6

Implications

The adoption of 3D printing has not occurred as rapidly as its most enthusiastic supporters had predicted. Whether in consumer or industrial markets, barriers to uptake are slowing growth. Several factors appear to be at work:

- • The skills for design, production, marketing, and process integration into existing workflows are scarce.

- • In a time when supply chains are becoming more tightly coupled via shared information flows, new organizational arrangements including outsourcing, and regulatory mandates, plans to implement 3D printing are no longer only a firm-level decision: multiple parties may all need to buy in.

- • Other facets of advanced manufacturing, including the use of “big data,” carbon fiber and other composites, robotics, and the Internet of Things (networked sensors and actuators), might be delivering more perceived value and/or lower barriers to entry.

- • 3D printing is as much a craft as it is a science, and the necessary knowledge base regarding everything from laser shapes to powder granularity to build orientation is neither deep nor widely distributed.

All of these barriers will be overcome in time, especially in industrial use cases. As we have seen with hearing aids, mass markets will be addressed with little fanfare when the technology fits and delivers tangible benefits. As this happens in more and more scenarios, there will be many unintuitive consequences and implications. Let us examine some of them here.

Decentralization

The digital era has witnessed many instances in which a formerly complex, expensive, and centralized process was pushed out to the edge of a network. In music production, a garage can be a fully functioning recording studio with professional software available for laptop PCs and even tablets; CD pressing plants are also being closed. In news gathering, many networks have dispensed with staffers and stringers, relying more heavily on citizen smartphone video; a New York Times photographer won a Pulitzer Prize for iPhone photos.1 Regarding consumption of news, meanwhile, newspapers are struggling to adapt to digital economics as paper is generally read only by older demographics: the notion of a millennial having a Washington Post delivered to her doorstep is nearly impossible to contemplate.

In some forms of manufacturing, processes that are currently performed in capital-intensive factories, often thousands of miles away from end customers, will migrate to smaller facilities. The former logic of economies of scale will still apply in some cases, but in others, the increase in responsiveness, personalization, and/or inventory reduction will favor decentralized productive capacity. This decentralization already can be seen in book publishing: rather than my university library purchasing a paper volume from a journal, I print out the article I need on my desktop (if I in fact want paper at all).

Navy ships already print some parts on board. Dentists already print some fixtures and implants on site. Downloadable 3D files are already helping repair broken oven knobs in both restaurant and home kitchens. Hospitals could well print some medical implants rather than ordering them from a central warehouse. Auto manufacturers could install small polymer printers at dealers to save on inventory costs for thousands of small but important plastic parts; Mercedes was already 3D printing spare plastic parts for its trucks as of 2016. Porsche went a step further and is using additive techniques to recreate obsolete parts—with “absolute fidelity to the original specifications”—for its classic models.2 FedEx/Kinkos and Staples have experimented with 3D printers in their retail locations, and this trend is likely to continue.

What does decentralization bring with it? Monitoring the production of sensitive items, such as firearms, becomes much more difficult when there are thousands of potential gunsmiths rather than dozens. Without central “choke points” that can be monitored and audited, authorities turn instead to watching strategic inputs: Sudafed (a key ingredient in meth labs) and certain agricultural fertilizers used in amateur explosives are no longer readily available in the United States. It is likely that some metal powders, replacement lasers, or alloy ingredients for doping could become harder to obtain when abuses are discovered.

At the same time, putting more productive capability closer to end users, without layers of intermediaries, can result in accelerated innovation. The smartphone app industry is a case in point: when enterprise software took huge teams years to write in the 1960s and 1970s, there were no social applications, no mass-market computer games, and no integration with GPS (as in Waze) or photography (as in Snapchat). Makers are likely to make things that large organizations never attempted or conceived of.

Decentralization can have the effect of decreasing the market power of centralized resources. A look at the fate of most newspaper, minicomputer, and photography companies illustrates the point vividly. Which manufacturing companies might be at risk of having their value replicated, albeit at lower but still acceptable quality, by smaller, more nimble players at the edge of the network? New organizational forms are likely to emerge, for somewhat complicated reasons.

When electric motors were invented in the late nineteenth century, textile mills and other factories used equipment driven by central overhead line shafts connected to individual machines by pulleys. The line shafts in turn were driven by steam or water power. This technology had the effect of orienting looms and other machines by their proximity to the power source. It took roughly thirty years for managers to discover that individual electric motors allowed machines to be arranged to support workflow, materials flows, or other considerations: early electric motors drove groups of machines, merely duplicating water power. In contrast, the new layouts had many benefits: productivity improved with more logical material handling and process design, overall power consumption declined because individual machines could be turned on or off without regard to others located nearby, and workplace lighting and safety improved. Without the drive belts all running to the ceiling, room was created for electric overhead cranes. The factory of 1930 bore little resemblance to a facility from just fifty years prior.3

Putting more productive capability closer to end users, without layers of intermediaries, can result in accelerated innovation.

