4Spars and Rigging

ALUMINIUM ALLOY MASTS – GENERAL GUIDE

ALUMINIUM ALLOY MASTS – GENERAL GUIDE

This scale is a rough guide to mast dimensions which is quick and convenient to use. For long-range cruising go up one or two sizes. Except where stated the dimensions do not include mast track.

ALUMINIUM ALLOY MASTS – SIZE SELECTION GRAPH

ALUMINIUM ALLOY MASTS – SIZE SELECTION GRAPH

(See graphs)

To find the diameter and wall thickness of a mast given:

1 The yacht’s waterline length

2 The height of the fore-triangle

Items 1) and 2) are first added. If they are in metric units use the top of the graph. If in Imperial units use the bottom. The plotting method is shown in the small graph.

Where the sum of items 1) and 2) intercepts the type of rig, read horizontally down for the area of the rectangle which will enclose the mast tube. Read on further across for the mast wall thickness.

When using this type of graph, it is important to make adjustments according to the type of yacht. For long-range cruising in severe weather conditions increase the mast size by one or two steps.

Example: An offshore racer having a waterline length plus foretriangle height added together to give a total of 22 m (75 ft) with a single spreader masthead rig. The mast section would be something approaching 27 × 103 sq mm (4.5 sq in) in area. The section might be 190 mm × 145 mm (7.48 in × 5.7 in) or 180 mm × 150 mm (7.09 in × 5.9 in). Its wall thickness would be of the order of 4 mm (0.16 in).

ALUMINIUM ALLOY – BOOM DIMENSIONS

ALUMINIUM ALLOY – BOOM DIMENSIONS

The graph for boom diameter against overall length is drawn in metric figures (left and bottom scales with solid lines) and also in ft and in (top and right-hand scales with dotted lines).

The graph is an approximate guide. For long-range cruising an increase of at least 10 per cent would be usual. For inshore racing special considerations apply but the diameter might be reduced.

ALUMINIUM ALLOY – SPINNAKER BOOM DIMENSIONS

ALUMINIUM ALLOY – SPINNAKER BOOM DIMENSIONS

The graph is for the maximum spinnaker boom diameter and is marked in metric figures (left-hand side and bottom scales with solid lines) and also in ft and in (right-hand side and upper scale with dotted lines). These booms normally taper considerably at each end, though some of the smaller or cheaper ones are parallel.

The graph is an approximate guide. For extended cruising, particularly when using twin-running headsails, these dimensions may well be increased. However, the larger the overall diameter of a boom, the more difficult it is to grasp in the hand. About 75 mm (3 in) is the biggest convenient diameter for most people. This fact may influence a choice towards a thinner maximum section with a thicker wall.

STANDING RIGGING SIZES

STANDING RIGGING SIZES

The thickness of standing rigging depends on many factors such as the boat’s intended use, the sail area, the mast height, and so on. The graph gives a preliminary working average but for serious cruising, sizes will often be one size larger and for ocean cruising perhaps should be two sizes up. For racing, the rigging is commonly as light as the designer and owner feel they can risk, and less than shown on this graph.

A backstay may be one size thinner, and is sometimes two sizes lighter than the shrouds, especially where its angle off the mast is appreciably larger than the angle the forestay makes with the mast. Another factor which allows it to be lighter is when it is a three-quarter rig with the forestay well below the masthead.

Since the rigging is relatively cheap but dismasting is expensive, it is better to fit one size too large than one size too small. Even when racing, it is important to remember that to win it is necessary to finish. The base of the graph is given in tonnes or tons which, for the purposes of this graph, are similar.

