7

Searching for Order

1965

For the most part, 1965 was a good year for manned space flight. Gemini astronauts flew five missions, all successful, one lasting two weeks and including the world’s first rendezvous in space. A series of unmanned flights banished many old specters of doom: three Pegasus satellites proved micrometeoroids were not as hazardous in near-earth space as some had prophesied, and two Ranger spacecraft, before crashing on the moon, sent back pictures that gave some assurance that Surveyor and Apollo could safely fly to and land on the lunar surface. Apollo’s eventual success seemed certain, but first all its far-flung pieces had to be brought together in some semblance of order. For Apollo, therefore, 1965 was a trying, yet fruitful, year.

PROGRAM DIRECTION AND THE COMMAND MODULE

Administrator James Webb knew that the futures of NASA and Apollo were interlocked and that the agency’s peak in appropriations and manpower would probably be reached in 1965 and 1966. But neither he nor the other NASA officials who spent six months each year justifying financial needs before the Bureau of the Budget and Congress could predict just when funding requirements would taper off. On one hand, only $5.1 billion of the $5.25 billion authorized for fiscal 1965 had been spent; on the other, there were indications that the $5.2 billion in the fiscal year 1966 authorization might not be enough. Apollo funding was more than $2.5 billion in 1965 and would exceed $3 billion in each of the next few years. The spacecraft alone accounted for a third of this, $1 billion a year.1

Almost as soon as he joined NASA, Associate Administrator for Manned Space Flight George Mueller had argued before Congress, the budget bureau, and his superiors that cost and schedule factors were intertwined: slowing the pace—and many asked, why the hurry?—meant stretching both time and payrolls. To hold costs down, Mueller believed in pushing, although not sacrificing, performance, reliability, and quality, continually admonishing his field centers to “get today’s work done today—and some of tomorrow’s work also.” But the drive for order needed more than Mueller’s prompting. On 15 January 1965, Apollo Program Director Samuel Phillips issued an “Apollo Program Development Plan.” Besides serving as a general reference, this document, in its 17 subdivisions, specified how the Apollo objectives would be reached, how performance and proposed changes would be evaluated, and how these changes, after approval, would be implemented. Its first section, Program Management, laid out the responsibilities for all participants in a pie-shaped chart, sliced to show each major piece of the program and the organization—industry or NASA (MSC, Marshall, Goddard, Kennedy, or Headquarters)—assigned to implement these duties. Other sections dealt with such items as scheduling, procurement, data management, configuration management, logistics, facilities, funds and manpower, and systems engineering. This directive pulled together, in one place, all the parts of Apollo and explained how the decisions to integrate them would be made.2

Mueller had revived the dormant Panel Review Board in late 1964,ay hoping to get a tighter rein on configuration control management of the spacecraft and launch vehicles and to speed up the manufacture and qualification of flight vehicles. Houston had established a Configuration Control Panel in 1963, but spacecraft development was in such a fluid state that panel authority was limited. By late 1964, however, ASPO Manager Joseph Shea was able to set up a stronger, more effective, Configuration Control Board to review and manage changes in the spacecraft.3

After much correspondence between Washington and Houston, Shea issued a Configuration Management Plan, outlining his board’s responsibilities and limitations and the functions of each of the program offices under his jurisdiction in carrying out the dictates of the board. But having a plan did not immediately turn the tide. Even after the document was published, Shea and his lieutenants tried in vain to stem mounting weights and slipping schedules. During a briefing at North American in April, Shea felt, as he had earlier, that engineering was getting out of hand and slowing progress on both Block I (earth-orbital) and Block II (lunar-orbital) command modules. Block I spacecraft 004 and 007 would be three and six weeks late leaving the factory, and North American had completed only 526 of nearly 4000 engineering drawings for Block II. Dale D. Myers, NAA Apollo Program Director in Downey, assured Shea that the company was beginning to catch up on its workload. Nevertheless, Myers reorganized his engineering department into six divisions reporting to his chief engineer, H. Gary Osbon: systems engineering (under Norman J. Ryker, ,Jr.), project engineering (Ray W. Pyle), vehicle systems (J. J. Williams), control systems (S. M. Treman), ground support equipment (D. K. Bailey), and planning and operations (C. V. Mills).4

Configuration control was a major factor in bringing order to Apollo, but there had to be some way to gauge how well it worked. In mid-August, Mueller and Phillips identified a series of reviews, inspections, and certifications that would be key checkpoints for Apollo:

- Preliminary Design Review (PDR)—to review the basic design during the detailed design phase;

- Critical Design Review (CDR)—to check specifications and engineering drawings before their release for manufacture;

- Flight Article Configuration Inspection (FACI)—to compare hardware with specifications and drawings and to validate acceptance testing (FACI could be repeated to make sure that any deficiencies had been corrected; it would also be repeated on every vehicle that departed significantly from the basic design);

- Certification of Flight Worthiness (COFW)—to certify completion and flight-qualification of each vehicle stage or spacecraft module;

- Design Certification Review (DCR)az—to verify the airworthiness and safety of each spacecraft and launch vehicle design (DCRs would include all government and contractor agencies with major parts of the programs and would formally review the development and qualification of all stages, modules, and subsystems);

- Flight Readiness Review (FRR)—a two-part review before each flight, held by the mission director in Washington, to confirm the readiness of hardware and facilities (the mission period would then begin with the commitment of support forces around the world).

