Fences

It has been said that good fences make good neighbors. If this is true, it would seem that good fences are a must in your neighborhood, right? So the key question is: what makes good fences?

The answer: this chapter.

It’s not easy to find a property that doesn’t have fencing, and there are several reasons why this is so:

• People are proud to define their property line, and fences provide definition.

• Homeowners often desire the privacy that fences offer.

• Fencing blocks an unattractive view and establishes a frame that showcases your picture-book yard.

• In some cases, fences create boundaries against unwanted deer, dogs, and other four-legged critters that might wander into your yard.

• Fences themselves show design character and style that make them a focal point.

• Fences highlight the slope and flow of your land. A hill crowned with a fence creates natural angles that attract the eye.

Perhaps the most compelling reason that fences are so prevalent? They’re doable. You can build a fence—it’s not tricky work—and as you do, you can enjoy the outdoors and accomplish a straightforward project at your own pace. It’s hugely satisfying work that in short order transforms your property.

In This Chapter:

Designing Fences: Slope

It’s considerably easier to build a fence when the ground is flat and level along the entire length of the proposed site line. But few landscapes are entirely flat. Hills, slight valleys, or consistent downward grades are slope issues to resolve while planning your fence. There are two common ways to handle slope: contouring and stepping.

With a contoured fence, the stringers are parallel to the ground, while the posts and siding are plumb to the earth. The top of the fence maintains a consistent height above grade, following the contours of the land. Most pre-assembled panel fences cannot be contoured, since the vertical siding members are set square to the stringers. Picket fence panels may be “racked” out of square for gentle contouring. Vinyl fence sections generally permit contouring.

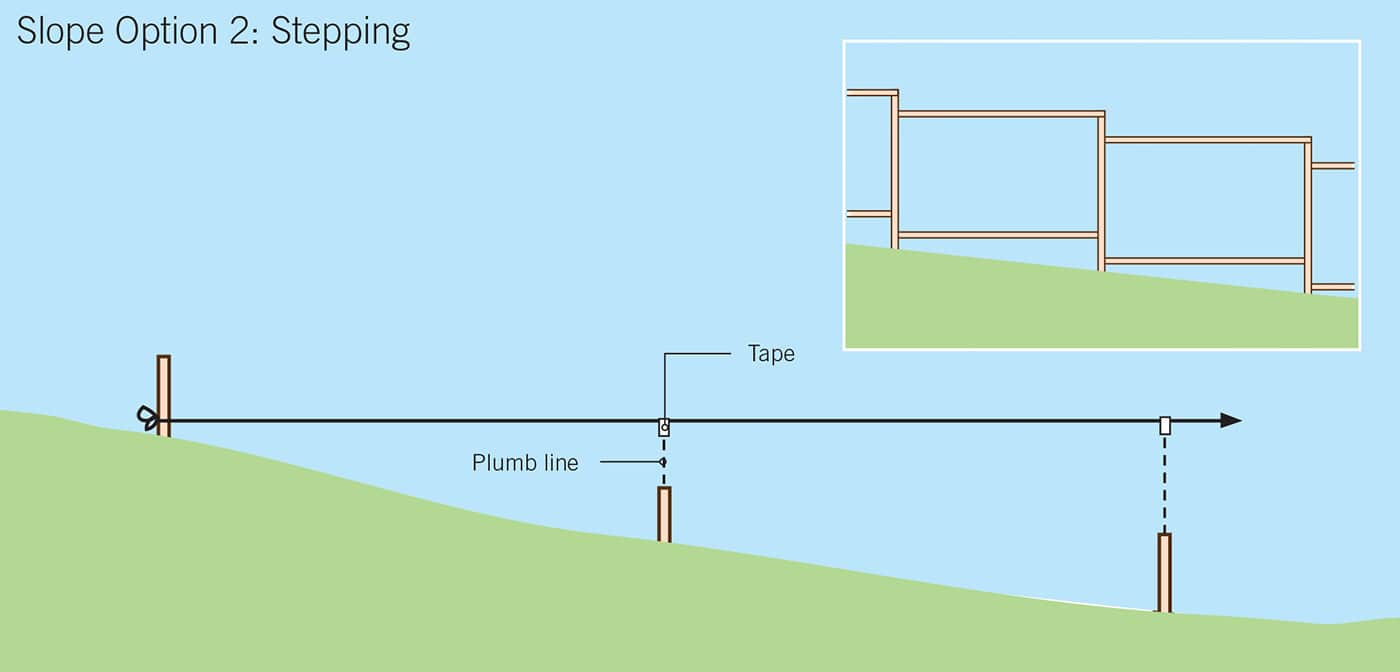

Each section of a stepped fence is level across the top, forming the characteristic steps as the ground rises or falls. Stepped fences appear more structured and formal. Pre-assembled panels may be stepped to the degree their bottoms can be trimmed for the slope or that additional siding (such as kick boards) can be added to conceal gaps at the tall end of the step. Stepped custom-built fences are more work than contoured fences since vertical siding boards must be trimmed to length individually and post heights may vary within a layout.

Solid planning and careful execution allow you to turn a sloped yard into a positive design factor when you build your fence or wall project.

Strategies for Managing Slope

Stepped panels are horizontal, maintaining an even height between posts. A good strategy for pre-built panel systems, stepping fences is the only way to handle slope when working with panels that cannot be trimmed, racked, or otherwise altered.

Racking a panel involves manipulating a simple fence panel by twisting it out of square so the stringers follow a low slope while the siding remains vertical. Stockade and picket panels are good candidates for this trick, but the degree to which you can rack the panels is limited. If the siding is connected to stringers with more than one fastener at each joint, you’ll need to remove some fasteners and replace them after racking the panel.

Contouring creates a more casual, natural-looking fence. Each individual siding board is set the same distance from the ground below and allowed to extend to full height without trimming. The resulting top of the fence will mimic the ground contour.

Bottom trimming creates a level fenceline with a baseline that follows the slope and contour of the land. On low slopes you can use this technique and trim the siding boards on pre-made panels that have open bottoms (in some cases you can raise the bottom stringer). Bottom trimming is best for site-built board and stringer fences, however.

Contoured Fences

A contoured fence rolls along with the terrain, maintaining a consistent height above the ground as it follows the land. Picket fences and others with individual siding work best for contouring. There are multiple tactics you can use to build a contoured fence. The scenario described below involves setting all your posts, installing stringers, trimming posts to uniform height above the top stringer and then adding the picket siding.

Contoured installation overview. Begin the layout by running a string between batter boards or stakes located at the ends and corners of the fenceline, adding intermediate batter boards or stakes as needed to keep the string roughly parallel with the grade. Mark the post centers at regular distances (usually 6 or 8 feet) on the string. Don’t forget to allow for the posts when measuring. Drop a plumb bob at each post mark on the string to determine posthole locations. Mark these locations with a piece of plastic pegged to the ground or by another method of your choosing.

Align, space, and set the posts (if appropriate for your fence type). Attach the lower stringers between posts. If you are using metal fence rail brackets, bend the lower tab on each bracket to match the slope of the stringer. Each stringer should follow the slope of the ground below as closely as possible while maintaining a minimum distance between the highest point of the ground and the bottom of the stringer. This distance will vary from fence to fence according to your design, but 12 inches is a good general rule.

Install all of the lower stringers and then install the upper stringers parallel to the lower ones. Make sure to maintain an even spacing between the stringers. Establish the distance from the upper stringer to the post tops and then measure this distance on each post. Draw cutting lines and trim the post tops using a circular saw and a speed square clamped to the post as a guide.

Make a spacer that’s about the same width as the siding boards, with a height that matches the planned distance from the ground to the bottom of each siding board. Set the spacer beneath each board as you install it. You’ll also want a spacer to set the gap between siding boards. Install the siding and add post caps.

Contoured fences can follow ground with either a regular slope or an irregular slope. Place a stake at the beginning and end of the fence line and at each corner. Add intermediate stakes to maintain spacing when the slope changes.

Stepped Fences

A stepped fence retains its shape and configuration regardless of changes in slope. The effect of the stepping up or down of whole panels it to create a more formal appearance, but it also lets you avoid cutting premade fence panels. The sacrifice is that you often end up with very tall fence posts and you may need to add filler wood between panel bottoms and irregular dips in the ground.

The following stepping technique works over slopes of a consistent grade. If the grade changes much, bracket each new slope with its own stake or pair of batter boards, as in the illustration on the previous page. Treat the last post of the first run as the first post of the second run and so on.

Alternatively, step each section independently, trimming the post tops after the siding is set. The scenario below describes a flat cap stringer, which some fences use to create a smooth top. If this is not needed on your fence, simply measure down the appropriate distances to position the inset or face-mounted stringers.

Stepped installation overview. Using mason’s string and stakes or batter boards, establish a level line that follows the fence line. Measure the length of the string from end stake to end stake. This number is the run. Divide the run into equal segments that are between 72 and 96 inches. This will give you the number of sections and posts (number of sections plus one).

Measure from the ground to the string at both end stakes. The difference between the two measurements is the rise of the slope. Divide the rise by the number of fence sections on the slope to find the stepping measurement.

Measure and mark the post locations along the level string with permanent marker “Vs” on tape. Drop a plumb bob from each post location mark on the string. Mark the ground with a nail and a piece of bright plastic.

Set the first post at one end and the next one in line. Mark the trim line for cutting to height and run a level string from the cutting line to the next post. Measure up (or down) from the string for the step size distance. Adjust marks if necessary before cutting the posts.

Repeat until you reach the end of the fence line. Avoid creating sections that will be too tall or too short. The bottom stringer should remain at least 4 inches above grade.

Cut all posts and then attach stringers or panels so the distance from the tops of the posts to the stringers is consistent.

Stepped fences (inset) can be installed on either regular or irregular slopes. To plan the fence, run a mason’s string between stakes or batter boards at the high end and the low end of the fence line; measure the distance from the string to the ground at both ends, then calculate the difference between measurements to find the total rise. Divide this amount by the number of fence sections to determine the stepping measurement for each fence panel. On irregular slopes, the amount of drop will vary from section to section.

Laying Out Fence Lines

Fence installations begin with plotting the fence line and marking post locations. Make a site map and carefully measure each post location. The more exact the posthole positions, the less likely it is that you‘ll need to cut stringers and siding to special sizes.

For walls, determine the outside edges of the footings along the entire site, as for a fence line. Then plot right angles to find the ends and inside edges of the footings.

Laying out a fence or wall with square corners or curves involves a little more work than for a straight fence line. The key for these techniques is the same as for plotting a straight fenceline: measure and mark accurately. This will ensure proper spacing between the posts and accurate dimensions for footings, which will provide strength and support for each structure.

