10

Process Excellence

Simplify Work and Minimize Bureaucracy

Process excellence advances a Fit for Growth transformation by optimizing processes to achieve sustainable efficiency and effectiveness while supporting differentiating capabilities. It takes a market-back view to identify the real sources of customer value in a product or service, determines which processes create that value, and simplifies or eliminates other processes. Process excellence improvements often leverage tools such as Lean, Six Sigma, and others, but the approach differs from these familiar continuous-improvement methods in important ways. Traditional methods work within existing structures to foster incremental, evolutionary improvement from the bottom up, independent of what the rest of the business may be doing. By contrast, process excellence applies a market-driven perspective to create a blueprint of the four macro business processes found in every company—innovation, sales and marketing, delivery, and support—and how they interact to deliver the targeted customer-value proposition (see Figure 10.1 ).

Then it takes a “fit for purpose” approach to select the right mix of techniques, and optimize and re-base the remaining sub-processes. This unique approach to simplifying entire parts of the business and core operations often releases sufficient cash savings to help self-fund the creation of new capabilities.

What Is Process Excellence?

Process excellence is an approach to optimizing how a company brings goods or services to market. It employs a range of tools and techniques to make processes more coherent, aligning them with the company's strategy so that they work together to consistently produce desired outcomes. The goal is not simply to reduce costs, but instead to reshape processes to fulfill customer needs at cost and service levels that meet organizational objectives. By doing that, it offers a solution to one of the most vexing concerns for today's corporate leaders: how to do more for the customer, for less. Respondents to the PwC 2015 Global Operations Survey reaffirmed that understanding customer value, having the flexibility to change direction, and managing complexity and costs are the top challenges companies face (see Figure 10.2 ). Process excellence enables leading firms to achieve these multiple objectives.

Change initiatives seeking the optimal balance of cost and customer value usually need to untangle a web of complex processes spanning multiple cost centers and departments. Most companies lack a clear understanding of their customers' true expectations, making it harder to focus, scope, and be more aggressive on process improvement efforts. Executives often start with the obvious: applying improvement tools to known process problems, or standardizing to a single model. But moving too quickly, while satisfying at first, often saps energy and creates distractions from core improvement opportunities. In addition, traditional process improvement methods often compete with—or are not coherent with—other on-going improvement initiatives such as digitization, outsourcing, and footprint optimization. Process excellence, by contrast, aligns with these transformation efforts and generates greater benefits and flexibility.

Process excellence advances transformation goals in four distinct ways: reducing process costs; improving quality; boosting revenue, either by creating new capabilities within existing cost structures, or improving products or the customer experience; and strengthening the balance sheet by reducing the capital levels required to run the business.

Reducing costs : Process improvements save money by reducing the labor and materials required for each step in a process. Typically this involves improving the efficiency of labor and assets by reducing the activity in a process, or by finding new sources of materials and labor (as described in Chapters 8 , “Outsourcing,” and 12 , “Strategic Supply Management”). Taking a market-back, macro-process view allows companies to re-base costs more quickly by leveraging multiple improvement levers (including simplification, automation, predictability, and quality improvements) across more cost areas.

Improving quality : Quality improves as a company eliminates process flaws and unnecessary complexity that may result in subpar products or services, or require costly manual workarounds that invariably fail to meet rising customer expectations and the demands of a growing business. Interestingly, the highest-quality processes often have the lowest costs.

Boosting revenue : Process excellence efforts free up time and resources that enable companies to invest in the products and features that customers value. Defining that sweet spot requires a fact-based, customer-back analysis, using one or a combination of many tools and methods available, to understand what customers truly value.

Strengthening the balance sheet : As processes become more efficient, working-capital needs decline for accounts receivable, accounts payable, and inventory, freeing up funds to pay for future phases of the transformation. Improvements in supply chain design, procurement processes, and manufacturing flow drive these savings. At the same time, optimized processes can reduce capital spending budgets by enabling a company to produce more without adding capacity, while generating resources for investment in additional improvements.

Process excellence operates at two levels—fostering better interplay among macro processes, while improving the key individual business processes within each category that support differentiating capabilities. The goal is to improve and align all processes to deliver broader benefits for the enterprise, by envisioning a master blueprint that shows how the four macro processes work in concert toward future-state objectives of the transformation. In contrast, typical process improvement techniques target discrete steps in individual processes or sub-processes, often in isolation.