These six checkpoints charted the course for the step-by-step flow of hardware from drawing board and shop floor to flight-ready vehicles at the launch site.5

While Headquarters was working on configuration control and the review plans, command module weight kept getting out of hand. Caldwell Johnson reminded Max Faget in August that, more than a year and a half earlier, he had pointed to weight control as the single most difficult technical problem. To “keep [the] spacecraft on its diet,” Johnson proposed putting pressure on the subsystem managers to begin a rigorous system of checks and cross-checks down through the subsystem level. Faget passed Johnson’s suggestions along to Shea, who, already aware that he had a fat spacecraft, was also being bombarded with warnings about the lack of reliability in Block I. Owen G. Morris, Shea’s Chief of Reliability and Quality Assurance, listed 71 possible failure points that North American had evidently done nothing to eliminate. Morris was not the only one to raise the reliability issue. Shea’s old adversary in the mode selection, Nicholas Golovin of the President’s Science Advisory Committee, wrote that he had heard of 50 items that accounted for “perhaps 95 percent of the unreliability of the Apollo system.” 6

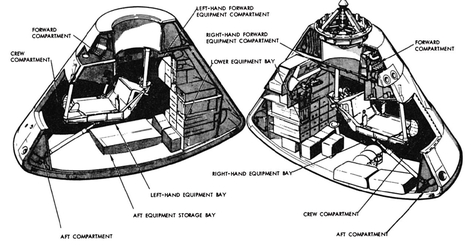

Cutaway views show the interior of the command module (for clarity, the center couch is not shown).

Not all the story was bleak, however. In November attention centered on a three-week Critical Design Review for the Block II command module. This event followed reviews of the lower equipment bay and upper deck in February; the guidance and control systems, crew compartment, and docking system in March; the extravehicular mobility unit in April; internal lighting displays and side access hatch in June; and the spacecraft—lunar module adapter in June and August. The major result of all these reviews was an entirely new inspection article called, in engineering shorthand, “EM3” (for engineering manufacturing module mockup), which demonstrated that North American was making progress toward a finished Block II design.

Alan Kehlet, North American’s Block II project manager, and assistants Gerald R. Fagan and Louis W. Walkover made the contractor’s presentation. Kehlet explained that the Critical Design Review was a formal, technical review of the Block II spacecraft as reflected in the program specification. The general format of the briefing was: “This is what the spec says it’s supposed to look like or supposed to do from a functional standpoint, and this is what the design is.”

Before Fagan and Walkover launched into discussions of each individual system, Kehlet told his listeners that NASA must shoulder some of the blame for schedule slips at North American:

This is the status of our vehicles in manufacturing.... You can see we are about four weeks behind in 2TV-1 [the Block II thermal-vacuum test article] and primarily [because of a] lack of secondary bond details.... The reason we’re having trouble with secondary bond details is [that] we are having trouble defining the wire routing in certain areas. The reason we’re having trouble with defining the wire routing is because the schematics came out late. And the reason schematics came out late was somebody didn’t define their system. And NASA and the [North American] project office get blamed for that. So it’s a chain event. ...7

For several months, Shea had been critical of Block II progress. He had complained in June that engineers, besides trying to develop the spacecraft, had adopted a stance of “as long as we are making the necessary changes, we might as well introduce these [others].” Therefore he asked the subsystem managers in Houston and Downey, who were causing some of the problems, to review both Blocks I and II and eliminate any unnecessary changes. There were plenty of subsystem or component problems to wrestle with, Shea knew, without constantly redesigning the lower equipment bay to fit changing components. In all fairness, however—and Shea knew this—the subsystem managers at North American and the Manned Spacecraft Center were caught in the trap of changing concepts. For example, the cancellation of onboard maintenance in favor of redundant or backup systems in the event of a malfunction resulted in modified parts and subsystems that would no longer fit in the equipment section.8

But sometimes a change was dictated by troubles that cropped up in supposedly uncomplicated areas. One such nagging problem that arose in 1965 was how to keep the command module windows clean. A fiber glass cap with a cork ablator, called a boost protective cover, was attached to the escape tower and fitted atop the spacecraft to protect the windows during tower jettisoning. When tests showed that the cover would crack and the plumes from the escape tower would deposit soot on the windows and possibly cause other damage, North American bonded Nomex (a nylon material strengthened with Teflon) between the fiber glass and cork layers of the cover to reinforce it.9

And in areas where problems were expected to arise, they did. Two of the tanks—one holding oxidizer and propellant for the command and service module’s reaction control thrusters (with which the spacecraft was steered) and the other housing reactants for the fuel cells that provided electrical power—were in trouble. The Bell Aerospace Systems Company furnished North American with “positive expulsion RCS tanks,” a system that forced propellant and oxidizer into the firing chambers where the fluids would ignite on contact. The oxidizer tanks kept failing, and Bell kept trying to fix them in an apparently disorganized manner. Eventually, the trouble was traced to the oxidizer, which had too little nitrous oxide in the nitrogen tetroxide, causing stress corrosion (or cracking) in the tanks. When the nitrous oxide was more carefully specified and controlled, the tanks stopped failing. The hydrogen and oxygen fuel-cell-reactant storage tanks, tucked in a service module bay, were also developing cracks. By August, Shea was worrying whether Beech Aircraft, who supplied them, would be able to diagnose and solve the problem in time for the early flights. With the aid of Langley Research Center, the trouble was traced to a reaction of the nitrogen tetroxide to the titanium used for the oxidizer tanks and tubing. Beech simply installed stainless steel components, and the problem ended.10

Shea found that the penchant for unnecessary changes in Block II was shared by some of the guidance and navigation system developers. On a visit to Honeywell in May 1965, he learned that 50 percent of the stabilization and control circuitry was new, 30 percent was slightly modified, and only 20 percent was identical with Block I wiring. Although he conceded that many of the changes were warranted, Block II had been used to justify nonessential circuits, as well. Shea believed that the Apollo office was inviting trouble; the changes had reached a point where more time would be lost in trying to eliminate them. Pressure was applied to make sure that North American kept its associate contractors on both the spacecraft and guidance and navigation systems up to date on changes; interface control documents would be used to prevent this kind of problem in the future.11

LUNAR MODULE REFINEMENT

Lunar module activities also focused on configuration control, schedules, and funds in 1965. J. Thomas Markley, program control chief, directed the Apollo engineers to be more conservative in their proposals to the Configuration Control Panels. Changes in the spacecraft must correct design flaws, not improve hardware. But stemming the flow of changes in the lunar module was not an easy matter; many were required because of its mission.12

