7

Frontiers

Additive manufacturing is farthest along in its evolution in polymer scenarios, as the tens of millions of SLA-printed hearing aids attest. Work in metal is slightly behind, because the technology is newer, although the importance of aerospace and defense applications is pushing the frontier rapidly forward. While there remains much to learn about metal and plastic, new materials are being explored in labs and startups. Each of these—mammalian tissue, building construction, food, clothing, micromachines, and electronic circuits—represents a set of solutions to a grand-challenge-scale problem. In conjunction with mainstream uses of additive manufacturing, in turn, the many new applications challenge existing methods for education, production processes, and capital allocation.

Bioprinting

In most countries and in the world at large, there are fewer organs for donation than there are people who need them. The trend toward self-driving cars in particular and greater usage of mass transit in an urbanizing world more generally is projected to increase the shortfall of available organs: motor vehicle accidents involving healthy young people are a major source of donor organs.

Bioprinting is an emerging technique within the field of tissue engineering to use 3D printing technologies to precisely place both living cells and biomaterials into constructs designed ultimately to replicate human organs. The technical challenges are considerable, but early successes include the printing of a human skin substitute currently used for cosmetics testing in place of animals.1 L’Oréal is teaming up with the biotech firm Organovo in the area of skin research, and the tech startup has also brought functioning liver tissue to market for pharmaceutical companies to employ in the new-drug development process. Nevertheless, it is essential to differentiate between bioprinting tissue and organs, which are currently too complex for the available technology. Three major approaches are being used—biomimicry, autonomous self-assembly, and mini-tissue building blocks—but detailed discussions of these are beyond our scope here.2

Bioprinting begins with a series of scans of the affected organ and surrounding area, much as with mechanical reverse engineering (see chapter 2). A crucial distinction is important to note: the tissue scans focus not only on what is where (structure), but also on what does what (function). Consider that bioprinting aims to place “cells, proteins, DNA, drug particles, growth factors, and biologically active particles,”3 so the design must accommodate not only all the biochemical processes to sustain those tissue components, but also blood flow and mechanical properties: how strong must human skin, or a liver, or a vertebra, be, not just in general but in its key structures? Also, tissue must sustain multiple fluid and material flows, including lymphatic and blood perfusion, not only in the specific tissue but connected to adjoining structures. All told, the variability and complexity of human tissue makes mechanical replication especially difficult. After the scans, a digital model is built in STM language (see chapter 2), then printed using bioinks in a bioprinter, the first one of which was commercialized in 2009.

Various techniques including 3D printing of inert or biofriendly materials have been used to create “scaffolds” upon which a body can grow replacement tissue. Eventually the scaffold should degrade, and until that point, the many requirements of successful tissue regeneration—including specific matches to each individual recipient in size, material strength, blood flow, function, and conformity to adjoining structures—mean that few scaffold-building materials and techniques have enjoyed wide success.

To summarize, the design of artificial tissue must address the following considerations:

- • Mechanical (for example, how strong, how stiff vs how pliable (and where), how much structural integrity in various states, such as standing vs lying down, in exercise vs asleep, in a dehydrated state).

- • Biological (such as which cell types are where, how cells are nourished, how the tissue forms).

- • Geometric (whether the tissue or organ fits where it needs to, both at implantation and later). Significantly, the replacement part cannot be markedly smaller than the original: human bodies do not readily tolerate internal voids.

- • Transport (growth factors, nutrients, drug delivery, oxygen, and waste removal must all be managed).

- • Bioprinting (much as with traditional 3D printing, this includes the amount of the material that is added, how fast, under what conditions: resolution, build speed, layer height).4

Divergence from Material Printing

Several key differences between material printing and bioprinting are worth noting. First, control of porosity aims in two opposite directions: with very few exceptions, in metal especially, hot isostatic pressing and other techniques are required to ensure uniform material distribution because voids can contribute to cracking. In bioprinting, pore size is a critical variable, yet current CAD technology does not represent these microstructures, nor can STL (efficiently) transmit such data to a toolpath for the extruders. Second, overhangs and other horizontal biological elements may not be able to be built with support structures to be removed in post-processing. Third, bioprinting involves many soft materials that are more difficult to control than predictable polymers or metals in rigid geometries: heart walls would be one example.

