2

Project Planning and Contracting

May through December 1961

By the end of April 1961, NASA’s three top executives—James Webb, Hugh Dryden, and Robert Seamans—knew that Apollo would soon become an approved project aimed at landing men on the moon. The agency’s engineers had done some thinking but little planning for that particular step, which they viewed only as a possible objective for the 1970s. When President Kennedy’s challenge in late May abruptly made moon landing a goal for the 1960s, adjustment within NASA to meet the new charge was not an easy task. Although transfers from other agencies and a few recently created offices had resulted in a relatively strong and versatile organization, in May 1961-and for months thereafter, for that matter-NASA was not really prepared to direct an Apollo program designed to fly its spacecraft around the moon. New and special facilities would be needed and the aerospace industry would have to be marshaled to develop vehicles not easily adapted to production lines, even though no one had yet decided just what Apollo’s component parts should be or what they should look like.

Despite all the committee and task group work done since NASA opened for business, not one of the vehicles, from the ground up, was sufficiently defined for an industrial contractor to develop and build. Because of the time limitation imposed by Kennedy, Administrator Webb asked Associate Administrator Seamans to get the pieces of Apollo that were nearly defined under contract. With no appropriate project office to implement this order, ad hoc committees and task groups still had to do the work. For the remainder of 1961, until NASA could recruit enough skilled people and organize them to carry out Apollo’s mammoth assignment, Seamans would continue to operate in this fashion.

COMMITTEES AT WORK

To begin upgrading NASA’s tentative planning from circumlunar flights to lunar landing missions, Seamans on 2 May set up an ad hoc group led by William A. Fleming of Headquarters.n The task was reminiscent of that given to George Low’s committee earlier in the year, but the Fleming team was to place more emphasis on the landing stage than Low’s group had. Since Seamans had given him little time to complete the study, Fleming settled on direct flight as the way to reach the moon. For the final approach to landing, his group concluded, a stage weighing 43 000 kilograms would be needed, with 85 percent of that being the fuel load.1

Once Fleming had selected the direct route, Seamans realized that he needed more options, so he formed a second committee, headed by Bruce Lundin from the Lewis Research Center, to study the choices. The eight-man committee o looked at rendezvous, mostly earth-orbit rendezvous, in which two or more vehicles would link up near the home planet and journey to the moon as a unit, and lunar-orbit rendezvous, which required a single vehicle to fly to the moon, orbit that body while one of its sections landed on the surface and returned, and then travel back to earth.

Lundin’s group believed that rendezvous offered two attractions: deciding on launch vehicle size—Nova or several proposed versions of an advanced Saturn—would not restrict future growth; and rendezvous would permit lunar landings to be made with smaller boosters, using rocket engines already under development. The Lundin team favored earth-orbit rendezvous, with two or three of the advanced Saturns. They considered it safer, although they conceded that lunar-orbit rendezvous would require less propellant and, in theory, could be done with a single Saturn C-3, one of the versions under consideration.2

NASA officials gathered on 10 June 1961 to hear what both Fleming and Lundin had to report. Although the audience asked a few questions after each presentation, it was obvious that neither commitee had made real progress. They did root out some difficulties that lay ahead and present some suggestions on how a lunar landing might be made. But, actually, little could be done at the time, and they knew it, since NASA did not know how much money Congress intended to appropriate.3

SPACECRAFT DEVELOPMENT DECISION

This sudden preoccupation in NASA’s highest echelons with the mode of flying to the moon put the spacecraft development planners in a quandary. Space Task Group engineers had the contractors’ feasibility study reports in hand and had used them and their own studies in drafting specifications for a spacecraft hardware contract. The major question was whether they would have to wait until all the pieces in the Apollo stack were defined before awarding the contract. Robert Gilruth went to Washington on 2 June to find out.

During a meeting with Abe Silverstein and his Space Flight Programs staff, a consensus developed on the six areas in which major contracts would be needed: (1) launch vehicles; (2) the spacecraft command center, which would double as the return vehicle; (3) the propulsion module, with extra duty as the lunar takeoff section; (4) the lunar landing stage, which would be both a braking rocket and a lunar launch pad; (5) the communications and tracking network; and (6) the earth launch facilities.4 To get these projects under way, Silverstein said, Seamans had approved letting the spacecraft development contract.5

Gilruth took this good news back to Virginia, but he and his men still had a question. What would industry be bidding on? The Space Task Group favored a modified Mercury capsule (a bell shape extended into a conical pyramid) and had worked on that design. Its chief competitor was a lifting-body design, with trims and flaps, championed by Alfred Eggers and his colleagues at the Ames Research Center.

Max Faget, leading spacecraft designer at the Space Task Group, later said that one of his major objectives was to make the Apollo command module big enough; they were just finding out all the problems caused by a too-small Mercury capsule. He set the diameter at the base of the Apollo craft at 4.3 meters, as opposed to Mercury’s 1.8 meters. When Faget asked Wernher von Braun, at Marshall, to fly some models of the craft, there was a problem. Since early Saturn vehicles did not have a payload, Marshall had used spare Jupiter missile nose cones on the first test flights. Douglas Aircraft Company had resized the Saturn’s S-IV stage to fit the Jupiter body, which was smaller than the Apollo command module. Marshall contended that enlarging the S-IV would cost millions of dollars, and Space Task Group did not argue the point. Until this time, the design concept for the Apollo heatshield had called for a sharp rim, as in Mercury, which increased the total drag and gave more lifting capability. Rather than decrease crease the interior volume, Faget’s design team simply rounded the edge to match the S-IV.

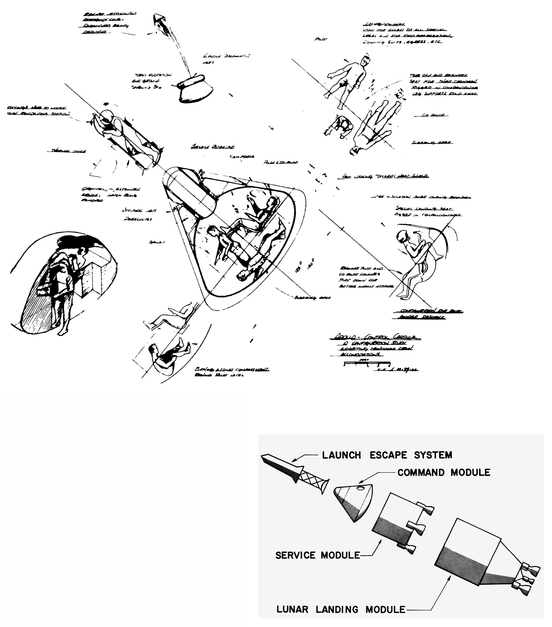

Space Task Group engineers sketched crew positions in the command module for an October 1960 configuration study of the “Apollo-Control Capsule.” The command module with airlock retracted is at the center, the bathing compartment sketched below it. At left center, a crewman in the extended airlock removes the hatch. At upper and lower right, legs of the third takeoff and reentry seat, rigged in the companionway, are folded away in flight and moved back into place for landing. At upper left, parachutes begin to deploy after rocket jettison for reentry. Spacecraft modules in the drawing at right were identified in the Space Task Group’s request for proposals from contractors for developing and producing the command module.