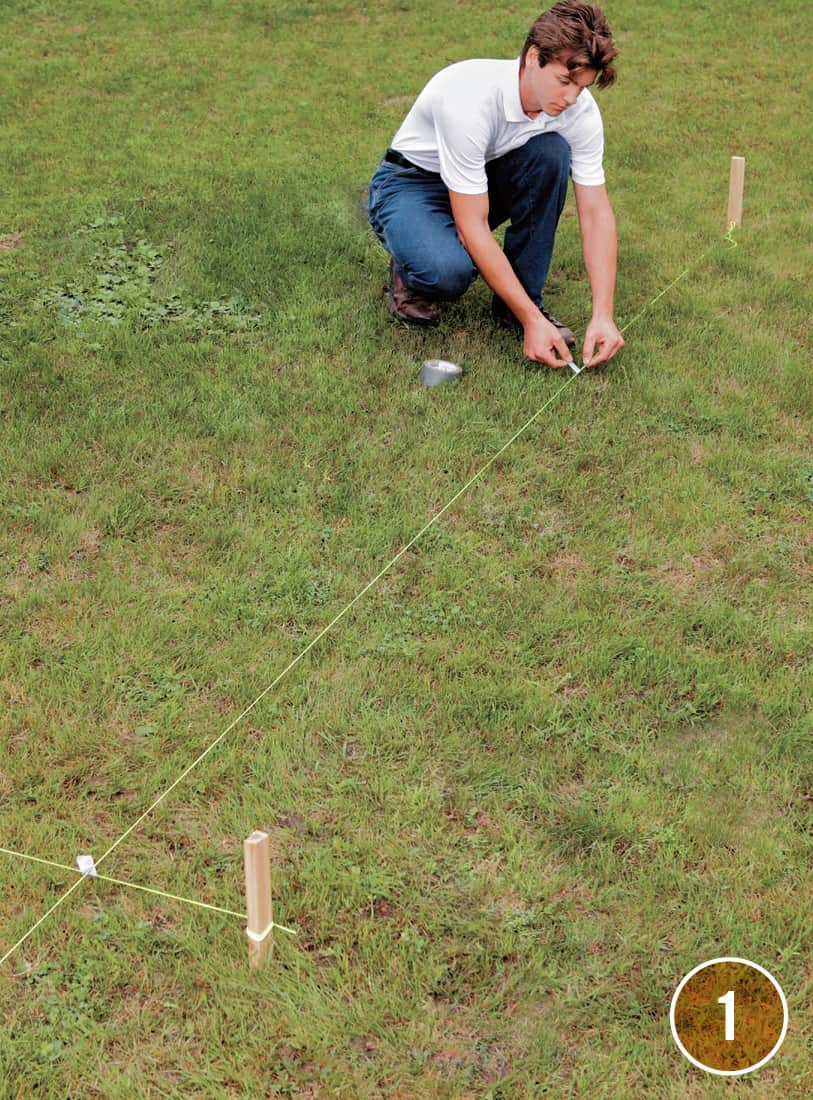

How to lay out a straight fence line. Determine your exact property lines. Plan your fence line with the locally required setback (usually 6 to 12 inches) from the property line, unless you and your neighbor have come to another agreement. Draw a site map. It should take all aspects of your landscape into consideration, with the location of each post marked. Referring to the site map, mark the fence line with stakes at each end or corner-post location.

Drive a pair of wood stakes a couple of feet beyond each corner or end stake. Screw a level crossboard across the stakes about 6 inches up from the ground on the highest end of the fence run. Draw a mason’s string from the first batter board down the fence line. Level the line with a line level and mark the height of the line against one stake of the second batter board pair. Attach a level batter board to these stakes at this height and tie the string to the crossboard so it is taut.

To mark gates, first find the on-center spacing for the gateposts. Combine the width of the gate, the clearance necessary for the hinges and latch hardware, and the actual width of one post. Mark the string with a “V” of masking tape to indicate the center point of each gatepost.

To mark remaining posts, refer to your site map, and then measure and mark the line post locations on the string with marks on masking tape. Remember that the marks indicate the center of the posts, not the edges.

Use a pair of wood stakes and mason’s string to plot the rough location of your fence or wall. Then, for greater accuracy, install batter boards to plot the final location.

Tips for Installing Batter Board

To install batter boards, drive a pair of short wood stakes a couple of feet beyond each corner or end of the rough planned fenceline. Screw a level crossboard across one pair of stakes, about 6" up from the ground on the higher end of the fence run. Loosely tie a mason’s string to the middle of the crossboard.

Stretch the mason’s line from the batter board to the second pair of stakes at the opposite end or corner of the run. Draw the string tight and level it with a line level. Mark the string’s position onto one of the stakes. Fasten a crossboard to the second pair of stakes so it is level and its top is aligned with the mark on the stake. Tie the mason’s line to the center of the crossboard.

Measure out from the starting points of the fence line and mark post locations directly onto the layout lines using pieces of masking tape (don’t forget to allow for the widths of your posts—see tips below).

Laying Out Right Angles

If your fence or wall will enclose a square or rectangular area, or if it joins a building, you probably want the corners to form 90-degree angles. There are many techniques for establishing a right angle when laying out an outdoor project, but the 3-4-5-triangle method is the easiest and most reliable. It is a simple method of squaring your fence layout lines, but if you have the space use a 6-8-10 or 9-12-15 triangle. Whichever dimensions you choose, you’ll find it easier to work with two tape measures to create the triangle.

How to Lay Out a Right Angle

How to Lay Out a Right Angle

Drive a pair of stakes along a known fence line and run a line that crosses the corner post location (this line should stay fixed as a reference while you square the crossing line to it). Drive a stake 3 ft. out from the corner post location, on the line you don’t want to move. You will adjust the other line to establish the right angle.

Draw one tape measure from the post location roughly at a right angle to the fixed line. Draw the tape beyond the 4 ft. mark and lock it.

Angle the second tape measure from the 3-ft. stake toward the 4 ft. mark on the first tape measure. The two tapes should intersect at 5 ft. and 4 ft.

Drive a stake at the point where the tape measure marks intersect. Run a line for this stake to another stake driven past the corner post location to establish perpendicular layout lines. The string tied to the second stake should pass directly over the post location.

Laying Out Curves

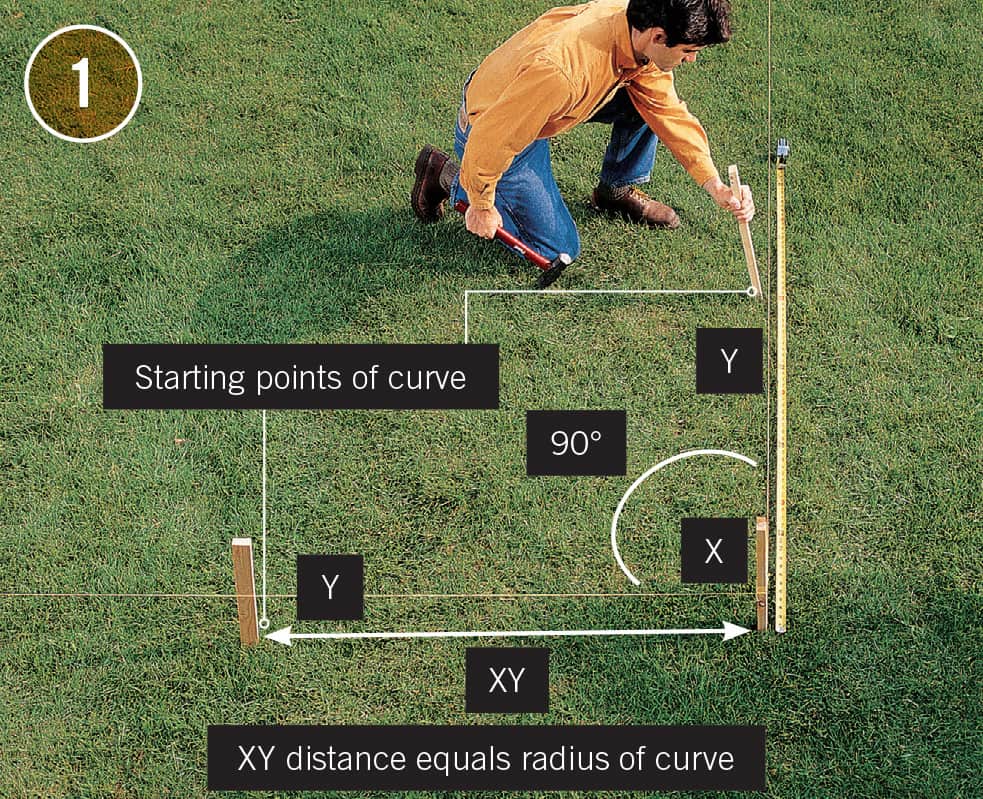

A curve in a fenceline or wall must be laid out evenly for quality results. One easy way to accomplish this is to make a crude compass by tying one end of a string around a can of marking paint and tying the other end to a wood stake, as shown in Step 3 below. The radius of the curve should equal the distance from the compass’ pivot stake to the starting points of the curve, so make sure to tie the string to this length.

How to Lay Out a Curve

How to Lay Out a Curve

Plot a right angle at the corner of the outline, using the 3-4-5 method (see page 140). Measure and drive stakes equidistant from the outside corner to mark the starting points for the curve (labeled “Y” here).

Tie a mason’s string to each Y stake, and extend the strings back to the corner stake. Hold the strings tight at the point where they meet. Then, pull the strings outward at the meeting point until they are taut. Drive a stake at this point to create a perfect square. This stake (labeled “Z” here) will be the pivot point for your string compass.

Mark the curve: Tie a mason’s string to the pivot point (Z) and to a can of marking paint. When the string is held taut, the can’s spray nozzle should be even with the stakes at the start of the curve (Y). Keeping the string taut, spray the ground in a smooth arc, extending the curve between the two Y stakes.

Setting Posts

Even among professional landscapers you’ll find widely differing practices for setting fence posts. Some take the always-overbuild approach and set every post in concrete that extends a foot past the frostline. Others prefer the impermanence, adjustability, and drainage of setting posts in packed sand or gravel. Some treat the post ends before setting the posts, others don’t bother. The posts may be set all at once, prior to installing the stringers and siding; or, they may be set one at a time in a build-as-you-go approach. Before deciding which approach is best for your situation, it’s a good idea to simply walk around your neighborhood and see how the posts for similar fences are installed, then assess which posts seem to be holding up the best.

Another area of dispute is at which point in the process posts should be cut to length (height). While there are those who advocate cutting all posts before installation and then aligning them in the ground before setting them (especially when installing chain link), the most reliable method is to trim the posts to height with a circular saw or handsaw after they are set in the ground and the concrete has set.