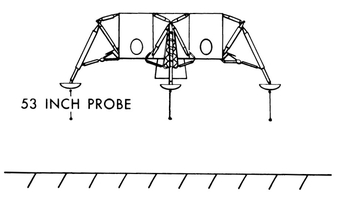

An example was the installation of frangible probes on the base of each foot pad to tell the crew the lander was a meter and a half above the surface and to switch off the descent motor. If the motor were still firing when the craft touched down, the engine nozzle would be damaged, landing stability might be affected, and the ascent stage might be impaired by debris kicked up by the engine exhaust.13

One configuration issue, a carry-over from 1963-1964, remained unresolved throughout 1965—whether to substitute an optical tracking system for the complex, heavy, and expensive rendezvous radar. In February 1965, the Configuration Control Board deleted the radar from the command module and added flashing lights to the lander. If the lone crewman in the command ship had to perform the rendezvous, he would use onboard optics, a ranging capability, and the VHF communications link between the spacecraft, which would also act as backups if the lander’s radar failed.14

In mid-March, Cline W. Frasier of the Guidance and Control Division suggested replacing the rendezvous radar in the lander with an optical system, as well. Consisting of a star tracker in the lunar module, a xenon strobe light on the command module, and a hand-held sextant for the lander’s pilot, the substitute would offer two advantages: a weight reduction of 40 kilograms and a cost saving of $30 million.15

The Apollo office, hesitant to take such a step, decided to pursue parallel development. In mid-April, Grumman was instructed to design the lander to accept either system and to slow down RCA’s radar development program. Radar-tracker studies at the Manned Spacecraft Center would be completed by September, and a contractor would be selected to design the tracker. William A. Lee in Shea’s office protested holding back RCA; the delay would force the deletion of the radar from the first and second landers, to be used on earth-orbital missions. This, said Lee, would be a violation of the all-up concept of flying only complete spacecraft. Changes in the radar program would be justified, he concluded, solely

by the implicit assumption that we will cancel the program eventually. The logic of this is very questionable, since it clearly says that the money being spent on this program is being wasted deliberately. We should either pursue the radar in a manner which would permit its use on the LEM, or we should cancel it. I can find no middle ground.... The small number of earth-orbital LEM flights can be justified only if we adhere rigorously to the ground rules of all-up flights and qualification prior to flight. It is too early in the LEM program to consider compromising these requirements, and to do so for budgetary reasons will almost certainly prove to be false economy.16

Probe sensor on lunar module landing gear, to alert astronauts that touchdown on the lunar surface was imminent.

In August, Houston amended its contract with AC Electronics to include the optical tracker as government-furnished equipment. Grumman grumbled but kept the spacecraft design flexible. Two months later, MSC’s Assistant Director for Flight Crew Operations Donald Slayton objected to the tracker because of its limitations in determining range and range-rate (approaching and departing speeds) data and the lack of experience in using the instruments. If an immediate choice had to be made, Slayton said, choose the radar. At the end of the year, Mueller, Shea, and Robert C. Duncan set up what they called a “rendezvous sensor olympics” to be completed in the spring of 1966. If either system lagged, the decision would be obvious; if both were successful, Duncan’s division would recommend a choice; if both failed, there would be a lot of work ahead.17

The optical tracker’s lighter weight was attractive, since weight was an important factor in 1965. The lander had gained even more weight during the early months of the year than the command and service modules. In May, Shea persuaded Mueller to approve an increase in lander weight to 14 850 kilograms, including crew and equipment. In June, Harry L. Reynolds warned Owen Maynard that it would be difficult to keep the spacecraft below even that figure. All that summer, the warnings continued. Caldwell Johnson wrote Shea in August that the lander might get too heavy to do its job. The next month Shea asked Houston management for help in solving the problem. He also formed a Weight Control Board (headed by himself) to act on reduction proposals.18

Really worried now, Grumman launched a two-pronged attack known as “Scrape” and “SWIP.” Scrape meant just what the word implies, searching the structure for every chance to shave bulk off structural members. But SWIP (Super Weight Improvement Program) was Grumman’s real war against weight.

Grumman project engineer Thomas J. Kelly led a SWIP team of a dozen experts in structures, mass property, thermodynamics, and electronics, whose task was to second-guess the whole design. This same team had recently and successfully shaved weight off the F—IIIB aircraft, and it knew what a tough job it was up against. When the SWIP campaign started, the engineering design was 95 percent complete. So designers pored over already approved drawings, looking for ways to lighten the craft. Grumman also pressured Houston officials to keep all government-furnished equipment for the lander within the specified weights. And Bethpage scrutinized parts supplied by its subcontractors and insisted that these weights be reduced wherever possible. Weekly reports and monthly meetings between Bethpage and Houston turned into forums for airing suggestions for further reductions and discussions of what had been done. The first such review, held at Grumman on 3 September, revealed that 45 kilograms had already been whittled from the structure by Scrape. The more extensive SWIP plan was outlined—what had been started, what was planned, and what would be expected by way of evaluation and cooperation from Houston’s Apollo subsystem managers.19

By the end of 1965, Scrape and SWIP had pruned away 1100 kilograms, providing a comfortable margin below the control weight limit. One of the more striking changes to come from this drive for a lighter spacecraft was the substitution of aluminum-mylar foil thermal blankets for rigid heatshields. The gold wrapping characteristic of the lander’s exterior saved 50 kilograms.20

Many of these weight-reducing changes made the lander so difficult to fabricate, so fragile and vulnerable to damage, that it demanded great care and skill by assembly and checkout technicians. Structural components took on strange and complex shapes, requiring careful machining to remove any excess metal—a costly and time-consuming process even after vendors had been found who would make these odd looking parts.ba21

THE LEM TEST PROGRAM: A PACING ITEM

Houston reviewed Grumman’s testing program during 1965 to make sure it covered everything from small components to the big test articles. On 15 April Grumman began test-firing the ascent engine at White Sands. Propulsion testing was also being conducted at Bell and STL. Although engine firing programs were behind schedule, Houston expected better performance shortly.22

