CHAPTER 3

Performance, Cost, and Price

Is It a Good Deal?

Having thought a bit about the quality problem, inhibitions to solving it, and the process by which quality might be improved, let us move to the seven areas that are critical to product quality, and which, in my mind, do not receive the consideration they deserve. These areas play a major role in how companies define and differentiate their products, but they are rarely analyzed and adequately thought through. They are, of course, interconnected, but by discussing them separately, we can perhaps break the problem of product quality into more manageable pieces.

In this chapter, I will say a few things about performance, cost to the producer, and price to the consumer—three factors that immediately come to mind when thinking about quality. I also want to touch on them because even though they are often expressed quantitatively, they cannot be as logically determined as people think or might like. Quantities are simple for producers and consumers to think about and measure. But as behavioral economists are now proving, we do not think about price logically. Nor do we about performance. I once owned an open sports car and a station wagon, and I could not convince myself that both speedometers read the true speed because my sports car seemed to be going so much faster at 65 miles per hour.

Performance, cost, and price are intimately connected. Consumers are more likely to say, “That’s a pretty good coffeemaker for $30,” rather than simply, “That’s a pretty good coffeemaker.” They want performance to be high and price to be low. The producer is more likely to want cost low, price high, and adequate performance to beat the competition. Ideally, and perhaps necessarily, both producers and consumers will be pleased. The producer will make a nice profit, and the consumer will feel that the product is a good deal.

Quantifying Performance

We like to quantify performance—miles per hour, degrees Centigrade, mean time between failures, pixels per square inch, amortization curve, gigahertz, tons, and so on. Our interaction with products is extremely complex, and putting numbers on such things as performance seems to simplify describing the product. But how can the smoothness of shifting gears in a high-quality manual transmission be measured? Or the sound of a live string quartet? Or, conversely, the response to a disposable diaper with low absorbing ability? A saw that will not cut well? Can we really quantitatively compare the performance of an automobile and a motorcycle?

It also simplifies the lives of both producers and consumers to focus on the performance of products when they are brand-new, but high-quality products should have a long lifetime, and performance should be considered over their lifetime. Performance should include reliability, durability, serviceability, and maintainability as factors, since failures, even if for reasons not directly the fault of the producer, reflect poorly on the performance of the product.

As an example, my wife’s car has a good reputation for performance and reliability, and it has lived up to this reputation since we bought it. Unfortunately, rodents recently chewed up the wiring harness, which cost some $3,000 to replace. Now my wife does not consider the car as high quality a product as she did, even though the producer obviously was not responsible for the rodents. I, too, view the car as of lesser quality than previously because not only is the wiring harness attractive to rats and mice, but the entire harness is a single assembly that is extremely difficult to repair or replace—it has bad serviceability. In addition, the situation has caused the carport where the car is parked to become an overwhelming collection of rat and mouse traps, poison bait, and sound-producing devices that annoy rats (and me). Checking with friends and neighbors, I’ve found that this problem is not an uncommon one, and in each case, although the automobiles were of different brands, the owners thought the producer of the car should have installed wiring harnesses that were easier to repair and less tasty to rodents—a perceived loss of quality.

Serviceability and maintainability are among my pet peeves these days. If a high-quality product is at all likely to have a failure in a part or subsystem, that part or subsystem should be easily repairable or replaceable. The cable harness in my wife’s car should at least have been modular so it would not have been necessary to remove the entire assembly. I had an iMac computer fail on me recently because of a widespread problem with bad capacitors manufactured by a company in Taiwan. These are old-fashioned discrete capacitors soldered into a sophisticated multilayer printed circuit board with lead-free solder, which melts at a higher temperature than the traditional lead-tin solder. The computer was no longer under warranty, and to have it repaired by a commercial service would have cost nearly as much as buying a new one.

I looked the problem up online and found many entries reporting identical failures, several of which included instructions on how to repair the computer, but each with a warning that the repair would take many hours. I took the computer apart to see if I could repair it (even though there were warnings in the literature and on the computer implying that I should not do so), and my office partner and I worked on the computer for many hours because I thought it was too good a computer and too beautifully made to throw away. Despite our education and experience, however, we failed, and my love affair with Apple slipped another notch. (The first notch, incidentally, was due to the difficulty of replacing the battery in an iPhone, a necessary activity every so often. It is a challenge to the user to do it and costs about $100 to have it done at an iStore.) Of course, when I replaced the computer, Apple made more money and I ended up with better performance and new features and programs, though I neither needed nor wanted them.

