5

Command Module and Program Changes

1963-1964

Once all the vehicles in the Apollo stack had been decided on, those already being developed would have to be changed to fit the new concept of Apollo. Most immediately affected was North American’s command module. The shape of this craft, a conical pyramid much like the bell-shaped Mercury, had been set very early. This blunt-body vehicle, however, had been designed only for earth-orbital and circumlunar flight, with some thought given to attaching propulsion stages to make a direct-flight, lunar-surface landing sometime in the future. Adoption of lunar-orbit rendezvous eliminated the need to land the command module on the moon but forced the inclusion of some means for docking that vehicle with the lunar module and transferring two astronauts into the lander for the trip down.

Command module development, then, took two routes. Configurations, systems, and subsystems had to be qualified and astronauts had to be trained in Apollo operations, which could be done in earth-orbital flight. It was therefore unnecessary to make any major changes on what came to be called the “Block I” spacecraft. But the time limitation set by the President did not permit waiting for the first version of the spacecraft to be completed and tested before starting on an advanced model, Block II, that could perform the new docking operation. The two spacecraft had many components in common, but development had become infinitely more complicated. Deputy Administrator Hugh Dryden termed the Apollo program “the largest, most complex research and development effort ever undertaken.” 1

All three of NASA’s manned space flight centers—at Huntsville, Canaveral, and Houston—had their hands full during 1963 and 1964. Marshall was wrestling with the mammoth Saturn V development program; neither of the propulsion systems, the F-1 and the J-2 engines, could be simply picked off the shelves and fitted with appropriate oxidizer and fuel tanks. There were troublesome days ahead before the contractor, Rocketdyne, succeeded in developing and qualifying these engines so they could be trusted to boost astronauts toward the moon.2 At the Cape, the Launch Operations Center was doing some educated guessing about the flight preparation facilities needed for the spacecraft and launch vehicles. And the Manned Spacecraft Center was working on three major programs: flying the last Project Mercury spacecraft (Mercury-Atlas 9) in May 1963 and getting spacecraft development under way in both Project Gemini and Project Apollo. Because of its modular configuration, Apollo had no immediate need for day-to-day coordination among the centers, which freed the program offices to work independently in solving their more pressing problems. But the program needed to be centrally managed—technically as well as administratively—far differently from Mercury, and it would have to be armed with a larger force to accomplish this. NASA Headquarters had, therefore, to become more technically oriented and would have to participate more in the daily activities of the program.

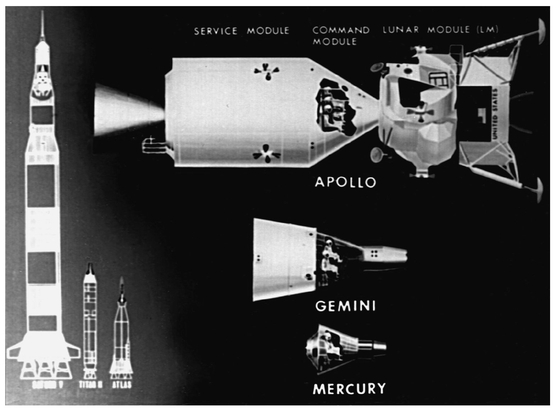

Comparison of spacecraft and launch vehicle configurations.

THE HEADQUARTERS ROLE

Shortly after Brainerd Holmes joined NASA Headquarters as its first Director of Manned Space Flight, he and Administrator James Webb contracted with General Electric for studies on reliability and quality assurance, analysis and integration of the complete Apollo vehicle (spacecraft and booster) , and procurement and operation of ground equipment to check out and certify the vehicles for flight. To fulfill this task, General Electric engineers would have to immerse themselves in the day-to-day activities of the space flight centers. No one in the field complained about General Electric’s role in the reliability, quality assurance, and checkout functions, since the centers wanted all the help they could get in these areas. But the suggestion that a contractor should tell government employees how to put their vehicles together (the integration clause of the contract) to fly a mission was resisted. Edward S. Miller of General Electric said: “The contractor role in Houston was not very firm. Frankly, they didn’t want us. There were two things against us down there. No. 1, it was a Headquarters contract, and it was decreed that the Centers shall use GE for certain things; and [No. 2] they considered us Headquarters spies.” For some time after the contract award, just exactly what General Electric would do was not exactly clear.3

In February 1962, General Electric engineers began holding monthly review meetings, but they met with little success in selling their plans for spacecraft and launch vehicle integration. After several of these gatherings, contractor officials complained in August that there was “little understanding by NASA people as to the role of GE.” That same month, General Electric nevertheless transferred 15 of its engineers to Houston. To get the contractor into Huntsville operations, the manager of the Headquarters office for integration and checkout accompanied several General Electric employees to Marshall to explain “GE roles in [the] Apollo program” to the center and Saturn contractor officials. Neither Boeing nor Chrysler wanted any “unannounced visits” by General Electric engineers, especially since the two principal Saturn contractors could not foresee any way in which General Electric could be of assistance to them. Marshall and the contractors were assured that all visits would be arranged in advance.4

General Electric’s other major task, however—designing, setting up, and operating ground equipment to check out the flight vehicles—was accepted at the field centers. Manned Spacecraft and Launch Operations Center representatives said they were satisfied with the contractor’s work in this area, and Marshall asked for more help. Even here, however, there were some reservations about turning General Electric loose. The Apollo manager in Houston, for example, warned the company, in capital letters, to do nothing unless it had “A WORK ORDER APPROVED BY THE APOLLO SPACECRAFT PROJECT OFFICE.” 5

Eventually, the General Electric contract called for almost a thousand persons, more than half of them stationed at Daytona Beach, near the Cape launch site, where they designed and assembled the ground checkout equipment needed to test the space vehicles for flight safety. The remainder went to the three NASA centers and to contractor plants, helping to ensure the receipt of good-quality hardware and performing specialized studies when they had a “work order.” 6

Webb had set up the General Electric contract to provide NASA Headquarters with the technical specialists to watch over and participate in Apollo’s far-flung development activities in both government and contractor establishments. He also wanted a bevy of engineering system specialists near at hand to assist Holmes in making technical decisions. Webb asked Frederick R. Kappel, President of American Telephone & Telegraph Company, to form a group to provide this talent for Apollo. Bellcomm, Inc., the new AT&T division, began operating alongside Holmes’ NASA Headquarters manned space flight engineers in March 1962. Holmes immediately directed the contractor engineers to work with Joseph Shea, his Office of Systems chief, first on the study of the mode issue and then on the defense of NASA’s decision to land on the moon via the lunar-rendezvous method.

