DELTA ANCHORS – SIZES AND SHAPES

DELTA ANCHORS – SIZES AND SHAPES1Boat Equipment

DELTA ANCHORS – SIZES AND SHAPES

DELTA ANCHORS – SIZES AND SHAPES

The advantages of the Delta anchor include excellent holding power, no moving parts, and the ability to self-stow and self-launch on and off a steamhead roller. The two bends in the shank are the secret of its self-stowing ability. Dimensions are shown below for metric units and overleaf for imperial units.

Delta anchors: dimensions and weights (metric units)

Delta anchors: dimensions and weights (Imperial units)

DANFORTH ANCHORS – PROPORTIONS AND SIZES

DANFORTH ANCHORS – PROPORTIONS AND SIZES

These figures are based on the standard Danforth anchor which has been developed and tested extensively. Wide variations from these proportions should be treated with caution.

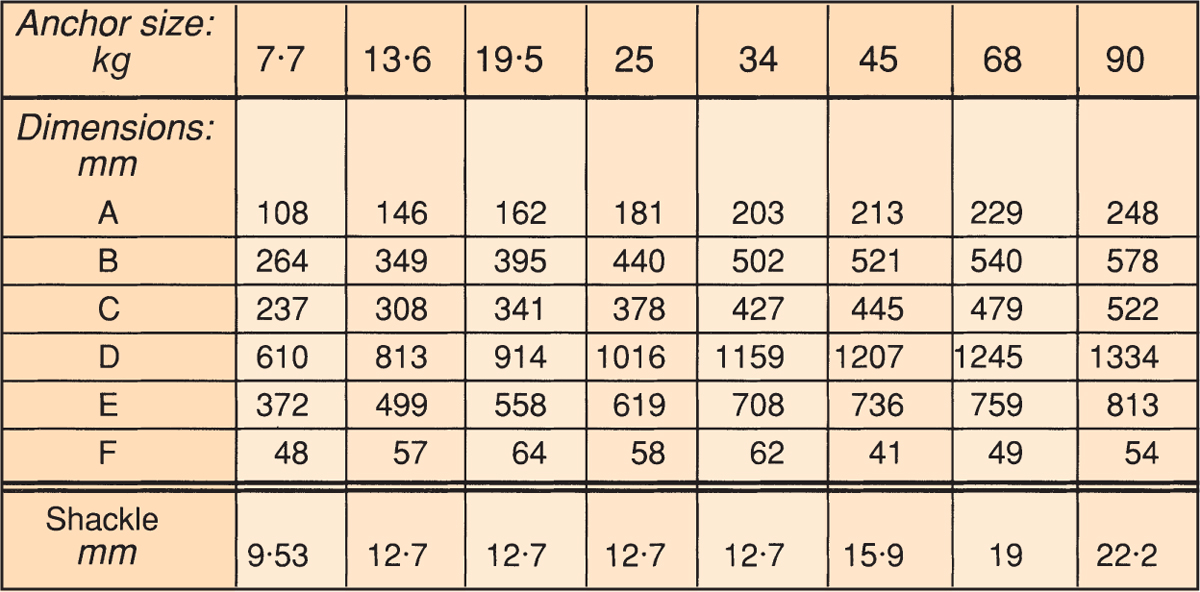

Danforth anchors: dimensions and weights (metric units)

Danforth anchors: dimensions and weights (Imperial units)

CQR ANCHORS – SIZES AND SHAPES

CQR ANCHORS – SIZES AND SHAPES

A CQR anchor is sometimes left hanging over a bow roller when a vessel goes to sea. It is important that there are at least three strong lashings on it: two on the shank and one to prevent the plough end from moving in severe conditions. These lashings are usually needed even if the anchor chain has been hauled in very tight by the anchor windlass. It may be necessary to fit a pad between the sharp point of the plough and the hull, or have stainless steel plates on the stemhead to deal with wear caused by the anchor when stowed on the stemhead roller.

CQR anchors: dimensions in millimetres

CQR anchors: dimensions in inches

FISHERMAN ANCHORS – PROPORTIONS AND SIZES

FISHERMAN ANCHORS – PROPORTIONS AND SIZES

A folding Fisherman anchor has the virtue of being effective in all types of holding ground. Where the seabed is covered with layers of kelp it is one of the few types of anchor that may penetrate the weed and obtain a firm grip on the bottom. In practice, anchoring in kelp is always risky.

This graph shows the proportions which have in practice been found to give an effective anchor. It is important that the palms are sharp and there must be good fillets where the shank meets the arms to ensure adequate strength.