Six lunar test articles (LTAs) formed the backbone of the ground test program. Bethpage shipped LTA-2 to Huntsville for vibration testing to see if it could withstand launch pressures, and LTA-10 to Tulsa, to check its fit in the adapter. LTA-1 was a “house” spacecraft, used to iron out problems during fabrication, assembly, and checkout. Three more LTAs were under construction: LTA-8 for thermal-vacuum testing in Houston and LTAs 3 and 5 for combined structural shakings, vibrations, and engine firings.23

Flight test plans for the early production landers were flexible to accommodate schedule differences with the command module. LEM-I naturally received the lion’s share of attention, since Grumman had to get it ready for an unmanned “LEM-alone” mission (Apollo-Saturn 206A). LEM-1 would have to be ready at least three months before the Block II ” command module, however, or its first mission would be part of a test of the combined spacecraft.24

But Grumman was moving slowly. In the spring of 1965, John H. Disher of NASA’s Washington Apollo office told Shea he believed LEM-1 would be a year late, making the lander a pacing item. Many factors contributed to LEM-I’s inertia, but ground testing topped the list. And the trouble in ground testing was getting equipment ready to make the tests. Grumman’s old bugaboo—ground support equipment (GSE)—had reared its ugly head. The significance of GSE shortages was not lost on Washington. At a program review on 20 April, Mueller told Houston managers to identify all lander GSE, along with the date it would be needed, as “sort of a thermometer” to bring the weaknesses in the system to Grumman management’s attention.25

In mid-May, Grumman officials looked at possible launch dates for the first vehicle but could decide nothing definite because of a pinch in fiscal year 1966 funding. Hardware production had to be cut back in an attempt to absorb some of the loss. In July, Houston directed Bethpage to delete LTA-4, a vibration test article, and two flight test articles (FTAs). To replace the FTAs, two LTAs would be refurbished when they finished ground tests. After trials with scale and full-sized models had been run at Langley and elsewhere, Houston also canceled a landing gear test model as an unnecessary expense.26

Grumman, at a program review on 6 July, then asked NASA to relax the rules on qualification testing and to permit delivery to the Cape of vehicles not fully equipped. Shea rejected this suggestion, ordering his subsystem managers to make sure that only all-up landers left the Grumman plant. Problems with some of the subsystems were a factor in this request. Bell in particular was having trouble with the redesigned injectors and tank bladders for the ascent engine, and manufacturing problems were harassing Hamilton Standard’s environmental control system. Subsystem manager Richard E. Mayo asked Donald Sullivan (head of a manufacturing unit in the Apollo office) to find out what was wrong. When he visited the Windsor Locks plant, Sullivan noted that, although Hamilton Standard was turning out high-quality parts, good solid management in assembling and integrating the system was lacking.27

Electrical and electronics gear, where design changes persisted throughout 1965, was also lagging. The abort sensor assembly (part of the abort guidance system), for example, was redesigned to incorporate continuous thermal control, a programmable memory for the computer, and a data-entry-display assembly. In mid-August R. Wayne Young, who had succeeded William Rector as the lander’s project officer, ordered Grumman project manager Robert Mullaney to stop making changes if the present system could do the job.28

Program spending began to equal schedules in importance. Just as the lander got rolling toward flight hardware production, it was caught in the budgetary squeeze imposed by Congress. Grumman had to shoulder most of the burden in holding expenses down. Expenditures had risen dramatically—from $135 million in fiscal 1964 to an estimated $350 million for 1966—as Apollo funding reached its crisis during spring and summer 1965. Grumman’s fiscal discipline lagged in technical problem-solving, subcontracting, and cost and schedule performance. To push the contractor toward a solution, Houston decided it was time to convert Grumman’s cost-plus-fixed-fee contract to an incentive agreement. With incentives to meet and penalties to face if they were not met, Grumman could be expected to overcome these deficiencies.29

The drive for incentive contracting had started in Washington in 1962, when NASA Associate Administrator Robert Seamans and John H. Rubel of the Department of Defense discussed the possibility of converting NASA contracts; defense procurement had called for incentive contracting, whenever possible, for some time. The use of incentives rather than a fixed fee, a turnabout in government dealings with industry, was controversial. Critics pointed to lengthy delays in negotiations that tied up engineers who otherwise could be working on program hardware and a “worsening of government—industry relations by causing contractual bickering.” Seamans and Mueller disagreed, insisting that incentives placed more responsibility on the contractor. It did take time and talent to work out the provisions, but it promised better performance.30

NASA had made only modest headway in this conversion during 1963 and 1964, but the agency intended to revamp the spacecraft contracts in 1965. Mueller wrote MSC Director Gilruth in April, stressing that incentives must reflect schedules, cost, and performance, in that order. To pave the way for incentive negotiations, Houston had to clear up a number of unresolved contract change authorizations, which would be reviewed by a board made up of Houston and Bethpage officials. The review began in mid-March and ended in April with participants deadlocked.31

Houston and Bethpage kept trying to work out the individual contract changes, but there was still no agreement in early June, after three weeks of negotiations. Gilruth and Shea then discussed the impasse with E. Clinton Towl, president of Grumman, and decided that it was pointless to convert the contract at that time. Houston did impose a LEM Management Plan on Grumman, hoping to control cost, schedules, and performance. Until the last quarter of the year, Grumman would be allowed to spend only $78 million, which was less than the contract costs estimated during the unsuccessful review. If Grumman could stay within this limit for a quarter, however, negotiations for the incentive contract could resume.32

In the interval Grumman concentrated on bringing its subcontractors into line and converting its agreements with them into incentive contracts, trying to demonstrate satisfactory control of the program. In September, Grumman submitted a proposal for contract conversion to NASA. Negotia-tions lasted until December and culminated in a contract with enough incentives to spur the contractor to maintain costs and schedules and to meet performance milestones. This arrangement, announced in February 1966, carried the lander program through 1969 at a cost of $1.42 billion. North American’s incentive contract was also negotiated (at an estimated $2.2 billion) during the latter half of 1965.33

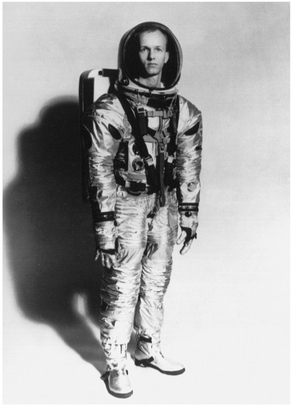

The 1965 version of the Apollo spacesuit and backpack. Changes were made before man eventually stepped out of the spacecraft onto the lunar surface.