Once the route studies were completed, Shea decided that Bellcomm engineers should dip into mission planning and produce some “reference trajectories”—a careful analysis of everything involved in flying the space vehicles from the earth to the moon and back. But when he took his newly formed Apollo Trajectory Working Group to a meeting in Texas, Shea met with resistance. John P. Mayer, speaking for the mission planners in Houston, said that his group had been doing this kind of work for the past two years. He told Shea bluntly that interjecting Bellcomm into mission planning was just one more attempt on the part of Headquarters to move into operational areas that properly belonged to the centers. Shea explained that Bellcomm would be a supporting group and would not try to second-guess the centers.7

General Electric employees monitor activities of a spacecraft test in the automatic-checkout-equipment spacecraft control room in 1965.

But many in Houston looked on Bellcomm representatives who attended many of the subsequent trajectory meetings as being, like General Electric, “Headquarters spies.” What continued to rankle Mayer and his colleagues in trajectory analysis was that Bellcomm, not always on the scene, simply could not keep up with the latest operations data, mission rules, and guidelines. As a result, Bellcomm sometimes gave Headquarters out-of-date information, and the field centers had to spend much-needed time in correcting misconceptions. Nevertheless, Bellcomm, never numbering more than 200 persons, did produce some useful evaluations on almost every aspect of Apollo throughout the decade. These engineers were among the first to push for the pinpoint lunar landings that were so successfully carried out after the first landing mission.8

Along with the mounting strength in contractor personnel, the Manned Space Flight Office in Washington (only a handful of people in Mercury’s early days) also increased in number. By February 1963, Holmes had a 400-man force, presided over by himself and his deputies, George Low and Joseph Shea. Low managed space medicine, launch vehicles, and office operations; Shea concentrated on engineering matters.9

Much of the energy of the Headquarters office and its contractors during 1963 was devoted to drafting an Apollo Systems Specification book. The aim of this document was to lay out the objectives, to define the technical approach for implementing these objectives, and to establish performance requirements. The task was difficult because many systems, especially those in the lunar module and the advanced command module, simply had not been studied in enough detail for anyone to state positively what was expected. Numerous pages were stamped “TBD”—to be determined. But there was some clarification of policy for Apollo. Up to this time, the main objective had been expressed only as landing a man on the moon and returning him safely before the end of the decade. The specification book intimated, for the first time, that exploration of the moon would not be limited to a single mission.10

A number of interesting specifications in the manual—intended for use as the Headquarters “bible” for all parties in the development of Apollo—remained valid throughout the program. For example, all parts of the spacecraft would be designed to minimize the fire hazards inherent in the use of pure oxygen atmosphere that North American had been directed to incorporate in the command module in August 1962. North American was instructed to design the command module so a single crew member could return the craft safely to earth from any point in the mission. And the service module would provide all spacecraft propulsion and reaction control needs (spacecraft attitude changes in pitch, roll, and yaw) from lunar transfer until it was jettisoned just before the spacecraft reentered the earth’s atmosphere.11

Hand in hand with definition of the system specifications were the systems review meetings sponsored by the Office of Manned Space Flight. The meetings had a two-fold aim: to gather information for the specifications book and to make sure that the centers coordinated all activities in Apollo’s complex development. At the first of these meetings, Shea found a gap in this coordination. Marshall was having trouble with F-1 engine combustion instability, yet an offer to help from Lewis Research Center—NASA’s leading propulsion organization—had been ignored.12

Other instances of this lack of cooperation may have occurred, but the three manned space flight centers had moved closer together, partially to defend the mode choice and partially to stave off the intrusion of General Electric into vehicle integration. On top of that, each center had a great many questions that needed to be answered by the other field elements. And they were working together on policies and mission rules that became the foundation for the lunar landing program. At a mission planning panel meeting, some of these ground rules emerged: two crewmen would land on the moon and one man would remain with the command module in lunar orbit; the lunar lander could stay on the moon from 21 to 48 hours; launch from the earth would take place in daylight to simplify recovery operations in the event of an abort; launch to the moon from earth orbit would begin within 4½ hours because of the boil-off characteristics of liquid hydrogen in the S-IVB stage; and the first lunar mission would be only a loop around the moon and return, since too little was known about the start and restart capabilities of the service module engine.13

Most of these committees—and there were many, many of them—took turns meeting at Houston, Huntsville, and Canaveral. By May 1963, the panels were so numerous that Holmes realized that something had to be done to keep track of them. He told Shea to form a Panel Review Boardaj as one more Headquarters tool for managing Apollo.

Shea convened the first meeting of the board in August 1963 at the Cape, and representatives of each panel summarized their past activities. The next item on the agenda was a session on standardizing the Interface Control Documents (discussed in the previous chapter) and the selection of Marshall as the repository for this documentation, to make sure it would be available for reference by the participating organizations. These periodic board meetings, besides keeping the Office of Manned Space Flight closer to the mainstream of center activities, gave the specialists a chance to learn what their colleagues were doing and an opportunity to oversee progress, costs, and schedules. Areas that might delay Apollo were discovered more quickly and dealt with more rapidly.14

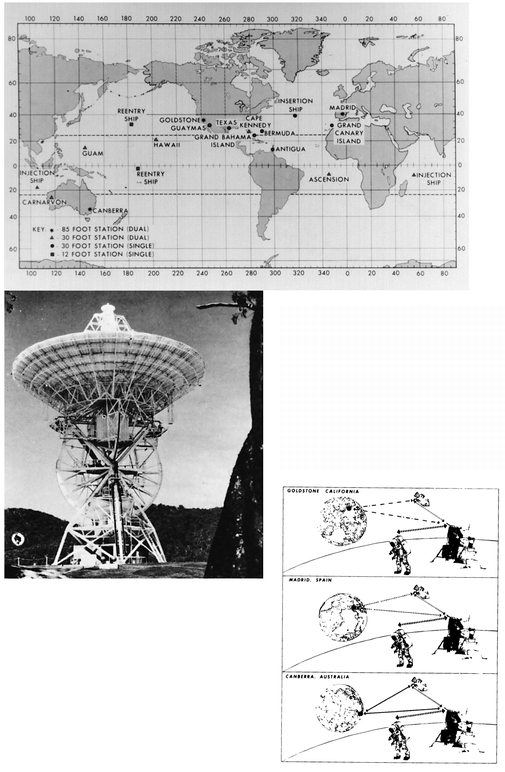

NASA Headquarters stepped in on occasion to arbitrate among the centers. At one time, telecommunications threatened to become a formidable issue in Apollo, with Houston, Goddard, and the Jet Propulsion Laboratory vying for control of the tracking network. The earth-circling band of stations—about a dozen and a half—used in Mercury were not equipped for the deep space communications of Apollo, but by 1963 a capability was developing in the unmanned spacecraft programs that promised to be suitable. Jet Propulsion Laboratory intended to build two sets of 26-meter dish antennas, with two antennas at each of three sites—Goldstone, California; near Canberra, Australia; and near Madrid, Spain—that would provide continuous communications coverage of the moon. One set would be equipped with the more advanced unified S-band system (a system that tied the signals for tracking, telemetry, voice, television, and command into a single radio carrier) for controlling, tracking, and acquiring data from unmanned spacecraft, like Mariner and Surveyor, in deep space. This system consolidated the functions of the many transmitters and receivers characteristic of Mercury into one.

