmission of the voice in one direction only.

A HISTORIC SHOUT.

Watson was waiting tensely in the room below, with the reception apparatus held against his ear. Suddenly he heard Dr. Bell shout excitedly:

“Mr. Watson! Come here; I want—!”

Struck with the realization that he had actually heard Professor Bell over the wire, Watson dashed jubilantly upstairs.

“I heard you! I heard you!” he gasped.

Then he noticed Professor Bell brushing frantically at his arms and clothing. He had accidentally spilled a bottle of acid upon himself. His summons over the wire, made with little hope it would be heard, was really one for assistance.

Mr. Watson said Professor Bell forgot about the acid when he learned his voice had been heard over the wire by his associate.7

Thus the first telephone transmission was a technological triumph but also a doubly human event. First, it was the result of an accident—nothing is more human than that. Second, it was a call for help—a 911 call before 911 was even a concept. The following year, with Hubbell’s backing, the Bell Telephone Company was founded and, within less than a decade, 150,000 subscribers owned Bell telephones. By 1900, there were some 600,000, a number that exploded to 2.2 million by 1905 and 5.8 million by 1910.8 (As of 2017, there are an estimated 5 billion mobile phone users across the globe.)9

Alexander Graham Bell was a man of intense humanity and curiosity, with an uncanny ability to see relations between the apparently diverse realms of sound—specifically, the human voice—and telegraphic transmission. The creation of the telephone was a work of individual genius, although other individuals had similar ideas. Between 1844 and 1876, at least five inventors—Innocenzo Manzetti (Italy, 1844), Charles Bourseul (France, 1854), Johann Philipp Reis (1861, Germany), Antonio Meucci (1871, Italian but working in the United States), and Elisha Gray (1876, United States)—built prototypes. The difference between them and Bell was that, while Bell was no businessman himself, he had the immediate backing of financiers who quickly created a corporation that was able to build the network infrastructure necessary to make the telephone “instrument” useful to people everywhere. In the Gilded Age, invention might be the work of an individual genius, but fully realizing an invention, disseminating it, selling it, and monetizing it, required big business and big industry.

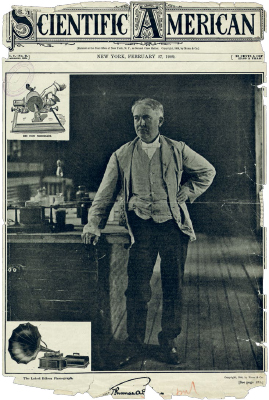

THOMAS EDISON INVENTS THE “INVENTION FACTORY”

The union of science and industry, of creative genius and commercial acumen, was, if anything, even more prolifically manifested in the next great Gilded Age inventor, Thomas Alva Edison. He received his first patent (0,090,646) in 1869, for an “Electrographic Vote-Recorder,” which enabled members of Congress to record votes by turning a “yes” or “no” switch. Edison promoted the device as a means of making congressional voting faster and more efficient—only to be informed by the congressional leaders to whom he demonstrated the device that the very last thing they wanted was to make voting faster and more efficient. The laborious roll-call method provided valuable time for twisting arms. Although his first invention worked, it failed to find a market, and Edison pledged to himself that, going forward, he would make sure people wanted a thing before he invented it. He thus instantly transitioned from inventor to inventor-entrepreneur. Within a very short time, he would evolve further into an inventor-marketer-industrialist. As such, over the next sixty-two years, he was awarded 1,093 US patents, the final one, US 1908839 A, for a “Holder for article to be electroplated,” filed on January 9, 1931,10 ten months before Edison died, at the age of eighty-four, on October 18, 1931. His record for patents held until 2015, when he was surpassed by American physicist Lowell Wood.

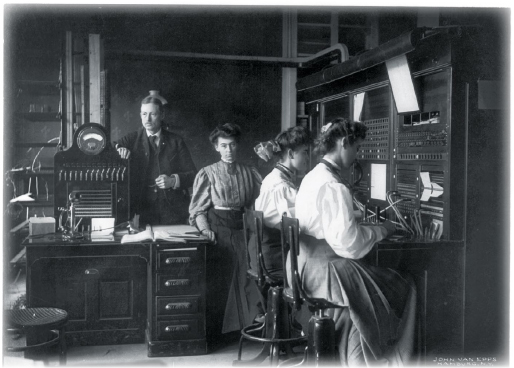

By the time Edison made the cover of Scientific American on February 27, 1909, his phonograph was enjoying spectacular commercial success.