In many industrial settings, additive manufacturing occupies a similar position to that of early electrification. Initially, 3D printing is considered as a replacement for casting or injection molding, and often found wanting for lack of economies of scale. In more advanced companies, engineers are consolidating many smaller components into additive builds, a significant improvement. Production planning and project management are simplified by having far fewer dependencies, overall weight is often reduced, and the strength of the single, lighter build is typically higher. Tolerances are tighter, scrap rates are frequently reduced, and overall costs drop as a result of better fit and improved output.4

But what needs to happen next is for complex products to be designed for additive manufacturing from the outset, not having 3D printing applied to a conventional design after the fact. This state of native rethinking of design is more likely to come in a small, nimble company without deeply established processes and mindsets: the Robot Bike example in chapter 4 provides a case in point. While DLM and other machines are anything but cheap, they do enable a small shop to compete on equal footing with millions of dollars in traditional metal-casting and -working machinery. Furthermore, a company designed from the ground up to exploit the advantages of additive manufacturing will likely employ new business models,5 organizational shapes,6 marketing channels, and other practices.

Business Aspects

Focusing on the economic benefits of additive manufacturing, it is important to see improvement on both revenue and cost sides of the ledger. Revenues can be increased in two broad categories: reaching new markets, and getting higher prices than are currently acceptable. Mass customization can address both of these dimensions, and personalized needs (whether for footwear or medical appliances, to take two examples) that could not be met with mass-produced products constitute one win. Secondly, meeting specific needs of specific customers allows producers to charge more: custom tailored suits are a familiar example.

Further wins from mass customization come with inventory reduction: in a pure demand-pull regime, there is no excess inventory because demand is known before production is completed. At the same time, lot sizes of one become possible without the traditional practices of postponement—which is late-stage completion of a product (Ikea furniture is a classic example of postponement, but not customization)—or other modifications of standard output.

Supply chains got very long in the early 2000s when manufacturers invested heavily in production in cheap-labor regions that were far from end customers. Unexpected events of many sorts—from the Icelandic volcano to port strikes to tsunamis—forced a rethinking of the risks of interruption of these long and fragile connections. Now, production of, say, a custom cardiac stent could occur a day before its implantation only a few feet away from its manufacture. Short supply chains reduce inventory, improve planning accuracy (and thus reduce scrap rates due to unsold inventory), and reduce missed deliveries and other shortages, known in the field as stock-outs.

The use of working capital also improves. Expensive tooling for a long production run does not have to be procured and paid for before a single item is produced. This reduction of sunk costs extends to raw materials: the metal or polymer powder for a single build can easily be expensed, while truckloads of raw metal or polymer compounds are potentially a much more costly proposition for large batches that need to be run. Finally, the capital investment in additive manufacturing equipment is highly adaptable: it is a thing that can make many different things. In contrast, stampers, molds, and dies are tightly constrained and difficult or impossible to adapt as market conditions change.

Research at the Technical University of Aachen in Germany has identified four areas where additive manufacturing can drive a profitable business market:

- 1. Short production runs such as prototypes or spare parts for obsolete products.

- 2. High production complexity such as race car parts, aerospace components, or cooling chambers that are impossible to mold or mill.

- 3. Highly customized items such as dental or medical implants or high-end sporting equipment.

- 4. Spatially remote production such as offshore oil rigs or at the extreme, the International Space Station.7

For years, research in 3D printing was focused on replicating the subtractive and formative manufacturing processes and materials of the past 150 years, albeit in smaller lots. More recently, additive machines have come into their own when entirely new materials become practical. Adidas is teaming with Carbon to 3D print running-shoe midsoles in a lattice framework that was previously impossible to produce. The first run of 100,000 pairs of the $300 shoes began shipping in 2018, shortly after Adidas made an investment in the startup and took a seat on Carbon’s board.8

Another example of a 3D-printer-centric material is an aluminum-ceramic composite pioneered by Elementum 3D, a startup focused on this new class of builds.9 One fascinating material the Elementum team has been able to print is nickel titanium, also known as Nitinol (named for its place of birth: NIckel TItanium Naval Ordnance Laboratory). It is highly desirable for a narrow class of high-performance applications, but exceedingly difficult to work.10 According to a PhD dissertation in surgical medicine,

NiTi has unique properties that could be very useful in surgical applications. . . . Using its thermal shape memory property, a material sensing a change in external temperature is able to convert to a preprogrammed shape. While NiTi is soft and easily deformable in its lower temperature form (martensite), it resumes its original shape and rigidity when heated to its higher temperature form (austenite). . . . Within a given temperature range, NiTi can also be strained several times more than conventional metal alloys without being plastically deformed. This superelastic property is also based on martensic transformation.11

This extraordinary material is used in everything from dental appliances to watch springs to cardiac stents to thermonuclear devices. Opening the alloy to new uses through additive manufacturing could produce breakthrough results.