The Mercury tracking stations, with 9-meter dishes and the new S-band radar, would communicate with the Apollo spacecraft in earth-orbital flight. Once the vehicle had traveled 16 000 kilometers into space, the 26-meter antennas—spaced equidistantly at 120 degrees longitude around the earth so one of the three always faced the moon—would take over. Later, the Jet Propulsion Laboratory was to build a 64-meter antenna at Goldstone (which then became the Goldstone Mars station) that gave Apollo clearer communications, especially in television reception. The laboratory wanted to construct two more of these stations, but the costs were too great. The British government, however, had a radar station with a 64-meter antenna at Sidney, Australia, that might be used.

Although some of the finer points on communications and control were haggled over for the next 15 months, in March 1963 NASA Associate Administrator Robert Seamans settled the basic issue of who was in charge and when. He assigned Goddard as the technical operator of the Manned Space Flight Network; during Apollo missions, the Manned Spacecraft Center would assume operational control. The Jet Propulsion Laboratory would be in charge of all unmanned mission communications, turning its facilities over to the other centers during manned flights. By the end of 1964, Headquarters had the communications and tracking requirements and assignments for Apollo pretty well in hand.15

Apollo tracking network in 1966, above. Radar stations with large antennas for continuous tracking and communications were at Goldstone, California; Madrid, Spain; and Canberra, Australia. At left, the “big dish” at Canberra points toward space. Below, communications with the moon as the earth turned. Astronauts on the moon’s surface also could talk to one another.

Other NASA Headquarters offices besides Manned Space Flight assumed lead roles for Apollo—especially in the area of scientific interest. Because of the complex engineering task, no one really expected that science would do more than ride piggyback. Almost the only concern the Houston center displayed was in the composition of the lunar surface soil, which would affect the design of the landing gear. Director Robert Gilruth sent a representative to a meeting of NASA’s Space Science Steering Committee to ask for help on the soil question and to remind the members that whatever scientific equipment they might develop would have to be adaptable to the lunar spacecraft.16 But there was one area in which the scientists could be of more immediate assistance. How to land Apollo on the moon had been decided; how to get it there would be worked out by the guidance experts. Where to land it and what the astronauts could do after they got there was still unsettled.

Shortly after President Kennedy had issued the lunar landing challenge, Homer Newell of the Headquarters science office had asked Harold C. Urey of the University of California at San Diego to suggest the best scientific sites for lunar landings. Urey told Newell of five kinds of lunar terrain of particular scientific interest:

High latitudes—to check for possible temperature differences from equatorial areas. [Professor Harrison Brown had theorized, Urey added, that water might exist beneath the surface there.]

Maria—to try to determine the depth of holes where great collisions had taken place and, on a second landing, to discover the composition of the material in such places as the Sea of Tranquility.

Inside a large crater—to look at an area, probably Alphonsus, where observers had seen gases rising from the interior.

Near a great rille, or “wrinkle,” in a maria—to attempt to find out what had caused it. [It had been suggested that water, rising from the interior, had cracked the surface as it dried.]

In a mountainous area—to observe crater walls.17

In 1962, a two-month summer study conference in Iowa was cosponsored by NASA and the National Academy of Sciences. The resulting deliberations, published as A Review of Space Research, outlined the broad objectives of a science program for Apollo. Conclusions were that the most important scientific tasks foreseeable for manned lunar explorations were educated observations of natural phenomena, the collection of representative samples of surface materials, and the installation on the moon of certain scientific monitoring instruments.

Late in 1963 and early in 1964, NASA Headquarters established science planning teams to recommend investigations of the lunar surface, designs for prototype long-life geophysical instruments, requirements for astronaut training, the building of a receiving laboratory for handling returned samples, and plans for the reduction and interpretation of geological, geophysical, solar, selenological, astrophysical, and other scientific data. Although the work of these teams was barely visible to outside scientists, NASA had some of the best specialists in the country helping to formulate its general objectives on the lunar science program.18

Five fundamental areas emerged as having the greatest potential:

Studies of the lunar lithosphere, the solid moon itself, its chemical and physical constitution, and the implications this should have for its origin in history.

Investigations of the gravitational and magnetic fields and forces around the moon, including experiments for the possible detection of gravitational waves.

Considerations of particles like solar protons and cosmic radiation, together with their effect on the lunar gravitational field and magnetosphere.

Establishment of astronomical observatories on the moon.

Studies of proto-organic matter, including the possibilities for exobiology.19

Realistically, everyone realized that the first manned visit to the lunar surface, limited to no more than 24 hours, would hardly satisfy the desires of most scientists. With proper planning, however, a bonanza of scientific results could be gleaned even from that first landing. In June 1964, the minerology and petrology planning team underscored these hopes by drawing an analogy between the lunar voyage and another historic event:

Some time before the year 1492, a group of workmen were standing in a shipyard looking at a half-constructed craft. One of them said “It won’t float”; another said “If the sea monsters don’t get it first, it will fall off the edge”; a third, more reflective than the others, said “What do they want to go for, anyway?”

The Apollo Project is primarily a glorious adventure, in which man will for the first time tread upon the surface of another celestial body. It will be a magnificent feat, and a milestone in the history of the human race. No other purpose or justification is necessary.

Important scientific knowledge will result from the landing. First among the scientific objectives of the Apollo mission will be the return of samples of the lunar surface materials. The study of such samples will tell us of the thermodynamic conditions under which they were formed; whether the moon is a differentiated body or not; and perhaps whether it was captured by the Earth or was formed from it in the distant past.20

Most of the work of NASA Headquarters on behalf of the scientific aims of Apollo by the end of 1964 had little impact on the organizations and contractors developing the program. All that the builders needed to know was how much space to allow—and this would be minimal—and a general idea of the future plans. When the time came to fly the missions, however, the planners, astronauts, and flight preparations technicians would have to pay more attention. The outline of what Apollo could contribute to science had been sketched; the details would be filled in later.