The command module’s rounded edges simplified another design decision. Faget wanted to use beryllium shingles on the afterbody, as he had in Mercury, to take care of reentry heating, but Langley engineers believed the spaceship would be traveling too fast for shingles to handle the heat. The design group decided to wrap an ablative heatshield around the whole command module. This wraparound shield had another advantage. One of the big questions about outer space was radiation exposure. James Van Allen, discoverer of the radiation belts surrounding the earth and named for him, had predicted exposure would be severe. Encapsulating the space vehicle with ablative material as an additional guard against radiation, even though it entailed a large weight penalty, was a big selling point for the heatshield.6

Space Task Group engineers were satisfied with their design, although none too sure that anyone else in NASA liked it. George Low, however, found merit in both the blunt- and lifting-body configurations and suggested to Silverstein that two prime spacecraft contractors be hired, each to work from a different set of specifications.7

Space Task Group engineers wanted no part of this dual approach. In early July, Caldwell Johnson summarized for Gilruth their reasons for insisting on the blunt-body shape. Johnson emphasized mainly the operational advantages and the experience gained from Mercury that would accrue to Apollo. He confined his discussion to the trip to the moon and back, making no mention of landing the craft on its surface.8 Those most concerned with the command module’s basic configuration were still looking at the problems connected with circumlunar flight: a vehicle that could fly around the moon and back to earth, sustain three men for two weeks, and reenter the atmosphere at much higher speeds than from earth orbit.

Gilruth’s Apollo planners pressed on, drawing up a hardware development contract for their chosen craft. This vehicle could be adapted for a lunar landing later, but that problem was shunted to the background for the time being. Jack Heberlig, a member of Faget’s design team for the Mercury capsule, drafted the hardware guidelines for the Apollo command center spacecraft. While Heberlig’s procurement plan was in final review at NASA Headquarters the first week in July, Robert Piland and John Disher were setting up a technical conference to apprise potential contractors of NASA’s requirements. Invitations were sent to 1200 representatives from industry and 160 from government agencies.9

From 18 to 20 July 1961, more than 1000 persons (representing 300 companies, the White House staff, Congress, and other governmental departments) attended a NASA-Industry Apollo Technical Conference in Washington. The first day, NASA engineers talked about space vehicle design, mission profiles, and navigation, guidance, and control. On the second day, the attendees heard papers on space environment, entry heating and thermal protection, and onboard systems. During these sessions, the Space Task Group speakers pushed their blunt-body shape.10

Gilruth’s men never doubted that the keystone to Apollo was the spacecraft itself. As they waited for higher authority to act, they continued to plan with Marshall a series of tests using a blunt-body capsule.11 By the end of July, Administrator Webb had approved the procurement plan, and Glenn Bailey, Gilruth’s contracting officer, had mailed out the requests for proposals.12

While waiting for the companies to respond, NASA awarded its first hardware contract for Apollo. After spending six months on a feasibility study, the Instrumentation Laboratory of the Massachusetts Institute of Technology (MIT) received a contract on 9 August to develop the guidance and navigation system.13

ASTRONAVIGATION-THE FIRST APOLLO CONTRACT

The guidance and navigation (or “G&N”) system was a central concern in spacecraft design. To get to the moon and back to earth was a monumental task. NASA and its predecessor, NACA, had little experience in this field; but neither had anyone else. When NASA opened for business in 1958, more work had been done in celestial mechanics for trips to Mars than to the moon. MIT, in fact, had an Air Force contract that included research on interplanetary guidance and navigation. Out of this came a relatively extensive study for an unmanned probe to pass by and photograph Mars. By the time it was finished, however, this kind of role in space belonged exclusively to NASA.

With the blessing of the Air Force, MIT engineers took the results of their study to NASA Headquarters on 15 September 1959. Their timing was bad; only two days earlier the Russians had crash-landed Lunik II on the moon (the first man-made object to reach that body) and had impressed the American space community by having built a launch vehicle powerful enough and a guidance system sophisticated enough to get it there. In this atmosphere, the MIT presentation netted only a small study contract. And when feasibility contracts for the Apollo spacecraft were awarded in November 1960, how to get the crew to the moon and back was still a question.14

Like other phases of Apollo, the G&N system drew on the past. The foundation had been laid by Kepler, Newton, and Laplace in theoretical celestial mechanics and had been advanced as a practical science by such devices as Foucault’s gyroscope (an instrument Sperry later made almost synonymous with his name). These and other achievements in aerial navigation and space guidance and control were not sufficient for a trip to the moon, although some engineers in the Apollo program did use the early classics in estimating fuel and developing computerized trajectory equations.15

To a great extent, lunar navigation development relied on such newcomers in the field as computers and a worldwide tracking and communications network. By the 1960s, the electronic computer had become an integral tool of science, technology, and business. Without its capacities for memorizing, calculating, comparing, and displaying astronomical amounts of data, the lunar landing program would have been impossible. Worldwide tracking and communications networks evolved out of meteorology, astronomy, telemetry, missilery, and automatic spacecraft experience into manned space flight planning and operations. Most of the credit for telecommunications work at NASA operations belongs to the Goddard center in Greenbelt, Maryland. Myriads of data collected from unmanned satellites were processed daily in its computer banks and transmitted to such agencies as the Weather Bureau and the Geological Survey. Guidance and control technology shared the same evolutionary roots as tracking and communications, but it also drew on advances in avionics, gyroscopics, maritime and aerial navigation, antisubmarine and antiaircraft fire control systems, and cybernetics.16

MIT was the obvious place for NASA to look for help in Apollo’s astronavigation problems. For many years, Charles Stark Draper, Director of MIT’s Instrumentation Laboratory, had been recognized as the man most directly responsible for the application of automatic pilots and inertial guidance systems.17 Achievements in such second-generation intercontinental ballistic missiles as the Polaris made Draper’s laboratory the logical sole-source choice for the Apollo system.