Here are some additional thoughts to help you decide how to set your posts:

• Tamped earth and gravel post setting have been increasing the life span and stability of posts for thousands of years by keeping the immediate surroundings of the post drier and firmer.

• The shallow, dish-shaped concrete footing breaks all the rules, but is often the only footing that works in very loose sandy soils. Check with local fence contractors to make sure it’s right for your area.

• Common posts are set high enough to be trimmed down to their final height. Posts with pre-cut mortises (such as split rail fence posts) or finials need to be set to the final height in the hole.

• Dig holes two times the post thickness for sand-set or gravel-set and closer to three times the diameter if concrete-set.

• For long-term strength, set all gateposts and end posts in concrete.

The most reliably long-lasting wood posts are pressure-treated with chemicals and labeled for ground contact. Species that are naturally rot resistant are unfortunately less so today than in yesteryear.

Once you’ve plotted your fenceline with batter boards and string, mark and dig the postholes. Remove the string for digging, but leave the batter boards in place; you will need these for aligning the posts when you set them.

As a general rule, posts should be buried at a minimum depth equal to 1/3 of the total post length (e.g., a post for a 6-foot-tall fence will be approximately 9 feet long, with 3 feet buried in the ground). Check with your city’s building department for the post depth and burial method required by the local building code. Posts set in concrete should always extend below the frost line.

Taking the time to make sure posts are vertical and positioned precisely is perhaps the most important aspect of a successful fence building project.

How to Set Fence Posts

How to Set Fence Posts

Set batter boards at both ends of the fence line. String a mason’s line between the batter boards and level it. Mark post locations on the string with masking tape according to your plan.

Transfer the marks from the string to the ground, using a plumb bob to pinpoint the post locations. Pin a piece of colored plastic to the ground with a nail at each post location.

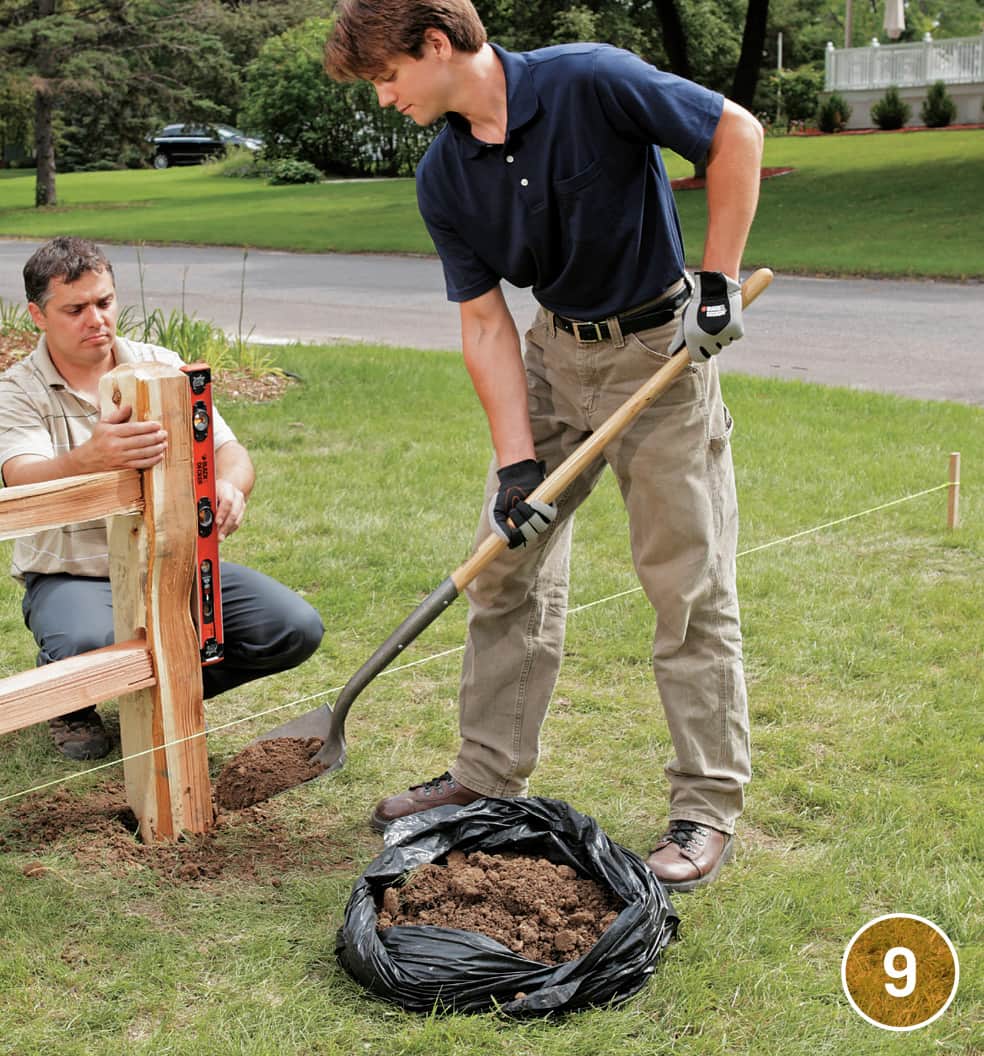

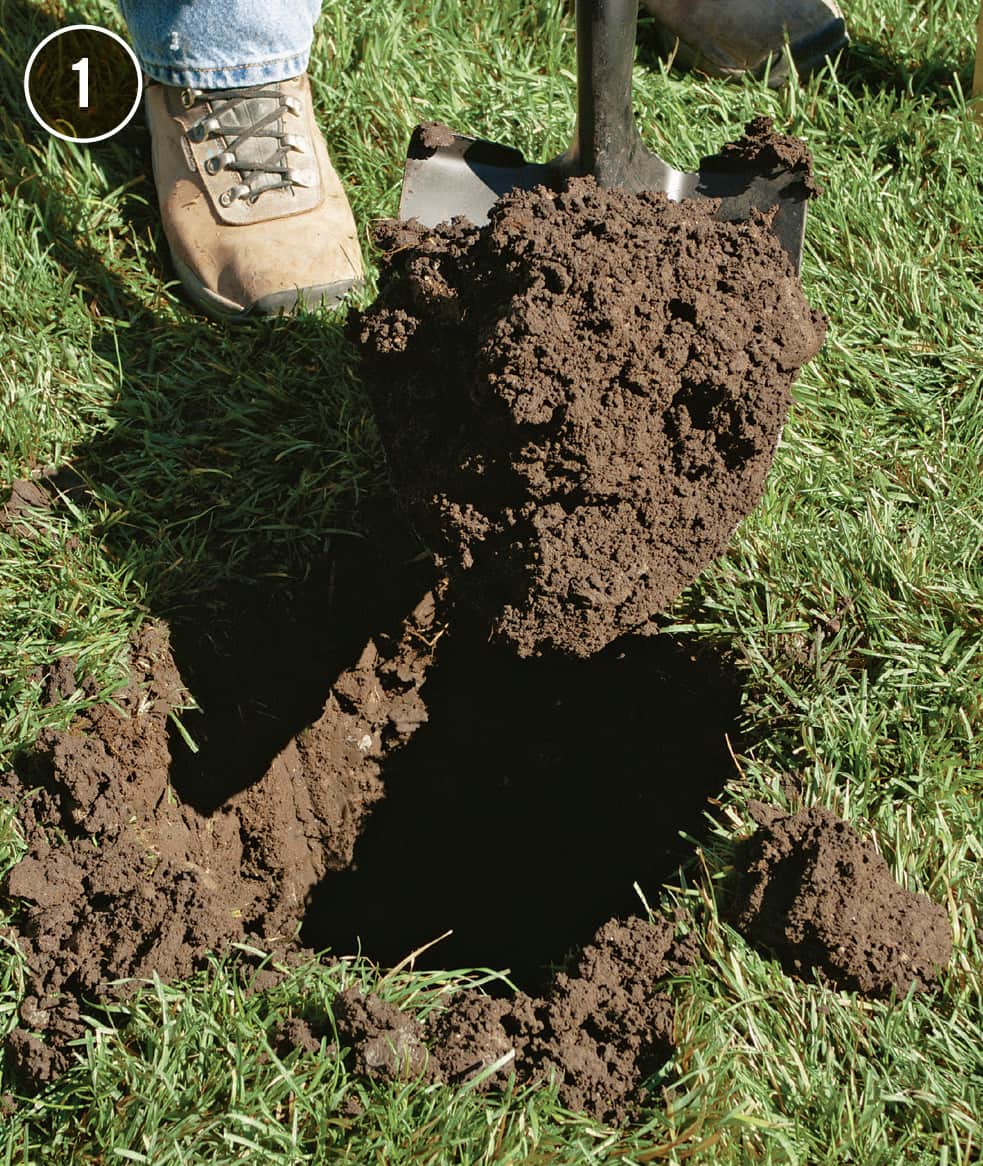

Dig postholes using a clamshell-type posthole digger (left photo) or a rented power auger (right photo). Posthole diggers work well for most situations, but if your holes are deeper than 30", you’ll need to widen the hole at the top to operate the digger, so consider using a power auger. Make a depth gauge by tacking a board onto a 2 × 4 at the hole depth from the end of the 2 × 4. As you dig, check the depth with the gauge. If you’ll be filling the posthole with concrete, widen the bottoms of the holes with your posthole digger to create bell shapes. This is especially important in locales where the ground freezes.