THE MANNED FACTOR

While various organizations struggled to get the spacecraft through the development phase, human factors experts concentrated on the progress of the spacesuit and the selection of astronauts. For some time, the suit had met turmoil, schedule delays, and technical problems. Early in 1962, Houston had forced a marriage between Hamilton Standard (for a portable life support system) and the International Latex Corporation (for the suit). Hamilton Standard managed the whole system, known as the extravehicular mobility unit. From the beginning, the arrangement proved unworkable.

Just how unworkable was revealed in the spring of 1964, when prototype suits used in the command module mockup review turned out to be incompatible with the Apollo spacecraft cabin. NASA officials had to fall back on Gemini suits for Block I earth-orbital flights. This substitution gave Hamilton Standard and International Latex a chance to straighten out their problems, but borrowed time did not spell progress. Early in 1965, Hamilton Standard announced that its system manager for the backpack had begun in-house work on backup components for the suit (such as helmets and suit joints). The company had thus become a competitor of its own subcontractor. In February, Hamilton Standard reported that it intended to cancel the International Latex contract, citing poor performance, late deliveries, and cost overruns. Houston concurred.

Houston had also started some remedial actions. In January, David Clark Company, maker of the Gemini suit, had received a contract for backup development of an Apollo Block II suit. After six months, Houston would compare David Clark’s suit with what Hamilton Standard, aided by B. F. Goodrich Company, was turning out. International Latex, informed that it was not being considered in the competition, nevertheless asked permission to submit an entry. When Crew Systems Division tested the three suits in June, International Latex had by far the best product.34

In mid-September, Gilruth and Low told Mueller and Phillips that Hamilton Standard would continue to manufacture the backpack. To eliminate the integration problems of the past, Houston would manage the total system and International Latex would develop the suit under a separate contract. This arrangement was agreeable to NASA Headquarters.35

The other major activity in human factors was the expansion of the astronaut corps. During 1962 and 1963, NASA had selected the second and third groups of pilots. These 23, the Gemini generation, with the original seven formed the basic pool for Apollo crews. In 1965, a new breed, called “scientist-astronauts,” joined the ranks in training at Houston. NASA Headquarters hoped to mollify some of the scientific grumblers and to strengthen its ties with the scientific community by emphasizing Apollo’s potential contribution to science—not only from the instruments that would send back information from the moon but from the men who would fly them there. Surprisingly, some of the drive to enlist these scientist-crewmen came from engineering-oriented Houston.

Robert B. Voas, human factors assistant to Gilruth and a key figure in setting up procedures for selecting Mercury pilots, had conferred with NASA Director of Space Sciences Homer Newell in Washington in 1963 about Houston’s views on scientists for the space program. Voas later met with Eugene M. Shoemaker (of Newell’s office), Joseph Shea, and George Low to discuss the most appropriate specialties. With an eye to lunar-surface, long-duration, and earth-orbital activities, the quartet agreed that the disciplines needed were geology, geophysics, medicine, and physiology.

At this September 1963 meeting, Voas emphasized that Houston wanted qualified pilots, but Shea saw no need for any previous flying experience. Why not take this opportunity to introduce methods for selecting and training nonpilots? In the end, the consensus was that candidates with flying backgrounds would be given preference but that applications from otherwise qualified men who lacked this training would be accepted. The National Academy of Sciences (NAS) should be asked to help recruit and select scientists for the program. Administrator Webb approved the recommendation.36

Harry H. Hess of NAS agreed in April 1964 to have his Space Science Board define appropriate scientific qualifications (age and physical criteria would be Houston’s responsibility). Hess established an ad hoc committee, which submitted its report to Newell in July. In October, NASA announced that it was looking for astronauts with scientific training. For the first time, the selection criteria did not include a requirement for test pilot proficiency. Selectees who were not qualified pilots would be taught to fly after they joined the program. More than 1000 applications had been received by December; 400 of these were forwarded to Hess’s board in February 1965 for academic ranking.37

In June, NASA announced that 6 scientist-astronauts had been chosen from 16 nominated by the science board. In the group were one geologist (Harrison H. Schmitt), two physicians (Duane E. Graveline and Joseph P. Kerwin), and three physicists (Owen K. Garriott, Edward G. Gibson, and F. Curtis Michel). Two of the men, Kerwin and Michel, were qualified jet pilots, but the others were not. These four reported to Williams Air Force Base, Arizona, on 29 July for a year of flight training before joining their colleagues in Houston.38

Gilruth wanted another team of pilot-astronauts, and he sent Slayton to Washington to argue the case before Mueller on 15 January 1965. Mueller was cool to the idea, but he later told Gilruth that he might bring another group on board in the fall. On 10 September, NASA announced it would recruit a fifth set of astronauts to ensure “an adequate number of flight crews for Project Apollo and future manned missions.”39

PORTENTS FOR OPERATIONS

While Phillips and Shea worked on Apollo spending, schedules, mission assignments, and crew selection, Wernher von Braun and his Marshall Space Flight Center colleagues launched a series of three satellites that calmed many of the fears about micrometeoroid hazards of manned space flight in earth orbit. Astronomers had warned about the dangers of space dust to extended spacecraft flights, but Project Mercury had encountered no insuperable difficulties. With Gemini plans for manned spacecraft spending as much as two weeks in space, however, it was imperative that NASA have data from unmanned missions.