Perhaps the Headquarters action that had the most significant effect on Apollo was a change of leadership in the Office of Manned Space Flight. When NASA had signed Grumman in 1962 to develop the lunar module, Holmes had wanted the agency to ask for a supplemental appropriation for Gemini and Apollo costs (see Chapter 4), but NASA’s top administrators—Webb, Dryden, and Seamans—had refused. Webb also refused to transfer funds from other programs to manned space flight. Holmes and Webb had different views of management methods and of the priority of the manned program versus the rest of the space effort. The Administrator feared an all-out effort to land a man on the moon—one that subordinated all else—would endanger NASA’s balanced program of seeking U.S. preeminence in space science and technology. The Manned Space Flight Director felt he had an overriding mandate from the President to win a race to the moon. The question of funds and priorities was taken to the White House. When President Kennedy cited the importance of the lunar landing, Webb agreed that it was important but said that he would not take responsibility for a program that was not properly balanced. Kennedy accepted his position.

Then in the first half of 1963 came the realization that Project Gemini was suffering from more technical troubles than had been anticipated, which would push the costs of that program past the billion mark, almost double the original estimates. Gemini schedule stretchouts followed. Holmes testified in March congressional authorization hearings that the administration refusal to ask for a supplemental appropriation had delayed the Gemini and Apollo programs four or five months. In the renewal of Holmes-Webb differences over priorities, the President again backed his space program administrator. Shortly thereafter, NASA announced that Holmes was returning to industry.21

Moving to concentrate his resources on resolving Gemini and Apollo problems, Administrator Webb had decided to conclude the Mercury program after the ninth mission and to realign NASA organization throughout Headquarters and the responsive field center elements. One of the first requirements was to find a new leader for manned space flight. After considering several candidates, Webb asked Ruben F. Mettler, President of Space Technology Laboratories, Inc., to take the job. Mettler refused but recommended George E. Mueller (pronounced “Miller”), his Vice President for Research and Development. Webb accepted the recommendation, and Mueller became NASA’s Associate Administrator for Manned Space Flight. With a doctorate in physics (Ohio State, 1951) and 23 years academic and industrial experience, Mueller had made many contributions to the country’s missile and spacecraft programs.

Mueller had worked on Air Force manned space flight studies as early as 1958; later his laboratory had provided NASA with data that helped in making the Apollo mode decision. Furthermore, Mueller was familiar with NASA’s relations with industry, both at Headquarters and the field centers, and had studied ground support equipment problems and tracking network issues as a system analysis contractor. But most useful to NASA was his recent work with the Air Force on performance, schedule, and budget constraints for the Minuteman missile. Derivatives of this background—program control offices, schedules and resources planning, and the subsystem manager technique—were to be incorporated into Apollo to strengthen Headquarters and field center control over cost, configuration, and schedules.22

Soon after joining NASA, Mueller asked Air Force Brigadier General Samuel C. Phillips to help him apply to Apollo the kind of configuration and logistics management procedures established for Minuteman. Phillips brought with him about 20 officers to fill key positions. Mueller realized that this sudden infusion of Headquarters-level personnel might be detrimental to relations between his office and the field activities. To forestall any resentment, he invited center directors Gilruth, Wernher von Braun, and Kurt Debus to be his houseguests, to get to know them informally and to discuss with them his plans for Apollo. Mueller then visited Huntsville, Houston, and Canaveral. After completing the circuit, he began pressuring the field elements to conform to a long-range plan of program management.23

In his attempts to inaugurate effective Headquarters control of Apollo, Mueller still faced vestiges of field center autonomy. The intercenter groups had gone far in working out system specifications and planning for vehicle integration; in Mueller’s view, however, they had not gone far enough. To get to the moon by the set time, he told von Braun, Gilruth, and Debus, Headquarters would have to be the final authority in administering a unified and coordinated plan of program control.24

Mueller decided to make some changes in one management tool instituted by Holmes in late 1961. In a meeting of the Manned Space Flight Management Councilak on 24 September 1963, Mueller said that too many persons were on the council and that it would henceforth be composed only of himself, von Braun, Gilruth, and Debus. This new, slimmed-down body would act as a board of directors in making decisions and managing Apollo and would expect to be frequently and thoroughly briefed on all Apollo matters, down to the nuts and bolts, by top technical managers. To make sure that the industrial leaders in the program were kept abreast of progress and problems, Mueller also intended to form an Apollo Executives Committee, of company presidents, which would tour the appropriate NASA facilities and then hold periodic reviews thereafter. These men, Mueller knew, could put pressure on their people to solve any development problems.25

Webb, Dryden, and Seamans recognized in mid-1963 that NASA (and Apollo) had grown too large for Seamans to continue as “operating vice president,” which he had been since 1961. They decided to give Seamans three “Associate Administrators” for specific activities: Mueller would manage the Office of Manned Space Flight and the three centers working on manned missions—Huntsville, Houston, and Canaveral. Homer Newell and Raymond L. Bisplinghoff would hold similar positions for the Office of Space Science and Applications and the Office of Advanced Research and Technology. Mueller revamped his own office, dividing it into five sub-offices (the five-box system)—(1) program control, (2) systems engineering, (3) test, (4) flight operations, and (5) reliability and quality—for each major program, Apollo and Gemini, reporting to a program director who would in turn answer to Mueller. Mueller kept the job of acting Apollo manager for himself and gave Gemini responsibility to Low. The manned spacecraft centers were directed to organize their program offices accordingly.26

While the reorganization was going on, Mueller asked two veterans in his office, John Disher and Adelbert Tischler, for a study of Apollo’s chances of landing on the moon by 1970. From the information they gathered on the existing technical problems, Disher and Tischler concluded that prospects were one in ten. After reading this pessimistic report, Mueller knew the adverse schedule trend would have to be reversed. When MSC Director Gilruth sent a representative to Headquarters in late September to find out if the four manned Saturn I flights Washington had planned could be reduced to three, Mueller saw an opportunity to begin tightening the schedules. He reviewed a Bellcomm study that recommended terminating the Saturn I launch vehicle program after the tenth flight, which Marshall estimated would save $280 million, and concluded that there was no reason to fly any manned Saturn I vehicles. Ironically, NASA had just selected 14 new pilots, bringing corps strength to 30.al Administrator Webb worried briefly that the astronauts might not get enough space flight experience with the cutback, but Mueller reminded him that Gemini would fill that gap. Mueller added that there was a much better chance of beating the deadline if NASA had to man-rate only two boosters, the Saturn IB and V, instead of three.27