Draper appointed Milton B. Trageser as project manager and David G. Hoag as technical director. These new Apollo leaders consulted with guidance theoreticians at Ames Research Center,p18 before starting on the contract. Reassured by these talks and by the in-house MIT work of J. H. Lanning in 1958 on preliminary designs for a Mars mission and of J. S. Miller and Richard H. Battin in 1960 on studies of applied mathematics, Draper’s laboratory was convinced that it had no near rivals in the field.19

When the MIT Instrumentation Laboratory signed a letter contract for Apollo on 10 August 1961, NASA officials assumed they had placed this complicated task in good hands. From the outset, there was a clear under-standing that MIT would do only the technical design and prototype development; when the manufacturing phase commenced, industrial contractors would take over. NASA monitors anticipated some problems in employing separate firms to make the guidance, control, and navigation equipment—but that worry could wait. In the meantime, Draper’s men were not completely sure that NASA people really understood the differences between the three terms.20

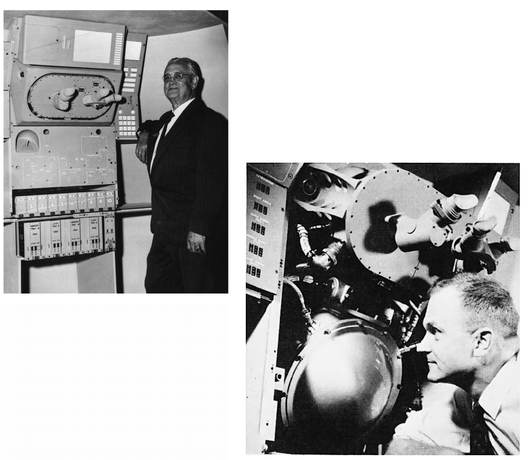

Navigating to the moon: MIT Instrumentation Laboratory Director C. Stark Draper inspects a mockup of the Apollo guidance and control system in the September 1963 photo above. David G. Hoag, technical design director at the laboratory, examines the inertial measuring unit that would measure changes in Apollo spacecraft velocity when propulsion systems were fired.

“Guidance,” to MIT, meant directing the movement of a craft with particular reference to a selected path or trajectory. “Navigation,” in space as on the seas, referred to determining present position, as accurately as possible, in relation to a future destination. “Control,” specifically in astronautics, was the directing of a craft’s movements with relation to its attitude (yaw, pitch, and roll) or velocity (speed and direction, a vector quantity). MIT’s expertise centered on the first two of these factors; NASA engineers (particularly those who had worked with earth-orbital flight) emphasized the first and third.21

Still, NASA’s Apollo engineers were encouraged by what they saw of the laboratory’s work and were assured by MIT that getting to the moon and back was simpler than guiding an antiballistic missile or circumnavigating the earth under water in a nuclear submarine.q

NASA officials had some doubts. In June 1961, Dryden requested Draper to come to Washington to discuss G&N problems with Webb. Webb asked if MIT could really get a man to the moon and back safely. Draper replied that he would be willing to make the voyage himself, if Webb would guarantee the propulsion system. Over the next few months, Draper continued to hear mutterings of disbelief. To display his confidence in his team, he wrote Seamans, saying:

I would like to volunteer for service as a crew member on the Apollo mission to the moon.... We at the Instrumentation Laboratory are going full throttle on the Apollo guidance work, and I am sure that our endeavors will lead to success.... let me know what application blanks I should fill out. ...22

Draper’s offer to serve as an astronaut caused a ripple of laughter throughout NASA Headquarters, but only for a moment. There were other problems to resolve. The basic rocket booster for the moon mission was still in question, and NASA’s administrators were in the process of selecting a spacecraft manufacturer.

CONTRACTING FOR THE COMMAND MODULE

The attention devoted to guidance and navigation did not halt preparations for a contract on the command module. Data from the feasibility studies and from Space Task Group’s in-house work were used to prepare a statement of work, detailing the contractor’s responsibilities and the scope of his obligations in designing, building, and testing the spacecraft.23

Project Apollo would have three phases: earth-orbital, circumlunar and lunar-orbital, and lunar landing. The prime spacecraft contractor would develop and build the command module, service propulsion module, adapter (to fit the spacecraft to a space laboratory for earth-orbital flights and to the lunar landing propulsion section for lunar missions), and ground support equipment. Although the prime spacecraft contractor would not build the lunar landing module, he would integrate that system into the com-plete spacecraft stack and ensure compatibility of the spacecraft with the launch vehicle.24

Just before leaving NASA early in 1961, Administrator Keith Glennan had revised the procedures for the establishment and operation of source evaluation boards. For any NASA contract expected to exceed $1 million, all proposals would have to be evaluated by such a board; for any contract that might cost over $5 million, all proposals would be judged by a special source evaluation board appointed by the Associate Administrator. The board’s findings would then be passed to the Administrator himself for final selection. On 28 July 1961, Seamans approved the overall plan for Apollo spacecraft procurement, appointed the source evaluation board members, and delegated authority for establishing assessment teams to assist the board. Then the Space Task Group issued its request for proposal to 14 aerospace companies.r25

Working arrangements for the development contract followed very closely those evolved for the feasibility studies. The deadline for the submission of proposals was set for 9 October 1961, giving prospective bidders more than ten weeks to work out their proposals. A conference was held on 14 August so NASA could explain the guidelines for the contract in detail. Almost 400 questions were asked at the meeting and answered; the answers were recorded and distributed. Seamans then appointed an 11-man Source Evaluation Board, headed by Faget and including one nonvoting member from Headquarters (James T. Koppenhaver, a reliability expert). The board consisted of six voting members from the Space Task Group (Robert Piland, Wesley Hjornevik, Kenneth S. Kleinknecht, Charles W. Mathews, James A. Chamberlin, and Dave W. Lang), one from Marshall (Oswald H. Lange), and two from Headquarters (George Low and Albert A. Clagett). Faget’s board directed the technical assessment teams and a business subcommittee to work out and submit a numerical scoring system for comparative analyses of the proposals.26

On 9 October 1961, five hopeful giants s of the aerospace industry brought their proposals to the Chamberlain Hotel, Old Point Comfort, Virginia. During the first two days of a three-day meeting, these documents were distributed among the members of the NASA assessment teams. The massive technical proposals, separated from those on business management and cost, were scrutinized and evaluated by more than a hundred specialists. Each group of bidders was then called in on the third day to make an oral presentation and answer questions. Gilruth persistently asked the proposal leaders, “What single problem do your people identify as the most difficult task in getting man to the moon?” 27 The industrialists’ answers to this question generally stressed the balance between performance, cost, and schedule controls for so complex an undertaking.

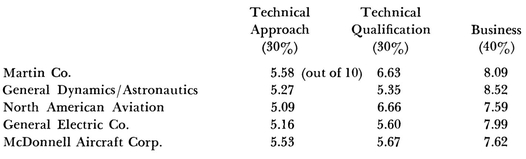

Several weeks of intensive study followed, as the assessment teams made their rankings of the proposals. Submitted on 24 November 1961, the report of the Source Evaluation Board summarized the scoring by the assessors and evaluators:

SEB Ratings of Apollo Spacecraft Proposals by Major Area

This step led to a summary rating, with Martin scoring 6.9, General Dynamics tied with North American at 6.6, and General Electric matched with McDonnell at 6.4 for final grades. The board was unequivocal in its final recommendation:

The Martin Company is considered the outstanding source for the Apollo prime contractor. Martin not only rated first in Technical Approach, a very close second in Technical Qualification, and second in Business Management, but also stood up well under further scrutiny of the board.

If Martin were not selected, however, the board suggested North American as the most desirable alternative.