The most promising of these soft materials is the class of hydrogels that combine hydrated scaffolds containing cells that can migrate in 3D space. This is in contrast to traditional scaffolding, in which cells can migrate only along the surface of the scaffold, so tissue growth is enhanced by better cell growth within the supportive (in several senses: mechanical, energy, microclimate) medium. Another avenue in early trials involves a building-block approach, using tissue spheroids that do not require scaffolding. At this juncture, the science (both physics and biology), the software (both design and machine toolpath generators), and the assembly hardware are all lacking.

Let us look at this problem in more detail. Bioprinters are not a large segment of the tissue engineering market, so there are few biomaterials optimized for the few 3D printers that are available. At the same time, the technology issues related to bioprinting are still in the lab-experiment phase, so material producers have little incentive to meet such limited and poorly defined demand. Printers need materials, and materials producers need hardware designs to stabilize.

What are the requirements for a good bioink? A standard textbook in the field identifies thirteen parameters, many of which trade off against others. Here is a sampling:

- • Which bioprinting technologies will the bioink support? Currently, laser-based tools, droplet placement, and extrusion methods dominate the young field.

- • How successfully can the biomaterial support the bioprinting process? Cell degradation, nozzle clogging, and customization of equipment (extrusion heads) are some considerations here.

- • How closely does the bioink mimic the behavior of live cells and tissue?

- • How practical is the bioink technology? Long preparation times, limited compatibility with other biomaterials, and the necessity for delicate hand labor are causes for concern.

- • What are the time scales for incubation both during and after bioprinting? Slower build times can result in faster tissue formation, for example.

- • Does the bioink induce an autoimmune response from the host, and if so, can it be successfully managed?

- • Bioink often contains components that need to degrade as live tissue growth replaces scaffolding. Managing this degradation is a complex process.5

What, then, are the requirements for a bioprinter? The same textbook identifies ten requirements:

- 1. High resolution and accuracy Bioink must simulate cell placement in native tissue.

- 2. High degree-of-freedom in motion Printer heads must be able to deposit bioink on curved and irregular surfaces, as will be required when printers will deposit cells onto live patients.

- 3. High-speed motion Bioprinters should support rapid fabrication of human-scale tissue for transplantation and other therapeutic applications, as well as fitting into high-throughput assays for cancer research and drug development.

- 4. Ability to dispense multiple types of bioink solutions simultaneously Native tissue is comprised of multiple types of cells, and laying down only one cell type at a time severely limits the ability to mimic live tissue.

- 5. Ease of use As bioprinting leaves the lab, the required skill levels available will by necessity drop from PhDs and post-doctoral fellows to the levels of the wider workforce.

- 6. Compact size Bioprinters must be treated with regard for biohazard safety, so they need to fit under standard protective lab equipment.

- 7. Ease of sterilization Similar to point 6, bioprinters need to support standard sterilization procedures.

- 8. Full-automation capability Much like metal or polymer printers that often run overnight, bioprinters cannot be continuously attended, particularly given long complex builds.

- 9. Affordability As with any technology, prices will need to drop to a level that will allow labs and researchers to afford the machines before experimentation and communities of practice will drive wider adoption.

- 10. Versatility Especially until standards and practices become normalized, researchers need to be able to adapt bioprinting technology to evolving needs.

In addition to the macro-level chicken-and-egg problem of bioprinters and bioinks both being in short supply, thus dissuading development of the complementary technologies, there are several concrete limitations. First, commercially available bioprinters are scarce, especially models that are not extrusion-based. Second, print-head cartridge/nozzle assemblies must be capable of a) handling a range of cell sizes without damaging any of them, b) supporting precise, consistent placement of those cells, and c) being easily and reliably loaded during a long, complex build. To date, all three of these conditions remain challenging to achieve consistently. Third, bioprinters are currently too big to fit into even a laboratory environment much less being able to integrate into a patient-care workflow, and they are also impractically slow. Fourth, today’s bioprinters do not have enough flexibility in their motion to be used in the creation of complex physical structures.6

