CHAPTER I

PRECISION LOCATING AND DIVIDING METHODS

The degree of accuracy that is necessary in the construction of certain classes of machinery and tools, has made it necessary for toolmakers and machinists to employ various methods and appliances for locating holes or finished surfaces to given dimensions and within the prescribed limits of accuracy. In this chapter, various approved methods of locating work, such as are used more particularly in tool-rooms, are described and illustrated.

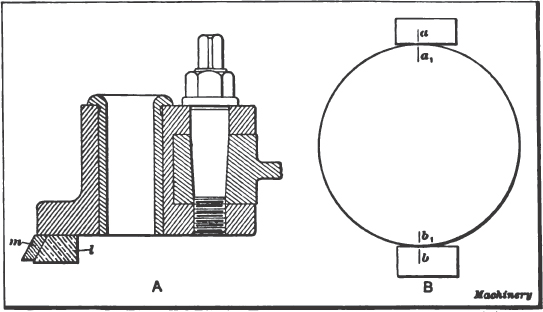

Button Method of Accurately Locating Work. — Among the different methods employed by toolmakers for accurately locating work such as jigs, etc., on the faceplate of a lathe, one of the most commonly used is known as the “button method.” This method is so named because cylindrical bushings or buttons are attached to the work in positions corresponding to the holes to be bored, after which they are used in locating the work. These buttons which are ordinarily about  or

or  inch in diameter, are ground and lapped to the same size, and the ends are finished perfectly square. The outside diameter should preferably be such that the radius can easily be determined, and the hole through the center should be about

inch in diameter, are ground and lapped to the same size, and the ends are finished perfectly square. The outside diameter should preferably be such that the radius can easily be determined, and the hole through the center should be about  inch larger than the retaining screw so that the button can be adjusted laterally.

inch larger than the retaining screw so that the button can be adjusted laterally.

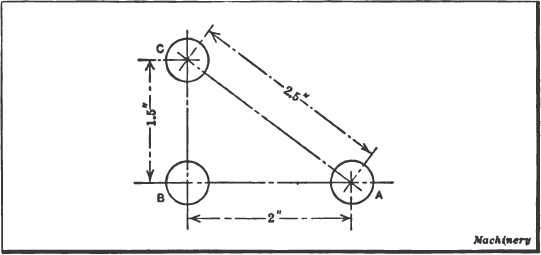

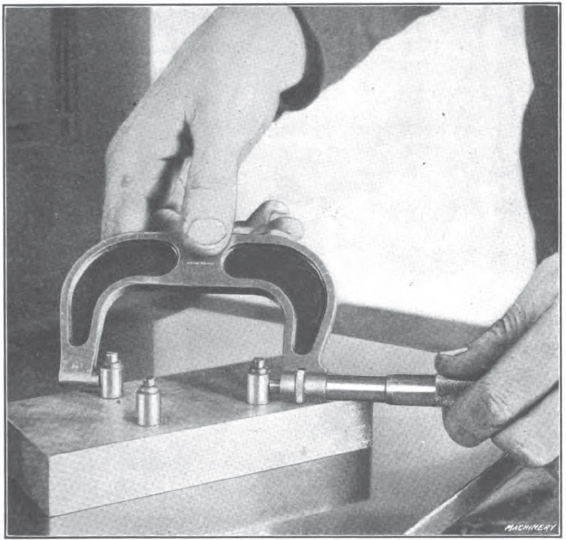

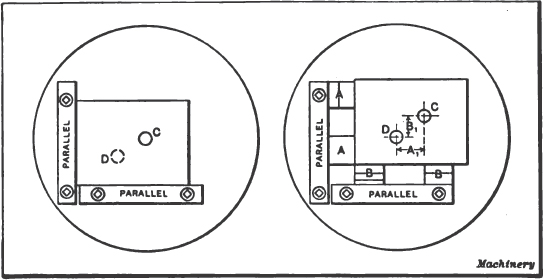

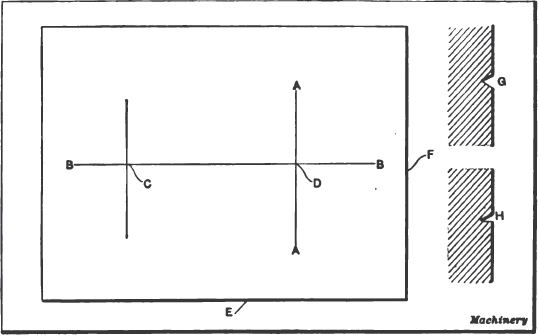

As a simple example of the practical application of the button method, suppose three holes are to be bored in a jig-plate according to the dimensions given in Fig. 1. A common method of procedure would be as follows: First lay out the centers of all holes to be bored, by the usual method. Mark these centers with a prick-punch and then drill holes for the machine screws which are used to clamp the buttons. After the buttons are clamped lightly in place, set them in correct relation with each other and with the jig-plate. The proper location of the buttons is very important, as their positions largely determine the accuracy of the work. The best method of locating a number of buttons depends somewhat upon their relative positions, the instruments available, and the accuracy required. When buttons must be located at given distances from the finished sides of a jig, a surface plate and vernier height-gage are often used. The method is to place that side from which the button is to be set, upon an accurate surface plate and then set the button by means of the height-gage, allowance being made, of course, for the radius of the button. The center-to-center distance between the different buttons can afterwards be verified by taking direct measurements with a micrometer (as indicated in Fig. 2) by measuring the overall distance and deducting the diameter of one button.

Fig. 1. Simple Example of Work Illustrating Application of Button Method

After the buttons have been set and the screws are tightened, all measurements should be carefully checked. The work is then mounted on the faceplate of the lathe and one of the buttons is set true by the use of a test indicator. When the dial of the indicator ceases to vibrate, thus showing that the button runs true, the latter should be removed so that the hole can be drilled and bored to the required size. In a similar manner other buttons are indicated and the holes bored, one at a time. It is evident that if each button is correctly located and set perfectly true in the lathe, the various holes will be located the required distance apart within very close limits.

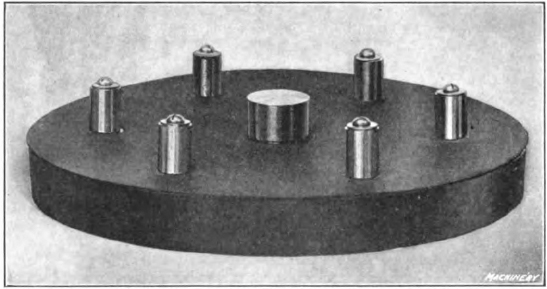

Another example of work illustrating the application of the button method is shown in Fig. 3. The disk-shaped part illustrated is a flange templet which formed a part of a fixture for drilling holes in flanged plates, the holes being located on a circle 6 inches in diameter. It was necessary to space the six holes equi-distantly so that the holes in the flanges would match in any position, thus making them interchangeable. First a plug was turned so that it fitted snugly in the  -inch central hole of the plate and projected above the top surface about

-inch central hole of the plate and projected above the top surface about  inch. A center was located in this plug and from it a circle of three inches radius was drawn. This circle was divided into six equal parts and then small circles

inch. A center was located in this plug and from it a circle of three inches radius was drawn. This circle was divided into six equal parts and then small circles  inch in diameter were drawn to indicate the outside circumference of the bushings to be placed in the holes. These circles served as a guide when setting the button and enabled the work to be done much more quickly. The centers of the holes were next carefully prick-punched and small holes were drilled and tapped for No. 10 machine screws. After this the six buttons were attached in approximately the correct positions and the screws tightened enough to hold the buttons firmly, but allow them to be moved by tapping lightly. As the radius of the circle is 3 inches, the radius of the central plug,

inch in diameter were drawn to indicate the outside circumference of the bushings to be placed in the holes. These circles served as a guide when setting the button and enabled the work to be done much more quickly. The centers of the holes were next carefully prick-punched and small holes were drilled and tapped for No. 10 machine screws. After this the six buttons were attached in approximately the correct positions and the screws tightened enough to hold the buttons firmly, but allow them to be moved by tapping lightly. As the radius of the circle is 3 inches, the radius of the central plug,  inch, and that of each button,

inch, and that of each button,  inch, the distance from the outside of the central plug to the outside of any button, when correctly set, must be

inch, the distance from the outside of the central plug to the outside of any button, when correctly set, must be  inches. Since there are six buttons around the circle, the center-to-center distance is equal to the radius, and the distance between the outside or any two buttons should be

inches. Since there are six buttons around the circle, the center-to-center distance is equal to the radius, and the distance between the outside or any two buttons should be  inches. Having determined these dimensions, each button is set equidistant from the central plug and the required distance apart, by using a micrometer. As each button is brought into its correct position, it should be tightened down a little so that it will be located firmly when finally set. The work is then strapped to the faceplate of a lathe and each button is indicated for boring the different holes by means of an indicator, as previously described. When the buttons are removed it will be found that in nearly all cases the small screw holes will not run exactly true; therefore it is advisable to form a true starting point for the drill by using a lathe tool.

inches. Having determined these dimensions, each button is set equidistant from the central plug and the required distance apart, by using a micrometer. As each button is brought into its correct position, it should be tightened down a little so that it will be located firmly when finally set. The work is then strapped to the faceplate of a lathe and each button is indicated for boring the different holes by means of an indicator, as previously described. When the buttons are removed it will be found that in nearly all cases the small screw holes will not run exactly true; therefore it is advisable to form a true starting point for the drill by using a lathe tool.

Fig. 2. Testing Location of Buttons

Fig. 3. Flange Templet with Buttons Attached

When doing precision work of this kind, the degree of accuracy obtained will depend upon the instruments used, the judgment and skill of the workman, and the care exercised. A good general rule to follow when locating bushings or buttons is to use the method which is the most direct and which requires the least number of measurements, in order to prevent an accumulation of errors.