When to Use Process Excellence

Companies may turn to process excellence when they need a step change in process efficiency that they cannot achieve with traditional continuous-improvement tools. But how can you tell if your company needs such sweeping change? In our experience, process excellence delivers superior results in five common scenarios:

- When quality and customer satisfaction are not competitive. The ultimate outputs of efficient processes are higher-value interactions with customers, happier employees who aren't burdened by wasteful activities, and confidence in delivering value every day.

- When processes are overly complex. Process excellence rationalizes and simplifies multiple complex processes comprising numerous functions, many business units, and large numbers of people.

- When data pose a challenge. Process excellence identifies the data required for each process, and addresses the challenges of delivering that information when and where it's needed.

- When significant technology initiatives don't deliver the expected value in business operations. Process excellence is a precursor to digitization and the use of tools like robotic process automation; often, companies turn to technology before prioritizing, rationalizing, and improving processes.

- When permanent, radical change is needed. By fundamentally transforming processes, process excellence drives strategic change that lasts for years.

A Guide to Process Excellence

As you try to get your arms around a process excellence initiative, it helps to remember that virtually every company conducts business through four macro processes: innovation processes that create new products or services; delivery processes that make and deliver products or services; sales and marketing processes that drive revenue and margin growth; and support processes that enable a company to manage itself and deliver basic administrative support to its employees. Each macro process encompasses certain core business processes that support your differentiating capabilities, and each category requires a different set of techniques and tools to improve processes. Optimizing these core processes generates the greatest value in a process excellence initiative, so focus your efforts there.

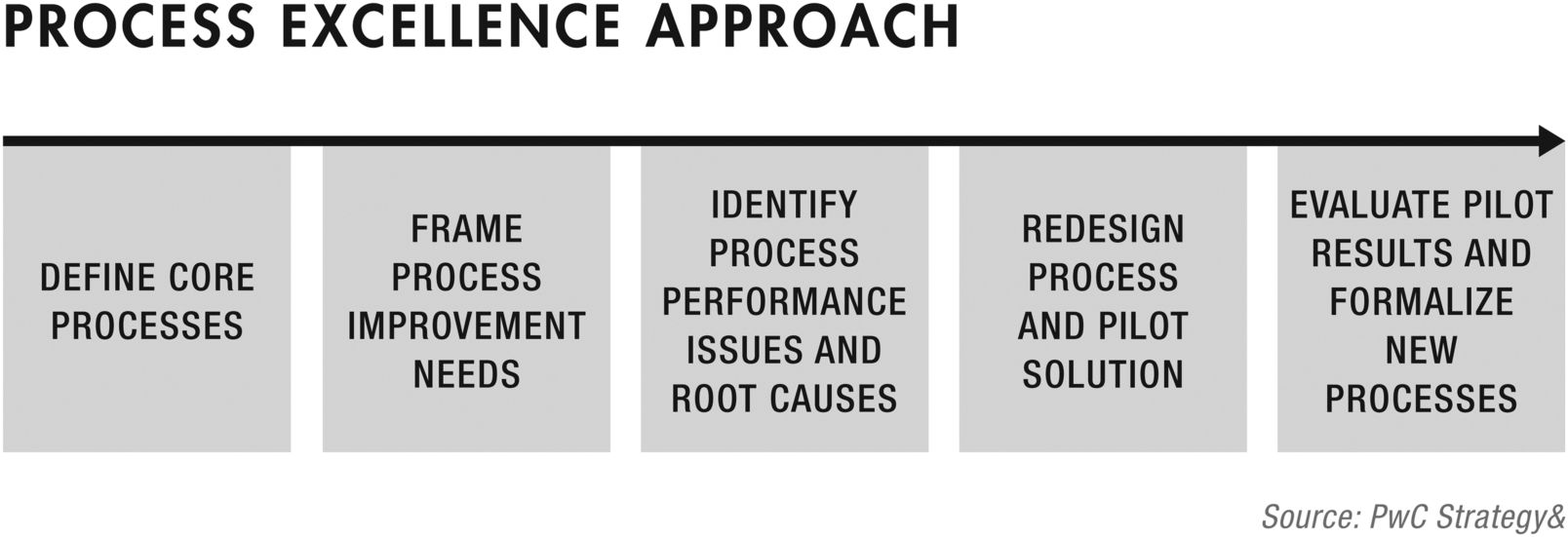

Building best-in-class processes involves five key steps. Start by defining your core processes, then use a customer-back analysis to identify your challenges. Gather the data you need to fully understand the current performance and the root causes of performance gaps. Use this information to develop and pilot a solution. Last, evaluate results of the pilot against your expectations and then formalize your new processes (see Figure 10.3 ).