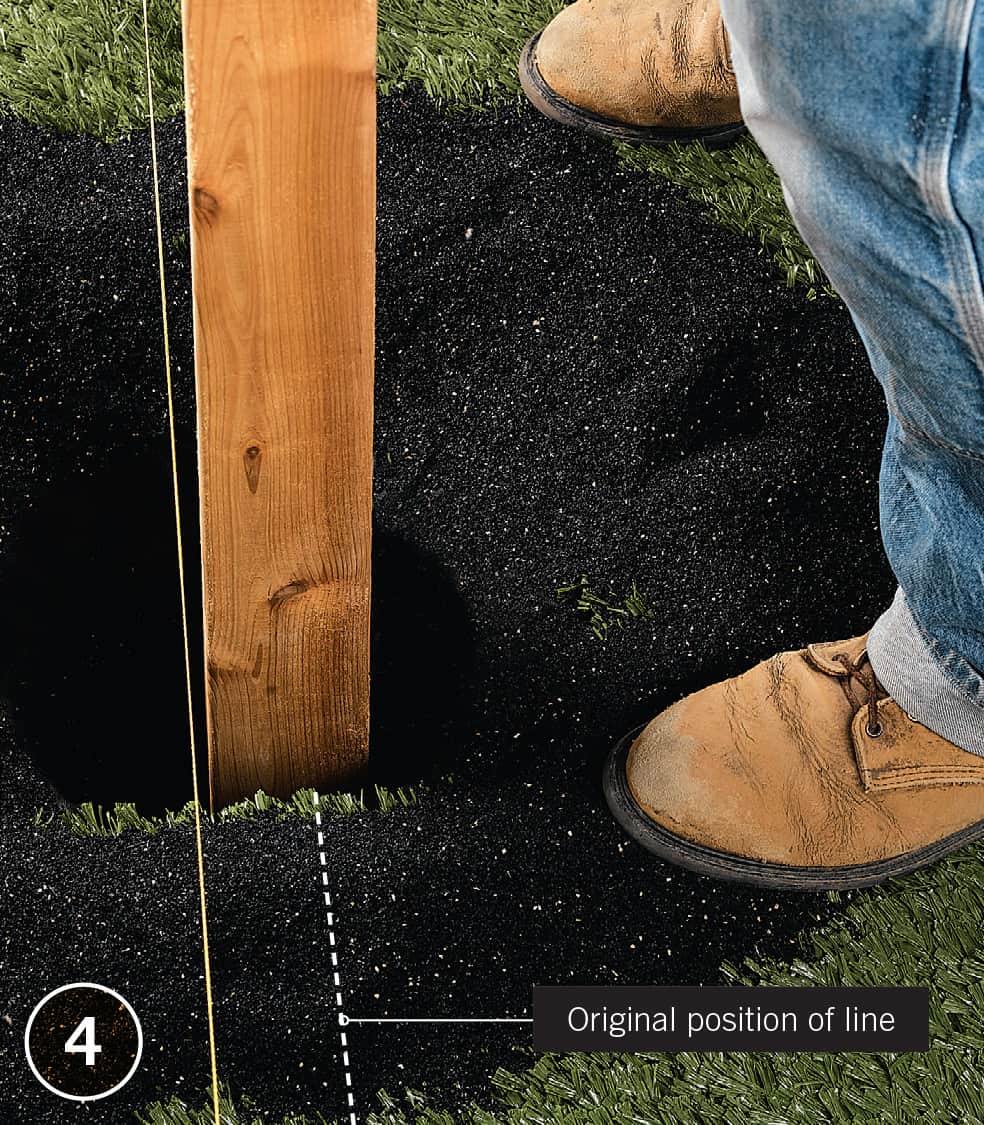

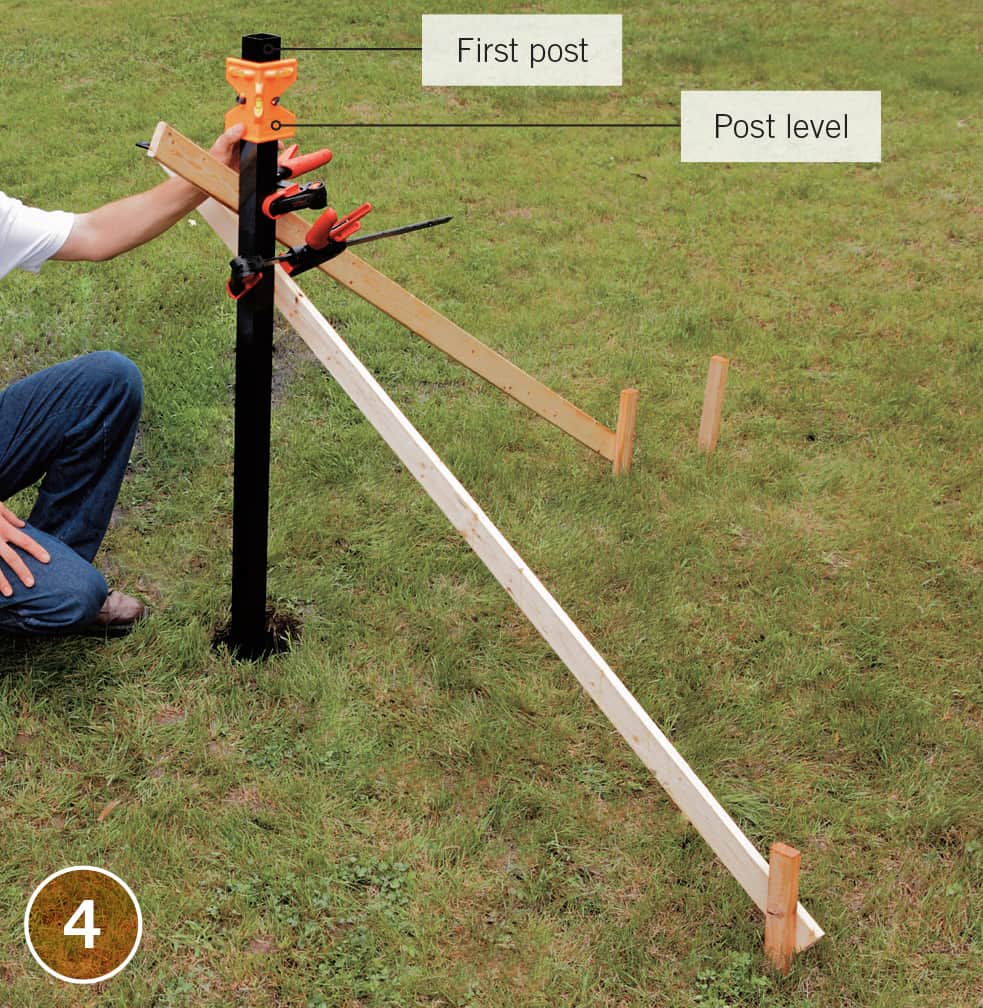

Reset the mason’s string as a guide for aligning posts. If you want the post to be in exactly the same spot it was laid out, shift the string half the thickness of the post. Pour a 6" layer of gravel into each hole for improved drainage. Position each post in its hole.

Align your post along one line (or two if it’s a corner post). Brace the post on adjacent sides with boards screwed to wood stakes. Adjust to plumb in both directions, anchoring each brace to the post with screws when plumb. As you plumb the post, keep the post flush against the line. Set the remaining posts the same way.

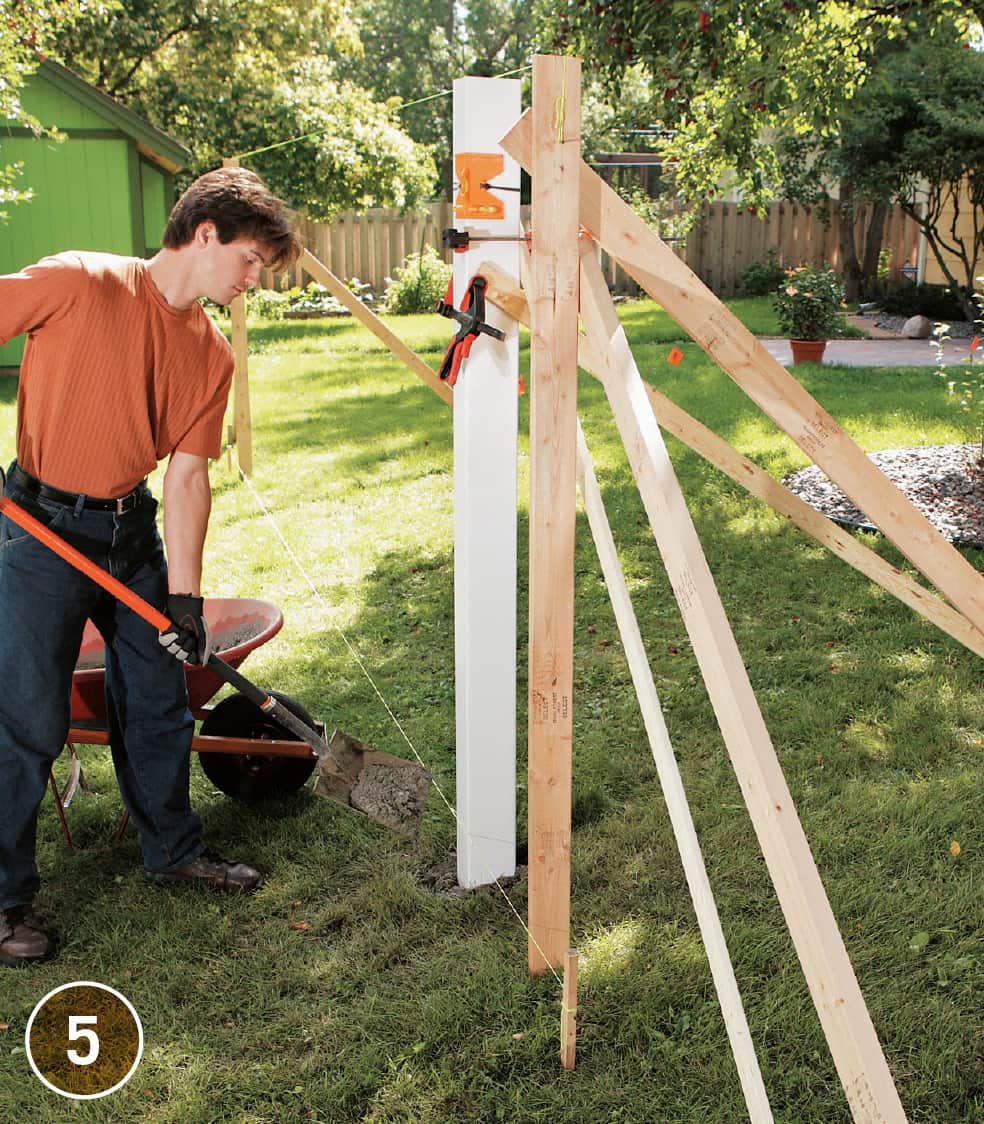

Mix concrete in a wheelbarrow and tamp into the hole with a 2 × 4 to pack the concrete as tightly as you can. Recheck the post alignment and plumb as you go, while correction is still possible.

TIP: Mask the post with waxed paper near the collaring point of the concrete to keep the visible portion of the post clean. Remove the waxed paper before the concrete sets up.