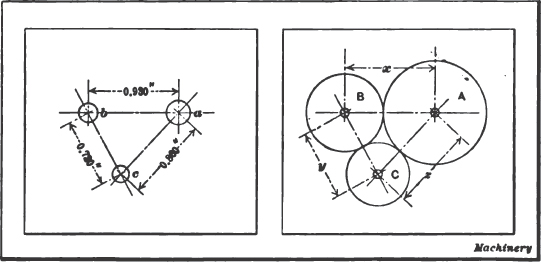

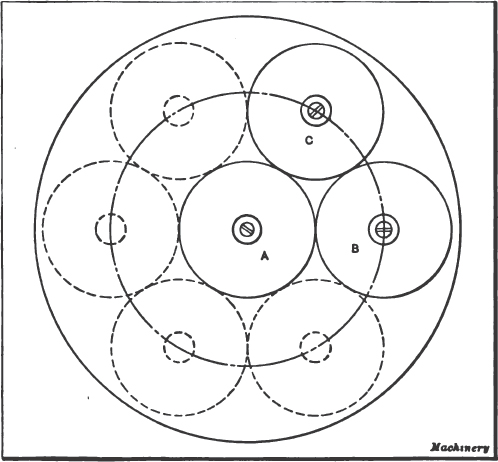

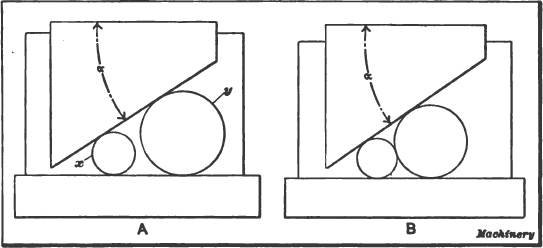

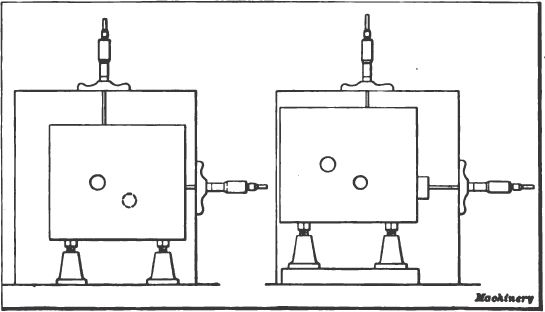

Locating Work by the Disk Method. — Comparatively small precision work is sometimes located by the disk method, which is the same in principle as the button method, the chief difference being that disks are used instead of buttons. These disks are made to such diameters that when their peripheries are in contact, each disk center will coincide with the position of the hole to be bored; the centers are then used for locating the work. To illustrate this method, suppose that the master-plate shown at the left in Fig. 4 is to have three holes a, b and c bored into it, to the center distances given.

It is first necessary to determine the diameters of the disks. If the center distances between all the holes were equal, the diameters would, of course, equal this dimension. When, however, the distances between the centers are unequal, the diameters may be found as follows: Subtract, say, dimension y from x, thus obtaining the difference between the radii of disks C and A (see right-hand sketch); add this difference to dimension z, and the result will be the diameter of disk A. Dividing this diameter by 2 gives the radius, which, subtracted from center distance x equals the radius of B; similarly, the radius of B subtracted from dimension y equals the radius of C.

For example, 0.930 − 0.720 = 0.210 or the difference between the radii of disks C and A. Then the diameter of A = 0.210 + 0.860 = 1.070 inch, and the radius equals 1.070  2 = 0.535 inch. The radius of B = 0.930 − 0.535 = 0.395 inch and 0.395 × 2 = 0.790, or the diameter of B. The center distance 0.720 − 0.395 = 0.325, which is the radius of C; 0.325 × 2 = 0.650 or the diameter of C.

2 = 0.535 inch. The radius of B = 0.930 − 0.535 = 0.395 inch and 0.395 × 2 = 0.790, or the diameter of B. The center distance 0.720 − 0.395 = 0.325, which is the radius of C; 0.325 × 2 = 0.650 or the diameter of C.

After determining the diameters, the disks should be turned nearly to size and finished, preferably in a bench lathe. First insert a solder chuck in the spindle, face it perfectly true, and attach the disk by a few drops of solder, being careful to hold the work firmly against the chuck while soldering. Face the outer side and cut a sharp V-center in it; then grind the periphery to the required diameter. Next fasten the finished disks onto the work in their correct locations with their peripheries in contact, and then set one of the disks exactly central with the lathe spindle by applying a test indicator to the center in the disk. After removing the disk and boring the hole, the work is located for boring the other holes in the same manner.

Fig. 4. An Example of Precision Work, and Method of Locating Holes by Use of Disks in Contact

Small disks may be secured to the work by means of jeweler’s wax. This is composed of common rosin and plaster of Paris and is made as follows: Heat the rosin in a vessel until it flows freely, and then add plaster of Paris and keep stirring the mixture. Care should be taken not to make the mixture too stiff. When it appears to have the proper consistency, pour some of it onto a slate or marble slab and allow it to cool; then insert the point of a knife under the flattened cake thus formed and try to pry it off. If it springs off with a slight metallic ring, the proportions are right, but if it is gummy and ductile, there is too much rosin. On the other hand, if it is too brittle and crumbles, this indicates that there is too much plaster of Paris. The wax should be warmed before using. A mixture of beeswax and shellac, or beeswax and rosin in about equal proportions, is also used for holding disks in place. When the latter are fairly large, it may be advisable to secure them with small screws, provided the screw holes are not objectionable.

Disk-and-button Method of Locating Holes. — The accuracy of work done by the button method previously described is limited only by the skill and painstaking care of the workman, but setting the buttons requires a great deal of time. By a little modification, using what is sometimes called the “disk-and-button method,” a large part of this time can be saved without any sacrifice of accuracy. The disk-and-button method, which was described by Guy H. Gardner in MACHINERY, September, 1914, is extensively used in many shops. Buttons are used, but they are located in the centers of disks of whatever diameters are necessary to give the required locations. As three disks are used in each step of the process, it is sometimes called the “three-disk method.”

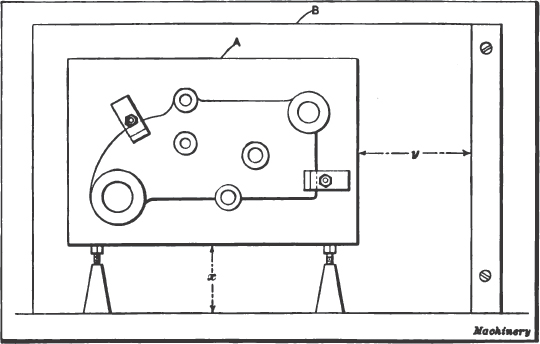

Fig. 5. Locating Equi-distant Holes on a Circle by Using Disks and Buttons in Combination

To illustrate the practical application of this method, suppose six equally-spaced holes are to be located in the circumference of a circle six inches in diameter. To locate these, one needs, besides the buttons, three disks three inches in diameter, each having a central hole exactly fitting the buttons. It is best to have, also, a bushing of the same diameter as the buttons, which has a center-punch fitted to slide in it. First, the center button is screwed to the templet, and one of the disks A, Fig. 5, is slipped over it; then a second disk B carrying a bushing and center-punch is placed in contact with disk A and a light blow on the punch marks the place to drill and tap for No. 2 button, which is kept in its proper place while tightening the screw by holding the two disks A and B in contact. Next, the third disk C is placed in contact with disks A and B and locates No. 3 button, and so on until the seven buttons are secured in position. The templet is then ready to be strapped to the lathe faceplate for boring.

Fig. 6. Example of Circular Spacing Requiring a Large Central Disk

Of course, it is not possible to use disks of “standard” sizes for many operations, but making a special disk is easy, and its cost is insignificant as compared with the time saved by its use. One who employs this method, especially if he also uses disks to lay out angles, soon accumulates a stock of various sizes. While it is desirable to have disks of tool steel, hardened and ground, or, in the larger sizes, of machine steel, casehardened and ground, a disk for occasional use will be entirely satisfactory if left soft.

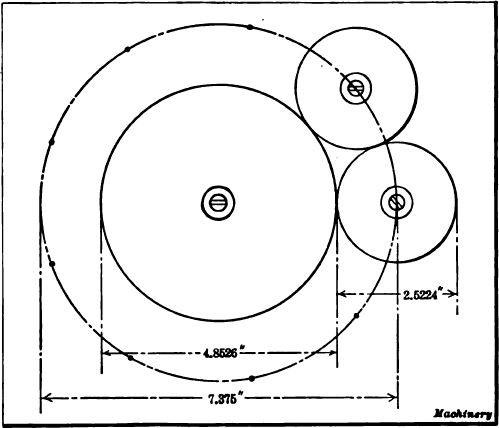

Two other jobs that illustrate this method may be of interest. The first one, shown in Fig. 6, required the locating of nine equally-spaced holes on a circumference of  -inches diameter. In any such case, the size of the smaller disks is found by multiplying the diameter of the circle upon which the centers of the disks are located by the sine of half the angle between two adjacent disks. The angle between the centers of adjacent disks equals 360

-inches diameter. In any such case, the size of the smaller disks is found by multiplying the diameter of the circle upon which the centers of the disks are located by the sine of half the angle between two adjacent disks. The angle between the centers of adjacent disks equals 360  number of disks. 360

number of disks. 360  9 = 40; hence, in this case, the diameter of the smaller disks equals

9 = 40; hence, in this case, the diameter of the smaller disks equals  multiplied by the sine of 20 degrees, or

multiplied by the sine of 20 degrees, or  × 0.34202 = 2.5224 inches.

× 0.34202 = 2.5224 inches.  − 2.5224 = 4.8526 inches, which is the diameter of the central disk.

− 2.5224 = 4.8526 inches, which is the diameter of the central disk.