North American Aviation [NAA] ... rated highest of all proposers in the major area of Technical Qualifications. North American’s pertinent experience consisting of the X-15, Navajo, and Hound Dog coupled with an outstanding performance in the development of manned aircraft (F-100 and F-86) resulted in it[s] being the highest rated in this area. The lead personnel proposed showed a strong background in development projects and were judged to be the best of any proposed. Like Martin, NAA proposed a project managed by a single prime contractor with subsystems obtained by subcontracting, which also had the good features described for the Martin proposal. Their project organization, however, did not enjoy quite as strong a position within the corporate structure as Martin’s did. The high Technical Qualification rating resulting from these features of the proposal was therefore high enough to give North American a rating of second in the total Technical Evaluation although its detailed Technical Approach was assessed as the weakest submitted. This relative weakness might be attributed to the advantage of the McDonnell Aircraft Corporation’s Mercury experience, and the other three proposers’ experience on the Apollo study contracts. The Source Evaluation Board is convinced that NAA is well qualified to carry out the assignment of Apollo prime contractor and that the shortcomings in its proposal could be rectified through further design effort on their part. North American submitted a low cost estimate which, however, contained a number of discrepancies. North American’s cost history was evaluated as the best.28

Word leaked out prematurely to Martin that it had scored highest in the evaluations. After two years of planning and five weeks of waiting, the Martin employees were informed over the public address system on 27 November 1961 that they had won the contest to build the moonship. The next day they learned the truth.29

North American won the spacecraft development sweepstakes. Webb, Dryden, and Seamans apparently chose the company with the longest record of close association with NACA-NASA and the most straightforward advance into space flight. The decision would have to be defended before Congress and would be the cause of some anguish later.30 When it was announced on 28 November, shouts of joy rang through the plant at Downey, California, as John W. Paup broke the news over the “squawk box.” 31

During December 1961, Space Task Group (renamed Manned Spacecraft Center on 1 November) and North American program directors and engineers met in Williamsburg, Virginia, to lay the technical groundwork for the spacecraft development program and begin contract negotiations.32 The spacecraft portion of Apollo had entered the hardware phase, although the launch vehicle (or vehicles) and the lunar lander had not.

INFLUENCES ON BOOSTER DETERMINATION

Concurrently with the agreement that Gilruth should get started on the spacecraft development contract, Associate Administrator Seamans realized that it was time to decide what the rest of the Apollo stack should comprise. The method chosen for the lunar trip—rendezvous or direct ascent—would affect Apollo’s costs and schedules, as well as the launch vehicle configuration.

A launch vehicle to support the moon landing was a big question mark when the President issued his challenge in May 1961. The Space Task Group wanted to get its opinions on the record—not really sure how big a vehicle would be needed but rather hoping that NASA would develop the Nova. Marshall wanted to build a big liquid-fueled rocket but was a little chary about tackling a vehicle the size of Nova. One aspect that caused the Huntsville center to hold back was the high cost projected for the F-1 engines. When he learned of Huntsville’s misgivings, Max Faget suggested that solid-fueled rockets be used for the first stage.

Faget thought the first stage should consist of four solid-fueled engines, 6.6 meters in diameter; these could certainly accomplish whatever mission was required of either the Saturn or Nova, whichever was chosen, at a reasonable cost. It made good sense, he said, to use cheap solid fuels for expendable rockets and more expensive liquid fuels for reusable engines. “We called the individual solid rocket ‘the Tiger’ because we figured it would be a noisy animal and would roar like a tiger,” Faget remembered. But he and his group could not sell their idea. Liquids were preferred by both Headquarters and Marshall, who insisted that the solids were too heavy to move from the casting pit to the launch pad. They also argued, he said, that solids had poor burning characteristics and were unstable. So the launch vehicle question dragged on, although pressure to make some sort of decision did not lessen.33

After the Fleming and Lundin Committee study reports had been distributed, Seamans met with several Headquarters program directors to discuss whether the advanced Saturn, called the C-3, recommended by Lundin’s team could make the voyage to the moon if the earth-orbital rendezvous approach were chosen. Silverstein warned that the vehicle’s upper stages were simply not well enough defined as yet.34 Seamans agreed. On 20 June 1961, he asked Colonel Donald H. Heaton to head a task forcet to study the C-3 and its possible employment in a manned lunar landing mission using rendezvous techniques.35

Heaton’s group followed Fleming’s lead in narrowing the scope of its investigations to a single mode—in this case, earth-orbital rendezvous—as the way to go. Most of the members agreed that this mode offered the earliest chance for a landing. Either the C-3 or its next larger version, a C-4, could be used. But the team urged that NASA begin work on the C-4, because it “should offer a higher probability of an earlier successful manned lunar landing than the C-3.” Moreover, a rendezvous capability would enable the C-4 to cope with future payload increases that the direct-ascent, Nova-class booster, with its fixed thrust, would be unable to handle.36

On 22 June 1961, Webb and Dryden met with several of their top lieutenants to see what useful items could be gleaned from the reports of all these committees for charting Apollo’s strategy. Abraham Hyatt, the new chief of Plans and Programs, criticized any plan that required development of two launch vehicles, one for circumlunar missions and another for direct flight. Hyatt suggested that NASA either build a huge launch vehicle with as many as eight F-1 engines in the first stage for both circumlunar flight and lunar landing or cluster half that number of these engines in a somewhat smaller vehicle and use rendezvous techniques.37

This meeting did produce several significant program decisions. Most important was the order for Marshall to stop work on the C-2, begin preliminary design on the C-3, and continue studies of a much larger vehicle for lunar landing missions. (By this time, what constituted a Saturn, in any of its versions, or a Nova was becoming hard to understand. For some clarification of the confusion, see the accompanying list.)38

Early in July, Seamans appointed a Lunar Landing Steering Committee, u with himself as chairman, to meet every Monday afternoon until an impending Headquarters reorganization was completed. During its three meetings in July, the committee considered the facilities and organization needed to manage Apollo and then turned its attention to launch vehicles. But nothing tangible emerged from these discussions, either, certainly no hardbound decision on a launch vehicle for Apollo.39

HELP FROM THE DEPARTMENT OF DEFENSE

Top-flight officials both in NASA and the Kennedy administration, when they recommended a moon landing program as the focus of America’s space effort, saw Apollo as a central element of a broad national space program. The United States needed not only to develop more powerful boosters, to match Russia’s, but to plan that development with a minimum of unnecessary duplication among agencies.40

Early in July 1961, Seamans and John H. Rubel, Assistant Secretary of Defense and Deputy Director of Defense Research and Engineering, agreed on the need for joint NASA-Defense planning. Seamans informed Webb that the two agencies would try to determine what boosters would best meet the requirements of both the Department of Defense (DoD) and NASA. The civilian agency’s central concern, of course, was a launch vehicle for Apollo.41

Apollo Launch Vehicles

Saturn C-1 (renamed Saturn I).v Configuration: S—I booster (eight H—1 engines, clustered, with 6.7-million-newton [1.5-million-pound] combined thrust), S—IV second stage (four engines using liquid-hydrogen and liquid-oxygen propellants, with 355 800-newton [80000-pound] total thrust), and S—V third stage (two engines like those in the S—IV stage, with 177 900-newton [40000-pound] total). In March 1961, NASA approved a change in the S—IV stage to six engines that, though less powerful individually, delivered 400 300 newtons (90000-pound thrust) collectively. On 1 June 1961, the S—V was dropped from the configuration.