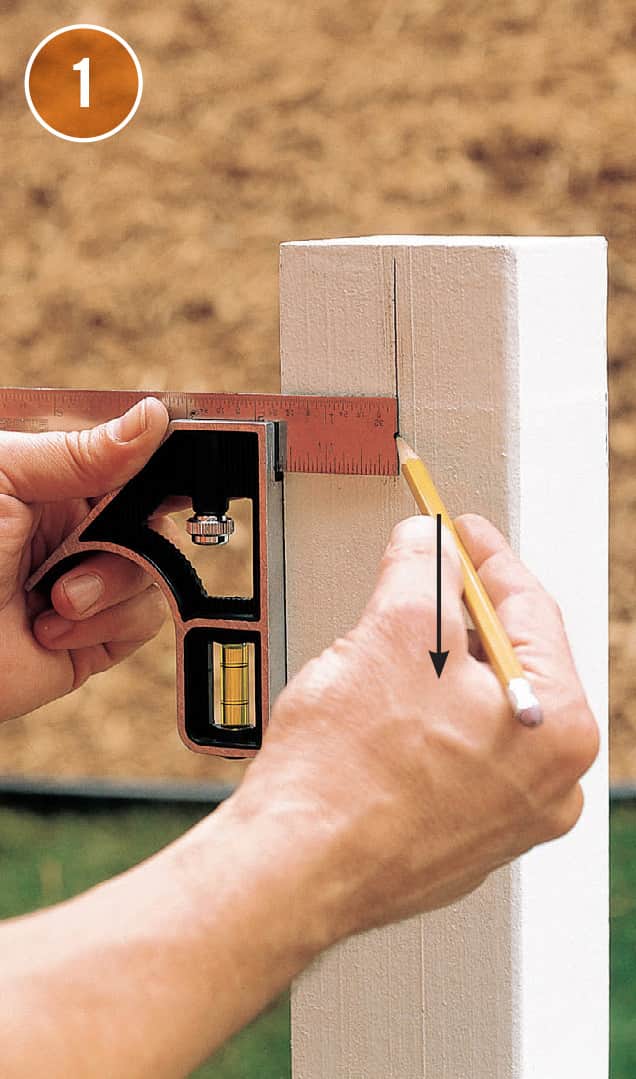

For reasonably level ground, draw a mason’s string from end post to end post at the height the posts need to be cut (for custom fences, this height might be determined by your shortest post). Mark each post at the string. Carry the line around each post with a pencil and speed square.

Wait at least a day for the concrete to set up and then clamp a cutting guide to the posts (a speed square is perfect). Cut along the trim line on each face of each with a circular saw to trim your posts (this is a great time to use a cordless circular saw). In most cases, you’ll want to add a post cap later to cover the end grain.

Picket Fence

The quintessential symbol of American hominess, the classic picket fence remains a perennial favorite for more than its charm and good looks. It’s also a deceptively effective boundary, creating a clear line of separation while appearing to be nothing more than a familiar decoration. This unique characteristic of a welcoming barrier makes the picket fence a good choice for enclosing an area in front of the house. It’s also a popular option for separating a vegetable or flower garden from the surrounding landscape.

Building a custom picket fence from scratch is a great do-it-yourself project. The small scale and simple structure of the basic fence design make it easy to add your own creative details and personal touches. In this project, you’ll see how to cut custom pickets and build a fence using standard lumber (plus an easy upgrade of adding decorative post caps). As an alternative, you can build your fence using prefab fence panels for the picket infill. You can also buy pre-cut pickets at home centers, lumberyards, and online retailers to save on the work of cutting your own.

Traditionally, a picket fence is about 3 to 4 feet tall (if taller than 4 feet, a picket fence starts to look like a barricade) with 1 × 3 or 1 × 4 pickets. Fence posts can be spaced anywhere up to 8 feet apart if you’re using standard lightweight pickets. Depending on your preference, the posts can be visible design elements or they can hide behind a continuous line of pickets. Spacing between the pickets is a question of function and taste: go with whatever spacing looks best and fulfills your functional needs.

A low picket fence adds curb appeal and a cozy sense of enclosure to a front yard or entry area without blocking views to or from the house.

Picket Fence Styles

Highlighting the posts (left) gives the fence a sectional look, and the rhythm of the pickets is punctuated by the slower cadence of the posts. To create this effect, mount the stringers on edge, so the pickets are flush with—or recessed from—the front faces of the posts. Hiding the posts (right) creates an unbroken line of pickets and a somewhat less structural look overall. This effect calls for stringers installed flush with—or over the front of—the post faces.

How to Build a Picket Fence

How to Build a Picket Fence

Install and trim the posts according to your plan. In this project, the pickets stand at 36" above grade, and the posts are 38" (without the post caps). Set the posts in concrete, and space them as desired—but no more than 96" on center.

Mark the stringer positions onto the posts. Measure down from each post top and make marks at 8" and 28 1/2" (or as desired for your design). These marks represent the top edges of the two stringer boards for each fence section.

Install the stringers. Measure between each pair of posts, and cut the 2 × 4 stringers to fit. Drill angled pilot holes and fasten the stringers to the posts with 3 1/2" deck screws or 16d galvanized common nails; drive one fastener in the bottom and top edges of each stringer end.

Cut the pickets to length using a power miter saw. To save time, set up a stop block with the distance from the block to blade equal to the picket length.

TIP: If you’re painting the fence, you can save money by cutting the pickets from 12-ft.-long boards of pressure-treated lumber. In this project, the pickets are 32" long; each board yields four pickets.

Shape the picket ends as desired. For straight-cut designs, use a miter saw with a stop block on the right side of the blade (the first pass cuts through the picket and the block). If the shape is symmetrical, such as this 90° point, cut off one corner, and then flip the board over and make the second cut—no measuring or adjusting is needed.

Prime or seal all surfaces of the posts, stringers, and pickets; and then add at least one coat of finish (paint, stain, or sealer), as desired. This will help protect even the unexposed surfaces from rot.

Set up a string line to guide the picket installation. Clamp a mason’s string to two posts at the desired height for the tops of the pickets.

NOTE: To help prevent rot and to facilitate grass trimming, plan to install the pickets at least 2" above the ground.

Install the pickets. Using a cleat spacer cut to the width of the picket gap, set each picket in place and drill even pairs of pilot holes into each stringer. Fasten the pickets with 2" deck screws. Check the first picket (and every few thereafter) for plumb with a level before piloting.

Add the post caps. Wood post caps (with or without metal cladding) offer an easy way to dress up plain posts while protecting the end grain from water. Install caps with galvanized or stainless-steel finish nails, or as directed by the manufacturer. Apply the final finish coat or touch-ups to the entire fence.

Post & Board Fence

Post and board fences include an endless variety of simple designs in which widely spaced square or round posts support several horizontal boards. This type of fence has been around since the early 1700s, when it began to be praised for its efficient use of lumber and land and its refined appearance. The post and board is still a great design today. Even in a contemporary suburban setting, a classic, white three- or four-board fence evokes the stately elegance of a horse farm or the welcoming, down-home feel of a farmhouse fence bordering a country lane.

Another desirable quality of post and board fencing is its ease in conforming to slopes and rolling ground. In fact, it often looks best when the fence rises and dips with ground contours. Of course, you can also build the fence so it’s level across the top by trimming the posts along a level line. Traditional agricultural versions of post and board fences typically include three to five boards spaced evenly apart or as needed to contain livestock. If you like the look of widely spaced boards but need a more complete barrier for pets, cover the back side of the fence with galvanized wire fencing, which is relatively unnoticeable behind the bold lines of the fence boards. You can also use the basic post and board structure to create any number of custom designs. The fence styles shown in the following pages are just a sampling of what you can build using the basic construction technique for post and board fences.

A low post and board fence, like traditional picket fencing, is both decorative and functional, creating a modest enclosure without blocking views. The same basic fence made taller and with tighter board spacing becomes an attractive privacy screen or security fence.

How to Build a Classic Post & Board Fence

How to Build a Classic Post & Board Fence

Set the posts in concrete, following the desired spacing (see page 148). Laying out the posts at 96" on center allows for efficient use of lumber. For smaller boards, such as 1 × 4s and smaller, set posts closer together for better rigidity.

Trim and shape the posts with a circular saw. For a contoured fence, measure up from the ground and mark the post height according to your plan (post height shown here is 36"). For a level fence, mark the post heights with a level string (see page 149). If desired, cut a 45° chamfer on the post tops using a speed square to ensure straight cuts. Prime and paint (or stain and seal) the posts.

Mark the board locations by measuring down from the top of each post and making a mark representing the top edge of each board. The traditional three-board design employs even spacing between boards. Use a speed square to draw a line across the front faces of the posts at each height mark. Mark the post centers on alternate posts using a combination square or speed square and pencil. For strength, it’s best to stagger the boards so that butted end joints occur at every other post (this requires 16-ft. boards for posts set 8-ft. apart). The centerlines represent the location of each butted joint.

Install 1 × 6 boards. Measure and mark each board for length and then cut it to size. Clamp the board to the posts, following the height and center marks. Drill pilot holes and fasten each board end with three 2 1/2" deck screws or 8d galvanized box nails. Use three fasteners where long boards pass over posts as well.

Mark for mitered butt joints at changes in elevation. To mark the miters on contoured fences, draw long centerlines onto the posts. Position an uncut board over the posts at the proper height and then mark where the top and bottom edges meet the centerline. Connect the marks to create the cutting line and make the cut.

NOTE: The mating board must have the same angle for a symmetrical joint.

How to Build a Notched Post & Board Fence

How to Build a Notched Post & Board Fence

The notched-post fence presents a slight variation on the standard face-mounted fence design. Here, each run of boards is let into a notch in the posts so the boards install flush with the post faces. This design offers a cleaner look and adds strength overall to the fence. In this example, the boards are 1 × 4s so the posts are set 6 ft. on center; 1 × 6 or 2 × 6 boards would allow for wider spacing (8 ft.).

NOTE: Because the notches must be precisely aligned between posts, the posts are set and braced before the concrete is added. Alternatively, you can complete the post installation and then mark the notches with a string and cut each one with the posts in place.

Cut and mark the posts. Cut the 4 × 4 posts to length at 66". Clamp the posts together with their ends aligned and mark the notches at 6", 9 1/2", 15 1/2", 19", 25", and 28 1/2" down from the top ends.

Create the notches. Make a series of parallel cuts between the notch marks using a circular saw with the blade depth set at 3/4". Clean out the waste and smooth the bases of the notches with a chisel.

Install the posts and boards. Set the posts in their holes and brace them in place using a level string to align the notches (see page 149). Secure the posts with concrete. Prefinish all fence parts. Install the 1 × 4 boards with 2" deck screws (driven through pilot holes) so their ends meet at the middle of each post.

How to Build a Capped Post & Board Fence

How to Build a Capped Post & Board Fence

A cap rail adds a finished look to a low post and board fence. This fence design includes a 2 × 6 cap rail and an infill made of alternating 1 × 4 and 1 × 6 boards for a decorative pattern and a somewhat more enclosed feel than you get with a basic three-board fence. The cap pieces are mitered over the corner posts. Where cap boards are joined together over long runs of fence, they should meet at a scarf joint—made with opposing 30° or 45° bevels cut into the end of each board. All scarf and miter joints should occur over the center of a post.