In sum, additive manufacturing has been demonstrated to be a profitable investment both in reproducing conventional manufacturing results in smaller lot sizes, in mass customization, and in “extreme engineering” scenarios such as highly complex (possibly consolidated) parts, exotic materials, or remote but critical locations. Most of these are straightforward and have already been discussed. Mass customization is a more modern concept, one previously not applied to manufactured products outside computers and high-end consumer electronics, that deserves a closer examination.

Potential for Mass Customization

One potential new business model could be based on mass production of unique items. Hearing aids have already proved the concept, and several startups are expanding the model to additional markets. Tailored Fits is a Swiss company that began by making custom orthotics for sports shoes and ski boots. (Orthotics have been successfully 3D printed since at least 2010.12) In 2018 the company expanded its market to include complete custom ski boots. There are many advantages:

- • Traditional Alpine ski boots are rigid and create painful pressure points in many wearers.

- • Boots that fit too tightly, even in spots, restrict circulation, leading to cold feet.

- • The dynamic loads borne by the boot/binding/ski system can be considerable, leading to the potential for injury if one component does not fit the skier or the style of skiing.

- • As baby boomers age, the skiing demographic is getting older.

- • Most people’s feet are different sizes, making a bad fitting boot nearly inevitable.

In contrast, Tailored Fits begins with a 3D scan of the skier’s legs and feet. A major hurdle was developing scanning technology that could be deployed to outdoor retailers and operated by store personnel. Mapping the right posture(s) to scan was also important: standing at relaxed vertical, or sitting down, does not mimic the pose of active downhill skiing. From the scans, Tailored Fits worked with an additive manufacturing vendor to build models for both soft boot liners and—eventually—hard outer shells in various types and grades of polymers.

The technology was just coming to market at press time. Expected benefits to the wearer were better comfort and superior performance. For the retailer, ski boots are expensive to buy and inventory because they are physically bulky, and every standard size represents a compromise for a given customer. Freeing up working capital and store space, combined with higher customer satisfaction, at a competitive price point, makes the technology attractive. For the startup, all of the above benefits matter, with the additional gain from parts consolidation and simplified assembly in the prototype: the inner liner is mounted in the external shell, a closure strap is added, and assembly is complete.13

Medical prostheses and implants are a near neighbor to the ski boots: recall that Tailored Fits began with orthotics. Similarly, the millions of dental crowns being additively fabricated all count as prostheses. But the potential market, for both artificial limbs and surgical implants, is vast, and when eyeglasses are added, even bigger. Many elements are already in place: 3D scanning is improving rapidly and coming down in cost, mapping software (to move from medical scans to production files, for example) is improving, and food and drug administrations around the world are approving more applications.

In many cases, polymer-based prosthetics work well: they are water-resistant, relatively cheap to produce, lightweight, and biologically inert. In some cases, plastic or ceramic parts are being used as “scaffolding” for the body to grow new tissue onto, sometimes using a specialized technique called robocasting; we will explore bioprinting actual tissue in chapter 7.14 Scanning removes the need for skilled artisans to hand-make prostheses, which traditionally were extremely expensive and did not fit well at the interface, in part because of the limitations of the available materials. In the case of eyeglasses, frames are already made of many polymers used in 3D printing, as are lenses (which have been 3D printed since 2009). A Dutch company printed integrated lenses and frames for the country’s king in 2013,15 resulting in stronger designs as well as new possible shapes and configurations given that there is no need for a lens-attachment system to be built at the factory prior to lens specification. Given that eyeglasses are about a $100 billion global industry and intimately connected both to personalization and to personal identity, expect to see the industry continue to expand its use of additive technologies.

For mass customization to take deep roots in the industrial landscape, the supply chain will need to be reconceived and reconfigured. Much as 3D printers are often tested on builds traditionally performed by subtractive and similar methods and found to be too slow and expensive, the supply-chain model begins with raw materials: the canonical order of operations is plan → source → make → deliver → [handle returns].16 In both cases, the defining capabilities of additive manufacturing are not being utilized to maximum advantage.