Saturn C—1B (renamed Saturn IB).w Configuration: S—IB booster (eight clustered uprated H—1 engines with 7.1-million-newton [1.6-million-pound] total thrust) and S—IVB second stage (one J—2 engine with 889600 newtons [200 000 pounds]). On 11 July 1962, NASA announced that the C—1B would launch unmanned and manned Apollo spacecraft into earth orbit.

Saturn C—2. Four-stage configuration: S—I booster, S—II second stage (not defined), S—IV third stage, and S—V fourth stage.

Three-stage configuration: S—I booster, S—II second stage (not defined), and S—IV third stage. Plans for the C—2 were canceled in June 1961 in favor of the proposed C—3.

Saturn C—3. Configuration: booster stage (two F—1 engines with a combined thrust of 13.3 million newtons [3 million pounds]), second stage (four J—2 engines with a 3.6-million-newton total [800000 pounds]), and S—IV third stage. Plans for the C—3 were canceled for a more powerful launch vehicle.

Saturn C—4. Configuration: booster stage (four clustered F—1 engines with 26.7-million-newton [6-million-poundl combined thrust) and a second stage (four J—2 engines with combined thrust of 3.6 million newtons [800 000 pounds]). The C—4 was briefly considered but rejected for the C—5.

Saturn C—5 (renamed Saturn V).v Configuration: S—IC booster (five F—1 engines, clustered, with total thrust of 33.4 million newtons [7.5 million pounds]), S—II second stage (five J—2 engines with total of 4.5 million newtons [1 million pounds]), and S—IVB third stage.

Saturn C—8. Configuration: First stage (eight F—1 engines, clustered, with a combined 53.4 million newtons [12-million-pound thrust]), second stage (eight J—2 engines with total of 7.1 million newtons [1.6 million pounds]), and third stage (one J—2 engine with 889600 newtons [200000 pounds]).

Nova. Configuration: several proposed, all using F—1 engines in the first stage. One typical configuration consisted of a first stage (eight F—1 engines, clustered, with 53.4-million-newton [12-million-pound] total thrust), a second stage (four liquid-hydrogen M—1 engines with combined thrust of 21.4 million newtons [4.8 million pounds]), and a third stage (one J—2 engine with 889 600 newtons [200 000 pounds]). Nuclear upper stages were also proposed.

With the approval of both Defense Secretary Robert S. McNamara and Administrator Webb,42 Rubel and Seamans set up a DoD-NASA Large Launch Vehicle Planning Group on 20 July. Although Nicholas Golovin, an applied mathematician and Seamans’ Technical Assistant, shared the chair with Lawrence Kavanau, a missile expert from the Defense Department, the group soon became known as the Golovin Committee.v

This committee, like all the others, found that, for Apollo, vehicle selection and mode were inseparable. At first the planners considered only direct ascent and earth-orbital rendezvous, but they soon broadened their study to include other kinds of rendezvous.43 When it became apparent that the committee intended to delve deeply into the mode issue, Harvey Hall (of NASA’s Office of Launch Vehicle Programs) asked that Marshall, Langley, and the Jet Propulsion Laboratory each study one particular kind of rendezvous—earth-orbit, lunar-orbit, or lunar-surface—and prepare a report for the Golovin group. Hall’s own office would study direct ascent.44

Worried that this latest in the series of Headquarters committees established to select a launch vehicle for Apollo would also get bogged down in the mode issue, Gilruth wrote Golovin about the degree to which rendezvous had pervaded recent thinking. “I feel that it is highly desirable,” he said, “to develop a launch vehicle with sufficient performance and reliability to carry out the lunar landing mission using the direct approach. ... I am concerned that rendezvous schemes may be used as a crutch to achieve early planned dates for launch vehicle availability, and to avoid the difficulty of developing a reliable NOVA class launch vehicle.” 45

Just as Gilruth had feared, Golovin’s group did get mired in the mode issue, leaving the choice of an Apollo launch vehicle still unsettled. On 18 September, one committee member said the group preferred rendezvous rather than direct flight, because smaller vehicles would be available earlier than the large boosters. Preliminary conclusions indicated that the manned lunar landing might be made with the C-4 more safely than with the Nova. Moreover, the C-4 would be more useful to other NASA and Defense Department long-range needs.46

Golovin himself disagreed with the majority of his group, insisting that direct flight was the safest and best way to go. He and those of his team who shared his belief talked to Seamans and Rubel about solid-fueled versus liquid-fueled rocket engines for Nova, the concept of modules (or building blocks) to achieve a variety of launch vehicles, and an S-IVB stage, which could be powered by a single J-2 engine.

Seamans, observing that some kind of advanced Saturn seemed to be inevitable, asked Golovin how many F-l engines should be in the vehicle’s first stage. Golovin replied, “Four—anything [less] is a waste of time.” Golovin also recommended that the advanced Saturn be engineered so it could become most of the Nova as well.47

At the committee’s general sessions on 23 and 24 October, debates grew hotter over solid- versus liquid-fueled engines for the Nova, the size of the huge booster, and the merits of five rather than four F-I engines in the advanced Saturn’s first stage. Heinrich Weigand and Matthew Collins objected strongly to any assumption that rendezvous in space would be easy. Weigand contended that his fellow committeemen were underestimating the difficulty of rendezvous and docking. He wanted a Nova with large solid-fueled rocket engines in its first stage. Collins also urged that direct ascent be given first priority.

Cochairman Kavanau warned that “lunar orbit rendezvous or direct is the only way to beat the Russians,” adding that he believed the C-4 could do the job either way. Golovin countered that “competition with the Russians is a permanent thing.” He insisted that both orbital operations and the development of large boosters would have to be studied for at least two years before any mode choice was possible.