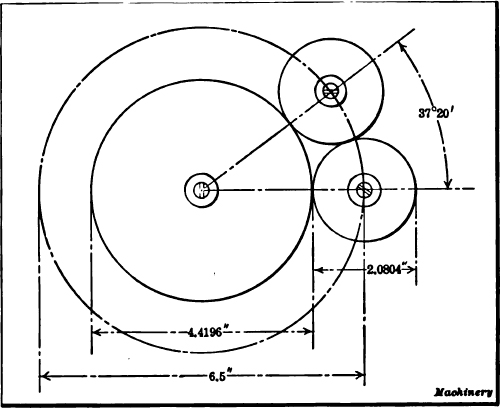

The templet shown in Fig. 7 required two holes on a circumference  -inches diameter, with their centers 37 degrees 20 minutes apart. To find the diameter of the smaller disks, multiply the diameter of the large circle by the sine of one-half the required angle, as in the preceding example; thus

-inches diameter, with their centers 37 degrees 20 minutes apart. To find the diameter of the smaller disks, multiply the diameter of the large circle by the sine of one-half the required angle, as in the preceding example; thus  × sin 18 degrees 40 minutes = 2.0804 inches, which is the diameter of the two smaller disks. The diameter of the larger disk equals

× sin 18 degrees 40 minutes = 2.0804 inches, which is the diameter of the two smaller disks. The diameter of the larger disk equals  − 2.0804 = 4.4196 inches.

− 2.0804 = 4.4196 inches.

Very accurate results can be obtained by the disk-and-button method. Of course, absolute exactness is equally unattainable with buttons and a micrometer, or any other method; the micrometer does not show the slight inaccuracy in any one chordal measurement, while in using the disks the error is accumulative and the insertion of the last disk in the series shows the sum of the errors in all the disks. It is only in cases like the one illustrated in Fig. 5 that we note this, and then, though in correcting the error we may change the diameter of the circle a very slight amount, an exceedingly accurate division of the circumference is secured.

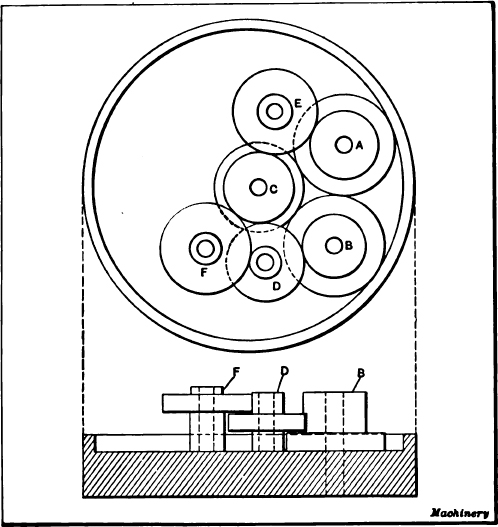

Use of Two- and Three-diameter Disks. — Fig. 8 illustrates, on an enlarged scale, a piece of work requiring great accuracy, which was successfully handled by an extension of the three-disk method. Fourteen holes were required in a space hardly larger than a silver half-dollar, and, although the drawing gave dimensions from the center of the circle, the actual center could not be used in doing the work, as there was to be no hole there; moreover, a boss slightly off center prevented the use of a central disk, unless the bottom of the disk were bored out to receive this boss, which was not thought expedient. Hence, the method adopted was to make the plate thicker than the dimension given on the drawing, and then bore it out to leave a rim of definite diameter, this rim to be removed after it had served its purpose as a locating limit for the disks.

As the holes A and B, which were finished first, were 0.600 inch apart and 0.625 inch from the center, the rim was bored to 1.850 inch and two 0.600-inch disks, in contact with the rim and with each other, located these holes. As hole C was to be equidistant from holes A and B, and its distance from the center was given, the size of the disk for this hole was readily determined. The disks for holes A, B and C have two diameters; the upper diameters are made to whatever size is required for locating the disks of adjacent holes, and they also form a hub which can be used when setting the disks with an indicator. Hole D was 0.4219 inch from B, and calculations based on this dimension and its distance from the center showed that it was 0.4375 inch from hole C.

A “three-story” disk or button was made for hole D. The diameter of the large part was 0.46875 inch and it overlapped disks C and B (the upper sections of which were made 0.375 inch and 0.4062 inch, respectively), thus locating D. Then hole F and all the remaining holes were located in a similar manner. The upper diameters of disks E and D were used in locating disks for other adjacent holes, as well as a hub for the indicator; for instance, to locate a hole with reference to holes C and D, the diameter of the new disk and the diameter of the upper part of disk D were varied to give the required location. The relation between the disks B, D and F is shown by the side view.

Fig. 7. Locating Holes at an Angle by Use of Disks and Buttons

Fig. 8. Locating Holes by Means of Two- and Three-diameter Disks in Contact

It had been decided that no screws should be used in attaching the buttons or disks to the work, as it was feared that the tapped holes would introduce inaccuracy by deflecting the boring tools; therefore, the following method was employed. After all the disks were fastened in place by clamps, a soft solder of low melting point was flowed about them, filling the work to the top of the rim. When the solder had cooled, the clamps were removed, the work transferred to the lathe faceplate, indicated in the usual way, and the holes bored by a “D” or “hog-nose” drill, guided by an axial hole in each disk, which had been provided for that purpose when the disks were made. It was thought that the unequal contraction of the solder and the plate in cooling might throw the holes “out of square;” however, careful measurements failed to show any appreciable lack of parallelism in test-bars inserted in the holes.

Accurate Angular Measurements with Disks. — For setting up a piece of work on which a surface is to be planed or milled at an exact angle to a surface already finished, disks provide an accurate means of adjustment. One method of using disks for angular work is illustrated at A in Fig. 9. Let us assume that the lower edge of plate shown is finished and that the Upper edge is to be milled at an angle α of 32 degrees with the lower edge. If the two disks x and y are to be used for locating the work, how far apart must they be set in order to locate it at the required angle? The center-to-center distance can be determined as follows: Subtract the radius of the larger disk from the radius of the smaller disk, and divide the difference by the sine of one-half the required angle.

Example. — If the required angle α is 32 degrees, the radius of the large disk 2 inches, and the radius of the small disk 1 inch, what is the center-to-center distance?

The sine of one-half the required angle, or 16 degrees, is 0.27564. The difference between the radii of the disks equals 2 − 1 = 1, and 1  0.27564 = 3.624 inches. Therefore, for an angle of 32 degrees, disks of the sizes given should be set so that the distance between their centers is 3.624 inches.

0.27564 = 3.624 inches. Therefore, for an angle of 32 degrees, disks of the sizes given should be set so that the distance between their centers is 3.624 inches.

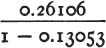

Another method of accurately locating angular work is illustrated at B in Fig. 9. In this case, two disks are also used, but they are placed in contact with each other and changes for different angles are obtained by varying the diameter of the larger disk. The smaller disk is a standard 1-inch size, such as is used for setting a 2-inch micrometer. By this method any angle up to about 40 degrees can be obtained within a very close limit of accuracy. The following rule may be used for determining the diameter of the larger disk, when both disks are in contact and the diameter of the small disk is known:

Fig. 9. Obtaining Accurate Angular Measurements with Disks

Multiply twice the diameter of the small disk by the sine of one-half the required angle; divide this product by 1 minus the sine of one-half the required angle; add the quotient to the diameter of the small disk to obtain the diameter of the large disk.

Example. — The required angle α is 15 degrees. Find the diameter of the large disk to be in contact with the standard 1-inch reference disk.

The sine of 7 degrees 30 minutes is o. 13053. Multiplying twice the diameter of the small disk by the sine of 7 degrees 30 minutes, we have 2 × 1 × 0.13053 = 0.26106. This product divided by 1 minus the sine of 7 degrees 30 minutes =  = 0.3002. This quotient added to the diameter of the small disk equals 1 + 0.3002 = 1.3002 inch, which is the diameter of the large disk.

= 0.3002. This quotient added to the diameter of the small disk equals 1 + 0.3002 = 1.3002 inch, which is the diameter of the large disk.

The accompanying table gives the sizes of the larger disks to the nearest 0.0001 inch for whole degrees ranging from 5 to 40 degrees inclusive. Incidentally, the usefulness of these disks can be increased by stamping on each one its diameter and also the angle which it subtends when placed in contact with the standard 1-inch disk.

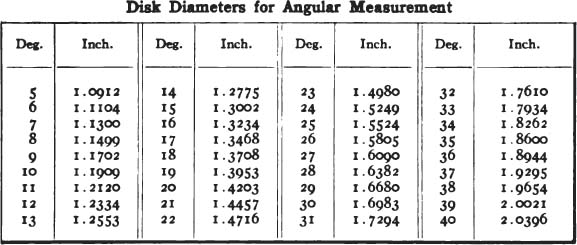

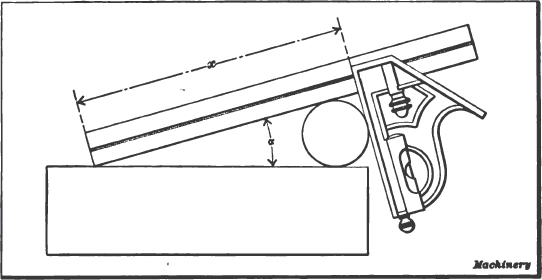

Disk-and-square Method of Determining Angles. — The method shown in Fig. 10 for determining angles for setting up work on a milling machine or planer, possesses several advantages. No expensive tools are required, the method can be applied quickly, and the results obtained are quite accurate enough for any but the most exacting requirements. As will be seen, an ordinary combination square is used in connection with a disk, the head of the square being set at different points on the blade according to the angle that is desired. Theoretically, a one-inch disk could be used for all angles from about 6 degrees up to a right angle, but in practice it is more convenient and accurate to employ larger disks for the larger angles.

The only inaccuracy resulting from this method is due to setting the square at the nearest “scale fraction” instead of at the exact point determined by calculation. This error is very small, however, and is negligible in practically all cases. The dimension x required for any desired angle α can be found by multiplying the radius of the disk by the cotangent of one-half the desired angle, and adding to this product the radius of the disk.

Example. — The square blade is to be set to an angle of 15 degrees 10 minutes, using a 2-inch disk. At what distance x (see Fig. 10) should the head of the square be set?

Cot 7 degrees 35 minutes = 7.5113, and 7.5113 × 1 + 1 = 8.5113 inches.

By setting the square to  inches “full,” the blade would be set very close to the required angle of 15 degrees 10 minutes.

inches “full,” the blade would be set very close to the required angle of 15 degrees 10 minutes.