Install and mark the posts. Set the 4 × 4 posts in concrete with 72" on-center spacing. Trim the post tops so they are level with one another and approximately 36" above grade. Prefinish all fence parts. Use a square and pencil to mark a vertical centerline on each post where the board ends will butt together.

Install the boards. For each infill bay, cut two 1 × 4s and three 1 × 6s to length. Working from the top of the posts down, fasten the boards with 2 1/2" deck screws driven through pilot holes. Use a 1 1/2"-thick spacer (such as a 2 × 4 laid flat) to ensure even spacing between boards.

Add the cap rail. Cut the cap boards so they will install flush with the inside faces and corners of the posts; this creates a 1 1/4" overhang beyond the boards on the front side of the fence. Fasten the cap pieces to the posts with 3 1/2" deck screws driven through pilot holes.

How to Build a Modern Post & Board Privacy Fence

How to Build a Modern Post & Board Privacy Fence

This beautiful, modern-style post and board fence is made with pressure-treated 4 × 4 posts and clear cedar 1 × 3, 1 × 4, and 1 × 6 boards. To ensure quality and color consistency, it’s a good idea to hand-pick the lumber, and choose S4S (surfaced on four sides) for a smooth, sleek look. Alternative materials include clear redwood, ipé, and other rot-resistant species. A high-quality, UV-resistant finish is critical to preserve the wood’s natural coloring for as long as possible.

Install the posts, spacing them 60" on-center or as desired. Mark the tops of the posts with a level line, and trim them at 72" above grade.

NOTE: This fence design is best suited to level ground. Cut the fence boards to length. If desired, you can rip down wider stock for custom board widths (but you’ll have to sand off any saw marks for a finished look).

Fasten the boards to the post faces using 2 1/2" deck screws or 8d galvanized box nails driven through pilot holes. Work from the top down, and use 7/8"-thick wood spacers to ensure accurate spacing.

Add the battens to cover the board ends and hide the posts. Use 1 × 4 boards for the infill posts and 1 × 6s for the corner posts. Rip 3/4" from the edge of one corner batten so the assembly is the same width on both sides. Fasten the battens to the posts with 3" stainless-steel screws (other screw materials can discolor the wood).

Split Rail Fence

The split rail, or post and rail, fence is essentially a rustic version of the post and board fence style (pages 150 to 154) and is similarly a good choice for a decorative accent, for delineating areas, or for marking boundaries without creating a solid visual barrier. Typically made from split cedar logs, the fence materials have naturally random shaping and dimensions, with imperfect details and character marks that give the wood an appealing hand-hewn look. Natural weathering of the untreated wood only enhances the fence’s rustic beauty.

The construction of a split rail fence couldn’t be simpler. The posts have holes or notches (called mortises) cut into one or two facets. The fence rails have trimmed ends (called tenons) that fit into the mortises. No fasteners are needed. Posts come in three types to accommodate any basic configuration: common posts have through mortises, end posts have half-depth mortises on one facet, and corner posts have half-depth mortises on two adjacent facets. The two standard fence styles are two-rail, which stand about 3 feet tall, and three-rail, which stand about 4 feet tall. Rails are commonly available in 8- and 10-feet lengths.

In keeping with the rustic simplicity of the fence design, split rail fences are typically installed by setting the posts with tamped soil and gravel instead of concrete footings (frost heave is generally not a concern with this fence because the joints allow for plenty of movement). This comes with a few advantages: the postholes are relatively small, you save the expense of concrete, and it’s much easier to replace a post if necessary. Plan to bury about a third of the total post length (or 24 inches minimum). This means a 3-foot-tall fence should have 60-inch-long posts. If you can’t find long posts at your local home center, try a lumberyard or fencing supplier.

A split rail fence looks great as a garden backdrop or a friendly boundary line. The rough-hewn texture and traditional wood joints are reminiscent of homesteaders’ fences built from lumber cut and dressed right on the property.

How to Build a Split Rail Fence

How to Build a Split Rail Fence

Determine the post spacing by dry-assembling a fence section and measuring the distance between the post centers. Be sure the posts are square to the rails before measuring.

Set up a string line using mason’s string and stakes to establish the fence’s path, including any corners and return sections. Mark each post location along the path using a nail and plastic tag.

Dig the postholes so they are twice as wide as the posts and at a depth equal to one-third the total post length plus 6". Because split posts vary in size, you might want to lay out the posts beforehand and dig each hole according to the post size.

Add 6" of drainage gravel to each posthole. Tamp the gravel thoroughly with a digging bar or a 2 × 4 so the layer is flat and level.

Set and measure the first post. Drop the post in its hole, and then hold it plumb while you measure from the ground to the desired height. If necessary, add or remove gravel and re-tamp to adjust the post height.

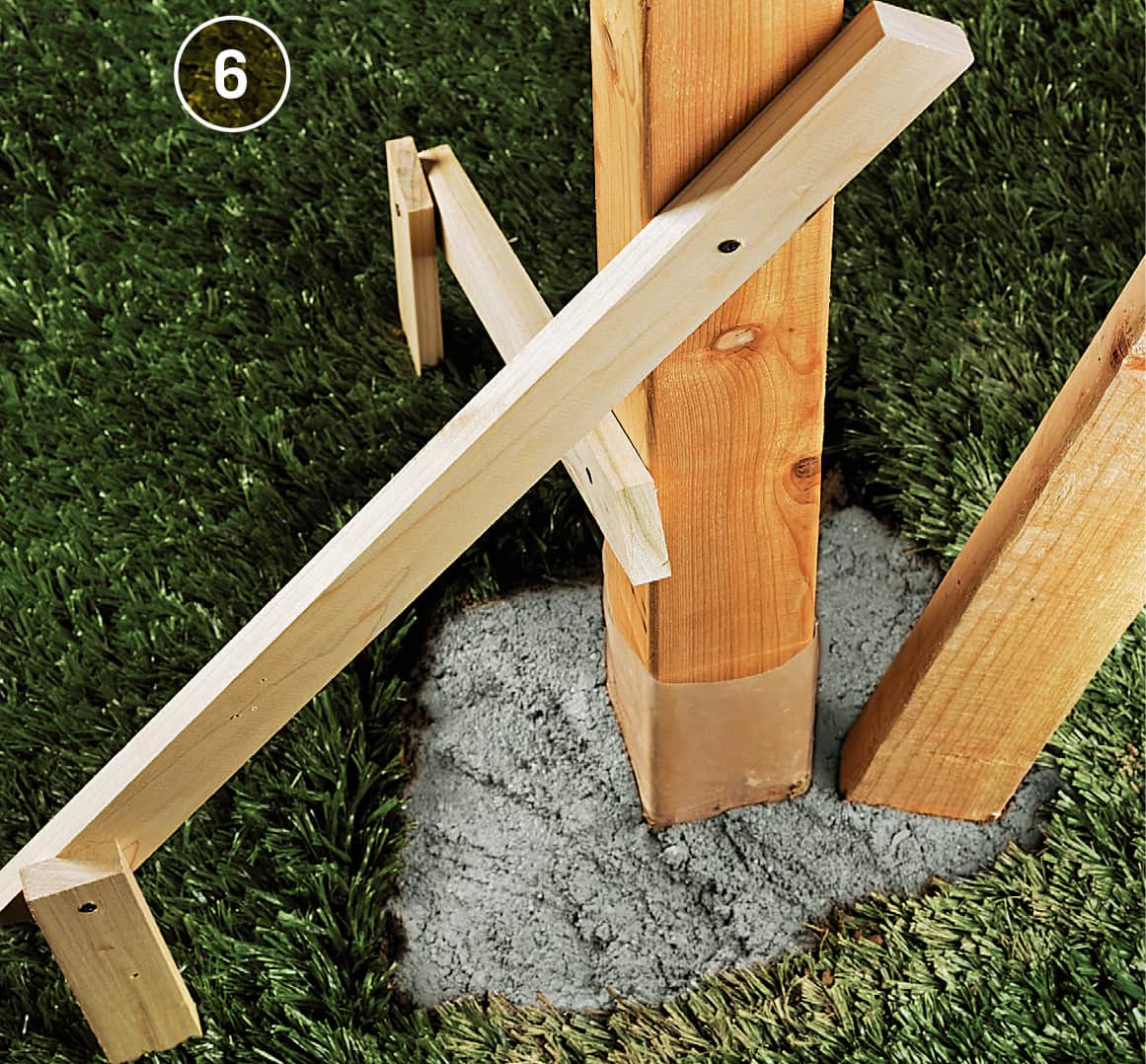

Brace the post with cross bracing so it is plumb. Add 2" of gravel around the bottom of the post. Tamp the gravel with a digging bar or 2 × 4, being careful not to disturb the post.

Fill and tamp around the post, one layer at a time. Alternate between 4" of soil and 2" of gravel (inset), tamping each layer all the way around the post before adding the next layer. Check the post for plumb as you work. Overfill the top of the hole with soil and tamp it into a hard mound to help shed water.

Assemble the first section of fence by setting the next post in its hole and checking its height. Fit the rails into the post mortises, and then brace the second post in place.

NOTE: Set all the posts at the same height above grade for a contoured fence. For a level fence, see Variation, right.

Secure the second post by filling and tamping with alternate layers of gravel and soil, as with the first post. Repeat Steps 5 through 9 to complete the fence.

TIP: Set up a mason’s string to help keep the posts in a straight line as you set them.

Wood Composite Fence

Wood composite fencing requires little maintenance and can last a lifetime. For many homeowners, this low-maintenance longevity justifies the high initial cost of the fencing. Manufacturers of composite products claim that they are less expensive than wood in the long run, when you factor in the repair, refinishing, and eventual replacement of wood fences over the years. Quality composite fencing is guaranteed for up to 25 years not to split, crack, splinter, or rot. Perhaps best of all, it never needs to be painted or sealed for protection from the elements.

Composite fences are made from a blend of wood fibers and plastic resins and can contain a high percentage of recycled materials (the country’s largest manufacturer of wood composite products uses seven out of every ten grocery bags recycled nationally). Most of the wood used comes from reclaimed sawdust from woodworking industries and discarded shipping pallets. The reuse of waste materials, combined with the fact that the fencing never needs to be finished and may never need to be replaced, makes wood composite one of the most environmentally friendly fence materials available.

Like vinyl fencing, composite systems are assembled from precisely manufactured components and panels. This makes it difficult to modify the length of fence sections, should your post spacing be off. For this reason, you might prefer to set the posts as you go (instead of all at once), using a fence stringer to determine the exact post placement. If your site is sloped, check with the fencing manufacturer for recommendations on stepping or contouring the fence to follow the slope.