To design a mass customization process from scratch, the key is to begin with unique units of demand: what is it that is being customized, and to what parameters? The hearing aid market is instructive in this regard: local audiologists measure the customer’s hearing loss and ear dimensions, then feed these data into the process. Where else can customizable goods find willing buyers who can be served by fitters and configurators with access to printing capacity in some shape or form? Absent a steady stream of such customized orders, the “mass” in mass customization fails to materialize at economically attractive levels.

Forecasting is a key step in any manufacturing process, and in the case of hearing aids, demographics provide a macro-level insight into how many people of what hearing-compromised ages live in a given area. Long corporate history—the Danish hearing aid company Oticon was founded in 1904—can also provide insight into fashion trends, seasonality, and other influences on demand. Thus the audiologist channel, the unique and reasonably predictable demographics of hearing loss (and the desire for its remediation), and corporate institutional memory all likely contributed to the success of hearing aids being manufactured with additive technology.

Starting from closer to scratch for, say, orthopedic prostheses or custom athletic shoes would be considerably more difficult. (Ski boots are much easier, sold as they are at a small number of retail outlets, to a generally affluent, price-insensitive market, and with acute physical discomfort as a motivator.) Once the demand is recognized and pooled, production capacity can be situated nearby, with little regard for iron ore (as in steel mills), skilled programmers (Silicon Valley), or nearby vineyards (wine presses). In the longer term, these geographic impacts will likely come from small rather than massive facilities, and will change the economic geography of a number of industries.17

Additive manufacturing and other recent developments in advanced manufacturing are emerging against the backdrop of globalization as it enters its own new phase. One can argue that globalization most recently dates to about 1989: the fall of the Berlin wall, the Tiananmen Square protests, the emergence of the affordable cell phone, and the World Wide Web specification all happened pretty much at the same time. In 2020, there will be a different world order: China is no longer an emerging power, the former Soviet Union has yet to coalesce into a coherent economic force, India has entered into more and more global discussions of trade and culture, and the automobile is being rapidly electrified and computerized. Africa remains mineral-rich and economically poor, OPEC could lose much of its influence as cars are weaned off gasoline, and most adults on the planet have or will soon have access to a smartphone.

In short, these new demand-driven production processes made possible in part by 3D printing (and other technologies, including cloud computing, 3D scanning, and new designer materials) will challenge the offshore model of mass production, but that model is itself evolving for other reasons having nothing to do with 3D printing, as the changes to the global automobile industry suggest. Mass urbanization, decreasing global poverty, asymmetric warfare (including battles fought in cyber domains), and improved social and economic status for woman in many countries (including Saudi Arabia)—all of these are reshaping economic life in gradual, subtle, but undeniably profound ways, and for 3D printing to become the economic force it has the potential to reach, its champions will need to recognize and surf these other waves of change.

Testing and Standards

For additive manufacturing to become a fully mature element of the productive infrastructure, it will need to move out of the current state. Many processes are “black boxes,” either because of proprietary tactics (such as being locked in to a machine manufacturer’s supplies) or because fundamental science and engineering questions remain unanswered. Production is still an art form, with frequent variability of outcomes given apparently identical inputs. Design tools do not reflect all the information needed at the CAD stage, including cost estimation as one example. The various modeling, production, and inspection software packages have gaps and limited interoperability: many measurements of a build are not automatically logged and analyzed, for example.

Efforts around the world are attempting to remedy this state of affairs. The International Organization for Standardization (ISO), ASTM (originally the American Section of the International Association for Testing Materials), and the American Society of Mechanical Engineers, to name a few organizations, all have published standards relative to additive manufacturing, but much remains to be codified. The US National Institute of Standards and Technology held a workshop on additive manufacturing in metals in 2012,18 followed by a similar session on polymer-based methods in 2016.19 Many essential issues emerged from these two meetings, which overlapped to a surprising degree. Here is a brief sampling:

Materials

- • How can materials be developed for both metal and polymer printing such that performance is predictable? Many materials currently exhibit high variability across batches. At the same time, the same powder can behave very differently in different machines. What process parameters can introduce or reduce this variability?

- • How can materials be reliably classified on more axes than only structural strength, such as bio-compatible, autoclave-safe, electronic, magnetic, and fatigue tolerant (in both metals and elastomers)?

- • How can material properties be reflected in design tools, allowing various parameters to be varied and compared?

- • How can the price of materials be reduced, increasing the total market? For example, quantities are often so small for a given formulation that many powder or filament manufacturers cannot economically justify serving a niche. According to one unnamed company representative, polymers for traditional manufacturing were outselling additive manufacturing purchases about 100,000 to 1 (by weight) as of 2016.20

- • How can materials be reengineered to support faster builds? That will require knowing more of the physics and chemistry of both inputs and the building process.