Edison’s life story became part of Gilded Age mythology and remains a cornerstone of American popular culture. Born in 1847 in Milan, Ohio, he was six years old when he and his family moved to Port Huron, Michigan, a Midwestern hamlet just beginning to enjoy prosperity through commerce with the rest of the country via the new Grand Trunk Railway, which linked it to Detroit and the world beyond. Like young Alexander Graham Bell, Edison was an intensely curious youth. Unlike Bell, his curiosity often got him into trouble and even branded him as a delinquent. Bored in the classroom, he attended school sporadically and finally received most of his elementary education at home, from his doting mother. Although his maverick ways became part of the Edison pop culture mystique, his educational experience was something Edison shared with many American boys of the mid-nineteenth century. Most children typically attended only a few years of elementary school before going to work full time. Yet young Tom Edison did not settle for just any menial job that came his way. At age twelve, he went to work as a “news butcher,” a concessionaire on the Grand Trunk Railway, purveying newspapers, magazines, candy, sandwiches, and other merchandise to passengers between Port Huron and Detroit. While it is true that most news butchers of the era were youths, Edison did much more than sell copies of the Detroit Free Press. He wrote, edited, and printed his own paper, liberally larded with items of local interest. From an early age, he was clearly an energetic, innovative self-starter—but this attitude was more representative of America at the threshold of the Gilded Age than it was unusual. Edison’s paper was one of many self-published local newspapers that came into being across the country, not a few published by mere teenagers. Still, Edison did introduce a genuinely unique wrinkle by using a small proofing press to print the paper aboard the moving train. It is likely that he did this not merely to amuse himself, but to market printed news with a freshness approaching real-time reporting. The railroad, an industrial technology foundational to the Gilded Age, was all about speed. The teenage Edison innovated a consumer product—call it real-time news—perfectly suited to the speed of rail travel. Although Edison, as a mature inventor, would create many devices for business and industry, he is best remembered for his consumer inventions—the phonograph, improvements to the telephone, motion pictures as popular entertainment, electric light for the home. These all accelerated the transformation of American society into a consumer civilization.

Exceptional though young Tom Edison was, he nevertheless had much in common with others his age, including an interest in the nation’s burgeoning railroads and, something that went along with them—the telegraph. His job as a railroad news butcher brought him into contact with telegraphers along the Grand Trunk, and this led to his increasing interest in electricity and its application. In 1863, he himself started working as a telegrapher, joining a fraternity of what today would be called nerds or geeks. Most telegraphers were irrepressible technological tinkerers, who gladly devoted much of their free time to modifying and tweaking the equipment they used. Very quickly, Edison saw that telegraphy demanded more than mere tinkering. Given the growing demand for instantaneous communication nationwide, the industry needed full-scale innovation and invention. After four years as a “tramp telegrapher”—an itinerant operator who built a reputation not only for speed and accuracy, but for practical innovation, Edison found a Boston businessman willing to back him, and he set up shop in that city as a professional inventor. Although his first patent, for his electric vote recorder in 1868, was a commercial failure, it gave him confidence in his ability to invent and innovate. The very next year, 1869, he moved to New York City and became a manufacturer of telegraph equipment, working primarily as a subcontractor for Western Union and other companies. Two years later, in 1871, he branched out into what today would be called R&D—research and development—opening a combined factory and laboratory-workshop across the Hudson, in Newark, New Jersey.

A modern-day photograph of the heavy machine shop in Edison’s laboratory–workshop–manufacturing complex in West Orange, New Jersey (now a National Historic Park).

It was Edison, not Bell, who invented commercially successful multiplexing telegraphy systems, enabling the simultaneous transmission and reception of multiple messages over a single line. In 1876, Edison used profits from his quadruplex telegraph equipment, which effectively multiplied the capacity of existing telegraph lines by a factor of four, to build his most famous laboratory-workshop complex, in then-rural Menlo Park, New Jersey. Here he created nothing less than a technology village, the forerunner of the innovation campuses of modern-day Silicon Valley. He called Menlo Park an “invention factory,” and from it flowed, with remarkable regularity, one wonder of technology after another. The year 1877 saw the release of his first civilization-altering consumer product—the phonograph—and, two years later, came the even more epoch-making incandescent electric lighting system.