After listening to the cochairmen express opposing views, Collins asked bluntly: “Are we going to recommend rendezvous or direct?” Reminded that this was not in their charter—they were supposed to be selecting a launch vehicle to support either rendezvous or direct flight—the group returned to the arguments over four versus five engines for the advanced Saturn’s first stage and the Nova’s configuration.48

And there the issues lay. Once again nothing was settled, although the October sessions wound up the Golovin Committee meetings. The group’s greatest value had been as a forum for discussions on vehicle models and possible configurations for Apollo. The committee’s conclusions—or lack of them—reflected compromises and conflicting opinions. After three months’ intensive study of numerous vehicle combinations and mission approaches, the question of a launch vehicle for Apollo was still unresolved.49

On 16 November, Webb and McNamara reviewed the areas explored by Golovin’s group and made several policy decisions. They agreed to halt the development of large solid rocket motors (6.1 meters or larger) as a backup for the F-I liquid engine, although the Defense Department would “continue to carry out advanced state-of-the-art technical development in the solid field.” And they decided that the Saturn C-4 should be developed for the rendezvous approach to Apollo.50

CHOICE OF FACILITIES

While the launch vehicle was being debated by committee after committee, Administrator Webb was making decisions on the numbers, kinds, and locations of the special facilities and real estate needed to launch men to the moon. Within five months—from June to October 1961—four new installations, all in the Gulf Coast states, had been added to NASA’s far-flung domain.51

Although size of the launch vehicle for Apollo had still not been decided, everybody agreed it would be big, too big for the launch pads at the Cape. The first thing NASA needed was a more adequate spaceport. To fabricate and assemble the lower stages of whatever rocket was selected would require a huge manufacturing plant, preferably one already in existence. The agency would need additional land, separate from the spaceport but near the factory, to static-test the booster. Safety and noise considerations demanded an immense area that could contain not only the test stands but a buffer zone as well. And, finally, if Gilruth’s team was to manage all manned space flight projects, as it had been assigned to do in January 1961, there would have to be a site for spacecraft engineering and development facilities.

The monstrous size envisioned for the launch vehicle and the need for these installations to be accessible to each other brought an additional factor into play. Since the booster would have to be transported by water, the agency would need ice-free waterways for year-round operations. NASA planners looked, logically, at the Gulf Coast, which had a temperate climate and an intercoastal waterway system. Two of the five states, Florida and Alabama, already had Apollo-oriented centers, which led to the reasoning that the new facilities should be situated nearby.52

Kurt H. Debus, as leader of NASA’s launch operations (first for Wernher von Braun, then for all of the agency’s flights from Cape Canaveral, Florida), had long dreamed of building a spaceport. In July 1961, he and Major General Leighton I. Davis, Commander of the Air Force Missile Test Center at the Cape, endorsed a report on eight proposed sites. Led by Major Rocco A. Petrone, Colonel Leonard Shapiro, and Colonel Asa B. Gibbs, the Debus-Davis study group evaluated Cape Canaveral (offshore); Cape Canaveral (onshore—Merritt Island); Mayaguana (in the Bahama Islands); Cumberland Island (off the southeastern coast of Georgia); Brownsville, Texas; Christmas Island; Hawaii; and White Sands, New Mexico. Only White Sands and Merritt Island were economically competitive, flexible, and safe enough to be considered further.53 On 24 August, NASA announced that it had chosen Merritt Island and that it would buy 323 square kilometers of land for the new NASA launch center.

Debus had well-thought-out ideas for mobile launch operations facilities: the big boosters would be assembled (stacked vertically) and checked out under protective cover and then moved to the launch pad. He drew up plans for personnel buildup, construction contracts, and administrative autonomy. On 7 March 1962, when Marshall’s Launch Operations Directorate became NASA’s Launch Operations Center, Debus was ready. (After the assassination of the President in November 1963, the new installation would be renamed the John F. Kennedy Space Center.)54

In Huntsville, von Braun viewed the facilities for an accelerated booster development program in a different light. His 6000 employees were housed in part of the Army’s Redstone Arsenal, on the Tennessee River. Although it was adequate for engineering development and static-testing of smaller rockets, the Marshall center could not handle the immense vehicles planned for the lunar voyage. Von Braun would need land and facilities elsewhere, but with access to the navigable waters of the Tennessee Valley Authority. A survey of government-owned war surplus plants revealed one near St. Louis and another (named Michoud) near New Orleans that were suitable for building the huge boosters. But the Mississippi River around St. Louis often froze over during the winter months. So Michoud, with a mammoth building that contained 0.17 square kilometers under one roof as part of a 3.5-square-kilometer complex along the water’s edge, was selected on 7 September 1961.x Designed as a shipyard, it had become a cargo aircraft factory in 1943 and a tank engine plant during the Korean conflict. Here the Chrysler Corporation and The Boeing Company would construct the first stages of the Saturn C-1 and, later, of the C-3, C-4, or C-5 (or whatever model was chosen).55

Influencing the Michoud decision was the need for a test operations area nearby where acoustics could be managed and controlled, as well as logistics. Von Braun’s team had always worried about the noise and vibration generated during static-testing (and so had the citizens of Huntsville). As boosters became larger, they became louder, and their low-frequency resonances threatened all kinds of structural damage. Using statistics gathered from Saturn C-I decibel and vibration levels, acoustics experts estimated that the advanced Saturn would require a much larger buffer zone.

Marshall occupied only about 65 square kilometers of the more than 161-square-kilometer Redstone Arsenal, and the Army needed the rest of the land for its own rocket development and test programs. But even the whole expanse would not have been large enough for the superbooster. What NASA required was about 400 square kilometers. So large a purchase could be touchy if not properly handled. NASA officials worked through Congress, while site survey teams operated through the executive branch and administrative channels on a gargantuan land deal not far from Michoud. Lieutenant Colonel S. F. Berry, detailed to NASA’s Office of Launch Vehicle Programs from the Army Corps of Engineers, helped the selection committee narrow the test site choices.56

On 25 October 1961, NASA announced that it would purchase outright 54 square kilometers in southwest Mississippi and obtain easement rights over another 518 square kilometers in Mississippi and Louisiana for the big booster static-test site. Simultaneously, the Justice Department filed suits of condemnation, under the law of eminent domain, in the United States District Courts in both states. The area, largely flat pine forest, was on the Pearl River, only 56 kilometers northeast of Michoud. Well suited to NASA’s needs because of its deep-water access and low-density population, the Pearl River site was bought for about $18 million. While engineers at Marshall drew up specifications for static-test stands, canals, and storage areas, nearly 100 families, including the whole community of Gainsville, Mississippi, had to sell out and relocate. There were few complaints, as most of the residents were pleased at the prospect of new economic opportunities.57

Meanwhile, Ralph E. Ulmer and Paul G. Dembling, facilities and legal experts at NASA Headquarters, were saddled with most of the worries connected with the whirlwind activities of site scouting and selection for the manned space flight center. For example, Ames Research Center Associate Director John F. Parsons, who led the search for the spacecraft development center, reported to Dembling and Ulmer, and no one else, on the whereabouts of his team and its need for advice and support. Webb, Dryden, and Seamans referred all inquiries to Dembling, in an effort to avoid undue pressures from persons and groups trying to advance local prospects.58

On 13 and 14 September 1961, Webb and Dryden reviewed all the factors in selecting the site for manned space flight activities and decided to move that NASA function to Houston.y NASA announced the decision on 19 September 1961. Gilruth and his Space Task Group would soon have a home of their own to manage, a place in which to develop the payloads for future rockets. Webb called it “the command center for the manned lunar landing and follow-on manned space flight missions,” intimating that an integrated mission control center would also be located in the Houston area.