The challenges continue. Bioprinters are insufficiently automated, requiring substantial skill and constant attention on the part of the operator. They cost so much that return-on-investment calculations still cannot justify their purchase. Current bioprinters lack sufficient resolution (both in their motion control and in the behavior of hydrogels after application) to build capillary structures, which are required for many long-term objectives in tissue and organ printing. Experience with bioprinters has come in experimental contexts so the shop craft and operator knowledge for wider-scale application are not widely available. Taken together, these obstacles pose significant barriers in any roadmap toward organ printing.7

Construction

Architects and civil engineers are helping lead the way toward developing additive methods for building construction. The initial efforts are not yet twenty years old, so many of the hurdles faced in polymers and metals (regarding stability and proof of durability in particular) are still being addressed. Just as with any tool, no technology is perfect for all applications, but there are several emerging areas where 3D-printed construction could be extremely attractive.

In the planning phase, architectural models are proven to be useful for everything from assessing sight lines to testing various weight-bearing concepts. Traditionally, the final model was expensive and fragile, limiting its use as an iterative design tool. More recently, plastics can be economically printed at sufficient resolution for models to become interactive conversation and collaboration tools in the design process, and some architectural offices are bringing their model-building capability in-house. Other offices use binder jetting and other color-capable technologies. Because architectural CAD often does not transfer to part fabrication, however, several data translation steps are required.

Several technologies are being employed beyond the model phase for actual fabrication. Apis Cor is a startup based in San Francisco and Russia. In December 2016 the firm built a four-hundred-square-foot house in twenty-four hours using a print head extruding concrete to form hollow halls, through which ran plumbing and electrical work. The cost was about $10,000, which is cheaper on a per-square-foot basis than a typical Habitat for Humanity frame house, some of which cost roughly $50,000 for 1,050 square feet.8

Enrico Dini is an Italian civil engineer and inventor of the D-Shape building technology. Unlike the arc-shaped walls built on-site in the Apis Cor house, D-Shape uses a traveling print head on a grid, very similar to bridge-finishing technology, to print rectangular building elements out of a variety of stone aggregate mixes including marble and volcanic rock. The building elements are then transported for modular construction at the job site.9

Behrokh Khoshnevis has been experimenting with 3D-printed building technologies since 1996. His company, Contour Crafting, grew out of his work as an engineering professor at the University of Southern California. Rather than building components, Contour Crafting works on site, laying down hollow concrete halls using a computer-controlled robotic gantry. While some other innovators stress the design freedom afforded by additive methods, Khoshnevis stresses the safety improvement that an automated approach offers over a reported 60,000 construction-related deaths annually, worldwide.

Apis Cor built a four-hundred-square-foot house in twenty-four hours using a print head extruding concrete.

Branch Technology is the firm founded by the architect Platt Boyd to build complex geometric shapes that are at once economical, visually dazzling, and extremely strong for their weight. As with D-Shape, Branch Technology manufactures building components in its shop rather than on site. Boyd left his architecture firm in 2015 after experimenting with 3D-printed plastic shapes that were terrifically strong: a two-ounce plastic structure held 160 pounds (Boyd’s body weight), then a carbon-fiber-reinforced plastic matrix, reinforced with spray insulation, weighed four pounds but successfully held three tons.10

Finally, WinSun is a Chinese firm concerned with economies of scale: as hundreds of millions of its citizens move to cities, China needs a lot of housing, fast. Thus the 3D-printed construction modules, emerging from a massive printer (490 feet long × 33 feet wide × 20 feet deep), are a step toward “dignified” (in the company’s words) housing made in part from construction waste and mine tailings. The houses are geometrically simple, sturdy, and cost less than $5,000 apiece.11

The potential for these methods is vast, ranging from rain- and wind-proof housing for the masses in some settings, to extraordinarily complex architectural statements of what is known as parametric design, a highly mathematical approach to form.12 In addition, Khoshnevis’s Contour Crafting proposes a radical approach to building pylons for wind turbines. Currently these structures are expensive, dangerous to build, and not as tall as conceptual ideals would suggest. Rather than having enormous cranes dangle massive steel structures from above for workers to mechanically join hundreds of feet off the ground, imagine three sets of parallel caterpillar tractor treads climbing up a cylinder of gradually decreasing radius and supporting a print head spraying successive layers of cement onto a circular base. The pylon could be much taller, stronger, and cheaper (not to mention less stressful for the constructors) than current designs. At several extremes—mass housing, innovative shapes, and safer construction of critical infrastructure—3D printing will literally reshape the construction landscape.