Hard on the heels of the Saturn I decision came another pronouncement that was just as startling—if not more so—to the field centers. At a late October meeting of the Management Council, Mueller told Debus, von Braun, and Gilruth that “we can now drop this step-by-step procedure” of flight-testing. All parts of the spacecraft and launch vehicle would be developed and thoroughly tested at manufacturing plants and test sites before being delivered to the Cape as ready-to-fly hardware. There would no longer be any need for piece-by-piece, stage-by-stage qualification flights of the vehicles. Each launch was to be prepared as though it were the ultimate mission, to avoid dead-end testing, with its narrow objectives and hardware components not intended for the lunar missions.28

Although the chances for getting to the moon within the allotted time may have improved, Apollo now had more launch vehicles and pads than were needed to do the job. When contracts were awarded, from late 1961 through 1962, step-by-step testing had been the norm. Hardware was purchased and facilities were built to carry out this time-tested practice. Mueller’s all-up decision changed the rules, limited the number of Saturn I launches, and made it likely that not all of the Saturn IBs contracted for would be flown in mainline Apollo. These results raise an interesting, though moot, question. If this decision had been made before the contracts were awarded, would there have been both a Saturn I and a IB? An earth-orbital and lunar-orbital version of the command module? Later, NASA had to find some useful employment for the excess vehicles, eventually assigning them to the Skylab and Apollo-Soyuz programs. But this did not worry Mueller in late 1963. His job was to figure out how to get men on the moon within the time set by President Kennedy.

Shortly after Headquarters reorganized for improved management of Apollo and Mueller made his changes to enhance the chances for meeting schedules, the whole nation was wracked by a series of traumatic events. President Kennedy was assassinated, and his alleged killer was murdered while the country watched. No one who had access to a television set can ever forget those days. In the soul-searching that followed, national goals and social priorities were questioned. Periodicals such as Science were soon attacking what they called NASA’s misplaced priorities, and books like The Moon-Doggle were expressing disillusionment with Apollo.29

Although caught up in the grief of the times, the Apollo worker—manager, engineer, technician—had been and still was deluged by the complex tasks inherent in developing and qualifying the vehicles.

COMMAND MODULE: PROBLEMS AND PROGRESS

The lateness of the decision on how to fly to the moon had forced the Manned Spacecraft Center and the contractor, North American, to delay work on the command and service modules. Once the choice was made, they realized that much of what had been done had no place in the lunar-orbit rendezvous scheme. But that was not the only problem. NASA still insisted on having an earth-orbital command module, even though it could not dock with the lunar module, to train crews and flight controllers in the basic functions of the spacecraft. The definitive contract for that vehicle, however, had not been negotiated. In late 1961, NASA had issued a letter contract to North American, which would be extended as necessary, outlining in general terms what the spacecraft would be like. When all of Apollo’s pieces were finally picked, it was time to reach an agreement with North American on the precise details of the spacecraft.

On’16 November 1963 in Cape Canaveral’s Blockhouse 37, NASA’s new manned space flight chief George Mueller briefed (left to right, front row seated) George Low, Kurt Debus, Robert Seamans, James Webb, President John Kennedy, Hugh Dryden, Wernher von Braun, Gen. Leighton I. Davis, and Senator George Smathers on Apollo program plans. The models on the table—Vehicle Assembly Building, Saturn V launch vehicle on crawler, and mobile seruice tower-represented key elements in the Apollo mission.

Charles Frick, the Apollo manager in Houston, assigned his special assistant, Thomas Markley, to negotiate the definitive contract with North American and its principal contractors. When deliberations started, on 7 January 1963, the Manned Spacecraft Center was facing crowded conditions in its temporary locations along the Gulf Freeway. Markley and his government team therefore met the contractor representatives in 16 rooms on the 13th floor of the Rice Hotel in downtown Houston. Signaling the start and finish of 15-hour work days, Monday through Saturday, with a cow bell, Markley and the groups completed the “basic contract package” on 26 January. The proposed contract then had to travel through administrative levels until it reached Webb for final approval or refusal. As the document journeyed through channels, the cost figures on the subsystems were revised. On 24 June, the estimated value was $889.3 million (without fee). When it was finally approved in August, the price, with $50-million fixed fee, was $934.4 million. For this sum, NASA was to receive 11 mockups (fac-simile models), 15 boilerplate capsules (test vehicles), and 11 flight-ready spacecraft.30

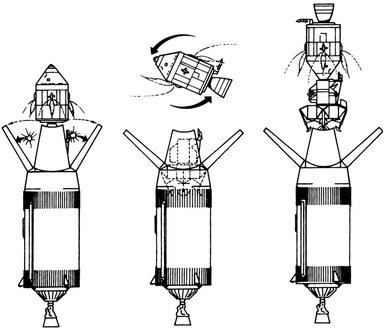

Once the S-IVB stage placed the spacecraft on a trajectory to the moon, the spacecraft— lunar module adapter panels would blossom outward 45 degrees (later they were discarded by explosion). The Apollo command and service modules would separate from the stage, pull away, turn around, dock with the lunar module, and then pull the LM away from the stage.

Under the letter contract, many of these items had gone into the manufacturing cycle, with scheduled delivery dates. Immediately after contract approval, Mueller sent his two deputies, Low and Shea, to Downey, California, to find out why North American was late on those deliveries. Harrison Storms, president of the division building the command module, briefed the visitors on the problems and admitted to a 10-month slip in schedule for the first command module earmarked for orbital flight. Storms counterattacked, however, reminding the NASA customers that some of their decisions had been late in coming and that orders to change some of the subsystems had slowed factory schedules—and were still doing so.31

Another item changed Apollo manufacturing plans in Downey. NASA officials learned that North American intended to build the spacecraft—lunar module adapteram in Tulsa, Oklahoma. The Air Force had decided to cancel the Skybolt missile development program and to keep using Hound Dog missiles, which were manufactured in Downey. When the Air Force ordered more Hound Dog vehicles and demanded that production in Downey continue, some Apollo work had to be done elsewhere.32

One chief aim of the 1963—1964 period was to get both versions of the command module far enough along for a formal mockup review board to accept them as the final configuration. With a great deal of this work being done simultaneously, the task was extremely onerous. John Paup, command module manager at North American who had fretted over the slowness of the mode decision, wanted to get the systems of the earth-orbital Block I spacecraft set so he could begin production on that vehicle. At the same time, he was anxious to get the exact differences between the two vehicles delineated. Joseph Shea, who had by now replaced Frick as Apollo manager in Houston, told Paup that Block II definition was not going to be easy to arrive at, with the Block I configuration still not settled.