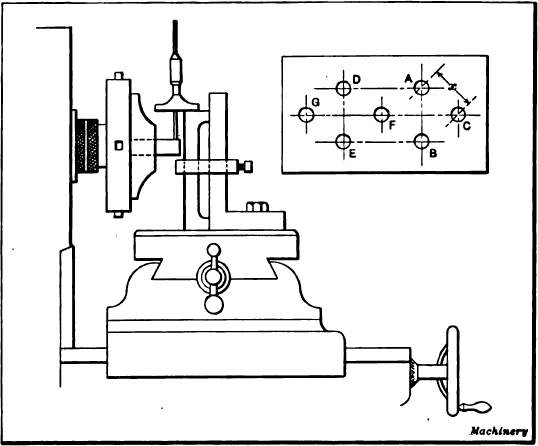

Locating Work by Means of Size Blocks. — The size-block method of locating a jig-plate or other part, in different positions on a lathe faceplate, for boring holes accurately at given center-to-center distances, is illustrated in Fig. 11. The way the size blocks are used in this particular instance is as follows: A pair of accurate parallels are attached to a faceplate at right angles to each other and they are so located that the center of one of the holes to be bored will coincide with the lathe spindle. The hole which is aligned in this way should be that one on the work which is nearest the outer corner, so that the remaining holes can be set in a central position by adjusting the work away from the parallels. After the first hole is bored, the work is located for boring each additional hole by placing size blocks of the required width between the edges of the work and the parallels. For instance, to set the plate for boring hole D, size blocks (or a combination of blocks or gages) equal in width to dimension A1 would be inserted at A, and other blocks equal in width to dimension B1 beneath the work as at B. As will be seen, the dimensions of these blocks equal the horizontal and vertical distances between holes C and D. With the use of other combinations of gage blocks, any additional holes that might be required are located in the central position. While only two holes are shown in this case, it will be understood that the plate could be located accurately for boring almost any number of holes by this method.

Fig. 10. Diak-and-square Method of Accurately Setting Angular Work

Incidentally, such gages as the Johansson combination gages are particularly suited for work of this kind, as any dimension within the minimum and maximum limits of a set can be obtained by simply placing the required sizes together. Sometimes, when such gages are not available, disks which have been ground to the required diameter are interposed between the parallels and the work for securing accurate locations. Another method of securing a positive adjustment of the work is to use parallels composed of two tapering sections, which can be adjusted to vary the width and be locked together by means of screws. Each half has the same taper so that outer edges are parallel for any position, and the width is measured by using a micrometer.

Fig. 11. Method of Setting Work on Faceplate with Size Blocks or Gages

The size-block method is usually applied to work having accurately machined edges, although a part having edges which are of a rough or irregular shape can be located by this method, if it is mounted on an auxiliary plate having accurately finished square edges. For instance, if holes were to be bored in the casting for a jig templet which had simply been planed on the top and bottom, the casting could be bolted to a finished plate having square edges and the latter be set in the different positions required by means of size blocks. Comparatively large jig-plates are sometimes located for boring in this way and the milling machine is often used instead of a lathe.

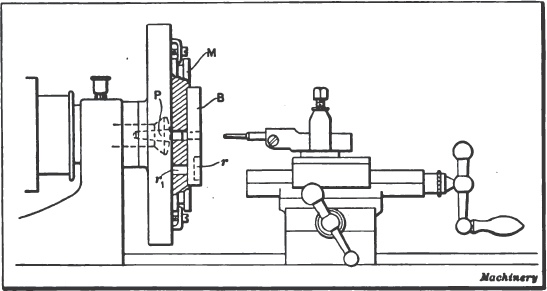

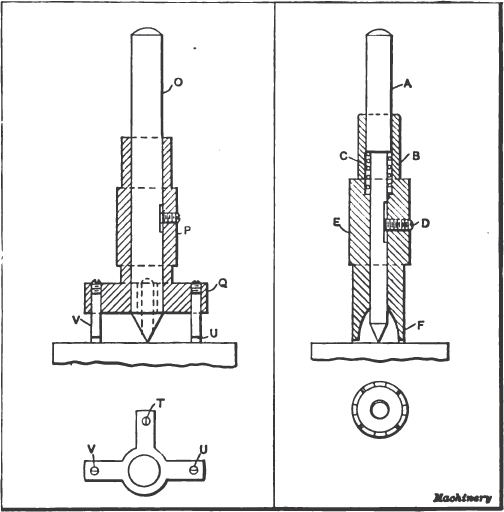

The Master-plate Method. — When it is necessary to machine two or more plates so that they are duplicates as to the location of holes, circular recesses, etc., what is known as a master-plate is often used for locating the work on the lathe faceplate. This master-plate M (see Fig. 12) contains holes which correspond to those wanted in the work, and which accurately fit a central plug P in the lathe spindle, so that by engaging first one hole and then another with the plug, the work is accurately positioned for the various operations.

Fig. 12. Master-plate applied to a Bench Lathe Faceplate

When making the master-plate, great care should be taken to have the sides parallel and the holes at right angles to the sides, as well as accurately located with reference to one another. The various holes may be located with considerable precision by the use of buttons as previously described. Of course, it is necessary to have a hole in the master-plate for each different position in which the work will have to be placed on the faceplate; for example, if a circular recess r were required, a hole r1 exactly concentric with it would be needed in the master-plate. The method of holding the work and locating it with reference to the holes in the master-plate will depend largely on its shape. The cylindrical blank B illustrated is positioned by a recess in the master-plate in which it fits. The work is commonly held to the master-plate by means of clamps and tap bolts or by screws which pass through the work and into the master-plate. Solder is sometimes used when it is not convenient to hold the work by clamps or screws.

The plug P which locates the master-plate is first turned to fit the spindle or collet of the lathe, and the outer or projecting end is rough-turned for the holes in the master-plate, which should all be finished to exactly the same diameter. The plug is then inserted in the spindle and ground and lapped to a close fit for the holes in the master-plate. The latter, with the work attached to it, is next clamped to the faceplate by the straps shown, which engage a groove around the edge of the master-plate. The first hole is finished by drilling to within, say, 0.005 or 0.006 inch of the size, and then boring practically to size, a very small amount being left for reaming or grinding. The remaining holes can then be finished in the same way, the work being positively located in each case by loosening the master-plate and engaging the proper hole in it with the central plug. It is apparent that by the use of this same master-plate, a number of pieces B could be made which would be practically duplicates.

The master-plate method of locating work can be applied in many different ways. It is used for making duplicate dies, for accurately locating the various holes in watch movements, and for many other operations requiring great precision. Master-plates are quite frequently used by toolmakers when it is necessary to produce a number of drill jigs which are to be used for drilling holes in different parts having the same relative locations, thus requiring jigs that are duplicates within very close limits.

Making Master-plate for Duplicating a Model. — When a master-plate is required, that is to be used in making duplicates of an existing model, the holes are bored in the master-plate by reversing the process illustrated in Fig. 12. That is, the central plug P is turned to fit the largest hole in the model and the latter with the attached master-plate blank is clamped to lathe faceplate. The first hole is then bored to within say 0.002 inch of the finish diameter, to allow for grinding, provided the master-plate is to be hardened. The central plug is then turned down to fit the next largest hole and the second hole is bored in the master-plate. This method is continued until all the holes are bored. In order to prevent any change in the position of the master-plate relative to the model, it may be secured by inserting dowel-pins through both parts, the work being held to the lathe faceplate by ordinary screw clamps. If the holes in the model do not extend clear through, a flat plate having parallel sides may be interposed between the model and master-plate to provide clearance between the two and prevent cutting into the model when boring the master-plate.

Fig. 13. Locating Equi-distant Holes in a Straight Line by Means of Disks and Straightedge

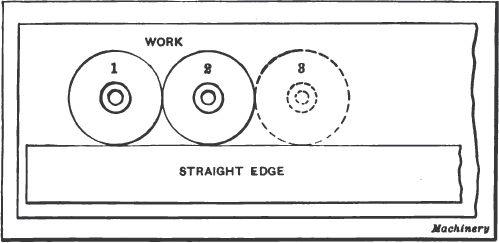

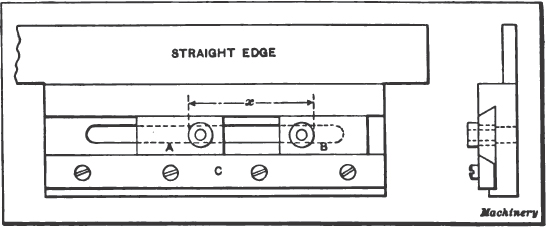

Use of Disks for Locating Equally-spaced Holes. — A simple method of spacing holes that are to be drilled in a straight line is illustrated in Fig. 13. Two disks are made, each having a diameter equal to the center-to-center distance required between the holes. These disks must also have holes which are exactly central with the outside to act as a guide for the drill or reamer. The first two holes are drilled in the work while the disks are clamped so that they are in contact with each other and also with the straightedge as shown. One disk is then placed on the opposite side of the other, as indicated by the dotted line, and a third hole is drilled; this process of setting one disk against the opposite side of the other is continued until all the holes are drilled. When it is necessary to drill a parallel row of “staggered” holes, the second row can be located by placing disks of the proper size in contact with the first row of disks.

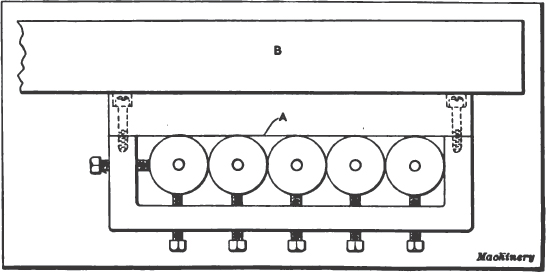

A method of using disks, which is preferable for very accurate work, is shown in Fig. 14. The disks are clamped against each other and along straightedge A by the screws shown, and if the outside diameters are correct and the guide holes concentric with the outside, very accurate work can be done. With this device there may be as many disks as there are holes to be drilled, if the number of holes is comparatively small, but if it is necessary to drill a long row of holes, the disks and frame are shifted along an auxiliary straightedge B, the hole in one of the end disks being aligned with the last hole drilled by inserting a close-fitting plug through the disk and hole.