Step 1: Define Core Processes

Every process excellence initiative starts with identifying your macro processes and how they interact. You start by defining Level 1 and Level 2 processes that are essential to your business and your differentiating capabilities. During this task you need to identify your differentiated processes and key supporting processes, then create a blueprint to ensure a coherent approach across the value chain.

Step 2: Frame Process Improvement Needs

Your next task is to determine how well a process meets important expectations of internal or external customers. Use four primary investigative tools to pinpoint these improvement opportunities and frame the issues you need to tackle:

- Cross-industry research that reveals best practices for each process;

- An assessment of broader market trends and how they affect your processes;

- A comparison of your current service levels with customer expectations and the service levels provided by competitors; and

- Customer interviews, surveys, user groups, and statistical testing that will provide deeper insight into how customers perceive your products or services, what they value, and what they can do without.

Tools such as conjoint analysis, critical-to-quality driver trees, and design for Six Sigma can help pinpoint what customers truly value and identify improvement opportunities.

After identifying improvement needs, describe them explicitly and develop a theme for your improvement initiative. Specify what you aim to accomplish, how it will create value, and how you will measure results.

Step 3: Identify Process Performance Issues and Root Causes

To fix the flaws you've identified, you'll need a deeper understanding of the processes in question. Gather Level 3 process data, including process-step activity times, the number of workers per step, the volume and variability of demand for the process, and the labor and material cost for each step. Calculate process step capacity, overall process flow rate, labor and material content, and idle time. Identify over- or under-utilized resources by computing an implied utilization rate for each process step.

Identify all sources of waste in your processes. Waste takes many forms, such as overproduction, idle time, overprocessing, excess inventory, reworking of flawed products, and unnecessary movements on the production line. Work with the line management and staff to identify and eliminate root causes of waste. A number of analytical tools are available to baseline the current performance levels and identify root causes of waste (see “Analytical Tools for Process Excellence”).

As your analysis progresses from the customer through the enterprise, opportunities to create additional value will become readily apparent. Based on this analysis, create a blueprint outlining the overall impact of process change across your organization. Developing the blueprint at the outset will enable you to quantify the benefits of process excellence and sequence the initiative to ensure that early stages generate enough value to self-fund later phases.

Step 4: Redesign Process and Pilot Solution

Launch initiatives to transform processes, relying on your analysis to determine which parts of each process to eliminate, consolidate, or automate. Use tools such as Lean to redesign processes, working with cross-functional teams of employees directly involved in each process under evaluation. Address the key factors that drive process efficiency, including the following:

- Determining the economic order quantity for each process—the optimal number of units that can be processed at one time to achieve the best trade-off between batching (which slows the process down) and inventory (which increases process costs).

- Establishing service-level requirements that will deliver the performance customers expect, and zero-basing all other activities that are not essential to delivering these outcomes.

- Smoothing production rates across each process by balancing work among various functions and process steps. Alternatively, explore pooling options to balance out the work.

- Realigning the organization structure of the process to match the throughput needed from each process step.

- Reducing variability of demand for process inputs, process steps, or the overall process. In cases where demand consistently exceeds supply, add capacity by replicating an efficient line, selectively adding workers, specializing tasks, or increasing automation.

As you plan your solution, consider all technology options for process improvement. For example, “smart factory” systems that track the location of labor and materials in real time enable manufacturers to smooth out production and maintain performance levels by anticipating production bottlenecks and reallocating resources accordingly. One manufacturer testing this technology already has seen significant benefits at the pilot plant: labor productivity up 20 percent; on-time deliveries up 15 percent; scrap and rework down 3 percent as a percentage of cost of goods sold (COGS); and total COGS spending down 10 percent.

As you standardize and simplify processes, make sure you balance the efficiency benefits of process standardization with the strategic value of customization. Building dedicated front-to-back business processes to accommodate every country, customer, and channel-specific requirement is most likely uneconomical. The trick is to “smart customize.” This involves segmenting customer-facing processes from back-office processes. Back-office processes that cut across businesses, countries, and customer segments should be ruthlessly standardized with tailoring reserved for “must-have” regulatory and legal requirements. For customer-facing processes, the key is to identify the threshold value of business size or customer size, below which the cost of process customization far outweighs the revenue benefits achieved from providing a tailored process or service to the business or the customer. Once this threshold value has been determined, it is best to limit (or better still incentivize) the process-customization choices offered to businesses and customers that fall below this threshold value to preserve scale economies.