Edison’s most famous patent was for the “Electric-Lamp.” With this simple product, the inventor created a demand for electric power that, in turn, spawned a new public utility, myriad new electrical devices, and a whole new infrastructure for a new “high-tech” global civilization.

In 1879 the prolific inventor patented an incandescent electric lamp, the “light bulb.” The far greater significance of this invention, however, was its role as the fertile seed of an entire system of inventions. The success of the incandescent lamp instantly created a need for electric power, which spurred Edison to create an utterly new utility, a complete system for generating, distributing, and retailing electrical energy. This entirely new industry forever changed the course of civilization, and it is what made Thomas Edison the quintessential inventor of the Gilded Age.

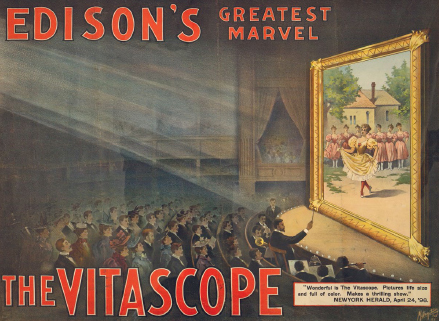

In 1887, Edison moved from Menlo Park to a larger laboratory-workshop-manufacturing complex in West Orange, New Jersey. Here, in 1888, he made extensive improvements to the phonograph, transforming it from a charming curiosity into a commercial product of enormous influence and profitability. In 1889, he formed Edison General Electric to turn his inventions into products and appliances of all kinds. The year before, he released the “kinetograph,” an early motion picture camera. It was not until 1894, however, that he paired the kinetograph with the kinetoscope, a motion picture viewer. Later that year, Edison opened the first commercial motion picture exhibition “parlor” in New York City. In a move prophetic of the computer age, having invented the hardware—phonograph and motion picture devices—he next founded a recording company and a movie production company to turn out the software for this hardware.

Not everything Edison invented turned to gold. He suffered numerous technical and commercial failures in his career, the costliest of which was a decade-long effort to develop a commercially viable process to electromagnetically separate high-grade iron from cheap, low-grade ore. Likewise, his efforts, early in the twentieth century, to develop a more reliable and practical storage battery to power electric vehicles was threatened by the sudden demise of electric car technology after Henry Ford, the last great innovator of the Gilded Age, successfully marketed his mass-produced Model T in 1908. The success of that vehicle ensured the triumph of the internal combustion automobile engine, fueled by gasoline. In typical Edison fashion, however, the inventor recovered from both disasters. He managed to convert much of his capital investment in the ore-separating enterprise—especially his heavy machinery—into an advanced plant for the manufacture of Portland (artificial) cement, and when his intended market for the storage battery disappeared, he innovated a host of new applications for the invention, ranging from powering electrical railway signals to providing lighting for houses and businesses isolated from electric lines.

Edison partnered with American inventor Thomas Armat on the latter’s electrically powered projector, launching it as the Vitascope to project Kinetoscope films. The Vitascope, touted here in a promotional poster from c. 1896, was initially featured in vaudeville theaters and, later, in specially built movie theaters.

HENRY FORD: DRIVING GILDED AGE INNOVATION

Although his world of invention made Edison quite literally a household name, the inventor was not made of the emotional stuff of the Gilded Age robber barons, and he never became wealthy on the scale of Carnegie or Rockefeller—or, for that matter, Henry Ford. Yet he and Ford became the closest of friends. Their families vacationed together, and the two men even bought neighboring winter homes in Fort Myers, Florida. Clearly, Edison bore Ford no grudge for having been the first of what would be a succession of automotive industrialists to “kill” the electric car. Besides, Edison’s storage battery technology eventually found its way into the gasoline-powered automobile in 1911, after inventor Charles F. Kettering was tasked by Henry M. Leland, the founder of Cadillac, to develop a practical electric starter system for automobiles; it replaced the temperamental and sometimes bone-breaking hand crank.

“Although his world of invention made Edison quite literally a household name, the inventor was not made of the emotional stuff of the Gilded Age robber barons.”

In some ways, Edison and Ford were quite similar in personality. They were both tinkerers with a genius for turning their tinkering into full-scale innovation and turning innovation into commercial success. They were both small-town Midwesterners with a connection to Michigan. Edison spent most of his formative years in Port Huron, and Ford was born and raised in rural Wayne County, not far from Detroit. They embodied what they thought of as the “simple” values of small-town middle America, and they shared a sincere belief in self-reliance and the potential of becoming anything you could dream of being—a belief that their own remarkable lives validated, a belief that became a driving mythos of the Gilded Age.