Composite fencing is manufactured with a blend of wood fibers and plastic resins. It is denser than vinyl fencing and available in a wide range of colors and textures; some even replicate the look of real wood. The privacy fence above is from the Seclusions line by Trex.

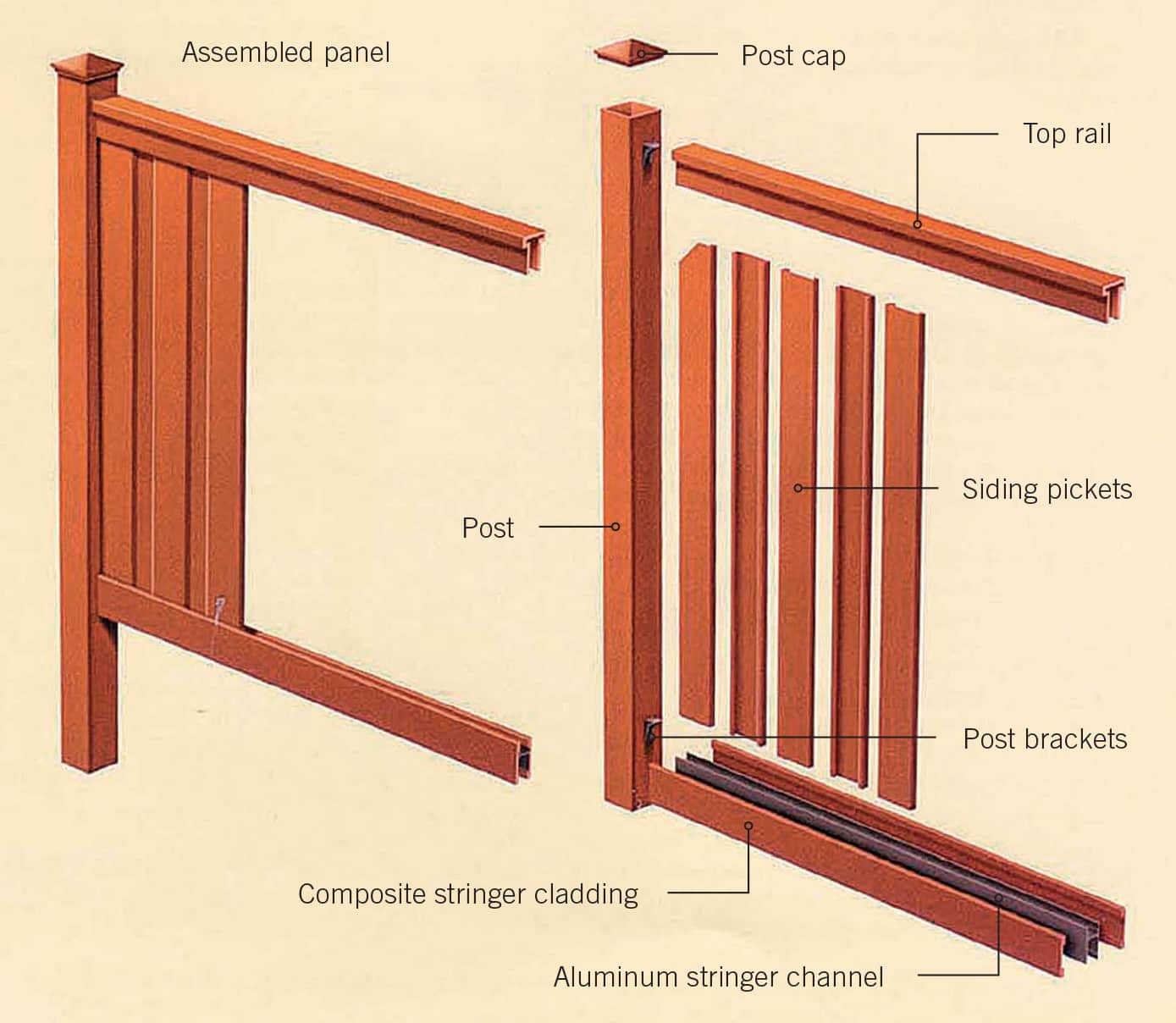

The composite fence system shown in this project is supported by hollow composite posts set in concrete. Bottom stringers include aluminum channels (for strength) clad with composite sleeves. The siding infill is made up of interlocking pieces (or pickets) that fit into the bottom stringer channels and are covered with a top rail. The bottom stringer and top rail are anchored to the posts with brackets.

How to Construct a Wood Composite Fence

How to Construct a Wood Composite Fence

Dig the postholes according to your fence layout. Be sure to follow the manufacturer’s directions for post spacing. Dig the holes 12" in diameter and 30" deep (or as directed). Add 6" of gravel to each hole and tamp it flat.

Set the posts in concrete using a layout string to ensure precise alignment of the post faces (see page 149). Brace each post with cross bracing so it is perfectly plumb. Fill around the post with concrete, up to 2" below ground level. Tamp the concrete with a 2 × 4 to eliminate air pockets. Let the concrete cure for 24 to 48 hours.

Install the post brackets with the provided screws, using the manufacturer’s template (inset) to center the brackets on the post faces. Install the bottom bracket onto each post first, measure up from the bracket and mark the position of the top bracket, and then install the top bracket.

Assemble each bottom stringer by sliding the composite cladding pieces over the sides of the aluminum stringer channel. For short fence sections, see Step 5.

Cut a stringer as needed for short sections of fence. Cut the aluminum channel with a hacksaw. Trim the composite cladding pieces to match the channel with a circular saw and carbide-tipped wood blade.

Set the stringer onto the bottom post brackets. Check the stringer with a level. If necessary, remove the stringer and adjust the bracket heights (you may have to adjust top brackets as well to maintain the proper spacing).

Fasten the stringer ends to the post brackets using the provided screws.

Trim the upper outside corner of the first picket so it will clear the top post bracket using a circular saw and carbide-tipped wood blade.

Install the first picket by slipping its bottom end into the stringer channel. Align the picket to the top post bracket, and fasten the picket to the post with three evenly spaced screws.

Assemble the fence panel by fitting the pickets together along their interlocking side edges and sliding their bottom ends into the stringer channel.

Fit the last picket into place after trimming its top corner to clear the post bracket, as you did with the first panel. Fasten the picket to the post with three screws, as in Step 9.

Set the top rail over the ends of the pickets until the rail meets the top post brackets.

Secure the top rail to each top post bracket, using the provided screws, driving the screws through the top of the rail and into the bracket.

Add the post caps, securing them to the posts with galvanized finish nails or an approved adhesive.

TIP: Some fence manufacturers offer more than one cap style (inset).

Vinyl Panel Fence

The best features of vinyl fencing are its resilience and durability. Vinyl fencing is made with a form of tough, weather-resistant, UV-protected PVC (polyvinyl chloride), a plastic compound that’s found in numerous household products, from plumbing pipe to shower curtains. A vinyl fence never needs to be painted and should be guaranteed for decades not to rot, warp, or discolor. So if you like the styling of traditional wood fences, but minimal maintenance is a primary consideration, vinyl might just be your best option. Another good option is wood composite fencing (see pages 160 to 163), which comes in fewer styles than vinyl but is environmentally friendly and can replicate the look of wood fencing.

Installing most vinyl fencing is similar to building a wood panel fence. With both materials, it’s safest to set the posts as you go, using the infill panels to help you position the posts. Accurate post placement is critical with vinyl, because many types of panels cannot be trimmed if the posts are too close together. Squeezing the panel in can lead to buckling when the vinyl expands on hot days, while setting the posts too far apart results in unsightly gaps.

Given the limited workability of most vinyl panels, this fencing tends to work best on level or gently sloping ground. Keep in mind that installation of vinyl fences varies widely by manufacturer and fence style.

Vinyl fencing is now available in a wide range of traditional designs, including picket, post and board, open rail, and solid panel. Color options are generally limited to various shades of white, tan, and gray.

How to Install a Vinyl Panel Fence

How to Install a Vinyl Panel Fence

Lay out the first run of fence with stakes and mason’s string. Position the string so it represents the outside or inside faces of the posts (you’ll use layout strings to align the posts throughout the installation). Mark the center of the first post hole by measuring in from the string half the post width.

Dig the first posthole, following the manufacturer’s requirements for diameter and depth (improper hole dimensions can void the warranty). Add 4" to 6" (or as directed) of pea gravel to the bottom of the hole and tamp it down so it is flat and level using a 2 × 4 or 4 × 4.

Attach the fence panel brackets to the first post using the provided screws. Dry-fit a fence panel into the brackets, then measure from the top of the post to the bottom edge of the panel. Add 2" (or as directed) to represent the distance between the fence and the ground; the total dimension is the posts’ height above the ground.

Set up a post-top string to guide the post installation. Using the post height dimension, tie a mason’s string between temporary 2 × 4 supports so the string is centered over the post locations. Use a line level to make sure the string is level. Measure from the string to the ground in several places to make sure the height is suitable along the entire fence run.

Set the first post. Drop the post in its hole and align it with the fence line string and height string. Install cross bracing to hold the post perfectly plumb.

TIP: Secure bracing boards to the post with spring-type clamps or duct tape. Fill the posthole with concrete and let it set completely.

Determine the second post’s location by fitting a fence panel into the brackets on the first post. Mark the ground at the free edge of the panel. Measure out from the mark half the post width to find the center of the post hole (accounting for any additional room needed for the panel brackets).

Complete the fence section. Dig the hole for the second post, add gravel, and tamp as before. Attach the panel brackets to the second post, set the post in place, and check its height against the string line. Assemble the fence section with the provided screws (inset). Confirm that the fence panel is level. Brace the second post in place (as shown) and anchor it with concrete. Repeat the same layout and construction steps to build the remaining fence sections.

Add the post caps. Depending on the product, caps may be installed with PVC cement or screws, or they may be fitted without fasteners. Add any additional decorative accessories, such as screw caps, to complete the installation.

Installing a Vinyl Fence Gate

Hang the gate using the provided hardware. Fasten the hinges to the gate panel with screws. Position the gate in line with the infill fence panels and screw the hinges to the hinge post. Install the latch hardware onto the gate and latch post. Close the gate, position the gate stops against the gate rails, and fasten the stops to the latch post with screws.

Ornamental Metal Fence

Ornamental metal fencing is so called to distinguish it from the other common metal fence material, chain link, which makes a useful fence, but is far from ornamental. Ornamental metal fences arguably offer the best combination of strength, durability, and visibility of any standard fence type. In general, most ornamental metal fences are modern iterations of traditional iron, or “wrought iron,” fencing and offer a similarly elegant, formal look (if perhaps not the same heft and handcrafted character).