Fig. 14. Special Dirt-jig for Precision Drilling

Adjustable Jig for Accurate Hole Spacing. — An adjustable jig for accurately spacing small holes is shown in Fig. 15. This form is especially adapted for locating a number of equally-spaced holes between two previously drilled or bored holes, and the accuracy of the method lies in the fact that a slight error in the original spacing of the guide bushing is multiplied, and, therefore, easily detected. There are two of these guide bushings A and B which are carried by independent slides. These slides can be shifted along a dovetail groove after loosening the screws of clamp-gib C. To illustrate the method of using this jig, suppose five equally-spaced holes are to be located between two holes that are 12 inches apart. As the center-to-center distance between adjacent holes is 2 inches, slides A and B would be set so that the dimension x equals 2 inches plus the radii of the bushings. A straightedge is then clamped to the work in such position that a close-fitting plug can be inserted through the end holes which were previously drilled or bored. Then with a plug inserted through, say, bushing B and one of the end holes, the first hole is drilled and reamed through bushing A; the jig is then shifted to the left until the plug in B enters the hole just made. The second hole is then drilled and reamed through bushing A and this drilling and shifting of the jig is continued until the last hole is finished. The distance between the last hole and the original end hole at the left is next tested by attempting to insert close-fitting plugs through both bushings. Evidently, if there were any inaccuracy in the spacing of the bushings, this would be multiplied as many times as the jig was shifted, the error being accumulative. To illustrate how the error accumulates, suppose that the bushings were 0.001 inch too far apart; then the distance to the first hole would be 2.001 inch, to the second hole, 4.002 inch, and finally the distance from the first to the sixth hole would be 10.005 inches; consequently, the distance between the sixth and seventh holes would equal 12 − 10.005 = 1.995 inch, or 0.005 inch less than the required spacing, assuming, for the sake of illustration, that the first and last holes were exactly 12 inches apart. In case of an error of 0.005 inch, the bushings would be set closer together an amount equal to one-fifth of this error, as near as could be determined with a micrometer, and all of the holes would then be re-reamed.

Fig. 15. Adjustable Jig for Accurate Hole Spacing

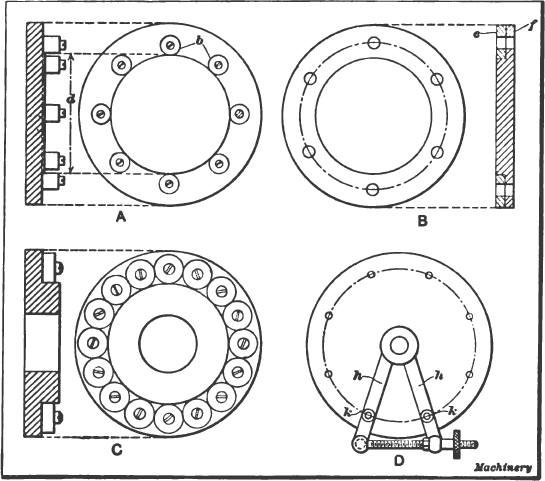

Methods of Accurately Dividing a Circle. — Sometimes it is necessary to machine a number of holes in a plate so that all the holes are on a circle or equi-distant from a central point, and also the same distance apart, within very small limits. A simple method of spacing holes equally is illustrated at A, Fig. 16. A number of buttons equal to the number of holes required are ground and lapped to exactly the same diameter, preferably by mounting them all on an arbor and finishing them at the same time. The ends should also be made square with the cylindrical surface of the button. When these buttons are finished, the diameter is carefully measured and this dimension is subtracted from the diameter of the circle on which the holes are to be located in order to obtain the diameter d (see illustration). A narrow shoulder is then turned on the plate to be bored, the diameter being made exactly equal to dimension d. By placing the buttons in contact with this shoulder, they are accurately located radially and can then be set equi-distant from each other by the use of a micrometer. In this particular case, it would be advisable to begin by setting the four buttons which are 90 degrees apart and then the remaining four. The buttons are next used for setting the work preparatory to boring.

Correcting Spacing Errors by Split Ring Method. — Another method of securing equal spacing for holes in indexing wheels, etc., is illustrated at B, Fig. 16. This method, however, is not to be recommended if the diameter of the circle on which the holes are to be located must be very accurate. The disk or ring in which the holes are required is formed of two sections e and f, instead of being one solid piece. The centers for the holes are first laid out as accurately as possible on ring e. Parts e and f are then clamped together and the holes are drilled through these two sections. Obviously, when the holes are laid out and drilled in this way, there will be some error in the spacing, and, consequently, all of the holes would not match, except when plate e is in the position it occupied when being drilled. Whatever errors may exist in the spacing can be eliminated, however, by successively shifting plate e to different positions and re-reaming the holes for each position. A taper reamer is used and two pins should be provided having the same taper as the reamer. Ring e is first located so that a hole is aligned quite accurately with one in the lower plate. The ring is then clamped and the hole is partly reamed, the reamer being inserted far enough to finish the hole in plate e and also cut clear around in the upper part of plate f. One of the taper pins is then driven into this hole and then a hole on the opposite side is partly reamed, after which the other pin is inserted. The remaining holes are now reamed in the same way, and the reamer should be fed in to the same depth in each case. If a pair of holes is considerably out of alignment, it may be necessary to run the reamer in to a greater depth than was required for the first pair reamed, and in such a case all the holes should be re-reamed to secure a uniform size.

Fig. 16. Four Methods of Accurately Dividing a Circle

The next step in this operation is to remove the taper pins and clamps, turn index plate e one hole and again clamp it in position. The reaming process just described is then repeated; the holes on opposite sides of the plate are re-reamed somewhat deeper, the taper pins are inserted, and then all of the remaining holes are re-reamed to secure perfect alignment for the new position of the plate. By repeating this process of shifting plate e and re-reaming the holes, whatever error that may have existed originally in the spacing of the holes, will practically be eliminated. It would be very difficult, however, to have these holes located with any great degree of accuracy, on a circle of given diameter.

Circular Spacing by Contact of Uniform Disks. — When an accurate indexing or dividing wheel is required on a machine, the method of securing accurate divisions of the circle illustrated at C, Fig. 16, is sometimes employed. There is a series of circular disks or bushings equal in number to the divisions required, and these disks are all in contact with each other and with a circular boss or shoulder on the plate to which they are attached. The space between adjacent disks is used to accurately locate the dividing wheel, engagement being made with a suitable latch or indexing device. When making a dividing wheel of this kind, all of the disks are ground and lapped to the same diameter and then the diameter of the central boss or plate is gradually reduced until all of the disks are in contact with each other and with the boss. For an example of the practical application of this method see “Originating a Precision Dividing Wheel.”

Spacing by Correcting the Accumulated Error. — Another indexing method of spacing holes equidistantly, is illustrated by the diagram at D, Fig. 16. An accurately fitting plug is inserted in the central hole of the plate in which holes are required. Two arms h are closely fitted to this plug, but are free to rotate and are provided with a fine-pitch screw and nut at the outer ends for adjusting the distance between the arms. Each arm contains an accurately-made, hardened steel bushing k located at the same radial distance from the center of the plate. These bushings are used as a guide for the drill and reamer when machining the holes in the plate.

To determine the center-to-center distance between the bushings, divide 360 by twice the number of holes required; find the sine corresponding to the angle thus obtained, and multiply it by the diameter of the circle upon which the holes are located. For example, if there were to be eleven holes on a circle 8 inches in diameter, the distance between the centers of the bushings would equal  = 16.36 degrees. The sine of 16.36 degrees is 0.2815, and 0.2815 × 8 = 2.252 inches. The arms are adjusted to locate the centers of the bushings this distance apart by placing closely fitting plugs in the bushings and measuring from one plug to another with a micrometer or vernier caliper. Of course, when taking this measurement, allowance is made for the diameter of the plugs.

= 16.36 degrees. The sine of 16.36 degrees is 0.2815, and 0.2815 × 8 = 2.252 inches. The arms are adjusted to locate the centers of the bushings this distance apart by placing closely fitting plugs in the bushings and measuring from one plug to another with a micrometer or vernier caliper. Of course, when taking this measurement, allowance is made for the diameter of the plugs.

After the arms are set, a hole is drilled and reamed; an accurately fitting plug is then inserted through the bushing and hole to secure the arms when drilling and reaming the adjacent hole. The radial arms are then indexed one hole so that the plug can be inserted through one of the arms and the last hole reamed. The third hole is then drilled and reamed, and this operation is repeated for all of the holes. Evidently, if the center-to-center distance between the bushings is not exactly right, the error will be indicated by the position of the arms relative to the last hole and the first one reamed; moreover, this error will be multiplied as many times as there are holes. For instance, if the arms were too far apart, the difference between the center-to-center distance of the last pair of holes and the center-to-center distance of the bushings in the arms would equal, in this particular case, eight times the error, and the arms should be re-adjusted accordingly. Larger bushings would then be inserted in the arms and the holes re-reamed, this operation being repeated until the holes were all equi-distant.

As will be seen, the value of this method lies in the fact that it shows the accumulated error. Thus, if the arms were 0.0005 inch too far apart, the difference between the first and last hole would equal 8 × 0.0005 = 0.004 inch. This same principle of dividing can be applied in various ways. For instance, the radial arms, if slightly modified, could be used for drilling equally-spaced holes in the periphery or disk of a plate, or, if a suitable marking device were attached, a device of this kind could be used for accurately dividing circular parts.