In other ways, the two men were very different. A childhood illness left Edison partially deaf, a disability that sometimes made him seem aloof and curt. Despite this, he enjoyed an excellent rapport with his staff of technicians, mechanics, and engineers. He encouraged them not only to come up with their own ideas and ways of solving problems, but to actually try them out. On every workbench in his laboratory/workshop, Edison distributed notebooks and pencils. He asked his “boys,” as he called them, to write down any ideas or observations that occurred to them as they worked. He wanted their ideas, their input, and he clearly relished the time he spent among his staff, going so far as to install a large pipe organ at one end of the main workroom at Menlo Park to provide musical entertainment. Edison believed that the labor of invention should be joyous. Indeed, Edison’s relations with his employees were marked by the same collegiality that characterized his attitude toward Henry Ford. For his part, Ford reciprocated collegial feelings to Edison—but never to his employees. It is true that Ford would, by 1914, pay his assembly line workers an unheard of $5-a-day wage, arguing that those who made Model Ts should earn enough to buy one. Yet everything about the Ford assembly line was inimical to Edison’s approach to labor. It subordinated men to machinery. Creativity was taken out of the work process because it only served to reduce productivity. Instead, each worker was trained to do a single repetitive task on a vehicle that moved past each worker on a system of conveyors and pulleys. It was up to each man to keep pace with the machine.

Fast friends, Henry Ford and Thomas Edison formed a two-man mutual admiration society. Here, c. 1930, Ford speaks directly into the ear of the inventor, who had been hearing-impaired since childhood, perhaps the result of illness, injury, or a combination of the two. Edison believed his “handicap” gave him a creative edge by minimizing distraction from his work.

In an era often marked by the oppression of the working class, Edison treated his employees with respect and kindness. He encouraged creativity, independent thought, and, not least of all, fun. Employees at his West Orange, New Jersey, plant are seen dancing on Lakeside Avenue in 1915.

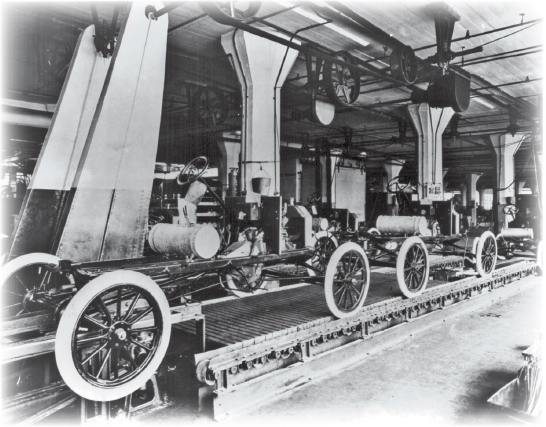

Introduced in 1913 in Ford’s plant, the moving assembly line was built to assemble Model Ts as quickly and as cheaply as possible. The first of these cars had gone into production earlier, in 1908, on a version of the assembly line that lacked the moving conveyor system. It was by no means the first automobile—the first production vehicle was built by Karl Benz, in Germany, in 1888—nor was it Ford’s first car. That would be the Quadricycle, an ethanol-powered engine on a frame fitted with four bicycle wheels, completed at two o’clock in the morning on June 4, 1896 in his Dearborn, Michigan, toolshed. But the Model T was very different from any of the earlier automobiles. Whereas these had been regarded as custom-crafted luxury items for the wealthy, the Model T would be cheap enough for most people of ordinary means to afford. To reduce costs, Ford designed in 1908 an assembly line along which specific workers built specific components and other workers fitted them to the vehicle. This rigorously standardized, numbingly repetitive system enabled Ford to get the per-car cost down to $950, far less than custom-built automobiles cost, but still beyond the reach of the average working family. Getting the assembly line to move past stationary workers made all the difference. In 1916, three years after the moving assembly line was introduced, the price of a Model T was down to $360. Ford had turned out 13,840 cars in 1909. In 1916, production rose to 585,388.11 By 1927, the last year the model was made, Ford had produced 14,689,520 Model T cars.12 It is a record that remained unbroken until the 15,007,034th Volkswagen® Beetle rolled off the line in 1972.13

Ford’s moving assembly line—shown here in 1913—was the brainchild of William “Pa” Klann, who was in charge of the Model T assembly plant at Highland Park, Michigan. Klann was inspired by the so-called “disassembly” line at a Chicago slaughterhouse, where carcasses were systematically butchered as they moved along a conveyor belt.