Today, most ornamental metal fencing is made with galvanized steel or aluminum. Both are finished with durable powder coatings for weather resistance, and most fence systems are based on modular components designed for easy DIY installation. Comparing the two materials, appearances are virtually identical, while aluminum is lighter in weight. It also tends to carry a longer warranty than steel products, probably because aluminum is a naturally rust-proof material. The other type of ornamental fence is iron, which is available in a variety of forms, including bolt-together modular systems.

Thanks to its exceptional security and visibility, ornamental metal fencing is a very popular choice for upscale yards. That’s why most manufacturers offer gates (with welded construction for strength) and code-compliant locking hardware as standard options. Some fence lines include special infill panels and gates with closer picket spacing than standard panels. If you’re installing your fence as a pool surround, check the local codes for requirements.

Ornamental steel, aluminum, and iron fences come in prefabricated panels up to 6 ft. in height and 8 ft. in length, with matching posts and optional decorative details. The most common color option is black (the better to mimic the look of wrought iron), but some products come in white, bronze, and other colors.

How to Install an Ornamental Metal Fence

How to Install an Ornamental Metal Fence

Lay out the fence line with stakes and mason’s string. Start at the corners, driving stakes a few feet beyond the actual corner so that the strings intersect at 90° (as applicable). Mark the approximate post locations onto the strings using tape or a marker.

Mark the first post location with ground-marking spray paint. Assemble the panel onto the first post and align it in the corner with the mason’s strings.

Dig the first posthole, following the manufacturer’s specifications for depth and diameter. Shovel drainage gravel into the hole, and tamp it with a 2 × 4 or 4 × 4. Set the post in the hole and measure its height above the ground. If necessary, add or remove gravel until the post top is at the recommended height.

Plumb and anchor the first post. Position the post perfectly plumb using a post level. Brace the post with cross bracing. Use clamps to secure the bracing to the post. Fill the hole with concrete and let it set.

Drill pilot holes for the brackets into the second post and first panel. Align the fence assembly with the first post and mark for the second post hole. Prepare the posthole as you did in Step 3.

Fill the second posthole with concrete and let it set. Here, we have a temporary brace to hold the post plumb and at the desired height. The first panel, complete with posts on either sides, is now set. Remaining posts along this fence line can be set by positioning posts with spacers to save time (see tip on this page).

Align the second panel on the other side of the corner post. Follow instructions in Steps 2 through 5 to set the post and install the panel. Repeat the same process to install the remaining fence sections. You can save time by positioning the posts with spacers (see tip on this page).

How to Cut Metal

How to Cut Metal

Measure and mark panels for cuts. Hold the panel up to the final post in the run and mark the cutting line. Often, designs will not accommodate full panels around the entire fence perimeter.

Cut panels to the appropriate length using a hacksaw, as needed.

Bamboo Fence

Bamboo is one of nature’s best building materials. It’s lightweight, naturally rot resistant, and so strong that it’s used for scaffolding in many parts of the world. It’s also a highly sustainable resource, since many species can be harvested every 3 to 5 years without destroying the plants. Yet, perhaps the best feature of bamboo is its appearance—whether it’s lined up in orderly rows or hand-tied into decorative patterns, bamboo fencing has an exotic, organic quality that adds a breath of life to any setting.

Bamboo is a grass, but it shares many properties with wood. It can be cut, drilled, and sanded with the same tools, and it takes many of the same finishes, including stains and exterior sealers. And, just like wood, bamboo is prone to splitting, though it retains much of its strength even when subject to large splits and cracks. In general, larger-diameter poles (which can be upwards of 5 inches) are more likely to split than smaller (such as 3/4-inch-diameter) canes.

Bamboo fencing is commonly available in 8-foot-long panels made from similarly sized canes held together with internal or external wires. The panels, which are rolled up for easy transport, can be used as infill within a new wood framework or they can attach directly to an existing wood or metal fence. Both of these popular applications are shown here. Another option is to build an all-bamboo fence using large bamboo poles for the posts and stringers and roll-up panels for the infill.

Quality bamboo for fencing isn’t hard to find, but you can’t pick it up at your local lumberyard. The best place to start shopping is the internet (see Resources, page 234). Look for well-established suppliers who are committed to sustainable practices. Most suppliers can ship product directly to your home.

How to Build a Wood-Frame Bamboo Fence

How to Build a Wood-Frame Bamboo Fence

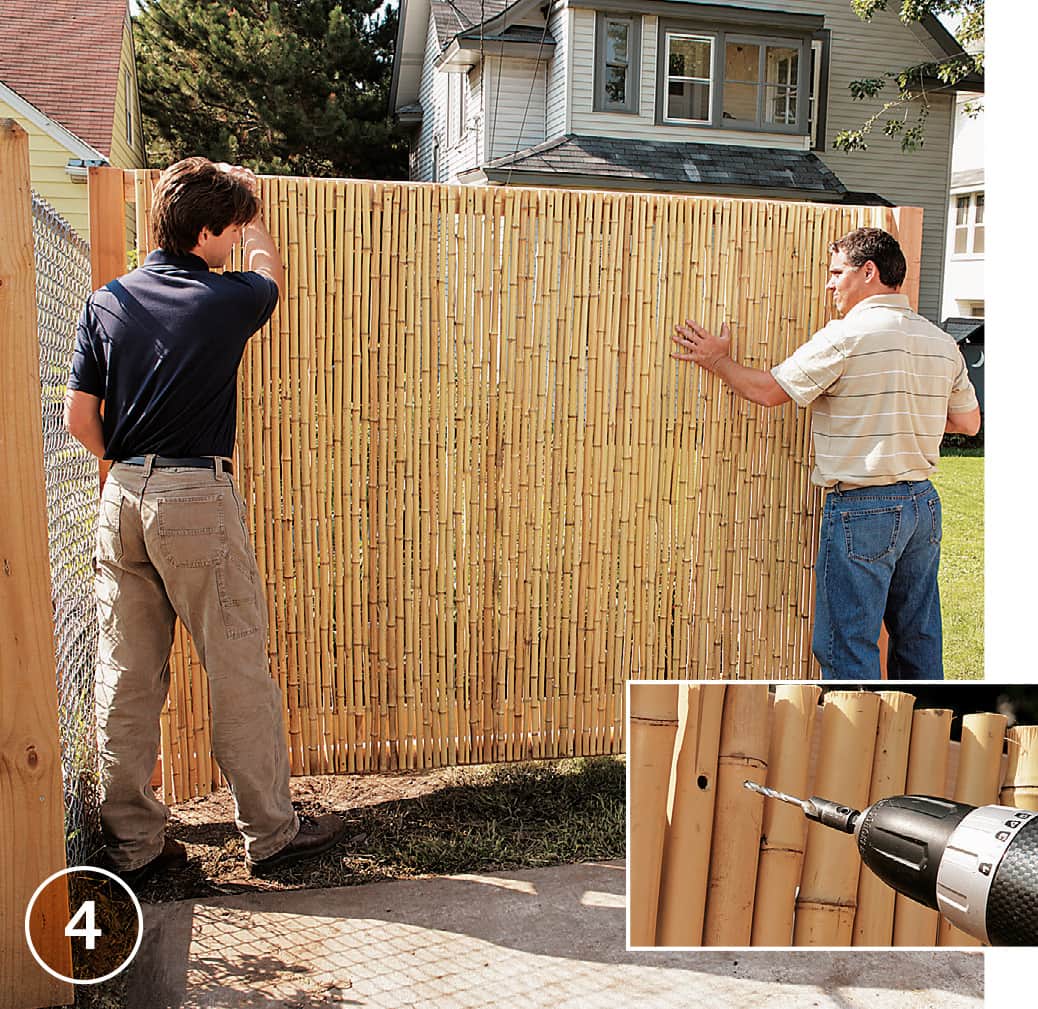

Install and trim the 4 × 4 posts according to the size of your bamboo panels, setting the posts in concrete. For the 6 × 8-ft. panels in this project, the posts are spaced 100" on-center and are trimmed at 75" tall (refer to the manufacturer’s recommendations).

Install the top 2 × 4 stringers. Cut each stringer to fit snugly between the posts. Position the stringer on edge so it is flush with the tops of the posts and with the back or front faces of the posts. Fasten the stringer with 3" deck screws driven through angled pilot holes. Use one screw on each edge and one on the inside face of the stringer, at both ends.

Mark the location of each bottom stringer. The span between the top of the top stringer and bottom of the bottom stringer should equal the bamboo panel height plus about 1". Cut and install the bottom stringers in the same fashion as the top stringers. Here, the bottom stringer will be installed 2" above the ground for rot prevention. Unroll the bamboo panels.

Flatten the bamboo panels over the inside faces of the stringers. Make sure the panels fit the frames on all sides. Using a countersink-piloting bit (inset), drill a slightly countersunk pilot hole through a bamboo cane and into the stringer at a top corner of the panel. Fasten the corner with a 2" deck screw, being careful not to overtighten and split the bamboo.

Fasten the rest of the panel with screws spaced 12" apart. Stagger the screws top and bottom and drive them in an alternating pattern, working from one side to the other. Repeat Steps 4 and 5 to install the remaining bamboo panels.

Cover the top and bottom ends of the panels with 1 × 4 battens. These finish off the panels and give the fence a similar look on both sides. Cut the battens so the ends are flush against the inside faces of the posts and fasten them to the panels and stringers with 2 1/2" deck screws driven through pilot holes.

Add the top cap. Center the 2 × 6 top cap boards over the posts so they overhang about 1" on either side. Fasten the caps to the posts and stringers with 3" deck screws. Use miter joints for corners, and use scarf joints (cut with opposing 30° or 45° bevels) to join cap boards over long runs.

How to Cover an Old Fence with Bamboo

How to Cover an Old Fence with Bamboo

Unroll and position a bamboo panel over one or both sides of the existing fence. Check the panel with a level and adjust as needed. For rot prevention, hold the panel 1" to 2" above the ground.

TIP: A 2 × 4 laid flat on the ground makes it easy to prop up and level the panel.

Fasten the panel with deck screws driven through the bamboo canes (and fence siding boards, if applicable) and into the fence stringers. Drill countersunk pilot holes for the screws, being careful not to overtighten and crack the bamboo. Space the screws 12" apart, and stagger them top and bottom (see facing page).

Install the remaining bamboo panels, butting the edges together between panels for a seamless appearance. If the fence posts project above the stringer boards, you can cut the bamboo panels flush with the posts.

TIPS FOR SPACING LINE POSTS AND GATEPOSTS

TIPS FOR SPACING LINE POSTS AND GATEPOSTS

TOOLS & MATERIALS

TOOLS & MATERIALS

MIXING CONCRETE

MIXING CONCRETE