A1.1 SCREW FEATURES

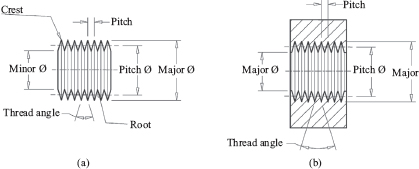

A mechanical screw is a cylinder or cone that has a helical ridge called a thread; hence, screws are threaded components. A helix has one or more turns, therefore, a screw can have several turns. If the helix is on the outside surface of a cylinder or a cone, it is an external thread. If the helix is on the inside surface of a hollow cylinder or cone, it is an internal thread. There are two types of mechanical screws, namely, screw fasteners and power screws. Screw fasteners are used to hold two or more components together in a detachable joint. Power screws are designed to transmit power and or motion but are not discussed in this Appendix. The ends of external threads are normally chamfered at 45° for easier starting and engagement. Figure A1.1 shows the elements of an external and internal thread form.

A1.2 STANDARD THREADS AND THREAD PROFILES

Screw threads have been standardized nationally and internationally. The International Standardization Organization (ISO) thread standard is the metric thread. The root of metric screws can be flat or rounded. Flat root profile screws are identified by the letter M, while rounded root profile screws are identified by letters MJ. The M profile thread is for general applications, while the MJ profile is preferred in high-fatigue stress environment. The national thread standard is the Unified National (UN) thread in the United States. It will be called the English thread in our discussions.

Figure A1.1. Thread nomenclature. (a) External thread. (b) Internal thread.

A1.3 THREAD SERIES

Thread series are based on the type of pitch. The metric thread has two series, namely, coarse and fine pitch series. For the same major diameter size, the fine pitch series has more threads or smaller pitches. The English thread has four series: coarse (UNC), fine (UNF), extra fine (UNEF), and constant pitch. English threads are characterized by threads per inch (TPI), the reciprocal of pitch. The coarse series has the least TPI, while the extra-fine series has the most TPI. In the constant pitch series, different major diameter sizes have the same pitch or TPI.

A1.4 THREAD CLASSES

A thread class of fit determines the manufacturing precision of the thread. Table A1.1 shows the classes of threads in the metric system, while Table A1.2 shows the classes of threads in the English system.

Table A1.1. Metric thread classes

Fit classes |

|||

Fit name |

Internal threads |

External threads |

Applications |

Free |

7H |

8g |

For quick and easy assembly |

Medium |

6H |

6g |

For general engineering applications |

Close |

5H |

4g |

For precision applications |

Table A1.2. English thread classes

Class name |

Applications |

Class 1 |

For quick assembly and when play is acceptable |

Class 2 |

For general-purpose applications and for threads of mass production |

Class 3 |

For precision tools, high-stress and vibration applications |

A1.5 THREAD SPECIFICATION

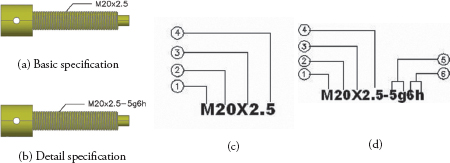

A thread specification provides necessary information about the thread for manufacture or purchase. Threads may be specified in basic or detailed format. Figure A1.2a shows a basic specification of a metric thread, while Figure A1.2b shows a detail specification. Figures A1.3a and A1.3b show the basic and detail specification of threads, respectively, in the English units. Table A1.3 gives the interpretations of the thread elements shown in Figure A1.2, while Table A1.4 gives the interpretation of the thread specification elements shown in Figure A1.3. The TPI element of English thread is the reciprocal of the thread pitch.

Figure A1.2. Metric thread specifications.

Table A1.3. Interpreting metric thread specification

Item |

Description |

1 |

Metric thread identifier |

2 |

Major diameter (mm) |

3 |

Separator |

4 |

Pitch (mm) |

5 |

Major diameter tolerance specification |

6 |

Minor diameter tolerance specification |

Figure A1.3. English thread specifications.

Table A1.4. Interpreting English thread specification

Item |

Description |

1 |

Major diameter or number reference |

2 |

TPI |

3 |

UN |

4 |

Coarse (series identifier) |

5 |

Class |

6 |

A: external thread and B: internal thread |

7 |

LH: left-hand thread; RH: right-hand thread |

8 |

Number of starts |

9 |

Separator |

10 |

Length value |

11 |

Length identifier |