ANCHOR ROPES AND MOORING WARPS – SIZES

ANCHOR ROPES AND MOORING WARPS – SIZES

•Anchor ropes – polyamide (nylon) or polyester (Terylene/Dacron).

•Polyamide is best as it stretches a lot and absorbs shocks.

•Never use a floating rope (such as polypropylene) on an anchor.

•Warps should all be of the same material or polypropylene (Courlene etc).

•All ropes and chains are detailed by diameter.

•Protect against chafing at the bow fairlead.

•A short length of plastic tube over a warp protects it at the bow fairlead. Light lines are needed, tied through holes at each end of the tube and close by onto the warp. These lines secure the tube and prevent it sliding along the warp. Rag wrapped round a warp can be used in an emergency.

See also here.

*See here for the formula which gives Thames tonnage

ANCHOR SIZES RELATIVE TO BOAT LENGTH AND TYPE

ANCHOR SIZES RELATIVE TO BOAT LENGTH AND TYPE

•Recommended sizes of ‘patent’ anchors such as Delta, Danforth, Bruce, CQR, Plough etc. For Fisherman types increase the weight by 20 per cent.

•Tested anchors are recommended.

•A light kedging anchor is likely to prove inadequate for inshore racing if the yacht has to anchor in severe weather in an unprotected anchorage.

•On long-range cruises, a yacht may have to ride out a hurricane – in these conditions a modest increase in weight and size of anchor may save the boat.

Anchor sizes: dimensions and weights (metric units)

Anchor sizes: dimensions and weights (Imperial units)

SHEET WINCHES – POWER RATIO

SHEET WINCHES – POWER RATIO

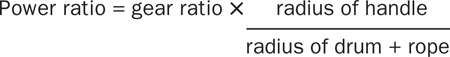

There is a good deal of controversy about the correct size of sheet winch to fit on a boat. This is because crew strengths vary, different yachts are used for different purposes, and some are much harder driven than others. Dominating all is the high cost of powerful winches, which is the reason why so many standard boats are marketed with winches of inadequate power.

The graph shows upper and lower limits for winches to suit the sail area of the largest genoa to be set, which should be taken as the basis. If the crew is weak or if the boat is to be raced hard in all weathers, go for the larger size of winch. If in doubt use the right-hand side of the graph curve. For multihulls increase the power ratio by 20 per cent.

WINCH SIZES

WINCH SIZES

See data here. Winches are catalogued by their size number. This number is an indication of the winch’s power or mechanical advantage. Thus a size 42 winch gives a power ratio of about 42:1. This ratio will be obtained when the winch is being used in its highest gearing.

The table of winch sizes overleaf is based on the standard sail plan dimensions, namely:

I1 = Distance from the deck to the top of the foretriangle, that is the point where the forestay meets the fore side of the mast.

I2 = Distance from deck to top of inner forestay, where it meets the fore side of the mast. This is roughly at the staysail halyard block.

J1 = The distance from the front of the mast at deck level to the bottom of the outer forestay.

J2 = The distance from the front of the mast at deck level to the bottom of the inner forestay.

P = Length of mainsail luff.

E = Length of mainsail foot.

In each case two figures are given for the Max (maximum) sail area, or Max ‘I’, or Max ‘P’ etc. The upper figure of each pair here is in sq ft, or ft; the lower one is sq m or m.

The winch sizes given in the tables here should be taken as the minimum because:

•Winches wear and become less efficient in time.

•Anyone who is tired, seasick, working in an awkward position or inexperienced needs an extra-powerful winch, and therefore one larger than the basic minimum.

•In severe conditions the efficiency of the crew is decreased at a time when the winch power may be of particular importance.

•Whereas many craft have been under-equipped with winches, few have been over-equipped.

•Some winchmakers give their products numbers which do not exactly correspond to the winch power.

Winch sizes

This table is based on information supplied courtesy of Peter Fairley, formerly of Harken UK Ltd.

CLEAT SIZES

CLEAT SIZES

The majority of cleats on standard and production boats are too small, especially for use in severe conditions. Broken and loose cleats are commonly found during surveys, which confirms that cleats on a wide range of craft should be larger. These graphs show cleat sizes for different types of craft and different purposes. In general, halyard cleats should be the same size as sheet cleats.

TOOLS FOR SMALL CRAFT

TOOLS FOR SMALL CRAFT

The selection of hand tools carried on board is at least partly a matter of personal preference and experience. The available space for stowage and working will also affect the size of the list.

Racing boats are usually skinned out and carry only the minimum equipment to deal with emergencies. At the other end of the scale, boats which have to be entirely self-reliant will carry all the tools listed here up to List E, even when the craft’s overall length is 12 m (40 ft) overall.