Several challenges need to be addressed before this can happen, however. First, building codes ensure public safety, in part by learning from past failures. Efforts are underway to create the room for experimentation, while preserving public safety, that 3D printing needs. Once codes allow 3D printing into construction, banks can lend money, clients can get certificates of occupancy, and these structures can actually get built and lived in. Second, just as failure modes for additively produced plastics and metals must be learned, so too do designers and engineers need to learn how these structures age. Without thirty years of data, building inspectors are hesitant to assume 3D-printed structures will not fail over time. Finally, while many materials are being investigated, finding the ones that combine aesthetic values, the necessary engineering properties, and successful implementation (such as not clogging extruder nozzles) will take time and experimentation.

Food

In contrast to bioprinting, food is an easy extension of existing extrusion technologies—some open-source plans even show how certain printers can be modified. In addition, commercial food processing already uses extruders and other additive technologies to make chips and cookies, among other things, so scaling these processing lines down to a single machine is logically straightforward. Most food printing uses some variation of a digitally controlled extrusion model; experiments using bioprinting of cells to create a meat-like product are farther out on the horizon and will not be addressed here. Chocolate powder and some sugars have also been successfully used in powder-bed technologies.

The future of 3D printed food can be viewed along six axes:

- 1. Extreme conditions Feeding passengers on a long trip through space could be achieved by having a printer as part of the galley, with large stores of vitamin- and protein-rich feedstock. Thus crew members’ appetites could be sated with some degree of spontaneity and consideration for flavor preference. NASA has 3D printed a pizza in space.

- 2. Food conservation Food waste is a massive, global problem. As the planet’s population rises toward the projected 9+ billion in 2050, salvaging some of the 1.3 billion tons of wasted food will be essential. 3D printing has the advantage of being able to take leftover meat and fish trimmings, spoiled fruits, and other safe but unattractive food and package it more palatably. In addition, unconventional protein sources such as insects and algae can be transformed into healthy and tasty products.13

- 3. High-end dining 3D printers can spread gels and purees with perfect consistency and tightly detailed precision. Some restaurants use the technology for dessert courses, sometimes in sight of the diners, who can watch their dish “grow” over the course of the meal. Chocolatiers and confectioners can already make intricate, captivating shapes, given how well sugar and chocolate can be worked through a nozzle. (Hershey has teamed with 3D Systems to make complex geometric shapes in chocolate.14)

- 4. Addressing certain disabilities Some individuals (about 4 percent of adults) have trouble chewing but still enjoy the taste of real food as opposed to liquid diets. 3D printing has been used to help some of these individuals meet their dietary requirements safely, without fear of choking, by reconstituting food powders into gels and other semistructured dishes. At the same time, individual dietary requirements such as low salt or extra potassium can be addressed in the blending of the powders.

- 5. Providing variety at home Some industry figures foresee home food printers functioning much like microwave ovens, delivering convenience and variety.15 Assuming traditional ingredients are used, printed food can be tasty and nutritious while also requiring a minimum of labor.

- 6. Institutional cooking 3D printing for food is currently not fast, but it is precise and repeatable. It could lend itself to tedious tasks such as frosting cupcakes or applying meringues, as the Focus printer from ByFlow, a Dutch startup launched in 2009, already has been used. Another startup, BeeHex in Silicon Valley, envisions 3D-printed pizzas, perhaps in the shape of the home team’s logo while fans are eating at the sports stadium.

The prospects for food printing appear to be wide open. Many existing food components can be extruded and then baked if necessary, such as pizza dough. Others can be made into cereal shapes or larger custom prints (a pancake maker already “prints” batter on the griddle to copy an image fed into the device). Cleanliness and freshness are critical, but they are easy to address if one has any familiarity with commercial kitchens.

The Foodini is a tabletop-sized 3D food printer launched in 2014 by the Natural Machines startup. It has been used in both fine dining and hospital applications, with an eye toward the home market once the product matures and the price point can drop. The choice of five different nozzle sizes means that stabilizers like maltodextrin are not necessary, and the machine can hold five different ingredient capsules. The company focuses on healthy eating, so many fresh foods can be accommodated. Precise pasta shapes and crackers, as thin as 0.5 mm, are possible; the crackers are done in about twenty seconds, while a pizza takes five minutes. The company’s founder envisions a supermarket having a machine to create ravioli to order, for example.16 Much as with additive manufacturing, customization is a major benefit of 3D printing, so individual tastes and dietary needs should be easier to satisfy than with the mass-production grocery model. Examples include custom Christmas cookies, athlete-specific nutrient bars, and attractive food shapes for picky young eaters.