As another example of the difficulty of quantifying performance, “more performance” is not necessarily better. My mother was fascinated by multiuse tools and insisted on buying them for me as birthday and Christmas gifts. Of course, I graciously thanked her for them, but in general they could not compete with my more traditional tools. Although they may be convenient for people who have neither the space nor the interest to acquire traditional tools, combination tools do not work for me, except for perhaps the classic Swiss Army knife.

Think about the proliferation of features on the products consumers buy—the so-called feature creep (additional capabilities added to products) being discussed as people realize the downside of dealing with too many bells and whistles. For most of history, the mechanizing of product function required a considerable investment. Additional features required additional mechanical articulations, which in turn required additional costly parts. The availability of low-cost integrated circuits containing the equivalent of millions of electronic components has changed that process. Product features no longer require expensive custom-manufactured mechanical subassemblies. Integrated circuits in automobiles can easily control ignition timing, fuel injection, and emission control systems. They can tune your radio and remember your favorite stations. With the proper sensors, they can tell you not only whether your seat belt is fastened or your door open but also how many times you applied your brakes that month, or maybe someday, whether you are wearing too much perfume, or if your kid has been making love in the backseat. How many of these functions should integrated circuits perform?

Have you been wondering lately whether you need all of the options in your cell phone? I personally could do without the one that seems to keep taking photographs of the inside of my pocket. Do you have trouble remembering how to use all of the features in your home entertainment system and your computer software? Do you really want your dryer to give you a choice as to how dry your clothes become? Do you still ask for wake-up calls because you don’t want to figure out how your hotel alarm clock works? (One of my colleagues claims it isn’t that she doesn’t want to figure out how the clocks work, she just doesn’t trust them.)

People seem to be caught in an endless loop of upgrading computers, operating systems, and application software. Users have applications so dated they can no longer open their e-mail attachments. If they decide to upgrade, they may find the new version does not like their old operating system. After installing the current operating system and the new application, the computer is slower. The next step is to buy a new computer and upgrade everything, only to find that they don’t know how to use all of the new features. By the time the users begin to become comfortable with all of these changes, the cycle starts again. I, like many of my friends, would love to avoid constantly upgrading in order to focus on using my computer rather than learning to deal with more “powerful” software, but I am trapped by the need to interact with the world. (Strangely enough, my friends and I would all probably qualify as fairly computer savvy.)

In 1996, Clifford Stoll wrote a book entitled Silicon Snake Oil. Despite its title, this was not an anticomputer rant. Stoll is a long-time computer user and expert. In fact, his experience dates from assembling an Altair kit in the early 1970s—and if you have been around computers for a long time, you will realize that this gives him impeccable credentials. However, in his book Stoll did have certain criticisms of computers, one of which was that he claimed he had always spent roughly half of his time working on his computer system rather than using it.1 This may have been an exaggeration, but I certainly sympathized with the gist of it. Although hardware has become more reliable and software more stable, increased complexity keeps the whole game akin to juggling.

We have reached a stage of technological sophistication where we must (or should) think not only of what we want products to do for us but also of what we do not want them to do. Many modern products seem as though the designers frantically tried to use more of the capability of the included chips and, in the process, delivered unnecessary and confusing functions. Designers making the best of the “information revolution” utilize increased technical capability to create devices that are easier to use. When it comes to options, “the more the better” no longer holds true, since the capability of computers is increasing more rapidly than the capability of human brains. Thirty years ago, the designers of products did not have the luxury of facing this problem.

The Complexity of Cost and Price

Cost and price are also extremely complicated topics. Customer perception of price depends on a large number of factors, including the wealth of the customer, the price of competing products, and how much the customer wants the product. Providers of products must consider not only the cost of time and materials and the desired profit margins but also the time value of the money involved and the availability of various sources of funding. Modern times have caused people to think about liability exposure, insurability, foreign exchange rates, and other subtleties as well. Consumers must worry about whether to buy, rent, or lease, pay cash or borrow (and if so from whom), pay for maintenance contracts or not, and buy direct or through the Web, as well as deciding about which model, what options, and whether to wait for a sale.

The increasing complexity concerning cost can be seen in the ongoing debate about “true cost.” Traditionally, the price of a product has included the cost of design, materials, and production plus associated profits and business expenses that are passed along to the buyer. True cost might also reflect social costs of environmental pollution, cleaning up after the product, or exploitation of scarce resources. For example, should the cost of an automobile include a quantity for the control of smog as well as the construction of roads? Should lumber’s cost include an amount for reforestation? Should the government compensate taxpayers by selling communication frequency bands to industries instead of giving them away? Should the price of air travel be sufficient to provide truly adequate air traffic control systems and airports? These questions, among many others, are now being considered.