NASA’s Office of Advanced Research and Technology and Marshall laid plans for a vehicle called “Pegasus” and hired the Fairchild Stratos Corporation to build it. By 1964, preliminary designs had been completed and ground testing begun. After considering various shapes, even some resembling parasols, Fairchild adopted a simple flat wing that would deploy in orbital flight to a span of 30 meters and expose 80 times more surface—a total of 700 square meters—than any previous detector in orbit.40

The last three Saturn I launches—numbered, in an odd sequence, 9, 8, and 10,bb and called Saturn-Apollo (SA) or Apollo-Saturn (AS), depending on which documents (Marshall or Manned Spacecraft Center) were read— carried both Pegasus satellites and boilerplate (BP) Apollo spacecraft. SA-9 (or AS-103) was launched from the Cape on 16 February, tossing its two payloads into separate orbits. During its fourth revolution, the Pegasus registered its first micrometeoroid hit; two weeks later the count reached only a score; and by May the total was not more than 70. When the other Pegasus missions, launched on 23 May and 30 July, encountered as little orbital debris, Apollo engineers were more confident that micrometeoroids would cause few problems in earth orbit to the thin-skinned service module and much less to the command module wrapped in its protective heatshield cocoon.41

Pegasus provided near-earth data to Apollo; another unmanned vehicle, Ranger, gave a view of the ultimate goal—the moon. After many failures and in July 1964 one resounding success, Ranger ended with two sterling flights, one in February and one in March 1965—much to the relief and credit of the Jet Propulsion Laboratory, the parent organization. Ranger VIII, aimed at the moon’s equatorial zone in the Sea of Tranquility, transmitted more than 7000 pictures before it crashed. Engineers and scientists had an opportunity to study features no more than 30 centimeters in size. Ranger IX, heading for the crater Alphonsus, made the three-day trip with scarcely a course correction. Telemetry from this vehicle, translated and fed through commercial television, gave the public its first close-up view of the moon.42

Manned space flight was a beehive of activities in 1965, with the Gemini program recording five outstanding missions. The Soviet Union had twice flown its multimanned Voskhod spacecraft—in October 1964 and March 1965—and the United States was eager to rejoin the competition. On 23 March after a 22-month hiatus in American manned flight, Virgil Grissom and John Young, in a three-orbit flight aboard Gemini III, fired their spacecraft thrusters and changed their orbit. For the first time, man was truly controlling a spacecraft and its direction and speed in space. But this was only a spacecraft qualification flight. More ambitious missions were ahead for Gemini, to test the abilities of the astronauts in space and ground crews in the control center and around the worldwide tracking network in preparation for Apollo.

The next two Gemini missions, IV and V, were stepped increases in endurance, four days and eight days, each flight with its individual flavor. James McDivitt and Edward White flew a four-day mission 3-7 June that featured extravehicular activity and a practice rendezvous with the second stage of their launch vehicle. White, using a hand-held jet gun, propelled himself through space and floated at the end of a snakelike eight-meter tether with considerable aplomb.bc The attempt to maneuver up to the spent booster stage was not so successful, however, causing some exponents of rendezvous to worry about the future. But little more than two months later, 21—29 August, Gordon Cooper and Charles Conrad embarked on an eight-day voyage and successfully carried out a “phantom rendezvous,” catching an imaginary moving target set up by the flight controllers. Deputy Administrator Hugh Dryden wrote President Lyndon Johnson that the success of Gemini V, clearing the way for a two-week endurance test, “has assured us of man’s capability to travel to the moon and return.” 43

Although Dryden did not live to see it (he died on 2 December), the year ended with the most exciting and ambitious space flight up to that time. Known to many as the “Spirit of ‘76,” the concurrent flight of two manned Gemini spacecraft proved the feasibility of both long-duration flight and rendezvous. It began with the launch of Gemini VII, piloted by Frank Borman and James Lovell, on 4 December. Eleven days later, Walter Schirra and Thomas Stafford flew Gemini VI-A to a rendezvous with their orbiting compatriots to cap a banner year in space.44

Gemini’s successes, although answering important questions, spawned some unwelcome suggestions for Apollo. White’s spectacular extravehicular operation touched off plans for a similar exercise in the first manned Apollo flight; Shea vetoed that idea in a hurry. An even grander scheme pitted Gemini against Apollo. LEO, for “Large Earth Orbit”—all the way around the moon—was championed by Charles Mathews and André Meyer of the Gemini office and subsequently endorsed by Gilruth and Mueller. Since LEO could put Americans in the vicinity of the moon earlier than Apollo, it would be a big leap forward in the space race, which still loomed large in the minds of many people. Four Russian Luna missions had unsuccessfully attempted soft landings during 1965, demonstrating that the Soviet Union was still interested in the lunar target. Seamans vetoed LEO, believing Apollo needed no more competition. But Congress got wind of the plan and started asking questions. When Representative Olin E. Teague wanted to know if there would be any advantages to such a mission, Webb answered that it would be expensive and would still not guarantee success in beating the Russians to a lunar landing. Apollo was operating on a thin margin of resources as it was; if Congress wanted to spend more money, he told Teague, “I believe it would be in the national interest to [give it to] the Apollo program.”45

So Gemini and Apollo were not to be rivals. Then could they perhaps assist each other? Howard W. Tindall, Jr. (whose specialty was mission planning and whose “Tindallgrams” achieved local fame), did not think so.bd They shared the mutual objectives of rendezvous, docking, and long-duration flight, but hardware and mission planning were so different and the respective managers were so busy trying to meet schedules that they could seldom afford the luxury of keeping abreast of each other’s program.46