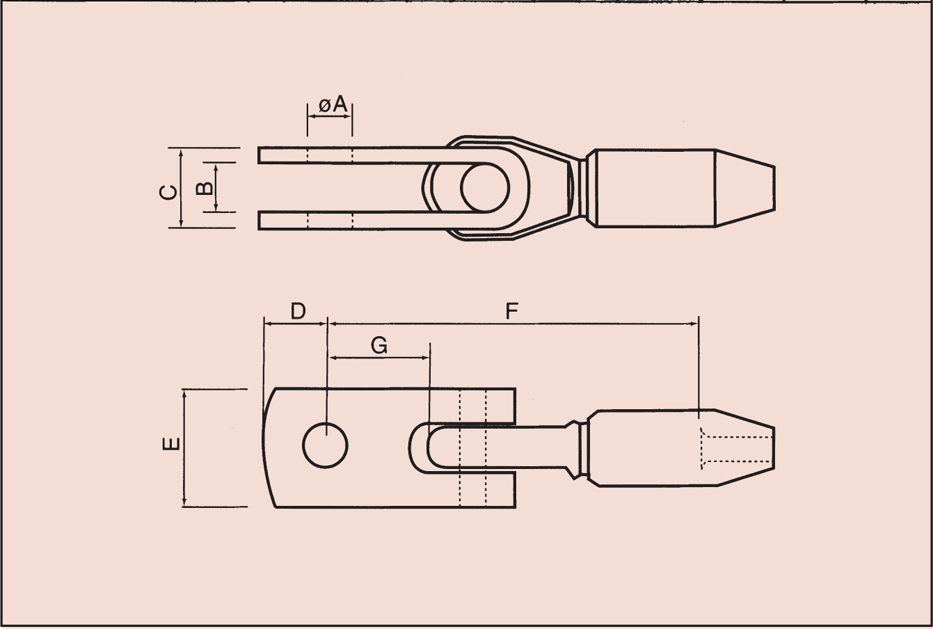

RIGGING SCREW PINS, FORKS AND STANDARD ENDS

RIGGING SCREW PINS, FORKS AND STANDARD ENDS

Since rigging screws break far more often than the wire, the screw should be one and a half times as strong as the shroud it is connected to. For ocean racing the factor should be three. However, where standard components are used the correct standing rigging screw must be bought to fit the standard rigging terminal, standard chain plate, toggle etc.

Note: Ropes of sizes other than those listed should be associated with the next maximum size above it in the table. The working depth l1 indicates the limit of parallelism of the facing sides of the fork slot. The threaded length of shaft (l2) is to be not less than nominal screw thread diameter (d3).

Where the pin is secured by a screwed nut the thread length is to be not less than the diameter of the screw thread.

Limits of tolerance of ± 0.3 mm (

in) are allowable on dimensions d1 and d2, plus 1.0 mm (0.04 in) on dimension l1.

in) are allowable on dimensions d1 and d2, plus 1.0 mm (0.04 in) on dimension l1.

NITRONIC 5O ROD RIGGING

NITRONIC 5O ROD RIGGING

GAMMA ROD RIGGING

GAMMA ROD RIGGING

COBALT ROD RIGGING

COBALT ROD RIGGING

CARBON ROD RIGGING

CARBON ROD RIGGING

SOFT KEVLAR RIGGING

SOFT KEVLAR RIGGING

PULTRUDED KEVLAR ROD RIGGING

PULTRUDED KEVLAR ROD RIGGING

TURNBUCKLES FOR ROD RIGGING

TURNBUCKLES FOR ROD RIGGING

TURNBUCKLES FOR HALF LENTICULAR ROD RIGGING

TURNBUCKLES FOR HALF LENTICULAR ROD RIGGING

WHITE KEVLAR 49 CABLE

WHITE KEVLAR 49 CABLE

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH EYES

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH EYES

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH BAILS

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH BAILS

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH HIGH-FATIGUE JAWS

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH HIGH-FATIGUE JAWS

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH HIGH-FATIGUE EYES

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH HIGH-FATIGUE EYES

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH T TERMINALS

KEVLAR 49 STANDARD LIGHTWEIGHT SOCKETS WITH T TERMINALS

MARINE EYES FOR KEVLAR 49

MARINE EYES FOR KEVLAR 49

HIGH-FATIGUE EYES FOR KEVLAR 49

HIGH-FATIGUE EYES FOR KEVLAR 49

HIGH-FATIGUE JAWS FOR KEVLAR 49

HIGH-FATIGUE JAWS FOR KEVLAR 49

SHACKLES – SAFE WORKING LOADS

SHACKLES – SAFE WORKING LOADS

Safe working load is approximately a quarter of the distortion load; ie the factor of safety is about four.

TITANIUM SHACKLES

TITANIUM SHACKLES

Typical strength figures though some makes may fall short of these loads.

U-BOLTS – TYPICAL DIMENSIONS AND STRENGTHS

U-BOLTS – TYPICAL DIMENSIONS AND STRENGTHS

Important: Read the notes below before using this table.

U-bolts vary according to the makers, so the figures given here are just guidelines. This is just one reason why big safety factors should be used when specifying or using a U-bolt. It should never be stressed up near its distortion load.