Like performance, cost and price are factors that should be considered over the life (and death) of the product. The true cost of a product to a customer includes not only the purchase price and any charges on financing but also repair and service, operating costs, insurance, and other costs incurred while owning the product. These costs should be made clearer by producers, as we are far from the days of caveat emptor, and it might actually benefit them to do so. In the case of a high-quality product, the purchase price might seem less daunting compared to the actual cost of owning and operating the product, and the repair and service costs on a higher-quality product should be less than those on one of lower quality.

Companies also expend tremendous effort attempting to change consumers’ perception of price and cost. We seem to be overwhelmed with “deals”—sales, rebates, coupons, discount clubs, frequent flyer miles, and so on. If you want examples, check out your local supermarket, shop for a car, or buy something on the Internet. Somehow, such things seem more appropriate to a carnival midway than the acquisition of a high-quality product. Some manufacturers of high-quality products, however, make non-discounting an aspect of quality—Apple, for instance, likes to control distribution through its own stores and website. The producer of high-quality products should attempt to minimize sales gimmicks, even though rebates make money (many people never apply for them) and sales (whether after Christmas, or in the form of “two for one” or “buy one, get one free” or $5.29 for one, $2.95 each for three or more) must be effective or they would not be so prevalent. Unfortunately, people are extremely susceptible to such deals, so they probably won’t go away.

The world is awash in advertising in all media featuring performance and price. An extraordinary amount of talent is directed to influencing what we need and want. I love to watch the annual Clio advertising winners because they provide an opportunity to witness pure human genius. The genius, of course, is focused on influencing consumers to more strongly desire the output of the client. No one is immune to the messages of the advertising profession, and to say that they surround us is an understatement. We accept TV movies that are trashed by commercial breaks. The Internet is being gobbled up by advertisements. We don’t even question the placing of products on the shelves of our stores, the billboards in the middle of wildflowers, or the graphics that cover the infield walls of our baseball parks (which themselves are named after companies). We even look forward to the ads in the Super Bowl telecast. We are also influenced by the likes and dislikes of people we admire and celebrities—it is not mere charity that causes fashion and jewelry designers to furnish actors and actresses at the Academy Awards ceremony with their wares. We have become conditioned to an amazing amount of input as to what we should buy, and companies are willing to spend a great deal of money to influence us because it is so effective.

But all this advertising and media attention may result in disappointment, as advertising tends to exaggerate the positive qualities of the product that might not lead the consumer to the desired outcome. If you believe the steamy romantic graphics of lipstick ads, you may be let down when Brad Pitt does not leave Angelina Jolie for you, even though you are wearing the lipstick. If you become overly impressed with the low cost of cubic zirconium, you may be surprised when you buy a fake diamond ring for your wife and find that she is not as impressed. It is easy to find beautifully made automobile advertisements that imply that if I buy a particular car, my life will be spent preventing gorgeous young women from forcing their way into it and all over me. Just think—drastically improved sex appeal for $30,000 (nothing down and a rebate, yet). Most advertisements for pickups show the trucks engaged in heroically rugged tasks (off-road racing, receiving huge loads of construction material, dwarfing other equipment). Somehow, the ads never show the damage that would result if a real pickup were put through such paces. If you pursue the low plane fares or hotel rates being offered, you may find that they are sold out.

For producers of high-quality products, honesty is the best policy.

The Balancing Act Between Performance and Cost

The relative importance of performance and cost vary widely, depending upon product and purchaser. A person buying a Ferrari or the military buying advanced weaponry may care far more about performance than price. The teenager desperately wanting an automobile or the underfunded business start-up needing office space may care more about price than performance. However, to some extent we always balance the two when evaluating products. Should price become too high or performance become too inadequate, widespread unhappiness occurs. An example of the former was the famous toilet seat that the government paid $600 for. An example of the latter was the Three Mile Island nuclear plant failure in 1979, which played a major role in turning the United States away from nuclear power. The explanation for the first was that the toilet seat was a unique item and the cost of its development could not be spread over a large number of products. The explanation for the core meltdown in Pennsylvania had to do with the complexity of the system and the training of the operators. But neither explanation seemed satisfying to many members of the media and the general public.

Traditionally, performance and cost goals and selling price are determined by marketing, competition, technical feasibility, organizational capability, and the intuition of various experienced people. They may be set from on high (“We choose to go to the moon this decade”—John F. Kennedy) or low (“Make a pin puller that doesn’t need a telemetry channel”—Bill Schimandle, a former boss at JPL). Eventually these goals assume definite, often quantitative form. At that point, they are typically seen as constraints (freezes) on the design. A better computer can be described in quantitative terms such as desired speed, memory, operating system features, and cost. Goals for a sports car might include performance figures such as acceleration, top speed, skid-pad characteristics, steering ratio, and braking distance as well as cost.