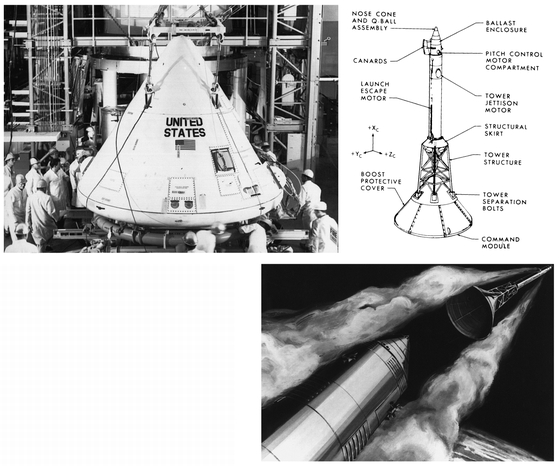

Paup contended that several areas of common interest between the two vehicles had to be resolved immediately. One of the debates was whether to use strakes, tower flaps, or canards to stabilize the command module in the event of a launch abort. Whichever was used, the object was to get the spacecraft down in what was called the “BEF” (blunt end forward) position. Strakes were semicircular devices near the top of the heatshield that would keep the vehicle from landing on its nose. Recent changes in the subsystems had shifted the vehicle’s center of gravity, which forced a lengthening of the strakes to handle the aerodynamic change. After heat-resisting ablative material was added to the longer strakes, however, they weighed too much. North American suggested using either tower flaps (fixed surfaces near the top of the launch escape tower) or canards (deployable surfaces on the forward end of the escape-rocket motor). Paup wanted to know which to install, and Shea told him to put canards on Block I and then look for some way to eliminate all these devices on Block II.33

Full-scale model of the command module, above: the strake aerodynamic devices may be seen at either side of the spacecraft just above the aft heatshield. On the drawing of the launch escape system at upper right, the canard aerodynamic devices are near the top of the escape tower. Jettison of the launch escape system (right), after successful launch, also pulls away the boost protective cover that protects the windows from flame and soot.

Full-scale model of the service module, resting on a mockup of a spacecraft—lunar module adapter, with panels off to reveal part of the internal arrangement.

Another decision that would influence both spacecraft was on whether to set the vehicle down on land or water, a question that had been under discussion since mid-1962. During a meeting in early 1964, a North American engineer reported that “land impact problems are so severe that they require abandoning this mode as a primary landing mode.” That was all Shea needed to settle that debate. Apollo spacecraft would land in the ocean and be recovered by naval ships as Mercury had been.34

Throughout 1963 and 1964, there were frequent meetings on command module subsystems that were common to both versions of the craft. Because space missions would be of longer duration, a concept had developed very early that the astronauts would repair or replace a malfunctioning part in the spacecraft during flight. This plan would require tools and spare parts to be carried on the missions and created another weight problem. At a subsystems discussion in April 1964, Shea told the North American engineers that NASA no longer favored this method of ensuring good working components in space. Instead, the contractor was to work toward reliability through manufacturing and test processes and by installing redundant systems. If something did go wrong, the crew should be able to shift to another system that could perform the same function as the malfunctioning one. Houston also wanted the contractor to upgrade its reliability program by improving its failure reporting practices, manufacturing schedules, engineering change controls, test plans, traceability methods, means of standardizing interface control documents, and ground support equipment provisioning.35

Houston had already taken measures in late 1963 to increase its control over and improve on subsystem development, chiefly to get the more advanced Block II command module under way. Shea asked Max Faget, chief of the Engineering and Development Directorate at the Manned Spacecraft Center, to pick experts in the engineering shops to act as subsystem managers. The managers were directed to oversee their components from design through manufacture and test. They were responsible for cost, schedules, and reliability. When changes in one unit became necessary, other systems had to be considered, and any conflicts resolved, before alterations could be made. The subsystem manager concept was therefore an excellent device for restraining engineers eternally eyeing good hardware for chances to make it better.36

North American and Grumman also made significant contributions toward controlling hardware development. As far back as mid-1962, John Disher had urged Houston to draft hardware development and flight test schedules through the first manned lunar landing. Houston submitted these schedules in October 1962. When 1963 rolled around, delays of one kind or another had made this paper nearly meaningless. Near the end of the year, North American invited the other two major contractors, Grumman and MIT, to help settle this issue. The contractors drew up charts on all three modules—command, service, and lunar—looking at development tests of subsystems, ground tests of partial and fully assembled modules, and Saturn-boosted flight tests of completed modules. Formally known as the “Apollo Spacecraft Development Test Plan,” their report to NASA, outlining the tests and exact uses of every piece of hardware for the years 1964 through 1968, was called “Project Christmas Present” by the contractors.37

A second move, led by Grumman, was made in the early months of 1964. Grumman officials had complained to Shea that the frequent changes in the lunar mission concept made it impossible for the design and development engineers to decide what components they needed. The general outline of the mission was pretty well set, but the haziness about specific refinements was playing havoc with attempts to design hardware to cover all normal and contingency operations. Shea told Grumman to see if it could get the requirements pinned down. North American and MIT crews soon joined the lunar module contractor team to come up with a “Design Reference Mission.”

First the group looked at what Apollo was supposed to accomplish: “Land two astronauts and scientific equipment on the near-earth-side surface of the moon and return them safely to earth.” A second major objective was to carry more than 100 kilograms of scientific equipment to be set up on the moon and to bring back more than 30 kilograms of lunar soil and rocks. To make sure this was understood, the study group would have to analyze every moment of a hypothetical mission—on the ground, in space, on the moon, and during the return to the earth—from the time the stacked vehicles were rolled toward the launch pad until the command module was recovered in the Pacific Ocean. In other words, the North American-led study concentrated on getting reliable hardware to the launch pad; the Grumman-sponsored task aimed at making sure that the equipment would be able to handle the job of getting to the moon and back.