Machine Performance

- • How can machines become more efficient?

- • How can builds be more consistent, both across printers and across builds on the same machine, perhaps under different operators?

- • How can machines perform more self-monitoring, self-diagnosis, and self-calibration?

- • How can the actual and usable build envelopes get larger?

- • How can build performance be monitored in real time? Many manufacturers forbid users from attaching thermal cameras, spectrometers, or other in-process data collectors.

Process Performance

- • How can additive design and manufacturing become more predictable? That is, how can desired properties of the final product such as strength or ductility be translated backward into build parameters?

- • When can design models couple additive design, materials selection, and manufacturing processes, allowing the designer to trade off different aspects in pursuit of weight, cost, strength, time, or other constraints?

- • When will predictive models relate inputs (thermal history of both the build chamber and the melting/sintering beam, tool path, speed, material particulars, desired geometry) to build success and part performance?

- • When can manufacturing processes be qualified and/or certified to reduce the need for part-level testing?

- • Where are the metrics with which to evaluate and verify models and simulation tools?

Boundary-Spanning Challenges

- • When will adequate, feasible sensor technology support real-time process control?

- • How can designers learn to think about additive methods natively, not as a translation from conventional machining and manufacturing?

- • What are the protocols, the physical hyperlinks as it were, between a 3D-printed part in the wild and its design and build history? How readily will a report of a failed part be connected to video, sensor, inspection, and other files documenting its path from CAD to physical completion?

- • When will there be standardized benchmark “torture tests” for metal printers similar to the Benchy boat21 (figure 6.1) for home 3D printers? That is, when can industrial users standardize the performance of their machines with open-source test files? The US NIST has recently launched a promising candidate, so the question will be if the NIST benchmark gets traction in the market.22

Figure 6.1 The Benchy boat is a publicly available design to test many aspects of desktop 3D printer performance. Photo under creative commons license https://upload.wikimedia.org/wikipedia/commons/6/65/3D-printed_3DBenchy_by_Creative_Tools.jpg

As this extensive list shows, the “devil is truly in the details,” and additive manufacturing still has a long way to go before it is incorporated into shop floors, supply chains, and project budgets on a routine basis.

Design Freedom

While it is not the imagine-sketch-print stereotype that some enthusiasts portray, additive manufacturing does require a substantially new design perspective, language, and skill set. The clumsy acronym DFAM—design for additive manufacturing—is an emerging extension of the much older “design for manufacturability” movement, taking into account the broader capabilities of additive techniques. Very few parts and even fewer processes are designed around the new types of material strength, geometric possibilities, and multi-material constructs that are becoming possible. Rather, much of the existing work has re-platformed subtractive processes and designs onto additive tools. DFAM seeks to engineer new approaches and concepts into the design language and toolset.

An early step in DFAM involves the recognition of each technology’s limits, such as minimum feature size, minimum wall thickness, and maximum overhang. Second, the effects of gravity on an additive build must be accounted for. In certain materials, making a circular hole on the vertical axis means the top will “fall” slightly (especially without support structures) whereas building the piece on its side ensures a more perfect roundness. Third, materials will exhibit different combinations of cost, performance, and build speed. The powder grain size of various metals affects both overall surface smoothness and minimum feature sizes, for example. Finally, build-preparation software does not always guarantee that the build-in-process does not have features that can interfere with the powder re-coater, especially if each powder layer is particularly thin in pursuit of a smooth surface finish. In summary, this process might be thought of as learning the “rules of the road.”

The most important “rule of the road” for additive manufacturing in metal is currently the optimal use and design of support structures. One research team estimates that 80 percent of build failures in powder-bed metal manufacturing result from inadequate design supports.23 The lack of experience with the concept in other manufacturing methods, the lack of accepted principles and design rules in engineering curricula, and the lack of industry-wide communications of successful approaches all contribute to the many failed builds in the course of a designer’s education.

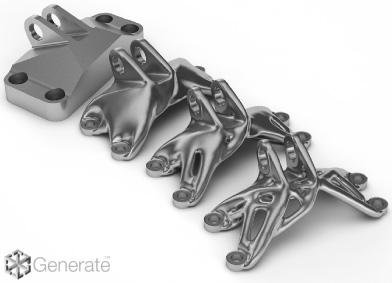

Currently, a primary component of DFAM is topology optimization, a mathematical technique built on finite element analysis that generates a material layout given predicted loads, size, and other constraints. The resulting shapes can be curvilinear and almost biological in their appearance, as is seen in a common example in which a traditional bracket is subjected to multiple rounds of the process (see figure 6.2).