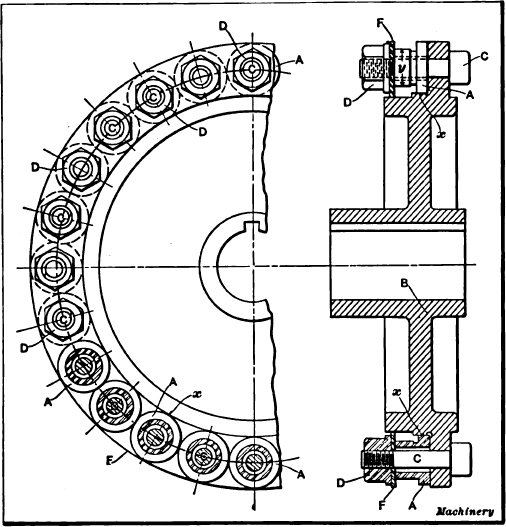

Originating a Precision Dividing Wheel. — There are various methods employed for making accurate indexing wheels for a definite number of divisions. One of these methods, suitable particularly for small numbers of divisions, employs a split wheel with a series of taper holes reamed through the two divisions. By shifting the two divisions from point to point (as explained in connection with sketch B, Fig. 16) and reaming and re-reaming the taper holes at each shifting, they may finally be brought very accurately into position. Another method that has been employed consists in clamping about the rim of the dividing wheel a number of precisely similar blocks, fitting close to each other and to the wheel itself. These blocks are then used for locating the wheel in each of its several positions in actual work. A third and simpler method (a modification of the one last described) consists in grinding a series of disks and clamping them around a rim of such diameter that the disks all touch each other and the rim simultaneously, as explained in connection with sketch C, Fig. 16. The wheel described in the following, which is illustrated in Fig. 17, was made in this way.

Disks A are clamped against an accurately ground face of the wheel B and are supposed to just touch each other all around, and to be each of them in contact with the ground cylindrical surface at x. They are held in proper position by bolts C and nuts D. The bolts fit loosely in the holes of the disks or bushings A so that the latter are free to be located as may be desired with reference to the bolts.

One or two improvements in the construction of this type of dividing wheel may be noted before proceeding to a description of the way in which it is made. For one thing, instead of having an indexing bolt enter the V-space between two adjoining disks, a smaller diameter y is ground on each of them, over which locking finger or pawl passes, holding the wheel firmly from movement in either direction. This construction has the advantage of a probable lessening of error by locating on each bushing instead of between two bushings; moreover, it gives a better holding surface and better holding angles than would be the case if this smaller diameter were not provided.

A second improvement lies in the method of clamping the bushings A in place. Instead of providing each bolt with a separate washer, a ring F is used. This ring fits closely on a seat turned to receive it on the dividing wheel B. When one bushing A has been clamped in place, the disk is locked from movement so that there is no possibility, in clamping the remaining bushings, of having their location disturbed in the slightest degree by the turning of the nuts in fastening them in place.

Fig. 17. A Precision Dividing Wheel

The bushings A, of which there were in this case 24, were first all ground exactly to the required diameters on their locating and locking surfaces. The important things in this operation are, first, that the large or locating diameter of the bushing should be exactly to size; and second, that this surface should be in exact alignment with the diameter in which the locking is done; and, finally, that the face of the bushing should be squared with the cylindrical surfaces. A refined exactness for the diameter of the locking surfaces is not so important, as the form of locking device provided allows slight variations at this point without impairment of accuracy. This dimension was kept within very close limits, however. The truth of the two cylindrical surfaces and the face of the bushing was assured by finishing all these surfaces in one operation on the grinding machine.

The sizing of the outer diameter of the bushing, which is 1.158 inch, had to be so accurate that it was not thought wise to trust to the ordinary micrometer caliper. An indexing device was, therefore, made having a calipering lever with a long end, in the ratio of 10 to 1, which actuated the plunger of a dial test indicator of the well-known type made by the Waltham Watch Tool Co. The thousandth graduations on the dial of this indicator would then read in ten-thousandths, permitting readings to be taken to one-half or one-quarter of this amount. The final measurements with this device were all taken after dipping the bushings in water of a certain temperature, long enough to give assurance that this temperature was universal in all the parts measured. It will be understood, of course, in this connection, that getting the diameter of these bushings absolutely to 1.158 inch was not so important as getting them all exactly alike, whether slightly over or slightly under this dimension; hence, the precaution taken in measurement.

Wheel B was next ground down nearly to size, great care being taken that it should run exactly concentric with the axis. As soon as the diameter of the surface x was brought nearly to the required dimension as obtained by calculation, the disks were tried in place. The first one was put in position with its loose hole central on the bolt and clamped in place under ring F. The next bushing was then pressed up against it and against the surface x of the wheel and clamped in place. The third one was similarly clamped in contact with its neighboring bushing and the wheel, and so on, until the whole circle was completed. It was then found that the last disk would not fill the remaining space. This required the grinding off of some stock from surface x and a repetition of the fitting of the bushings A until they exactly filled the space provided for them.

This operation required, of course, considerably more skill than a simple description of the job would indicate. One of the points that had to be carefully looked out for was the cleaning of all the surfaces in contact. A bit of dust or lint on one of the surfaces would throw the fitting entirely out. The temperature of the parts was another important consideration. As an evidence of the accuracy with which the work was done, it might be mentioned that it was found impossible to do this fitting on a bench on the southern or sunny side of the shop, the variations of temperature between morning and noon, and between bright sunshine and passing clouds, being such that the disks would not fit uniformly. The variation from these minute temperature changes resulted from the different coefficients of expansion of the iron wheel and the steel bushings. The obvious thing to do would be to build a room for this work kept at a constant temperature and preferably that of the body, so that the heat of the body would make no difference in the results. It was found sufficient in this case, however, to do the work on the northern side of the shop where the temperature was more nearly constant, not being affected by variations in sunshine.

Generating a Large Index Plate. — An index plate was required for cutting some large gear rings, 10, 12 and 14 feet in diameter, respectively. These gears, which were for driving vertical boring mills, had to be cut very accurately as they were to be driven by two pinions located diametrically opposite each other. Such a drive requires much greater accuracy in the gear than when there is only one driving pinion. Suppose a gear has 176 teeth and that every pitch is 0.001 inch too large over the first half of the gear, and 0.001 inch too small over the last half; this error would be so small that there would be no appreciable defect in the drive, so long as there is only one pinion; but space No. 89 would be 0.088 inch out of place, and, when there are two pinions, it would be this space which would be acted upon by the second pinion, while the first pinion engages space No. I. Now, 0.088 inch is entirely too much of an error to be neglected; in fact, such an error would condemn the whole drive, and yet, the individual error in the spaces would be so small as to make it almost impossible to avoid them. It is this possibility of errors accumulating which makes it so difficult to originate a correct dividing plate. The following method of generating a large index plate was described by A. L. DeLeeuw in the August, 1905, number of MACHINERY.

The gears to be cut were to have 150, 176 and 210 teeth, respectively, of  diametral pitch. They were to be cut on the slotter, as there was no gear cutter large enough to handle such work. The section of the gear was like that shown at A, Fig. 18, the fit being at a. A number of bolts were to secure the gear to the table of the boring mill which it was to drive. The ordinary way to cut a gear of this type was to turn it up and fit it to a spider or index plate. The bolt holes in this spider were used as jig holes to drill the holes in the rim of the gear, thus making all gears interchangeable. The spider had notches milled in its outer circumference. This was done on the gear cutter, with the result that if the gear cutter had any errors, those errors would be reproduced in the spider. As a rule, the diameter of the spider was very much larger than the diameter of the dividing worm-wheel on the gear cutter, so that the errors of the worm-wheel were not only copied, but even enlarged. All this was absolutely inadmissible on this job, so new spiders were made and provided with as many holes as the gear was to have teeth. These holes were all drilled at equal distances from the center, and very accurately spaced; and the spacing and drilling were done in such a manner that the errors could not accumulate.

diametral pitch. They were to be cut on the slotter, as there was no gear cutter large enough to handle such work. The section of the gear was like that shown at A, Fig. 18, the fit being at a. A number of bolts were to secure the gear to the table of the boring mill which it was to drive. The ordinary way to cut a gear of this type was to turn it up and fit it to a spider or index plate. The bolt holes in this spider were used as jig holes to drill the holes in the rim of the gear, thus making all gears interchangeable. The spider had notches milled in its outer circumference. This was done on the gear cutter, with the result that if the gear cutter had any errors, those errors would be reproduced in the spider. As a rule, the diameter of the spider was very much larger than the diameter of the dividing worm-wheel on the gear cutter, so that the errors of the worm-wheel were not only copied, but even enlarged. All this was absolutely inadmissible on this job, so new spiders were made and provided with as many holes as the gear was to have teeth. These holes were all drilled at equal distances from the center, and very accurately spaced; and the spacing and drilling were done in such a manner that the errors could not accumulate.

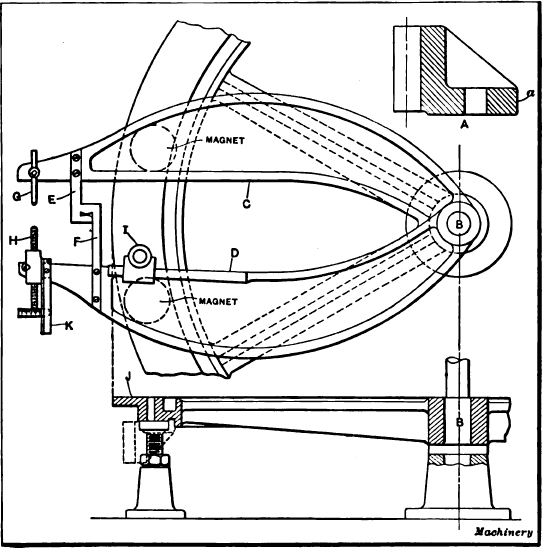

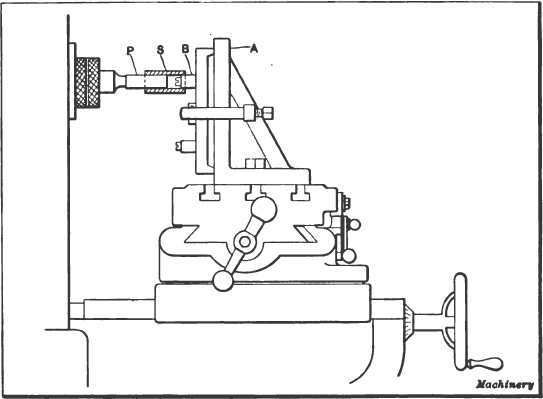

Dividing Mechanism for Generating Index Plate. — The plate or spider to be divided was first turned true and with a smooth surface J, Fig. 18, on the side to be used for dividing. The gear is shown in place by the dotted lines although it was not attached to the spider while the spacing was being done. The spider was pivoted on a stud B held in a stand. The outer rim of the spider was supported by numerous jack-screws, with brass caps, allowing the spider to slide over the jacks, but preventing it from sagging. The jack-screws were locked in position, as shown. On stud B two arms C and D were mounted as shown by the plan view. These arms are about 7 feet 8 inches long from the center of the stud to the outer end. They are cast iron, and were made as light as was consistent with the required stiffness. Both arms were free to turn around the stud B. The bearings on the stud were, of course, one above the other, but the main part of the arms were in the same plane. When in position they formed a pair of large jaws. A hardened steel hook E and another hook F were fitted to the end of each arm, and these hooks coming in contact when the arms were a certain distance apart made this distance the maximum space between them.