When drilling holes to fit a U-bolt, the washer plate serves as a template or guide. It is important to have a strong backing pad on the same side of the supporting panel as the nuts in order to spread the load widely. Circumstances vary, but as a rough guide, the backing pad thickness typically should be at least four times the T dimension, which is the thickness of the rod forming the U-bolt. Assuming the backing pad is square, then each side should typically be at least of the order of ten times the C dimension.

The U-bolt should be bedded in a waterproof non-hardening compound which should be under the top plate and under the washer plate, also under the doubler pad. This compound must be used so copiously that when the nuts are tightened the compound is seen to squeeze out all round the plates and the backing pad.

STAINLESS STEEL FLEXIBLE WIRE – BREAKING LOAD AND WEIGHT OF RUNNING RIGGING

STAINLESS STEEL FLEXIBLE WIRE – BREAKING LOAD AND WEIGHT OF RUNNING RIGGING

STAINLESS STEEL WIRE ROPE – BREAKING LOAD AND WEIGHT OF STANDING RIGGING

STAINLESS STEEL WIRE ROPE – BREAKING LOAD AND WEIGHT OF STANDING RIGGING

GALVANISED STEEL FLEXIBLE WIRE – BREAKING LOAD AND WEIGHT OF RUNNING RIGGING

GALVANISED STEEL FLEXIBLE WIRE – BREAKING LOAD AND WEIGHT OF RUNNING RIGGING

GALVANISED STEEL WIRE ROPE – BREAKING LOAD AND WEIGHT OF STANDING RIGGING

GALVANISED STEEL WIRE ROPE – BREAKING LOAD AND WEIGHT OF STANDING RIGGING

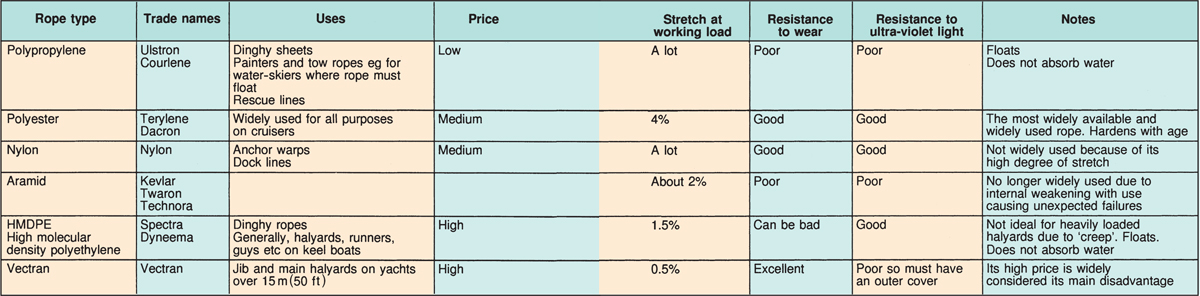

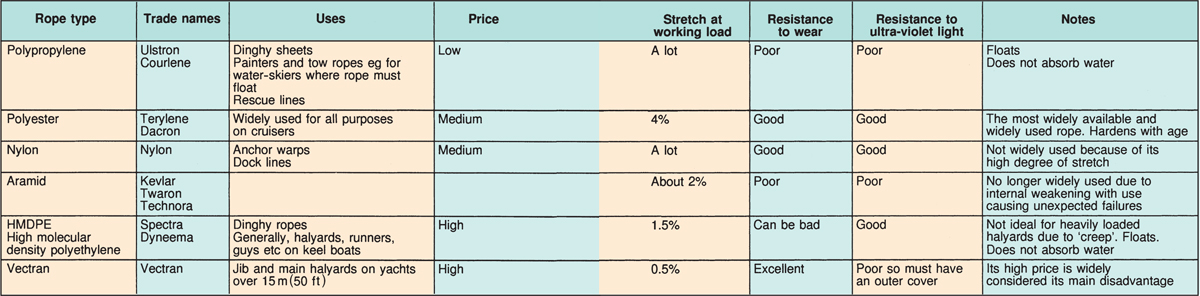

QUALITIES OF MAN-MADE FIBRE ROPES

QUALITIES OF MAN-MADE FIBRE ROPES

ROPE DAMAGE

ROPE DAMAGE

A feature of rope with a strong core and an outer protective sheath is that the latter sometimes wears out much sooner than the core. To prevent this the rope should not be secured so that the same length is always subject to chafe. For instance, when leaving the boat after sailing, the halyards should be secured differently each time. As an example, a headsail halyard may have its shackle secured to different positions on the pulpit each week.