Apollo also had some operational successes in 1965—none as spectacular as the Gemini flights but one at least more breathtaking than expected. Several dozen newsmen gathered at White Sands Missile Range, New Mexico, on 19 May to watch Mission A-003, an abort test of a boilerplate spacecraft at an altitude of 35 000 meters. At 6 that morning, the Little Joe II ignited and rammed its payload skyward. A few seconds after liftoff, a fin-vane at the base of the booster stuck and started the 13-meter-tall spacecraft-booster combination spinning like a bullet. Twenty-six seconds into the flight and still on a true course, the vehicle started coming apart. The abort-sensing system signaled the launch escape tower rocket to fire and pull the spacecraft away at an altitude of 4000 meters. While newsmen watched the fluttering remains of the Little Joe II, BP-22’s parachutes lowered it gently to the desert floor. Apollo had another answer: the launch escape system worked in a real abort situation.47

Little more than a month later, on 29 June, the launch team in New Mexico prepared to test an abort off the pad. The year before, a similar test had proved the escape tower rocket could jerk the spacecraft safely away from an exploding launch vehicle. But both the spacecraft and its escape system had since gained weight. In the second test, the rocket pulled the spacecraft higher in the air and farther downrange than expected.48

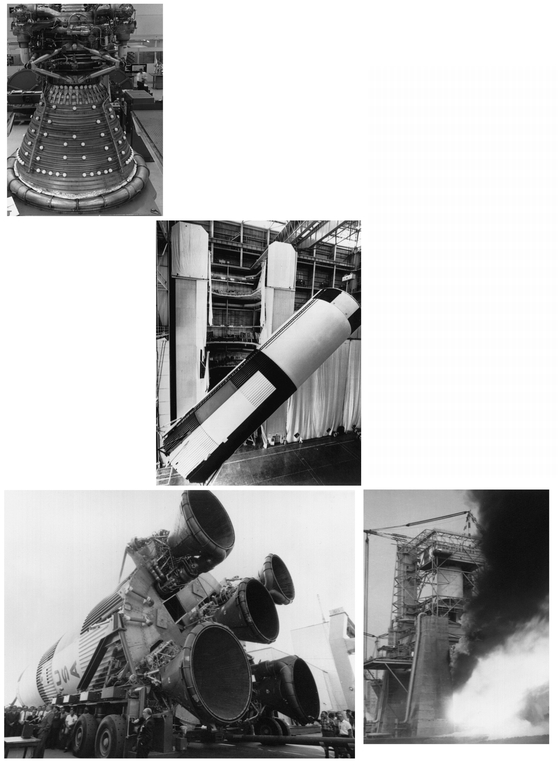

Perhaps one of the more heartening events during 1965 was the static-firing at the Mississippi Test Facility of the S-IC, the first stage of the Saturn V. The five F-I engines, burning for six and a half seconds, produced the designed 33.4 million newtons (7.5 million pounds) of thrust, as much power as five Saturn Is lashed together. Going on up the Saturn V stack, the S-II second stage was static-fired in April and the S-IVB third stage in August, with excellent results.49 Although the Saturn I, with its ten straight launch successes, had already proved the clustered-stage concept, Mueller and his staff breathed easier after the Saturn V tests.

The F-I engine at upper left, one of five fitted into the Saturn V’s S-IC first stage, being prepared at the Rocketdyne Plant in California for shipment to the Michoud launch vehicle assembly plant in Louisiana. At upper right an S-IC stage at Michoud, 27 June 1965, is removed from its vertical assembly tower. After installation of wiring and components, this ground test version—the first in the Saturn V development program—would be shipped by barge to Marshall Flight Center in Alabama. Marshall Director Wernher von Braun (at the microphone in the center photo) held a brief ceremony 26 September 1965, accepting the first flight S-IC. Below, S-IC-T is fired for 2½ minutes at Marshall in an August 1965 ground test.

Only solar radiation remained a worry of first rank at the end of 1965. During the year, a Solar Particle Alert Network was set up to study sunspots and to develop some techniques for predicting solar storms, so Apollo crews could take protective action against dangerous doses of radiation. The cyclical nature of sunspot behavior was, fortunately, fairly well understood. By using existing observatories and adding a few more (one at Houston), NASA intended to plan Apollo missions to avoid the periods of greatest solar activity.50

A new hazard discussed with increasing frequency during the year was the danger of back contamination from pathogenic organisms aboard a returning lunar spacecraft. The possibility of contaminating other planets during space exploration had long been recognized; now the risks of returning materials to the earth after exploratory voyages had to be faced. The United States Public Health Service was brought in to advise NASA on care of lunar samples and crews. Sharing the apprehensions, Congress hastily authorized the construction of a special quarantine facility in Houston. The Lunar Sample Receiving Laboratory, hurriedly built during the next two years, was one of the most elaborately safeguarded biological facilities in the world.51

Another indication that the operational phase of Apollo was approaching was Mueller’s creation in July of a Site Selection Board to recommend lunar landing areas. Gilruth sent William Lee and William E. Stoney, Jr., to serve on this board, as well as on the Ad Hoc Surveyor/Lunar Orbiter Utilization Committee (which Gilruth believed belonged in the same basket, anyway). The next month, John E. Dornbach’s Lunar Surface Technology Branch compiled lists of candidate sites. In October, NASA announced that ten areas had been selected and that they would be photographed by Lunar Orbiter cameras during 1966.52

Picking sites and building a facility to handle samples and crews on their return to earth were good starts toward operations, but some communications and control systems problems remained to be ironed out. Early in its planning, NASA had seen the need for a “real-time computer complex” (RTCC) for instantaneous information on and control of manned space missions. Located at Goddard during all of Mercury and the early part of Gemini, the complex linked 17 ground stations around the globe and permitted observers to monitor manned flights on virtually a continuous basis. In addition, Mercury, Gemini, and Apollo needed digital applications in six other areas: premission planning and analysis; space flight simulations to aid manufacturers and astronauts; launch operations, so data could be instantly checked and analyzed; physiological monitoring of crewmen in flight, using biosensors; postflight mission analyses, so data on each flight could be catalogued and filed for future reference; and in the arena of worldwide testing, known to NASA by the fishy-sounding acronym CADFISS, for computer and data-flow integrated subsystems.