Most Space Task Group “Virginians”—both native and otherwise—were not very happy over the prospect of a transfer to Texas. But NASA’s opportunity to accept a politically arranged gift of four square kilometers of saltgrass pastureland was too good to refuse.z Of course, there were the usual charges of undue political influence, largely from the areas that had been turned down. The fact that there were Texans in powerful political positions—Vice President Johnson and Congressman Albert W. Thomas (chairman of the House Independent Offices Appropriations Committee)—provided much of the ammunition for a brief barrage of critical newsprint. (Later, when NASA spent more than $1 million to acquire an additional two square kilometers for better frontage, the accusations of “special interests” were revived.) But the Houston area met all the technical criteria for the new center. The seventh (soon to be sixth) largest city in the country, Houston had the utilities, transportation, and weather, as well as all the cultural, academic, industrial, and recreational specifications.59

Webb knew that facilities and construction were critical to success in landing on the moon during the 1960s. He called on the Army Corps of Engineers for assistance, rather than face the costly and time-consuming struggle of staffing a NASA office for this one-time task. The Corps would be invaluable in acquiring land at both Merritt Island and Michoud and in constructing new facilities at the Cape, at Michoud, and at Houston. Webb asked Lieutenant General W. K. Wilson, Chief of Engineers, to join him in this enterprise almost as a partner.60

Although the acquistion of real estate had demanded his close attention, the Administrator had never lost sight of the urgency of the Apollo launch vehicle and lunar landing mode questions. These needed to be resolved before the Corps of Engineers and NASA’s facilities engineers could do very much about designing the supporting installations.61

THE LAUNCH VEHICLE: QUESTION AND DECISION

Late in September 1961, Webb announced a major reorganization of NASA, effective 1 November. Technical issues had to be resolved and leadership to be improved. Committees—no matter how many—could study problems and recommend solutions, but they could not make decisions or run a program.

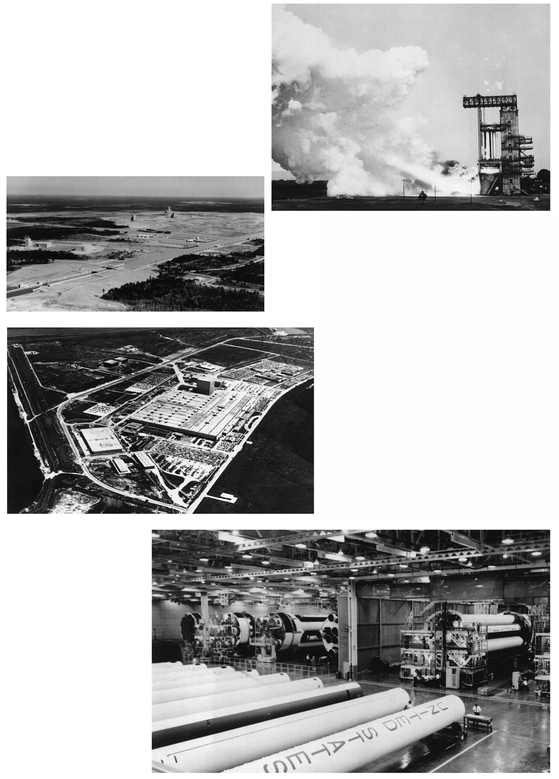

Booster stages for Redstone, Jupiter, and Saturn vehicles were tested at Redstone Arsenal near Huntsville, Alabama. Above, in 1960, Saturn C-1 first-stage engines are static-fired for the first time. When the Saturn booster grew in size, NASA obtained land in a less populated area, in Mississippi on the Pearl River near the Gulf of Mexico. In the 1968 photograph at upper left, test stands appear beside the waterways. To assemble the large Saturns, NASA needed a plant, preferably one already built. The Michaud facility (at lower left), close to New Orleans, suited the requirements. Inside Michoud in 1968 (below), Saturn IBs are on the assembly line.

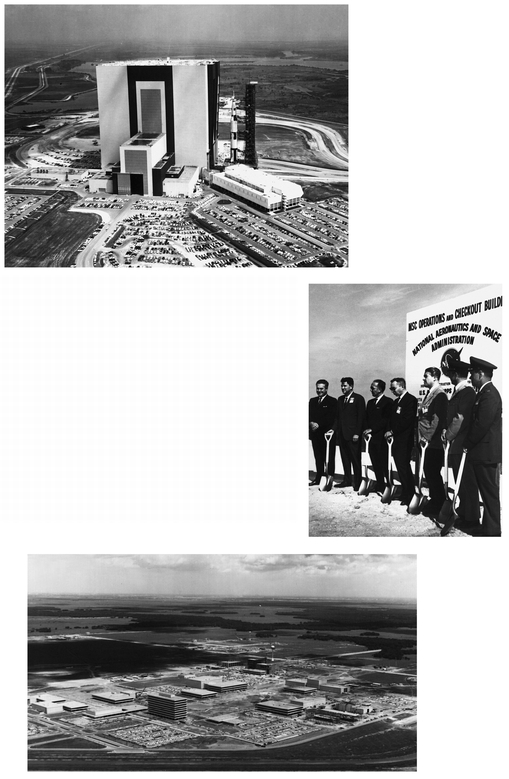

Kennedy Space Center’s Vehicle Assembly Building (above; earlier called the Vertical Assembly Building) stands high on Florida’s Atlantic coast; the Saturn 500-F launch vehicle rides on a mobile crawler toward the launch pad in the 1966 photo. Modules of the Apollo spacecraft were tested in Florida in the Manned Spacecraft Operations Building. At right, NASA officials Walt Williams, Merritt Preston, Kurt Debus, Brainerd Holmes, and Wernher von Braun—assisted by Col. E. Richardson (Air Force) and Col. H. R. Parfitt (Army Corps of Engineers)—are ready to spade dirt, to mark the beginning of construction of the building in January 1963. Below is a 1964 photograph of the new Manned Spacecraft Center at Clear Lake near Houston.

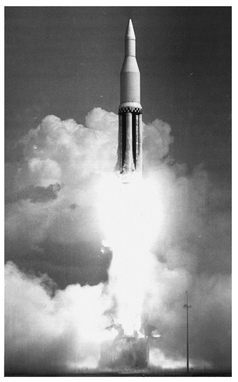

Maiden launch of the Apollo program: Saturn SA-1 from Cape Canaveral, 27 October 1961.

Webb, Dryden, and Seamans had scoured the country for the right man to take charge of the Office of Manned Space Flight and Apollo. On 21 September, Webb appointed D. Brainerd Holmes as Director of OMSF, to head all manned space flight activity for Headquarters. Three days later, the Administrator announced a major shakeup at NASA’s top levels that saw Silverstein return to Cleveland as Director of the Lewis Research Center.

Holmes was an electrical engineer who had been project manager for the ballistic missile early warning system across the Arctic Circle. He came to NASA from the Radio Corporation of America’s Major Defense Systems Division. Webb and Holmes intended for Headquarters to take a larger part in Apollo than it had in Mercury. To strengthen this position, they hired Joseph F. Shea, from Space Technology Laboratories, Inc., as Holmes’ deputy, to concentrate on systems engineering.