When the sheath is stripped off (to save weight and windage), care is needed to ensure the core does not suffer any chafe. For instance a main halyard which has been ‘stripped’ should have a length of sheathing left where the halyard passes over the sheave both in the ‘stowed’ position, when on moorings, and in the ‘in use’ position when the sail is hoisted.

Spinnaker halyards continue to fail, usually at or near the sheave, sometimes after quite a short period of use. When a vessel is involved in a long reach or run which involves having a spinnaker up for days on end, special precautions are needed in the area of the sheave. Sometimes wear occurs on the edges of the sheave cage, sometimes on adjacent fittings. One answer is to use the traditional precaution, namely a short length of chain in the wearing area.

This chain, which must be of the best quality, is heavier than rope, and needs a proper chain-to-rope join, but the added weight is a small penalty to pay for reliability. One accidental spinnaker drop can lose much time, and cause damage to the sail.

ROPES OF MAN-MADE FIBRES – DIAMETER, CIRCUMFERENCE, BREAKING LOAD, WEIGHT

ROPES OF MAN-MADE FIBRES – DIAMETER, CIRCUMFERENCE, BREAKING LOAD, WEIGHT

Terylene/Dacron 3-strand (Polyester multifilament)

The recommended working load is ⅓, or for offshore cruising ⅕ of the breaking loads given here.

Nylon 3-strand (Polyamide multifilament)

The recommended working load is ⅓, or for offshore cruising ⅕ of the breaking loads given here.

Ulstron/Courlene 3-strand (Polypropylene multifilament)

The recommended working load is ⅓, or for offshore cruising ⅕ of the breaking loads given here.

POLYESTER ROPES – RECOMMENDED SIZES FOR RUNNING RIGGING

POLYESTER ROPES – RECOMMENDED SIZES FOR RUNNING RIGGING

Note: All rope sizes are diameters. For ocean cruising use one or two sizes larger.

DINGHY RUNNING RIGGING – LENGTHS, DIAMETERS, TYPES OF ROPE FOR PICO AND LASER

DINGHY RUNNING RIGGING – LENGTHS, DIAMETERS, TYPES OF ROPE FOR PICO AND LASER

*Prestretched †Matt ††Control line

RUNNING RIGGING – TYPICAL LENGTHS FOR A VARIETY OF SMALL CRAFT

RUNNING RIGGING – TYPICAL LENGTHS FOR A VARIETY OF SMALL CRAFT

SHEAVE SIZES – FOR ROPE CORDAGE

SHEAVE SIZES – FOR ROPE CORDAGE

Note: Rope sizes are diameters.

LOADS ON SHEETS AND BLOCKS

LOADS ON SHEETS AND BLOCKS

In all the following calculations, a factor has to be allowed for shock loadings, for instance when a mainsail gybes violently, or when a severe gust strikes or sea conditions are severe. It is not unreasonable to build in a safety factor by doubling the answers to the following calculations.

The load on the mainsheet is:

The dimensions are in ft and the answer is in lb. The answer assumes that the sheet is at the aft end of the boom. If the sheet comes off further forward then multiply the answer by 1.25 when it is ⅕ of the boom length from the aft end. Multiply by 1.33; if it is ¼ of the boom length from the outer end, multiply by 2 if it is in the middle of the boom. Divide by 2.2 to get the answer in kg.

The load on the headsail sheet is:

Sail area of headsail x (wind speed)2 x 0.005

The dimensions are in ft and the answer is in lb. Divide by 2.2 to get the answer in kg.

LOADS ON BLOCKS

The load on a block depends on:

1 The tension in the rope passing through it.

2 The angle the block turns the rope (see illustration).

3 The amount of friction in the block which includes the friction of the sheave’s bearing and the friction where the rope touches the block cheek. The rope should never touch both cheeks but sometimes it does. Here, as in so many maritime areas, there are complications.

The table shows the percentage of the load in the rope which the block has to withstand. However when shock loading occurs, for instance during a severe gybe, or during a heavy gust, the loading on the block can be much greater and can double.

ALUMINIUM ALLOY MASTS – GENERAL GUIDE

ALUMINIUM ALLOY MASTS – GENERAL GUIDE

in) are allowable on dimensions d1 and d2, plus 1.0 mm (0.04 in) on dimension l1.

in) are allowable on dimensions d1 and d2, plus 1.0 mm (0.04 in) on dimension l1.