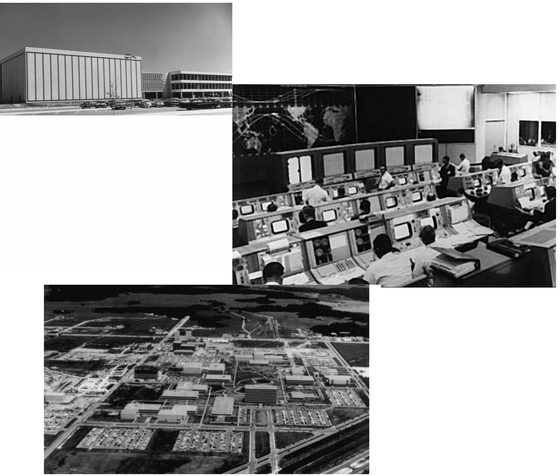

Mission Control Center, Houston, above. At right, the mission operations control room during the Gemini V flight in August 1965. The room is in the windowless part of the building. Below, Manned Spacecraft Center during the mission. Mission Control is at the center, just to the right of the multistory building under construction.

After lengthy technical and administrative arguments, NASA moved the computer complex to Houston to form an “integrated mission control center.” The center would have four main duties: processing global signals for display to flight controllers, computing and sending antenna-aiming directions to the global tracking stations, providing navigation information to the spacecraft, and simulating all mission data for personnel training and equipment checkout. By spring of 1965, Houston’s computer complex was nearly ready, with five IBM 7094 model II computers on the line. Flight Director Chris Kraft assured Mueller the complex would be ready to control Gemini IV in June, and he was right. In September, a supplemental Univac 1230 was added to the complex, and plans were laid to replace the 7094s with new IBM 360 model 75s. Although the 7094s remained in service until 1968, modifications and upgrading provided a daily capacity of 80 billion calculations.53

Besides the enormous ground-based complexes, American industry had developed small computers for aeronautics and astronautics. While MIT’s Instrumentation Laboratory was developing the Apollo guidance and navigation system, a major part of which was the onboard computer, throughout the computer industry there were breakthroughs in technology, based on microminiaturization, transistors, integrated circuits, thin-film memories, high-frequency power conversion, and multilayer interconnection boards.

Mercury had flown without onboard computers, but Gemini needed a digital computer and visual displays to control ascent, rendezvous, orbital navigation, and reentry. IBM delivered the first computer for a Gemini spacecraft in 1963, but NASA had been shopping around for a computer source for Apollo even earlier. In May 1962, NASA and MIT had selected Raytheon. Drawing on MIT’s experience with Polaris missiles and nuclear submarines, Raytheon produced a general-purpose prototype by mid-1965.

The first Block I computer embodied significant advances over other computers. But it was soon discontinued because NASA decided to delete inflight maintenance and because the design was not satisfactory in either malfunction detection or packaging. The next, or Block II, version corrected these weaknesses. Weighing 31 kilograms and consuming only 70 watts of power during normal operation, the Block II “brains” incorporated redundant systems and had the largest memory of any onboard spacecraft computer to that time (37 000 words) .54

THE COURSE AND THE FUTURE

Two major questions faced NASA planners during 1965. Was Apollo on course, at what was essentially its midpoint, to meet the goal of a lunar landing before the end of the decade? And what should follow Apollo in the manned space flight arena?

To find the answer to the first question, the House Subcommittee on NASA Oversight, led by Teague, set up a special staff in June to assess schedules, funding, and spacecraft management. After three months of probing, a staff study published under the title Pacing Systems of the Apollo Program identified seven bottlenecks in Apollo. For the lander, pacing systems were the descent engine, rendezvous radar, weight growth, and ground support equipment; for the command and service modules, they were engineering drawing releases, subassembly delivery and certification, and tooling and fabrication of the heatshield. The subcommittee concluded that NASA was applying its resources effectively to these problems and the program was progressing on schedule.55

NASA leaders, meanwhile, were worrying about what would come after Apollo, in view of the rising demand for dollars for human resources on the domestic front and military commitments abroad, particularly in Southeast Asia. Out of this concern came a new Headquarters program office called Apollo Applications (AAP) , headed by David M. Jones, an Air Force major general assigned to NASA. Mueller had two objectives in setting up this office: preserving the Apollo team and using the hardware to get some pay-offs in science and earth resources.

To Houston this was evading the issue. In a lengthy letter to Mueller, MSC Director Gilruth manifested “deep concern that ... a critcal mismatch exists between the present AAP planning, the significant opportunities for manned space flight, and the resources available for this program.” Speaking both for himself and his deputy, George Low—who as much as anyone within NASA had helped chart the course for Apollo—Gilruth proposed that “the next major step in manned space flight should involve a large permanent manned orbital station,” which would be “an operational step leading to man’s exploration of the planets.” As structured, he said, AAP would simply maintain the status quo in the production and flight of Saturn-Apollo hardware. “Merely doing this, without planning for a new program, and without doing significant research and development as part of AAP, will not maintain the momentum we have achieved.”56

Thus the total climate of opinion surrounding Apollo had altered. No longer did the moon seem the all-important—and all-consuming—goal it had been. Other objectives in the new ocean of space were taking shape. But conditions were not ripe: 1966 would be a year of progress for exis ing manned space flight programs, not a curtain-raiser for any major new57 projects. In one more flight, Little Joe II would complete its series of Apollo tests; after five more missions, which made orbital flight routine, Gemini would phase out and Lunar Orbiter and Surveyor would phase in; and Saturn and Apollo vehicles would taste the first fruits of success.

ing manned space flight programs, not a curtain-raiser for any major new57 projects. In one more flight, Little Joe II would complete its series of Apollo tests; after five more missions, which made orbital flight routine, Gemini would phase out and Lunar Orbiter and Surveyor would phase in; and Saturn and Apollo vehicles would taste the first fruits of success.