Figure 6.2 Topology optimization helps in “lightweighting” a bracket, reducing the structure to the minimum size and thicknesses necessary for the loads it will carry. Note that extensive post-processing has also been performed. Photo credit: Frustum

Topology optimization is itself one aspect of a larger emerging concept called generative design. Generative design is more free-ranging than topology optimization, exploring a larger space of potential solutions. After initial conditions are specified, algorithms explore a wide variety of available possibilities, generating (or “growing”) a range of forms often featuring unorthodox geometry. Autodesk makes software tools that do both. As Greg Fallon, the vice president of Simulation stated, “While optimization focuses on refining a known solution without any notion of manufacturability, generative design helps the engineer explore a whole cadre of functional and manufacturing design options.”24 With many former constraints on manufacturability now reset, these tools will likely play a key role in greater expression of what 3D printing is truly capable of.

Both topology optimization and generative design can drive the use of cellular, lattice, or mesh structures, typically in the interior of a part. The benefits in strength, weight, and aesthetics are appealing (see figure 6.3). Additionally, similar interior “cells” or fins can be used to improve the fluid dynamics of a gas or liquid through an aircraft engine, internal combustion engine, or even a water faucet. These structures lower cost because less material is consumed, and reduce build time as well. An important constraint in the use of lattices and honeycomb structures is the computational load these geometries place on both design and structural analysis software. To oversimplify, it might be that these geometric forms are easier to build than to computationally model or analyze.25

Another facet of DFAM is parts consolidation, in which multiple components can be combined into larger 3D printed parts. This technique can speed assembly and streamline supply chains, albeit at the cost of much more expensive repair parts when the larger assemblage fails. Fewer joints also can reduce noise, leakage of fluids, and other aspects of the device’s operation. Challenges remain at this early state: how many parts can be, versus should be, consolidated? For what reasons? If multi-material builds and/or embedded moving parts are considered, how are these considerations weighed, given that they fall outside of the tradition DFM methodology? If there are internal channels for fluid flow, how does topology optimization for the channels interact with topology optimization of the overall structure? GE’s LEAP nozzle and related research have helped prove the viability of parts consolidation, but the implications—for design, for vendor management, for manufacturing process design, for repair—will take years to fully parse. See figure 6.4 for an example: seventeen components were combined into a single additive build of a hydraulic manifold, with weight savings of 60 percent.

Figure 6.3 2x magnification of a 3D printed self-supporting lattice. Photo credit: CIMP 3D

Farther in the future, there is interest in functionally graded materials, which combine different materials to achieve a performance objective: to achieve new levels of thermal performance, for example, the best properties of ceramics and metals might be combined. In other instances, metal circuit traces are included within polymer parts. While a voxel is a standard unit of volume in additive manufacturing, a maxel is a proposed term to describe a structural unit of a functionally graded material. Because of the precise nature of additive manufacturing, new materials combinations with desired properties for aerospace and microelectronics applications in particular are being explored.

Figure 6.4 Part consolidation in metal additive manufacturing. Proto credit: CIMP 3D

Education and Jobs

The long-term relationship between 3D printing and the US education system looks to be both complex and evolving. The low (initial) cost and dramatic increase in student engagement make printers very popular in K–12 schools in many countries. They are being used in both STEM and design-centered curricula, emphasizing the connection of math to production in the former and shortening the plan-design-make-evaluate cycle (in essence, helping students fail faster while iterating) in the latter.

At the same time, just as when PCs were enthusiastically introduced into elementary education in the 1990s, the purchase price of the machines often turns out to be a minor factor in predicting long-term pedagogical success. Lesson plans, allocating classroom space, supplies and repairs, and a steady stream of doable yet relevant projects all require more money, time, and access to expertise than many initial estimates allowed.

More critically, it’s not clear that hardware purchases alleviate the shortage of computer science-capable teachers in K–12. In late 2017, a public-private partnership pledged $500 million to improving computer science instruction. For example, only one state (Arkansas, home to Walmart) requires K–12 computer science education; Virginia and Rhode Island were expected to follow suit. Only thirty-three states count computer science credits toward high school graduation. Thus between weak curricula and a shortage of capable teachers, buying 3D printers without the institutional scaffolding to support sustained, systematic learning is likely to produce little significant effect.26

Later in the education pipeline, high schools and universities are doing little to prepare graduates for an additive manufacturing future. Curricular innovations are extremely rare, in part because faculty lack the expertise to run the machines and teach with them, in part because many machines run as closed systems with proprietary inputs, and because the cross-cutting skills “break” the departmental specialization model that is currently in place. Computer science, materials science, supply-chain management, mechanical engineering, industrial engineering, optics, metallurgy, polymer chemistry, and solid-state physics could originate in four or five different colleges within a university, never mind a single major. Bridging the gap between faculty research and vocational preparation in various combinations of these fields remains challenging.