But we should keep in mind the nature of the process that produces the goals that constrain and guide the designer or manufacturer of the product. Like many engineers, I started at the bottom and assumed that some godlike person above me was setting the performance and cost goals I was to work to. When I was higher on the totem pole, however, I realized that setting performance and cost goals was definitely done by mortals. Some of these mortals do seem to have godlike qualities (Bill Hewlett, Steve Jobs), but having been involved in setting performance and cost goals for many products, I can state that most do not. Obviously, setting these quantitative and specific goals is good for meeting schedules and integrating subsystems. For achieving high quality, however, it is helpful if people at all levels have a sense of the amount of uncertainty in the process that sets product goals, as quality may be overlooked. Relatively small interventions in the design of the product may result in relatively high gains in quality.

Performance, cost, and price also look different when examined from different viewpoints. As an example, consider farm equipment. In 1830, some 250 to 300 hours of labor were required to produce 100 bushels of wheat. By 1890, due to improved equipment, this amount of wheat could be produced with 40 to 50 hours of labor. By 1965, the same amount of wheat could be produced with 5 labor hours. The total is now down to 2 to 3 labor hours due to modern equipment.2 This is an astounding increase in human productivity, as defined simply by the ratio of output to labor.

From the technical performance standpoint, the performance of such equipment is high, in that it is necessarily reliable and does its job extremely well. How about price? In the present farming environment, increasing automation still seems to make economic sense, or farmers probably wouldn’t buy it. The operators of the combine certainly would not choose to return to an open-air seat in the direct sunlight in the midst of clouds of dust and chaff. Farmers don’t mind at all paying fewer dollars in wages and worrying about fewer pieces of equipment. Neither do they mind being able to farm more acres with fewer people, since large farms seem to be the only ones making money these days, partly because subsidy income is proportional to acreage. From the perspective of the farmer, the performance is high and the cost bearable. From the standpoint of the producer, sales and profit are paramount. Since farmers keep upgrading and since the John Deeres of the world are doing OK, the modern combine looks all right from their viewpoint—reasonable performance and cost. So is there a downside?

By changing perspectives, almost any product can be found to have a downside as performance, cost, and price increase. Increasing performance means faster airplanes, bigger computers, and more powerful medical diagnostic equipment. But faster airplanes may carry fewer people. Would passengers perhaps pay more for a slower but more luxurious ride? Bigger computers and more powerful medical diagnostic equipment might require more highly trained operators, as well as being more expensive to produce. And more access to money is necessary to obtain this more expensive equipment—a barrier to smaller businesses.

Think again about farming equipment. The farmers I know love big, powerful, technically sophisticated machinery. Although I am not an agricultural economist, I suspect that from a pure performance standpoint, some of them buy higher-performance equipment than they need sooner than they need it. Not only is new equipment expensive to purchase and maintain, but it also loses its value rapidly. New harvesters cost more than $500,000 and can no longer be casually maintained and repaired by amateurs. The modern tomato harvester, which is capable of harvesting 50 to 70 tons per hour (a lot of catsup), electronically sorts the fruit by color, those not ripe enough ending up either on the ground or in a cull container. I have yet to meet a farmer capable of repairing the extremely sophisticated sensing and decision-making equipment used to do the automatic sorting. In case of failure, farmers need to call on highly paid experts to come replace the expensive modules.

There are other more subtle drawbacks to modern farm equipment, including that it isolates individuals from the farming process—this is a double-edged sword. Much farming labor is on the odious side. But farmers do like to grow things. One of my sons owns a farm in the Sacramento Valley. Last year he harvested part of his wheat crop with a 1960s harvester that I had restored. Although he did sit in the open air in a cloud of dust, and spent a lot more time harvesting the crop than he would have with a modern harvester, he loved it. He has the farm because he likes the process, and the older harvester definitely involved him more intimately than a modern one would.

Pulling back further, look at what has happened to farming. It provides jobs for fewer and fewer people and no longer allows farmers to compete on a small scale. I often hear people begrudging the loss of the small farm. From the standpoint of the sustainability advocate or the champion of the family farm, the huge, expensive, fuel-gulping machines used now might be thought of as lesser quality than older machinery. Equally negative thoughts might be expected from the farmer whose complicated combine or tomato harvester has failed at a time when the crop must be harvested and rain is imminent. So in the case of major farm equipment, the performance of the machinery is high, but the cost, including purchase, operation, and maintenance, is also high. The benefit to the producers of the products is high, and the benefit to the farmers is positive, but what about the benefit to society? Oddly enough, the same thing is happening in many situations where work is being automated. Tool and die makers? Printing press operators? Vanishing breeds. What is the cost of the jobs lost through automation?