These lists are based on the need to deal with emergencies afloat, including damage control and repair. They are also worked out on the principle that some maintenance will be done afloat, and on larger craft alterations will be carried out on board without extensive shore facilities. The dividing line between these requirements will be a matter of owners’ preference.

Only the best tools are adequate for work afloat and even the best lack proper corrosion resistance. It seldom pays to buy second best even on the principle that annual replacement of tools is part of the ship’s maintenance schedule. When tools are wanted afloat they are needed badly and breakages are intolerable.

Chisels, screwdrivers, saws etc should have hard plastic handles. Full corrosion protection should be carried out including the use of oil-impregnated tool-kit lining papers, the use of lanolin etc on blades and edges.

These lists are cumulative. For example, list C consists of all tools in list C plus those in lists A and B.

LIST ‘A’ IS FOR BOATS UP TO 6 M (2O FT) OVERALL

Knife, with marline spike or multi-purpose blades

Medium-large screwdriver (size 330 mm (13 in) overall length) or multi-type screwdriver with several blades.

Mini-mole grip or pliers

Oil can

If the vessel has an engine – set of engine tools

LIST ‘B’ IS FOR BOATS UP TO 9 M (3O FT) OVERALL

Wire cutters for largest size of rigging (only required if the vessel is a sailing yacht)

Junior hacksaw and four spare blades

Surform

Hand drill

Set of about eight twist drills (from 2 mm to 6 mm ( in to ¼ in))

in to ¼ in))

Counter-sink for steel (12 mm (½ in) size), with shank to fit hand drill. This tool can be used for wood or soft metals in emergencies.

Pair of pliers, single joint side-cutting type (180 mm (7 in) length)

Small screwdriver set (handle and various accessories)

Metre rule (folding type which shows millimetres and inches)

Adjustable spanner to open up to 40 mm (1½ in) or big enough for stern gland etc

Engine and generators’ spares including pump impeller and belts

Spare oil and fuel filters, spare sump oil

Sail repair kit including needles, threads, palm and beeswax

An assortment of bolts and screws

Epoxy glue pack

LIST ‘C’ IS FOR BOATS UP TO 12 M (4O FT) OVERALL

Portable or table vice

Engineer’s ball pein hammer (0·75 kg (1½ Ib) size)

Ratchet brace with assorted drill bits (8 mm to 30 mm (⅜ in to 1½ in))

Two screwdriver bits (6 mm and 9 mm (¼ in and ⅜ in))

Centre punch

Chisel (12 mm (½ in))

Mole grip

Full-size hacksaw, of the type which will take any size of blade

Packet of assorted fine, medium and coarse hacksaw blades

Special wood-cutting hacksaw blade

Bilge pump, fresh water pump, toilet spares

Spare starter motor, alternator, brushes

Under-water epoxy and some fibreglass cloth

Rigging spares such as Sta-Lok terminals

Hose clamps, spare tubing, and alloy and stainless steel sheet

Laptop and phone charging and battery recharging units

General electrical spares, cable, end clips, crimps etc

LIST ‘D’ IS FOR BOATS UP TO 15 M (5O FT) OVERALL

Hand saw (500 mm (20 in))

Full set of counter-sinks for ratchet brace

Swedish file (medium cut on one side, smooth on the other)

Rat-tail file

Round (cylindrical) surform

Large screwdriver

Square (250 mm (10 in))

Pinch bar or wrecking bar

Plane (50 mm (2 in) cutter width)

Electric drill to work off ship’s power, shore power or the cordless type precharged ashore. To take up to 10 mm (⅜ in) drills

Set of twist drills from 6 mm to 10 mm (¼ in to ⅜ in)

Carborundum stone – double-sided, coarse and fine

Chisels, 6 mm (¼ in) and 19 mm (¾ in)

Mole grip with bench cramp on handle

Two small cramps

Expanding bit (size 12 mm to 35 mm (½ in to 1½ in))

Adjustable spanner to fit largest nut on board

Cold chisel (10 mm (⅜ in))

Stubby screwdriver

Wood scraper(s)

Full packets of fine, medium and coarse hacksaw blades

Spares for cooker, autohelm, fridge, water-maker etc

Sheet material of rubber, gasket, plastics etc

LIST ‘E’ IS FOR BOATS UP TO 18 M (6O FT) OVERALL

Pad saw

Tenon saw

Adjustable spokeshave

Mallet

‘Soft’ hammer with a selection of faces or tips

Large hammer, eg 2 kg (5 Ib)

Small hammer, eg 0.2 kg (½ lb)