To meet these gaps, several initiatives are underway. The European Union launched its ADMIRE project (knowledge Alliance for AdDitive Manufacturing between Industry and univeRsitiEs) most immediately focused on creating a masters degree program. Founding partner universities came from France, Germany, Portugal, and the United Kingdom. Cincinnati State (located in close proximity to GE’s aircraft division where many additive efforts are underway) is launching a two-year certificate program.27 For more advanced learners, Penn State announced two new masters programs (one in science, one in engineering) in additive manufacturing and design in 2017.28

Eight universities worldwide are getting advanced metal printers from GE:

- • Auburn University

- • Boston University

- • Iowa State University

- • North Carolina State University

- • Ohio State University

- • University of Cincinnati

- • US Naval Academy

- • University of New South Wales.

Before the winners were announced, interest in GE’s announcement was strong: more than 250 universities submitted applications, along with more than five hundred primary and secondary schools. Four hundred of the latter category will receive desktop polymer printers.29

Intellectual Property

The decentralizing tendencies of digital technologies generally are also at work in 3D printing. As barriers to entry are lowered in that a single machine can replicate the work of casting, molding, and machining operations, the number of entities in a given market is likely to increase, sometimes by a factor of ten: hundreds of thousands of desktop polymer printers can do some of the work of thousands of injection molding and related firms. With greater numbers comes both anonymity and increased supply-chain complexity: finding which printer generated a given plastic figurine may be impossible. Counterfeiting is likely to be a major issue, whether for antique-car parts or expensive aerospace components.

If a company makes machines that can copy protected property, is the machine-maker liable for illegal copies? In 1980 Universal Studios sued Sony over the Betamax videorecorder. A US district court held for Sony, a circuit court reversed the verdict in Universal’s favor, then the US Supreme Court issued the final word: “The sale of copying equipment, like the sale of other articles of commerce, does not constitute contributory infringement if the product is widely used for legitimate, unobjectionable purposes. Indeed, it need merely be capable of substantial noninfringing uses.”30 While that sounds definitive (a 3D printer need only be capable of noninfringing use to be legal), the courts and the US Congress took a far more favorable view of rights-holders’ positions with regard to digital copying and downloading of music and movies. When 3D printing comes to its Napster moment, if that were to occur, it’s possible yet another standard will emerge.

The traditional defense against such copying lies in patent law. 3D printing raises two major challenges to these laws, according to an early law journal article on the topic: first, IP rights holders are confronted by new rights claims by 3D printer users, such as the right to repair an existing patent-protected item. Second, additive methods provide the technology’s users with new means of infringement that may not have been prohibited at the time the statutes were drafted.31

One key factor in patent law relating to 3D printing involves the role of software—the build file—in the ultimate item’s creation. Case law on software is far from coherent or technically nuanced, and the notion of a build file as a “computer program” can be problematic.32 If party A is accused of stealing party B’s ideas, what precisely is stolen? Did party A intend to steal a patented object? How can party B prove that intent? Does making a picture (a 3D scan) of a gear constitute theft? What about copying a “sliced” CAD file? If the software is not the theft, what then is stolen, exactly?33 If 3D scanning generates a reverse-engineered replica of the original part, what computer “program” is responsible: AutoCAD, Magics, the build file (not an executable, presumably), or the embedded software in the printer? As of 2014, patent infringement litigation based on items created in a 3D printer had not yet occurred.34

Intellectual-property holders do have several avenues to consider. For example, a topology-optimized shape for a given part might qualify for a design patent, insofar as it has novel aspects of appearance and unique features that add value and functionality.35 More promising is the domain of trade secret law, which does not require a filing (as with patents) and has a lower burden of proof. Given that software’s ability to be patented is currently unclear, build files can more definitively be protected as trade secrets. That said, additive manufacturing is an extremely dynamic area, with many good ideas being discovered independently, and trade secret protections do not apply to reverse engineering. A final option is to copyright the build file, at a minimum, and perhaps other aspects of the process, but they must “qualify as an expression of an idea rather than the idea itself.”36

All of the above applies to the US legal context, but there are significantly different standards in play elsewhere in the world. The World Intellectual Property Organization cites both Australian and European Union standards in its guide to 3D printing. After Brexit, the United Kingdom, where some leading additive innovation is occurring, occupies a legal limbo given both the strong British legal tradition and the more recent EU membership. “Trade dress,” referring to visual trademarks and related signaling, is at once global and local, and how it gets defined with relation to 3D printing will likely matter significantly for the future of IP protection. Spare parts in particular are predicted to be a battleground for the interpretation of trademark.37