The group soon realized it had to pick out an arbitrary mission launch date—it chose 6 May 1968—to give realism to the plan and to focus attention on every move, every procedure, in the minutest detail. Working out the specific position of the moon on that date in relation to the earth, members drew up a precise launch trajectory. Then, assuming a given number of hours spent in flight and on the moon, they calculated the corrections in the return trajectory that would have to be made to accommodate changes in the moon-earth position. The task was not an easy one. It took four months of “working like hell” to produce three thick volumes describing the sequence of events and related actions. The work would have to be updated later, of course, but the contractors had a better understanding after the exercise of what their subsystems should be and what they should do. Thus, long before the astronauts embarked on an actual lunar landing mission, the mission planners, government and contractor, had spent untold hours agonizing over every minute of that trip.38

The design reference mission study led neatly into the requirement for North American to accelerate Block II command module work. That vehicle had moved slowly following the lunar-orbit mode decision, but it would have been almost impossible to increase the speed. Until Grumman got the lunar module design relatively well set, North American engineers would have only the most general ideas of how the two vehicles would rendezvous and dock, which limited them to guesses about the influence of the docking equipment on the command module weight. The following spring, however, new mission rules gave them a clearer picture of what they were designing toward: the crew members would be able to stay in their couches during docking and the connection between the command and lunar modules would be rigid enough to maintain a pressurized pathway through which the astronauts could travel between the craft.39

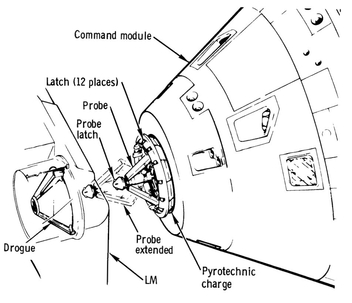

By mid-1963, North American engineers had begun work on an extendable probe on top of the command module that would fit into a dish-shaped drogue on the lunar module. They considered three possible ways of docking: (1) soft docking (latching with enough separation between the craft to make sure that pilot errors could not impair flight safety and then reeling the vehicles together), (2) hard docking (going straight in and latching without preliminaries) as a backup mode; and (3) transferring the crew by extravehicular means (getting out of one spacecraft in free space and climbing into the other vehicle) in an emergency situation. It was now apparent that the main difference between the Block I and Block II space-craft was that Block II would be equipped with the means for docking and the pressurized crew transfer tunnel, but Block I would not.40

North American engineers favored probe and drogue devices to dock the command module with the lunar module. The CM probe would slip into the LM’s dish-shaped drogue, and 12 latches on the docking ring would engage, to lock the spacecraft together, airtight. The astronauts could now remove a hatch, take out the docking devices, and travel between the two spacecraft. When operations were finished, they would return to the CM, reinsert the devices, install the hatch, and release the latches to disengage from the LM.

By March 1964, Manned Spacecraft Center and North American were close to agreement on the design of the Block I command and service modules. A Mockup Review Boardan was getting ready to go to Downey, with a team of systems and structural specialists, to examine every part of the proposed model and decide what items to accept. Following NASA tradition in engineering inspections, the board would consider four categories of changes: items (1) approved for change, (2) accepted for study, (3) rejected outright, and (4) found not applicable. The review board would rule on the suggested changes on the basis of technical accuracy, desirability and feasibility, and the impact on cost and schedules.

At the end of April 1964, a hundred persons gathered at North American’s Downey plant. After being welcomed by contractor officials, members of the board and their specialists watched as several astronauts simulated operating the vehicle. Next came a walk-around for a general examination of the spacecraft mockup and such special displays as wiring, cutaway models of subsystems, parachute packing, and electrical connectors. Managers and counterpart engineers from NASA and the manufacturer then split up into small groups to examine minutely and evaluate each piece. More than a hundred requests for changes (RFCs) were written on the spot for consideration by the board; 70 were approved, 14 were designated for further study, and 26 were rejected.

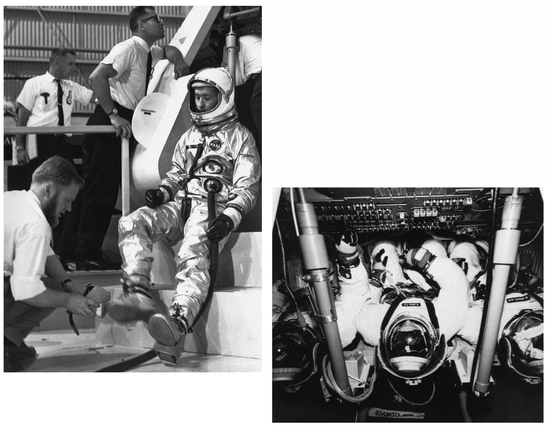

The spacecraft couches worried the board members a great deal, since the crewmen, wearing pressurized suits, fitted too snugly into their seats. As a matter of fact, an astronaut lying in a couch could not move easily, even in an unpressurized suit. Three pilots lying side by side in the couch area would be virtually immobilized. By July, adjustments had been made to alleviate this situation and to cover other suggestions by the board and its assistants. After a second mockup review, in September, NASA told North American to begin production of the Block I, earth-orbital command and service modules.41

After Project Christmas Present and the decision to use redundant systems rather than making repairs en route to the moon, work on the Block II spacecraft began to move a little faster. Since two large vehicles, the command-and-service-module combination and the lunar module, would be boosted into space, a weight-reduction program became of major importance. North American met this challenge principally by shaving kilograms off the command module heatshield and the service module structure.42

During the spring of 1964, continuing problems with the Block I and Block II vehicles triggered a change in management at North American. Dale D. Myers, program manager of the Hound Dog missile, took over as Apollo manager, replacing John Paup. Myers, a company employee since 1943, later remarked: “The first thing I did when I got on the program was to work out with Joe Shea ... a program definition phase for Block II that [lasted from April] till October. We set up all the milestones we had to go through ... in getting to the definition of the Block II vehicle.” 43

NASA and North American engineers at the April 1964 command module mockup review (above) closely examine all pieces of the Apollo command and service modules. While several engineers on the platform inspect the CM recovery system, the forward heatshield waits to be lifted into position. Groups of engineers of the various specialties (right) meet to discuss and list requests for changes for consideration by the NASA Review Board.

Astronaut James McDivitt (left) receives assistance with a shoe cover before entering the command module to check out the cabin from a pilot’s viewpoint. One of the most worrisome items astronauts found in the CM arrangement was an “elbow-shoulder clearance problem.” Four years later, in 1968, this problem still vexed astronauts Walter Schirra, Donn Eisele, and Walter Cunningham, the first crew to fly an Apollo spacecraft.