Full set of files

Set of bradawls

Set of gouges up to 20 mm (¾ in)

Set of cold chisels from 6 mm to 25 mm (¼ in to 1 in)

Set of socket spanners and/or ring spanners, and/or open-ended spanners

Set of Allen keys

Spanner to fit keel bolt nuts where applicable

Chain-type pipe wrench

Nail punch 1½ mm ( in)

in)

Inside/outside calipers

Two large clamps (jaw opening at least 250 mm (10 in))

Mechanic’s vice with swivel base – 90 mm (3½ in) jaw width

Woodworker’s vice

Soldering iron (electric to work off ship’s supply, or traditional type heated by an external source)

Blow-lamp (to use the same fuel as other items on board, eg Calor or paraffin)

Adaptor to turn electric drill into a reciprocating saw

Bench pedestal to turn electric drill into grinder etc

Set of tools for electric drill including wire brushes, grinding points, buffs etc

Adjustable cutters or set of hole cutters

Magnet with lanyard

Breast drill with chuck opening to 16 mm (⅝ in)

Metal drills up to 16 mm (⅝ in)

Set of wood drills up to 16 mm (⅝ in), which have shanks to fit 8 mm (⅜ in) electric drill

Paint brushes, two each size: 12 mm, 25 mm, 35 mm and 50 mm (½ in, 1 in, 1½ in and 2 in)

Bevel gauge

Spirit level – at least 300 mm (12 in) and plumb gauge

Tap wrench and set of taps, 4 mm to 16 mm ( in to ⅝ in)

in to ⅝ in)

Stocks and dies, 4 mm to 16 mm ( in to ⅝ in)

in to ⅝ in)

SAFETY EQUIPMENT – CRAFT UNDER 5.5 M (18 FT) LOA

SAFETY EQUIPMENT – CRAFT UNDER 5.5 M (18 FT) LOA

All the above items are on the British MCA list.

Experience suggests the items here are almost as important.

SAFETY EQUIPMENT – CRAFT BETWEEN 5.5 M (18 FT) AND 13.7 M (45 FT) LOA

SAFETY EQUIPMENT – CRAFT BETWEEN 5.5 M (18 FT) AND 13.7 M (45 FT) LOA

LIGHTS AND SHAPES

LIGHTS AND SHAPES

Masthead

These show from 22.5 degrees aft of the beam on the port side right round forward to 22.5 degrees aft of the beam on the starboard side, making a total arc of 225 degrees showing forward and onto the beam.

Side

These are green on the starboard side and red on the port side and shine from dead ahead to 22.5 degrees aft of the beam making the arc for each light 112.5 degrees.

Stern

This is a white light placed at or near the aft end of the vessel and showing over an arc from 67.5 degrees on the port side round aft to 67.5 degrees on the starboard side, making a total arc facing aft of 135 degrees.

Towing

This is yellow and shows over the same arc as the stern light.

All-round

This shows a light to a total arc of 360 degrees.

Arc restrictions

Sometimes lights have to be mounted so they are partly obscured by adjacent spars, instruments and so on. For instance, ‘not under command’ lights are mounted well below masthead height, so the mast must obscure part of the arc of the lights. It is required that the arc which is obscured is 6 degrees or less and this often means setting such lights out on platforms or brackets to clear the mast.

Location and spacing of lights

•On a power-driven vessel of 20 m (65 ft 7 in) or more in length, the forward masthead light must be at least 6 m (19 ft 8 in) above the hull. If the beam exceeds 6 m (19 ft 8 in), then the height above the hull is to be the same as, or greater than, the beam. However, the light need not be more than 12 m (39 ft 4 in) above the hull.

•When two masthead lights are carried, the after one shall be at least 4.5 m (14 ft 9 in) higher than the forward one.

•The masthead light of a power vessel of 12 m (39 ft 4 in) length, but less than 20 m (65 ft 7 in) length, shall be placed at a height of 2.5 m (8 ft 2 in) above the rail.

•On a vessel of less than 12 m (39 ft 4 in) overall length, the masthead light must be at least 1 m (3 ft 4 in) above the sidelights.

•On a power-driven vessel the sidelights must be located at a height above the hull not greater than three-quarters of the height of the forward masthead light and not so low as to interfere with the deck lights.

•On a power-driven vessel of less than 20 m (65 ft 7 in) overall length, where the sidelights are in a combined lantern, they shall be more than 1 m (3 ft 4 in) below the masthead light.

Shapes displayed during daylight

•On a towing vessel and on the vessel being towed when the overall length of the two exceeds 200 m (656 ft) the diamond shape is carried on the towing vessel and on the towed vessel.