Step 5: Evaluate Pilot Results and Formalize the New Processes

Use the pilot to test your hypotheses and business case for process improvements. Ask yourself if the pilot yielded benefits in line with expectations across your overall blueprint for the core business processes. Make adjustments, and then accelerate implementation of process excellence initiatives in a series of waves to create value coherently throughout the enterprise.

Aligning Process Excellence with Other Cost Levers

Process excellence creates the greatest value when aligned coherently with other cost levers. For example, levers such as footprint optimization and digitization are closely tied to process excellence and should be sequenced appropriately.

Effective alignment raises important questions, including: Which processes can I combine into shared services? Should I transform a process first and then move it to a different location, or move it first? When should I digitize processes? How does process transformation change my talent needs? To answer these questions, you'll need a detailed understanding of the processes and challenges, as outlined in Step 3, and an overall view of how your processes align, as discussed in Step 1.

Start by establishing an improved target process and aligning it coherently with the other core processes. Then deploy other cost levers to drive significant additional value. Digitization should follow the initial waves of process excellence; large-scale implementation of foundational data and systems should wait until process excellence initiatives are well underway. Making process excellence tools and skills available across your organization will enable you to move and consolidate processes before they are fully optimized, and ensure that process optimization doesn't end when the initial transformation effort is over.

- Win commitment to enterprise-level process change from senior executives. The core process excellence initiatives affect the entire enterprise; therefore, they require formal buy-in and commitment from most senior executives.

- Put value capture first. Successful initiatives simplify challenges and isolate waste by segmenting processes across many dimensions. The most important segmentation is between activities that create value the customer is willing to pay for, activities that don't create value for customers but are necessary to operate a business, and activities that add no value at all.

- Self-fund. Sequence process excellence initiatives to generate savings early in the transformations—even those requiring structural changes. These initial savings can be used to fund later stages of the program. Making a program self-funding will focus the team on high-value areas and generate the scale and confidence to pursue the overall program.

- Eliminate steps. Elimination is often the best form of optimization. It creates dual synergies. First, it eliminates process steps that don't add value, driving savings and simplicity. Second, it raises customer and employee satisfaction.

- Get and trust the data. Tools such as Lean often give executives their first look at detailed data that reveals process issues. Unlike anecdotal information that often obscures the real issues, these insights enable executives to make strategic decisions that will create value.

- Keep the target blueprint in mind. Companies drive large-scale value only when they look beyond individual process initiatives to spur change across the organization.

- Take advantage of technology. Automation has become an essential element of process optimization, reducing labor costs and eliminating human error that saps efficiency. Today's digital technologies can be implemented in concert with Lean process improvements, without a costly and time-consuming reconfiguration of underlying enterprise resource planning (ERP) systems. This combined “Lean and digitization” approach is a catalyst that scales up process excellence initiatives faster and accelerates improvement across a wide range of processes.

- Create a “living will” for the project team. Plan for the eventual dissolution of the dedicated team formed to support a process excellence project, and make sure they transfer their skills to line workers and managers who must carry forward the process improvements.

-

Enlist employees to drive process improvements.

Improve your employees' capabilities to identify process issues and improve them. Some tactics include:

- Create leading and lagging indicators to shed light on process performance.

- Meet with teams daily to assess performance, drive accountability, and foster teamwork.

- Coach teams on problem-solving techniques, including regular desk-side sessions to improve capabilities and increase motivation.

- Establish one “best way” of working to reduce variation in performance. Sustain the best way through regular process-checking procedures.

- Motivate staff by recognizing and reinforcing the behaviors that improve performance.

- Allowing opt-outs. Unless there are significant timing issues, all four major processes must undergo the analysis phase of process excellence.

- Ignoring the 80/20 rule. Not every process needs the full suite of Lean or Six Sigma tools. Blindly applying every available methodology consumes time and money without delivering more value than a smaller set of tools would produce in less time.

- Overlooking variability and predictability. Failing to reduce or eliminate variability at every stage of a process—from inputs to outcomes—squanders opportunities to drive efficiency, reduce delays, and save money.

- Leaving it to the line. Line managers have enough on their plates without taking responsibility for a companywide process excellence effort. Form a specialized team to spearhead the initiative.

- Boiling the ocean. Improving all your processes a little bit will yield less value than improving your most important processes a lot. Focus on the core processes that drive your differentiating capabilities and look to eliminate the others.