Clothing

There are many facets to the apparel industry and 3D printing is poised to reinvent several of them. 3D body scanning to determine either conformance with ready-to-wear clothing or to generate custom fitted shoes, clothing, and accessories shows great promise. 3D printing of plastic mannequins (representing actual people in a new global market, for example) facilitates clothing design. Additive manufacturing of orthotics and footwear insoles has the potential to make mass produced shoes much more customizable: if the footbed fits precisely, the base shoe model may feel comfortable. Adidas is launching a mass-produced running shoe with an uncustomized 3D printed midsole (at $300 per pair) and will no doubt be closely watched by its competitors in the multibillion-dollar global athletic-wear industry. Buttons, zippers, and belts could be made in a variety of designs out of a wide variety of materials. “Smart” clothing can be manufactured with sensors and other circuitry embedded in the garment. All of these developments are underway.

The most critical component in most garments, however, is fabric, and it is not yet possible to additively fabricate comfortably draping cloth out of most polymers; one observer described the current designs as looking and feeling “a lot like chain mail.”17 Once again, replicating an existing fabrication technique with additive manufacturing proves to be a poor fit: the textile industry’s move to automation is hundreds of years old and has not materially changed, even when synthetic threads were introduced after World War II. The more relevant question is rather, what can additive technologies, particularly of the multi-material variety, do that could never be done with looms and sewing machines?

We have already seen that protective equipment that fits perfectly is an easy win. Whether for sports, the military, or civilian first responders, helmets, masks, and protective armor are a natural fit for the technology. The architect Neri Oxman at the MIT Media Lab has used 3D printing for everything from microfluidics to buildings; her Anthozoa project brought a 3D-printed dress utilizing new technology from Stratasys to Paris Fashion Week in 2013. In another of her experiments, when those multiple materials include biofilms, the garment (made in conjunction with New Balance and the Media Lab’s Tangible Media Group) can respond to the wearer by, for example, opening vents to evaporate sweat.18 Finally, Ministry of Supply is an MIT spinout exploring the frontiers of performance fabrics, some of which utilize 3D printing techniques, in professional attire rather than athletic wear.19

Machines, Macro and Micro

3D printing can be used, mostly in laboratory settings, at an extremely small scale to build microelectronics, microfluidic devices for molecular biology research (including DNA analysis), and enzymes. Because of the need for biomimetic materials to react to their surroundings and evolve over time, a new concept is gaining traction: 4D printing, with the fourth dimension being time.20 Advances are being made in which biomaterials (hydrogels) are programmed to change shape in water, for example, mimicking the behavior of cell walls in plants.21 Such microscopic-scale manipulation opens many new pathways for research and eventual commercialization in tissue engineering, life science research, and so-called soft robotics.

A related set of innovations relates to so-called assembly-free parts, that is, 3D-printed parts with hinges or valves built during additive layering. A widely cited article from 2004 explains how researchers used stereolithography (a 3D Systems SLA machine) to print a robotic hand (palm and finger) with voids into which electrical components were then attached. All movement in the device was achieved by joints that were printed without any further assembly.22 Research continues into the various options for printing movable parts at both large and small scales.

More recently, researchers have suspended nanoparticles of iron oxide (the main component of magnetic computer media) in curable polymer “inks” that allow for the printing of functional materials with variable electrical, magnetic, and mechanical properties. Such research aligns with other work to use 3D printing to create circuit elements such as resistors, capacitors, and inductors;23 these can often be printed on flexible media. Nano Dimension has recently introduced a 3D printer for circuit board prototyping that should also be able to evolve to certain production tasks.24 The prospect of increasingly “smart” materials that also embed actuator capability (either biological or electromechanical) is increasingly practical, leading to the development of new types of robotic—sense–think–act—implementations. Highly precise machines from nScrypt are being used in a variety of applications, ranging from human cells to electronic resistors and adhesives, suggesting that these robots could emerge at the juncture of life science, computer hardware, materials science, and other disparate disciplines.25

Design Technology and Skill

The range of research and innovation related to 3D printing in its broadest definition is vast. From the atomic level of both living and inorganic matter all the way up to jumbo jets and architectural structures, the hows, whats, and whens of making are being redefined. Inevitably, the “who” matters a lot, too, at the skills level but also within existing capital, legal, and organizational structures: makers of almost anything can be located almost anywhere. This changes the existing rules for everything from arms regulation to building codes, and so far the technology’s capabilities are outrunning ways to think about it.