Fig. 18. Dividing Mechanism for Generating a Large Index Plate

The arm C is provided at its extreme end with a piece holding a hardened steel pin G rounded at its end. This piece could be swiveled so as to allow the pin to point in various directions. When once adjusted, the swiveling piece was clamped in position. The other arm D had a similar swiveling piece which was split and provided with a clamping screw. It was tapped out and held a micrometer screw H, which could be clamped by means of the split bearing and clamping screw. The end of the screw H was rounded over, and the head was made large and divided so that one division corresponded to 0.0005 inch. No attempt was made to have this screw or the divisions on the head very accurate, for, as will be seen later, great accuracy would serve no purpose. A pointer K was fastened to the swiveling piece. This pointer was simply a piece of sheet steel with beveled edge, and long enough to always be over the screw head. The piece G and the screw H were adjusted so as to be in line when against each other. In this manner, the movement of the arms relative to each other was limited in both directions; one way by the hooks E and F and the other way by the parts G and H.

Operation of Precision Dividing Mechanism. — The method of operating this spacing or dividing mechanism shown in Fig. 18 was as follows: One arm was pulled back until the hooks came in contact, when it was clamped to the spider. Then the other arm was moved up until the screw H struck the pin G; this arm was then clamped and the other released. The first arm was then pulled back again, and these operations were repeated, thus moving both arms all around the spider. The arm D was provided with a planed edge, to which a piece I was securely fastened. This piece is shown in detail at A, in Fig. 19. It consisted of a slide or jig having a bushed hole to be used later for drilling the holes. It also carried a brass block l which was carefully scraped to a bearing on the spider. To the block was screwed a glass-hard steel piece m having a beveled edge, and located about 0.001 inch above the spider. This steel piece formed a scribing edge for marking lines on the spider. A line was marked on the spider and the screw set so as to get approximately the correct division. The arms were then brought around as described, and, after the required number of spaces were made, the distance from the scratch edge to the starting line was noted. This would give some idea as to how much correction was to be made, and the correction was made by means of the micrometer screw. The whole method was one of trial, and practically the same as spacing with a pair of dividers; except that where dividers fail, this method succeeds. Any one who ever tried to space with dividers knows how impossible it is to get the same result twice. The point slips off in some minute hole of the iron, or the angle at which the dividers are held varies, or some other little thing happens, which makes the result unreliable. If one succeeds in setting the dividers so as to come back to the starting point, say, after 176 steps or divisions, this same setting will give entirely different results if the same man goes around once more.

Fig. 19. (A) Jig and Scribing Block shown at 1, Fig. 18. (B) Diagram Illustrating Preliminary Method of Dividing Index Plate

The clamping of the arms C and D, Fig. 18, is accomplished by means of electro-magnets fastened to the under side of the arms. The magnets were wound so that they would stay cool on a 220-volt circuit, when in series with a 110-volt 16-candle-power lamp. This lamp acted as pilot lamp, indicating when the current was turned on, and also indicating when something was wrong with the winding. It is obvious that holding the arms in position by means of magnets is far superior to clamping, as the latter method would easily throw them out of square. Even the magnets were liable to cause trouble. If the surface of the plate is not perfectly level, smooth, true, well supported at frequent intervals, and on a rigid foundation where it is not disturbed by vibrations of nearby machines, and if the magnets are not scraped nicely to a bearing with the plates and also to the arms, and if they are not protected so that no dirt can creep between them and the plates, and if one of several other things is not provided for, there is trouble; and the difficulty is that this trouble does not become evident until one has gone clear around the circle, and even then it may not be discovered immediately. One may find an accumulated error of  inch after going once around; after correcting for this amount, and going around once more, one may find an error in the other direction. Trial after trial may not produce any better result, and one may think that it is simply bad luck in estimating the correction to be made; whereas, in reality, it is simply the result of poor working conditions. Great care and considerable patience are necessary, but with those elements at hand, the method gives fine results.

inch after going once around; after correcting for this amount, and going around once more, one may find an error in the other direction. Trial after trial may not produce any better result, and one may think that it is simply bad luck in estimating the correction to be made; whereas, in reality, it is simply the result of poor working conditions. Great care and considerable patience are necessary, but with those elements at hand, the method gives fine results.

To start the spacing, two lines diametrically opposite each other were marked on the plate. To get these lines correct, the following method was employed: Two stations were erected approximately at opposite ends of a diameter of the plate. These stations were merely castings blocked up to the proper height, so as to bring their top surfaces level with the top of the plate. A piece of sheet brass was fastened to one of the stations, whereas the other station received an adjustable piece of sheet brass. Lines were drawn on these pieces of brass so as to be nearly in line with each other and with the center of the spider. This, of course, was merely guesswork. These lines were extended onto the plate, so that the lines appeared as shown by the diagram B, Fig. 19. The two lines on the brass are marked a and b; and the two extensions of these lines on the plate a1 and b1. The plate was now turned until b1 came exactly opposite a. Now, if the lines a1 and b1 are exactly diametrically opposite each other, then the line a1 is bound to come exactly opposite the line b. This, of course, was found not to be the case. The distance between a1 and b was carefully divided into two equal parts, and a new line a1 and b (one an extension of the other) was drawn on the brass and on the plate. Then another half turn was given to the plate, and the line a1 was brought opposite the line a, and the error (if any) noticed. This was repeated until no further error was discovered. The object of dividing the plate into two equal parts was simply to facilitate the first attempts at spacing, as an appreciable error could be discovered by going only halfway around. The lines a1 and b1 were not used, however, for the final spacing.

The approximate distance was measured from the center of the stud B, Fig. 18, to the center of the micrometer screw H. From this measurement, the circumference of the circle, described by the screw point, was computed. This was divided by, say, 176, and the quotient was the distance from the point of the hardened plug to the point of the micrometer screw. A pair of inside calipers was then used to set the screw to this distance. Then, 88 such distances were spaced, and the result noted. Suppose the scratch block was  inch from the line b1, Fig. 19; then an adjustment was made of

inch from the line b1, Fig. 19; then an adjustment was made of  part of

part of  inch, or about

inch, or about  thousandths of an inch, which corresponds to about

thousandths of an inch, which corresponds to about  divisions of the micrometer screw head. It would have been a difficult matter to estimate the amount of correction to be made, if not assisted by the micrometer screw. One must not expect to secure the correct adjustment the first time, but considering the difficulty of the job it is surprising how few trials are necessary to get perfect spacing. It never took more than one day (of ten hours) to get a perfect spacing, after everything was arranged. When the scratch block comes to the edge of the first line, after the required number of steps, the spacing is considered finished. It remains, however, to prove that this result was not obtained by some hidden defect; therefore, the spacing was checked by a second trial. If the scratch block came against the outside edge of the first line again, it was considered safe to proceed with the next operation of drilling the holes.

divisions of the micrometer screw head. It would have been a difficult matter to estimate the amount of correction to be made, if not assisted by the micrometer screw. One must not expect to secure the correct adjustment the first time, but considering the difficulty of the job it is surprising how few trials are necessary to get perfect spacing. It never took more than one day (of ten hours) to get a perfect spacing, after everything was arranged. When the scratch block comes to the edge of the first line, after the required number of steps, the spacing is considered finished. It remains, however, to prove that this result was not obtained by some hidden defect; therefore, the spacing was checked by a second trial. If the scratch block came against the outside edge of the first line again, it was considered safe to proceed with the next operation of drilling the holes.

Method of Drilling Equally-spaced Holes in Index Plate. — Before drilling the holes, the spacing arms C and D, Fig. 18, were indexed around again, and a line drawn along the scratch block (attached to jig I) at every step or division, thus marking a line for every hole to be drilled. This operation was an additional check on the accuracy of the spacing. As there were to be 210 holes in the largest spider, stepping around three times (once for the last trial, once for checking and once for marking the lines) required 630 spaces. The lines drawn were, at the most, 0.002 inch wide. A magnifying glass was used, to see if the scratch block came up against the line; so that it is safe to say the total error was less than 0.002 inch; hence, the error in the individual spaces was an exceedingly small amount.

One of the two arms was now removed from the spider, the arm with the drill jig remaining. A radial drill had previously been put in place, and the dividing arm was secured against the radial drill column. The spider was rotated under the arm by means of block and tackle, so that the consecutive lines coincided with the scratch block. A magnifying glass was used to locate the spider accurately. The hole was then drilled  inch small. The holes were to be 1-inch ultimately, so that a

inch small. The holes were to be 1-inch ultimately, so that a  inch drill was used. The drill was then replaced by a reamer 0.002 inch below size, and the reaming was done by power, the drill jig bushing being replaced by a new one corresponding in size with the reamer. After this operation was completed, the jig bushing was removed and a new one inserted, having a bore exactly 1 inch in diameter. This jig was used for reaming by hand.

inch drill was used. The drill was then replaced by a reamer 0.002 inch below size, and the reaming was done by power, the drill jig bushing being replaced by a new one corresponding in size with the reamer. After this operation was completed, the jig bushing was removed and a new one inserted, having a bore exactly 1 inch in diameter. This jig was used for reaming by hand.