Apollo’s acceleration brought an administrative change for the Space Task Group, in addition to the physical move from Virginia to Texas. Re-designated the Manned Spacecraft Center, it dropped its one-program image as a task force for Mercury and assumed its role as the center for all manned space flight programs. Gilruth continued as Director.62

By November 1961, then, the agency had been reorganized to conduct the program more efficiently; sites and facilities had been identified to build, check out, support, and launch the lunar vehicles; and contracts had been awarded for the command section of the spacecraft, the guidance and navigation system, and various engines and stages of the launch vehicle. Much of the Apollo puzzle had been pieced together, but the principal questions of booster configuration and mission mode were still unanswered, although there were hopes for a solution in the near future.

On 27 October, the engine cluster concept of launch vehicle stages was successfully demonstrated. A little after 10 in the morning, the eight barrels of the Saturn C-I spewed flames as the booster lifted off from Cape Canaveral. This maiden launch of the program, carrying only dummy stages filled with water, augured well for a successful flight test program and for Apollo in general, but the 5.8 million newtons (1.3 million pounds) of thrust generated was far short of that needed to get men to the moon and back safely.63

On 6 November, Milton Rosen (now NASA Director of Launch Vehicles and Propulsion) told Seamans and Holmes that he was setting up another special in-house committee to try to pin down the large launch vehicle development program. Although he admitted that he would be repeating much of the work of Golovin’s Large Launch Vehicle Planning Group, Seamans and Holmes encouraged Rosen to proceed, hoping this committee might produce some tangible results.

The committee membersaa came almost entirely from Rosen’s office. Noticeably lacking were spacecraft people, with only John Disher to represent them until David Hammock, of Gilruth’s center, belatedly joined the group. The team examined specific areas—problems of orbital rendezvous, configuration of the advanced Saturn, plans for Nova, future potential of solid-fueled rocket motor development, and NASA’s possible use for the Defense Department’s Titan III.64

Rosen’s committee spent most of its two weeks of concentrated effort closeted in a motel room in Huntsville, near the Marshall center.65 But, when Rosen reported to Holmes on 20 November, he had to concede that there were still differences within the committee on rendezvous versus direct flight and on solid versus liquid motors. He nonetheless contended that the group as a whole was in accord:

We took the view that the Golovin Committee had opened doors to a room which should be explored in order to formulate a program. Our report consists of a finer cut of the Golovin recommendations—it is more specific with regard to the content and emphasis of a program.66

The Rosen Committee concluded that rendezvous (preferably a single operational maneuver) could be performed in either earth or lunar orbit, but the latter had the advantages of a single Saturn launch from the earth, using the C-4 or C-5, and a smaller, specially designed landing craft. A missed rendezvous, however, would prove fatal in lunar orbit. Moreover, the lunar lander, or ferry, which could place only a small payload on the moon, would permit a very limited staytime and would restrict the amount of scientific equipment that could be carried to the lunar surface. Although his group found earth orbit, where a missed rendezvous would mean only an aborted mission, more attractive, Rosen said, there was as yet no way of judging its difficulties or of estimating realistic schedules for development of docking and refueling techniques.

By this time, NASA officials in many quarters viewed the advanced Saturn as having at least four F-I engines in its first stage. Rosen, convinced that NASA must build the biggest booster possible, recommended sliding a fifth engine in at the junction of two very strong crossbeams that supported the other four engines, With this extra power, he later said, either rendezvous mode—earth or lunar orbit—was possible.

Actually, Rosen himself favored direct flight; he believed it was a safer and surer way to reach the moon within the decade. He recommended the development of a Nova with eight F-1 engines in the first stage, which would be no more difficult, technically, than a five-engined Saturn.

Rosen’s group opposed large solid-fueled rockets for manned lunar landing. There were too many technical problems to ensure a reasonable degree of reliability. Since the liquid-fueled F-I and J-2 engines would be built for the Saturn C-5 anyway, why not use them in the Nova? The S-IVB stage should be used for the third stage of both the C-5 and Nova.67

On 4 December 1961, Holmes learned that Seamans essentially agreed with the committee’s recommendations.68 Later in the month, Holmes established the Manned Space Flight Management Council—composed of himself, his principal subordinates at Headquarters, and senior officials from the manned space flight centersab—to set high-level policy for all manned space activities.69 At its first meeting, on 21 December, the council voted to develop the Saturn C-5.70

Early in January 1962, Holmes prepared a preliminary plan for the super-Saturn. He urged Seamans to release some of the money that had been authorized for an advanced Saturn, since negotiations with the three prospective contractors ac were being delayed by the indefinite status of 1962 funding.71

In deciding on the C-5, the planners endowed the Apollo launch vehicle with flexibility. It could serve as the booster for earth-orbit, circumlunar, and lunar-orbit missions. By launching two C-5s, a lunar landing could be made by earth-orbit rendezvous. And the C-5 seemed the best vehicle for the lunar-orbit rendezvous mode as well.72

At the end of 1961, however, it was tacitly assumed at NASA Headquarters that the mode would be earth-orbit rendezvous. There was no distinct break, no real dividing line, marking the drift away from direct flight; the shift was so gradual that Seamans was unaware of the full import of changed feelings within the Office of Manned Space Flight and the field centers. “My own recollection is that we really kept both the direct ascent and the Earth orbit rendezvous as real possibilities,” he later commented.73

Paralleling the switch to earth-orbit rendezvous, with direct flight as a backup, was the broadening realization also that the physical and financial realities of designing, building, and testing both the C-5 and Nova, almost concurrently, were perhaps beyond NASA‘s—and the country’s—economic ability.74

When Holmes became chief of NASA’s manned programs, he had been confronted with two pressing technical problems—mission approach and the launch vehicle for Apollo. Within a few weeks the management council had settled the vehicle configuration. Holmes then assigned Joseph Shea to investigate the mode question further.75 Although earth-orbit rendezvous was gaining ground in Washington, the devotees of direct flight were not giving in easily. And in the field elements things were no better: Marshall was united on earth-orbit rendezvous, but the Manned Spacecraft Center was split between direct flight and lunar-orbit rendezvous. Actually, the mode issue had smoldered almost from the day NASA opened for business, creating camps that favored one route or another and raising passions of individual promoters to the point of conducting evangelical missions to gather converts. The next chapter explores some of the deep-seated prejudices.

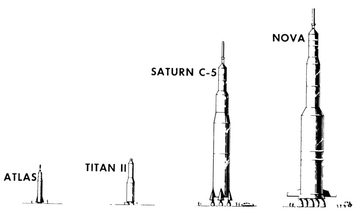

Comparative sizes of manned space flight launch vehicles: Atlas for Mercury earth-orbital flight; Titan II for Gemini earth-orbital flight to perfect rendezvous procedures and study long-duration flight; Saturn C-5 chosen for Apollo; Nova, which would have been required for a direct flight landing on the moon.