Where Edison’s consumer-focused inventions brought a kind of magic to the people—light, sound, and entertainment—and were perceived as the work of craftsmen-wizards, the Model T was an ambiguous symbol of Gilded Age industrial technology. On the one hand, it was a sturdy, reliable, generic product of the early perfection of mass production that fostered a consumer-driven society. It bestowed upon virtually all economic classes equal and unprecedented mobility, and it began the unification of the nation through a vast network of roads and transformed great swaths of rural America into suburbs of the nation’s cities. But it also took the relation of labor and management to a low of worker alienation. Indeed, it changed the very nature of labor.

“Where Edison’s consumer-focused inventions brought a kind of magic to the people and were perceived as the work of craftsmen-wizards, the Model T was an ambiguous symbol of Gilded Age industrial technology.”

None of this happened by accident. In 1911, Frederick Winslow Taylor published his Principles of Scientific Management, which codified everything that Gilded Age industrialists, culminating in Henry Ford, did or were doing to “rationalize” production processes. A foreman at Philadelphia’s Midvale Steel Company during the 1880s, Taylor had observed that, despite the growing mechanization of the plant, the rate of production was still largely dependent on the pace and methods set by the more skilled workers. From this observation, he reasoned that the “excessive idiosyncrasy” of craftspeople would always impede the rate of production. To maximize productivity, therefore, managers, not workers, had to assume control of the entire production process, prescribing methods and setting the pace. Moreover, they had to do this scientifically, basing their systems on meticulous observation and analysis of each manufacturing step—indeed, of every movement made by every worker. By collating these observations, managers could determine the best method for getting a job done, whatever that job was. This was a step—a necessary step in an increasingly mechanized world—toward making human workers as efficient as machines.

Taylor invented a new profession—management consultant—and his method, soon universally called Taylorism, created controversy, excitement, and despair in the American workplace. Without question, Taylorism increased productivity, ensuring that the United States would emerge from the Gilded Age into the twentieth century an industrial titan among nations. Capitalists even argued that Taylorism bettered the lot of unskilled labor. Anyone could be trained to do the repetitive tasks assembly-line work demanded, they pointed out, and thus more jobs were made available to the growing numbers of unskilled laborers immigrating into the country during the early twentieth century. Moreover, Taylorism prescribed a system of “scaled piecework rates” as an incentive for workers to move faster and achieve higher output—so while the pace might be difficult (literally inhuman, as a matter of fact), at least compensation was commensurate with production.

Or so it was claimed. In truth, while more productive workers were rewarded—and, conversely, less productive workers penalized—both tended to make less than they would have if their pay had been hourly. The net result was a dehumanization of the workplace, as workers were deprived of autonomy and were thereby alienated from motives of craftsmanship. Widening the already yawning gulf between labor and management, Taylorism, the final flower of Gilded Age industrial civilization, was instrumental in creating the productive but paradoxical character of twentieth-century American industrial life. On the one hand, it drove production costs as low as they could possibly be driven, thus making many more consumer products available to many more consumers. Arguably, this empowered the working class and promoted the growth of a substantial middle class, thereby increasing social equality and enhancing the American democracy. Yet the hidden cost—hidden because it could not be calculated in dollars and cents—was in the sacrifice of happiness, hope, and a fulfilling sense of purpose among legions of workers who spent eight, ten, or twelve hours, six out of seven days in every week, serving a tyrant made of gears, pulleys, and moving belts.

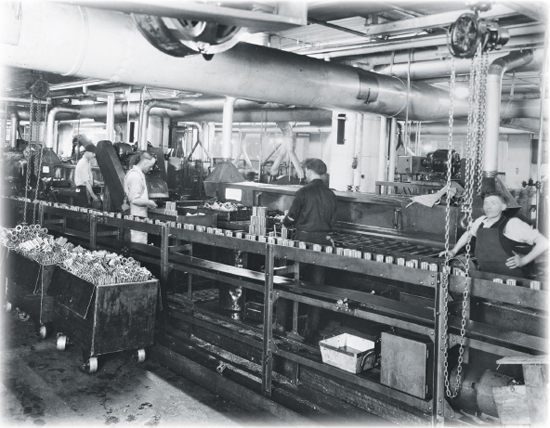

Workers prepare subassemblies for installation on a Ford Model T in 1924.