One might naturally wonder why the second arm was removed and a different method used for drilling than for spacing. There were two reasons why this was done. The first one is that, when drilling by the spacing method, the spindle of the drill must follow the arms which would occupy different positions on the spider; hence, the arms and spider would have to be shifted under the drill spindle for each hole, or, in the case of a radial drill being used, the drill spindle might be aligned with the jig. This would mean very careful adjustment repeated many times. By leaving the drill spindle stationary, and one arm blocked against the column, the relative adjustment of drill spindle and the jig is preserved. The second reason is of an entirely different nature. Electro-magnets were used for the purpose of holding the arms in place, as previously mentioned. This proved to be an excellent method; in fact, it would have been absolutely impossible to hold the arms without springing, and with uniform pressure by other means; but, when drilling, chips would crowd in between the magnet and the spider, in spite of all precautions, even though the plate was cleaned after drilling a hole. These little chips would tilt the arm forward and crowd the drill. For these reasons, the magnets were not used while drilling, the clamping being done by an ordinary C-clamp. It is true that the setting of the arm was not so perfect as when done by means of the spacing method, but it was good enough for the purpose, for it must not be forgotten that it was not the object to get a gear with absolutely even pitches, but one with reasonably correct pitches, and without an accumulation of errors. This latter requirement was taken care of by the method of spacing; a good mechanic can set an edge so close to a fine line that the error is not appreciable in a gear of  diametral pitch.

diametral pitch.

Application of the Large Index Plate. — It may be of interest to know something about how the large index plate, generated as described in the foregoing, was used when cutting large gears. The gear cutting was done on a slotter, specially designed and used for cutting internal and external gears which are too large in diameter or of too great a pitch to be cut on an ordinary gear cutter. The table is very long and in the shape of a cross, thus giving a large surface for the support of the spiders, without making the table too heavy. For unusually large gears additional supports are provided, in the nature of stands placed around the machine, each on its own foundation. A T-slot runs the long way of the table and exactly in line with the center-line of the ram. A stud and bushing held in this T-slot, serve as pivot for the spiders. The lower end of the ram has a square hole to take the tools which are placed in a horizontal position. The shank of the tool is planed to a gage so that the center-line of the tool has always the same distance from the planed side of the shank. Inserting the tool in the square hole, and forcing it up by means of set-screws against one side of this hole, brings the center-line of the tool in line with the center-line of the machine, and thus with the center-line of the gear to be cut. The gear blank is fed toward the tool until within one or two hundredths of an inch of the required depth, when the power feed is thrown out, and the blank is further fed by hand. A stop prevents the operator from making a mistake as to depth. In addition, several other precautions are taken. The pitch line and the bottom line of the teeth are marked on the blank by means of a scratch gage. In case the teeth are blocked out in the casting (for the purpose of securing a better casting, at least around the teeth) the operator first goes once around, outlining the tooth shape on the blank, to make sure that there is sufficient stock for every tooth. . In order to do this outlining he brings the tool down to within  inch from the blank, and marks around it with a scratch awl. A screw is used to move the blank when it is unusually heavy, otherwise the spacing is done by hand. For indexing the gear the holes in the index plate were engaged by a pin located under the spider and held by a suitable bracket. The pin was withdrawn by means of a lever.

inch from the blank, and marks around it with a scratch awl. A screw is used to move the blank when it is unusually heavy, otherwise the spacing is done by hand. For indexing the gear the holes in the index plate were engaged by a pin located under the spider and held by a suitable bracket. The pin was withdrawn by means of a lever.

The gears proved to be accurately spaced, and the two driving pinions showed a perfect bearing on the gear teeth. Though the side clearance in the teeth was only 0.01 inch, such a thing as a bearing on the back of a tooth never occurred.

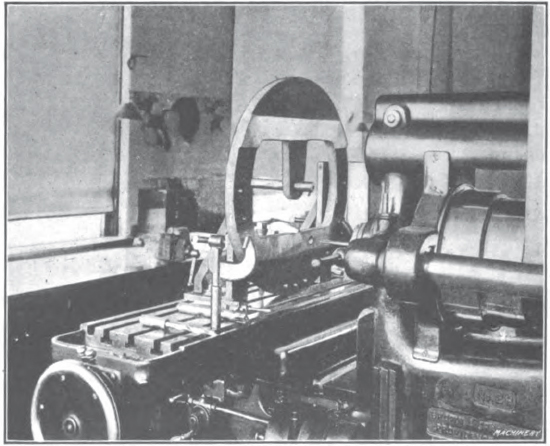

Locating Work for Boring on Milling Machine. — It is often desirable to perform boring operations on the milling machine, particularly in connection with jig work. Large jigs, which because of their size or shape could not be conveniently handled in the lathe, and also a variety of smaller work, can often be bored to advantage on the milling machine. When such a machine is in good condition, the necessary adjustments of the work in both vertical and horizontal planes can be made with considerable accuracy by the direct use of the graduated feed-screw dials. It is good practice, however, when making adjustments in this way, to check the accuracy of the setting by measuring the center distances between the holes directly. For the purpose of obtaining fine adjustments when boring on the milling machine, the Brown & Sharpe Mfg. Co. makes special scales and verniers that are attached to milling machines, so that the table may be set by direct measurement. By attaching a scale and vernier to the table and saddle, respectively, and a second scale to the column with a vernier on the knee, both longitudinal and vertical measurements can be made quickly and accurately, and the chance of error resulting from inaccuracy of the screw, or from lost motion between the screw and nut, is eliminated.

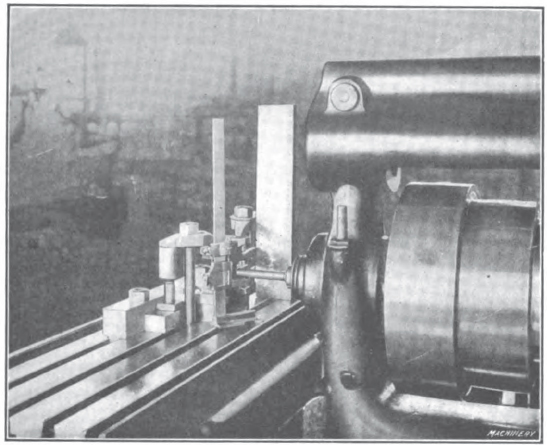

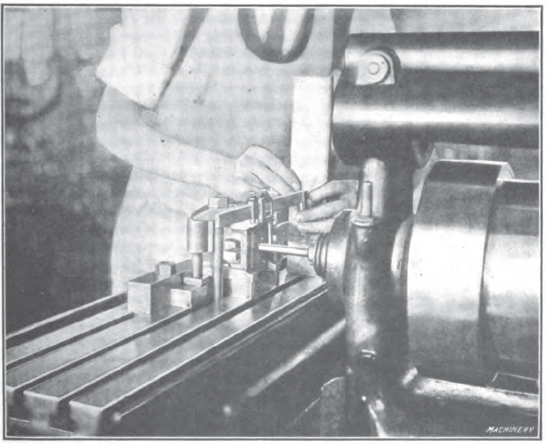

Checking Location of Holes by Micrometer-and-plug Method. — One method of checking the accuracy of the location of holes bored in the milling machine, is to insert closely fitting ground plugs into the bored holes and then determine the center-to-center distance by taking a direct measurement across the plugs with a micrometer or vernier caliper. For example, if holes were to be bored in a jig-plate, as shown in Fig. 1, assuming that hole A were finished first, the platen would then be moved two inches, as shown by the feed dial; hole B would then be bored slightly under size. Plugs should then be accurately fitted to these holes, having projecting ends, preferably of the same size. By measuring from one of these plugs to the other with a vernier or micrometer caliper, the center distance between them can be accurately determined, allowance being made, of course, for the radii of each plug. If this distance is incorrect, the work can be adjusted before finishing B to size, by using the feed-screw dial. After hole B is finished, the knee could be dropped 1.5 inch, as shown by the vertical feed dial, and hole C bored slightly under size; then by the use of plugs, as before, the location of this hole could be tested by measuring center distances between C—B and C—A.

An example of work requiring the micrometer-and-plug test is shown set up in the milling machine in Fig. 20. The large circular plate shown has a central hole and it was necessary to bore the outer holes in correct relation with the center hole within a limit of 0.0005 inch. The center hole was first bored and reamed to size; then an accurately fitting plug was inserted and the distances to all the other holes were checked by measuring from this plug. This method of testing with the plugs is intended to prevent errors which might occur because of wear in the feed-screws or nuts, that would cause the graduated dials to give an incorrect reading. On some jig work, sufficient accuracy could be obtained by using the feed-screw dials alone, that is, without testing with the plugs, in which case the accuracy would naturally depend largely on the condition of the machine.

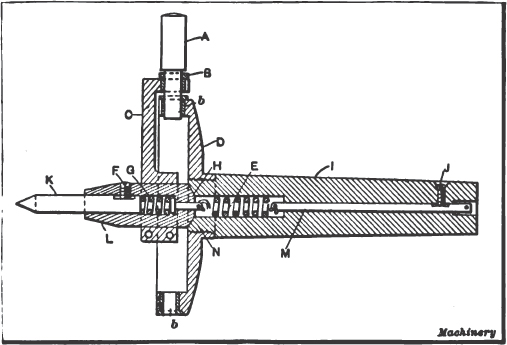

Combination Boring Tool and Test Plug. — A method that is a modification of the one in which plugs are used to test the center distance is as follows: All the holes are first drilled with suitable allowance for boring, the location being obtained directly by the feed-screw dials. A special boring-tool, the end of which is ground true with the shank, is then inserted in the spindle and the first hole, as at A in Fig. 1, is finished, after which the platen is adjusted for hole B by using the dial as before. A close-fitting plug is then inserted in hole A and the accuracy of the setting is obtained by measuring the distance between this plug and the end of the boring-tool, which is a combination tool and test plug. In a similar manner, the tool is moved from one position to another, and, as all the holes have been previously drilled, all are bored without removing the tool from the spindle.

Fig. 20. Example of Precision Boring on Milling Machine