Why Are There Problems?

In a capitalistic system, we like to assume that market forces will take care of problems having to do with performance, cost, and price, and they should. Products are produced for profit, so there is not much motivation to design and manufacture them unless people are going to buy them. The market and competition should pull performance up and prices down. Many factors make this behavior likely, including the advancement of technology. Many readers may have heard of the Moore curve, named after Gordon Moore, one of the founders of Intel Corp. The Moore curve says that the number of components on a single integrated circuit seems to double each 18 months with an accompanying decrease in cost per component. This advancement has been going on since 1958 and has been the major factor in the incredible improvements (per dollar) in the performance of computers over the past 30 years.

The performance/cost ratio of a product increases as producers and users become more familiar with it. People, materials, and processes are not perfect. Initial versions of a product will have weaknesses that will become apparent only after the product is built and used. Subsequent versions of the products give the builders a chance to remedy these weaknesses using not only their own experience but also inputs from users. Economies of scale also occur when a product’s success results in increased numbers in production. Initially, a product is quite expensive, since its cost must include the expenses of developing it, the associated tooling, and the initial production. As time goes on, design and tooling are amortized and new approaches developed to produce the product at lower cost. Initial prototypes of automobiles may cost half a million dollars, but three years later you can buy them at the dealer for a small fraction of that price.

As more time passes, newer materials and processes can be incorporated, the design and production can be further refined, and the price continues to drop. These increases in the performance/cost ratio reflect themselves in services as well. Over time people learn to decrease mistakes, develop more efficient routines, and acquire more effective technology. In real dollars, the modern supermarket delivers a tremendous variety of products with impressively low operating costs. Consider airplanes: the real cost of a round-trip airfare across the United States has dropped precipitously in my lifetime. The time required for a cross-country flight has dropped from 20 hours (with four stops) to 5 or 6 hours (with no stops). The price of tickets and the time to travel from San Jose to Nashville oscillate widely, but this is due to the strange jousting in the airline business, not to achievable performances and costs. Why, then, are performance and price not always what they could be?

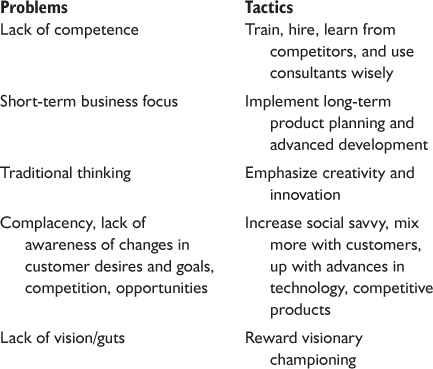

One possible answer might be the complacency mentioned in Chapter 2. When things are good, people unfortunately (or fortunately) act as though they will remain that way. Witness the economic bubbles and subsequent busts of the 1990s and the early part of this century. Think of the companies that have gotten into trouble because they delay too long in moving to a new technology or those that do not realize performance criteria are changing. Another reason for lack of improvement in price and performance might be that performance goals are set too low. A third might be weaknesses in design and production leading to higher costs and/or poorer performance. Or it could be that the producer is attempting to take an unrealistic profit. But the likely answer is simply that we buy much more than what we usually call performance in our products.

Consider luxury products: Louis Vuitton bags, the Bugatti Veyron sports car, Manolo Blahnik shoes, Patek Philippe watches, Purdey shotguns, and five-carat engagement rings. These are indeed fine items, but most people I know would not consider the performance alone of such things to be worth the high cost. Performance-wise, I am delighted with my discount store luggage, my Toyota pickup, my New Balance shoes, my Seiko watch, and my wife’s lack of interest in diamonds, and I don’t need a shotgun. But many people buy luxury items and obviously think they are worth the cost. Much of the value of such products lies in the less-tangible characteristics considered in the remainder of this book. The same is true for the much less expensive products that most of us purchase. The seductive power of quantification causes us to be overly attracted to performance and to neglect many aspects of quality that are less measurable but nonetheless highly important. It is to these issues that we will turn in the next chapter.

Chapter 3 Thought Problem

Considering performance and cost, choose an industrially produced product that in your opinion ranks very high and one that ranks low—in other words, one that performs beautifully for the money and one that is overpriced and/or low in performance for its cost. Again, in the case of the low-ranking one, what could be done to improve it, and why do you think that improvement has not happened?