Shea and Myers assigned teams at Houston and Downey to guide the definition phase of Block II. Alan Kehlet led the contractor team, and Owen Maynard headed the NASA group. Both men had worked on Apollo spacecraft design as far back as the feasibility studies of 1960. Under their leadership, teams concentrated on such activities as charting and evaluating changes caused by abandoning the inflight repair concept, finding places in the cabin for the lunar sample boxes, studying the design of the pressurized tunnel that permitted the astronauts to move from one vehicle to the other, eyeing the probe and drogue docking mechanism, reviewing the heatshield and service module weight-reduction programs, and modifying the service module design to provide an empty bay to hold the scientific experiment equipment.44

Maynard and Kehlet planned to hold their Block II design review meeting in August, but it was 29 September before 130 board membersao and specialists had something at Downey to examine. But even this was not a complete mockup of the advanced command module, as some NASA officials had expected. The contractor presented mockups of the command module interior, including the arrangement of the upper deck and lower equipment bay, and the service module with two of its four bays exposed. Although the couches from the April Block I review were still featured, the harnesses had been modified to afford roomier seating. The hatches—inner and outer—were the same as for Block I, and the spacecraft exterior reflected only the changes from Block I. New systems, such as docking and crew transfer, were sketched out in little detail.

After the specialists had examined the mockup, they submitted 106 requests for changes. The board accepted 67, recommended 23 for further study, rejected 12, and returned 4 as not applicable. What worried everyone, government and contractor employees alike, was the lack of good, solid information on how this vehicle and the lunar module would work together on rendezvous and docking. Across the continent at Grumman’s New York plant, however, the lunar module contractor had a mockup that would be ready for formal review in October. That would give North American a clearer picture of the exact changes necessary in its spacecraft. In five months, after these changes had been studied and incorporated, a formal Block II command and service module review would be held. Meanwhile, one engineer from Houston and one from Downey would be assigned to each of the 67 requests for changes that the board considered critical.45 Essentially, then, waiting for the lunar module to settle into its final form became a way of life for North American engineers.

But some of the decisions on what would constitute the North American spacecraft were not influenced by the lunar module, nor were they based on theoretical studies and ground tests. Some came from actual missions.

At White Sands, New Mexico, on the morning of 13 May 1964, a Little Joe II launch vehicle rammed Boilerplate (BP) 12 to an altitude of 4700 meters, to see if the launch escape system could propel the spacecraft away from the booster after it had reached transonic speed. Only one incident marred an otherwise successful flight. A parachute riser broke during descent, collapsing one of the three main parachutes. The boilerplate landed safely on the two remaining parachutes, in what one engineer later called “a welcome unplanned result of the test.” 46

As 1964 drew to a close, the Little Joe II abort test program at White Sands was nearing its thirdap and, in many ways, most crucial launch. Because of their fixed fins, the first two solid-fueled rockets had been somewhat erratic in flight. Jack B. Hurt’s people at the Convair plant of General Dynamics in San Diego then built a relatively simple attitude control and autopilot system for the rest of their vehicles to allow hydropneumatic operation of “elevons,” like ailerons, in each of the four fins while in flight. In addition, for the “max q” (maximum dynamic pressure) and high-altitude abort tests coming up, small reaction control motors were installed in the fin fairings to increase the precision of aiming control to the test points desired. Vehicle No. 12-51-1, as it was called, with four Recruit and two Algol motors, was the most powerful Little Joe II yet flown, intended to develop 1500 kilonewtons (340 000 pounds of thrust) to lift itself and its cargo—BP-23 and the launch escape tower—more than 9 kilometers high. The whole assemblage, weighing 41 500 kilograms, was pointed toward the north at a point in space where the launch escape system, fitted with canards, would pull the capsule and boost protective cover away from the Little Joe II while traveling at a speed of mach 1.5. This area was in the middle of the region where a Saturn V ought to experience max q.

At precisely 8:00 on the morning of 8 December, Little Joe II roared upward, straight and true. Thirty-six seconds later—almost out of sight and two seconds, or 900 meters, early—the planned abort took place. After an 11-second coast period, the canards deployed, and the capsule tumbled four times in its turnaround before stabilizing blunt-end forward and jettisoning the escape system. The boost protective cover shattered slightly more than expected, but the two drogue parachutes deployed. Its three main parachutes opened, and BP-23 drifted gently to rest, 11 000 meters uprange from the launch site, after 7.5 minutes of flight. Max q had been higher than predicted, but all else had worked well; at the end of 1964, Little Joe II, with its payload, was ready for more stringent flight tests.47

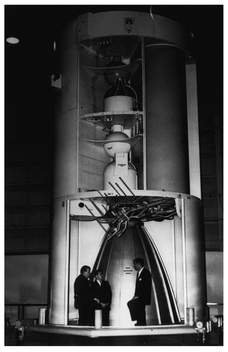

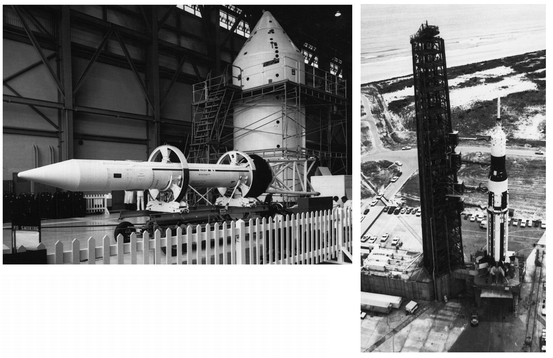

Full-scale models of the Apollo command and service modules and launch escape tower (foreground) are received in a hangar at the Kennedy Space Center for the first launch of an Apollo spacecraft by a Saturn vehicle—mission SA-6, 28 May 1964. At right, SA-6 spacccraft and launch vehicles ready to go.

Across the country, in Florida, engineers and technicians from California, Texas, Alabama, and elsewhere were grooming the first Apollo-configured spacecraft model to ride aboard a Saturn I booster. Although Saturn I was no longer part of the manned Apollo program, the SA-6 launch on 28 May did prove that Marshall could build a booster to fit the command module. In the jargon of the trade, “The mission was nominal.” After 54 earth circuits, BP-13 reentered the atmosphere east of Canton Island in the Pacific Ocean on I June. No spacecraft recovery was planned. Just three and a half months later, on 17 September, a nearly identical test of the seventh Saturn I and Bop-15 had equally satisfactory results.48

Thus, in the closing months of 1964, the final form of the command ship was emerging, the management team was in better shape to handle the program, and the mission planners had a clearer picture of the multitude of steps necessary in the performance of a lunar mission. During this two-year period, the lunar module also assumed definite shape.