•An auxiliary sailing vessel with sails up and motoring exhibits a conical shape located forward, apex down.

•A vessel fishing exhibits two cones with the apexes together in a vertical line, one above the other. If the vessel is less than 20 m (65 ft 7 in) in length, she may exhibit a basket instead.

•A vessel ‘not under command’ exhibits two balls in a vertical line.

•A vessel restricted in her ability to manoeuvre exhibits two balls with a diamond between, all in a vertical line.

•A vessel dredging, or engaged in underwater operations, exhibits two balls in a vertical line on the side where an obstruction exists and two diamonds on the side where other vessels may safely pass.

•A small vessel which cannot exhibit the correct shapes owing to her size, when engaged in diving operations exhibits a rigid international code flag A which is at least 1 m (3 ft 4 in) high. This flag is swallow-tailed, the half nearest the pole being white and the other half blue.

•Vessels constrained by draught display a cylinder.

•A vessel at anchor displays a ball and a vessel aground displays three balls in a vertical line.

•When two or three lights are to be carried in a vertical line, they are spaced as follows:

On a vessel over 20 m (65 ft 7 in) overall length, lights are to be at least 2 m (6 ft 6 in) apart and the lowest light is to be at least 4 m (13 ft 1 in) above the hull, except where a towing light is required.

On a vessel of less than 20 m (65 ft 7 in) overall length, lights are to be not less than 1 m (3 ft 4 in) apart and the lowest of these is to be at least 2 m (6 ft 6 in) above the hull, except where a towing light is required.

•When three lights are carried, they are to be equally spaced.

•The lower of the two all-round lights on a fishing vessel shall be at a height above the sidelights not less than twice the distance between the two vertical lights.

•When at anchor, and two anchor lights are carried, the forward light is to be at least 4.5 m (14 ft 9 in) above the aft one.

•On a vessel of 50 m (164 ft) or more in length, the forward anchor light is to be at least 6 m (19 ft 8 in) above the hull.

•When two masthead lights are fitted on a power-driven vessel, the horizontal distance between them shall be not less than one half the overall length of the vessel, but need not be more than 100 m (328 ft).

•The forward light is not to be more than one-quarter of the length of the vessel from the stem.

•On a power-driven vessel of 20 m (65 ft 7 in) overall length, the sidelights shall not be placed in front of the forward masthead light. They shall be placed at or near the side of the vessel.

Shapes – dimensions

These are to have the following dimensions:

•The ball is to have a diameter of not less than 0.6 m (2 ft).

•The cone shall have a diameter at the base of not less than 0.6 m (2 ft) and a height equal to its diameter.

•A cylinder shall have a diameter of not less than 0.6 m (2 ft) and a height of twice the diameter.

•A diamond shape consists of two cones as defined above, having a common base.

•The vertical distance between shapes shall be at least 1.5 m (4 ft 9 in).

•In vessels of less than 20 m (65 ft 7 in) overall length, smaller shapes may be acceptable commensurate with the size of the vessel.

LIGHTS AND SHAPES NEEDED ON SMALL CRAFT

LIGHTS AND SHAPES NEEDED ON SMALL CRAFT

LAYING UP BOATS

LAYING UP BOATS

Boats are designed to float, and when doing so the hull is supported throughout its length. So when she is ashore, the same boat needs proper supports all fore and aft. Many modern craft are lightly built and the bow and stern props are particularly important.

All the struts need to be well under the hull, then the angle between the prop and the hull shell is not too far off 90 degrees. A strong wind from any direction often causes boats to vibrate, and this can loosen the props. Well-secured diagonal battens, athwartships as well as fore and aft, prevent the props from becoming loose even when the hull is buffeted by a gale.

If the ground is even slightly soft, the base of each strut has to be on a plank or some such to spread the load over a big area. Even with all these precautions, the wedges at the ends of the props need hardening in regularly, especially when a gale is forecast.

When laying up a boat with a long straight keep it is vital to make sure the tops of the keel blocks are all in a straight line. If they are not, the hull may subtly change shape during the winter and, among other problems, each propeller shaft may bind at the P-bracket and at the stern gland. The ground is seldom exactly level so some packing is often needed on top of some of the blocks.

It is common to see keel blocks near the bow and stern, with nothing in between, and this may cause serious long-term hull damage. Because the engines in a power boat form such a high percentage of the total weight of the vessel, a large keep block is needed exactly under the engines. There have to be plenty of side props, because sometimes one gets accidentally displaced. The consequences of having a boat tip over are expensive, complex and long-lasting and can take ages to put right.