Furthermore, theft of intellectual property is possible without actually possessing the object or the file: researchers have discovered the acoustic side channel—the noises made by the 3D printer—can be recorded and used to reconstruct the shape being printed. This same attack has successfully been used on cryptography machines, ATMs, CPUs, and computer keyboards, but there is no indication the vulnerability in 3D printers has been exploited outside a research lab.38

Other Legal Aspects

Although the public curiosity and uproar have subsided, many people’s main awareness of 3D printing was focused on the story that broke in 2013 of Cody Wilson, a law student at the University of Texas who developed and distributed via the internet plans to print a single-shot plastic gun, which he named the Liberator. Wilson’s firm, Defense Distributed, released the plans on May 6 and more than 100,000 downloads were recorded. The United States Department of State then demanded that Wilson retract the plans, which he did, under the rationale that the State Department regulates the flow of technical data related to arms, and is charged with enforcing the Arms Control Act of 1976. Copies of the files are still available at file sharing websites such as The Pirate Bay, however.39

The Liberator is much more useful as a discussion point than as a weapon: at least one trial of the gun resulted in its shattering, and in the United States, handguns with safer designs, more capacity, and much greater reliability are readily available. The Liberator does have the potential to pass unnoticed through airport screening: even though Wilson included a metal nailhead as a firing pin, the rest of the product is both radiographically invisible and highly ineffective. The barrel is not rifled, the energy of firing is widely dissipated, and reloading takes both several minutes and some hand tools when the bullet’s cartridge gets jammed in the soft plastic. Furthermore, many home makers have been stymied when trying to use the files on a MakerBot-class device: most if not all successful firings have been with weapons made in $100,000 commercial machines.

All of that said, the Liberator and some other developments point up substantial legal issues. It is possible to print the lower receiver (the serial-number-bearing trigger mechanism that both connects all parts of the weapon together and regulates whether the weapon is manual, semiautomatic, or fully automatic) of an AR-15 rifle, the weapon of choice for school shooters in the United States. The modification would dodge a proposed ban on high-capacity magazines and has been tested manually firing six hundred rounds without a jam.40 Furthermore, Defense Distributed has since developed and circulated plans for a “ghost gun,” an untraceable AR-15 (such weapons have unsurprisingly been used in mass shootings). Rather than 3D printing, the key digital fabrication tool is a $1,500 CNC mill with a USB stick sold by Defense Distributed that shapes a block of aluminum (cost: $80) and essentially automates a weekend of work that a capable home gunsmith could do with a drill press.41

The availability of gun-making and gun-modifying hardware pushes the ideological distinctions applied to software and communications networks to a new extreme. Richard Stallman, who founded the Free Software Foundation, famously argued that software should be free as in freedom, not free as in beer. Later advocates including Eric Raymond (who wrote the seminal essay “The Cathedral and the Bazaar”) developed the more user-friendly “open-source software” offshoot of the movement, with less talk of either constitutional interpretation or kegs. In communications as well, between “burner” cell phones, tools like PGP, and the Tor network aimed at preserving anonymous internet usage, privacy advocates can limit their digital breadcrumbs, potentially for illegal purposes. Digital privacy and libertarianism enters a new phase when the conversation involves not only virtual but physical instantiations.

A related controversy began brewing in late 2017 when an Australian physician named Philip Nitschke announced he was putting plans online for a 3D-printed suicide machine called the Sarco. Rather than injectable chemicals, the machine features a chamber into which the patient climbs (entering a PIN after completing a pre-euthanasia questionnaire) and which doubles as a casket after the oxygen is replaced by nitrogen. The base onto which the pod is affixed can be reused. His reasoning for the invention is to address the paradox of suicide being legal in many locales, but assisting suicide being prohibited.42

Conclusion

Regardless of ideological interpretations or enthusiasms, the fact is that decentralizing industrial production limits the ability of governments or commercial entities to regulate the uses of capital equipment that is now shrunk down to household scale. (In a related development, Oxford Nanopore has released a pocket DNA sequencer that sells for $1,000 and plugs into a USB port.)43 The former tools and mechanisms of regulating manufacturing and distribution of drugs, weapons, words, images, and sounds no longer scale downward to potentially millions of locations. How that regulation will occur going forward is likely to be fiercely contested, with numerous unexpected consequences repeatedly resetting the debate.

As these contests occur at the edges of many cultures, the mainstream issues concerning design practice, shop floor technique, and education for both current and future additive manufacturers will continue to evolve. Curricula will be developed and shared, standards and practices will evolve, and more success in mass customization will continue to reshape both public perception of 3D printing and the propensity for firms to invest in it.