As the shapes and configurations that can be made help inform the products that should be made, designers will discard one set of constraints for another. This transition takes time and it places surprising stresses on many other parts of the organization. In addition, the ability to design around the limitations of additive manufacturing will emerge against the backdrop of experience, some of it no doubt hard-won. Finally, much expertise will be encoded in software, whether in generative design at the front end of the life cycle or in machine control systems that will take guesswork out of the management of even complex metal builds.

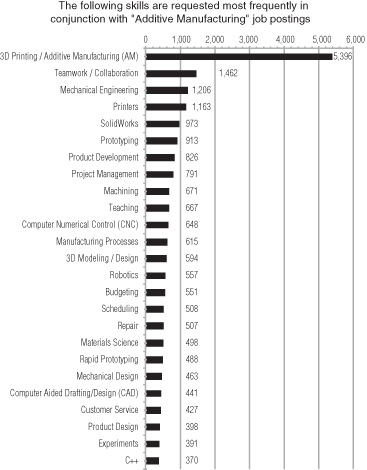

As good as that software can become, however, additive manufacturing is facing a massive skills shortage. Crossing two disciplines is hard enough: to become expert in metal printing within a factory environment requires knowledge across a half-dozen academic disciplines plus knowledge of accounting, management, regulation, HR, and other business-related domains. For all the intellectual bootstrapping that tenacious engineers and machine operators have achieved, schools and universities will have to do better. Figure 7.1 shows one view of the skills shortage as of 2018.

Scaling up the Technology

Regardless of domain, 3D printing needs to advance along several vectors for the technology to see higher and better uses:

- 1. Materials science needs to generate new gels, powders, and slurries. That is, the capabilities of 3D printing are substantially limited by the previous generations of building materials. This is as true of nutrient proteins as it is of aircraft metals, and as true of mammalian cells as it is of materials for clothing and footwear. Composites are but one field that will improve.

- 2. Multi-material printing must enter the mainstream, whether for tissue, clothing, or food, to become practical. In industrial scenarios, expect to see many more functionally graded materials.

Figure 7.1 Skills shortages reported by Burning Glass Technologies as of 2018.

- 3. Capital investment is limited in some cases by mass production business models and thus financial modeling assumptions. As we saw at GE, even a massive success had to be hidden from finance and accounting because it didn’t fit existing expectations. For mass customization at enterprise scale, everything from material procurement to customer service must be redesigned. The resulting period of upheaval, trial and error, and new winners and losers (both inside the company and in an existing industry) will be disorienting.

- 4. Talent is scarce, both inside the educational pipeline and inside the world’s factories: on shop floors, in labs, in new-product development, and in production engineering.

- 5. 3D printers have to improve in their build volume, in their predictability, in their reliability, and in their flexibility. For some manufacturers, this might require altering the “black box” business model of closed hardware and/or resupply.

- 6. Enterprise information systems are not premised on mass customization, on production processes that can generate gigabytes of data in a few hours, or on lot sizes of one.

- 7. Entire ecosystems will be reset. Parts consolidation can mean a substantial reduction in the supplier base. The location of final or intermediate production is freed from many geographic and historical constraints. Testing, validation, and regulation of this new class of technologies may well be performed by new entities, or old entities with dramatically new remits. The sales channel for mass customization may be entirely new, with all that implies.

All of these developments are in process, some happening faster than others. With so many wild cards, predicting anything with certainty is unwise (as the industry learned through hard experience after 2014’s stock market peaks). In addition, because 3D printing is in its essence decentralized, keeping abreast of any one domain gets more difficult every year. One thing is sure: the demand for what additive manufacturing can create will not be shrinking any time soon.