4. MUNITIONS AND GUNS

Among the several munitions programs in general, as well as from the podium of the revolutionary courses in particular, patriotic rhetoric celebrated above all the popular production of saltpeter. People and country were proclaimed to be at one in a procedure carried out in plain view for all to emulate. “The soil of the Republic is rich in this resource,” so runs the introduction to the decree of 14 frimaire an II (4 December 1793) summoning the whole nation to extract it. Royalism had systematically rejected a generalized production of weapons. “Now that liberty offers its brave defenders everywhere the thunderbolts that will strike down tyrants, it must multiply in the same proportion the material that launches them.” If every citizen sets himself the goal of producing a pound of saltpeter, the almost instantaneous result would be a 25 million pound supply, “more than enough to lay low all the tyrants’ slaves.” The apparent difficulty of converting each and every citizen into a saltpeterman “would be nil for republicans ready to do their utmost for their fatherland.” Let patriots say to themselves:“The salvation of the human race may depend on the last pound of saltpeter concealed in my dwelling.”116

On 30 pluviôse (18 February), the day before the opening of the first revolutionary course, a deputation appeared before the bar of the Convention bearing a tribute of the first 6,804 pounds of saltpeter already harvested in the section of the Gardes-Françaises. The delegates concluded their address by singing a Marseillaise of Saltpeter, of which the first and third stanzas run:

Et cet esprit, c’est du salpêtre!117

All that, and far more, pertains to the popular as distinct, but not finally separate, from the technical aspect of the revolutionary production of salt-peter. For the whole story was more than a one-act drama. Performance of sans-culottes in city parks and peasants in village squares was real, wide-spread, and politically exhilarating. There the masses did the work of the Saltpeter Corps in the old regime, which had been limited to extraction of the salt from masonry, debris, alleys, cellars, caves, barnyards, stables, dove-cotes, manure piles, unfloored country kitchens, and certain natural deposits. Once obtained, crude saltpeter had to be refined, a task formerly reserved to the Régie des Poudres. Expansion and acceleration of the latter process required persons versed in chemical industry. Though included in the epithet “revolutionary” by the protagonists, enlargement of scale and innovative techniques for refining evolved commensurately with the growing needs of the armies throughout the time of political affect and afterward. It was in this phase, naturally enough, that participation of scientists was instrumental as well as hortatory.

It will be best to consider extraction and refining in order, beginning with a further caveat, to the effect that revolutionary saltpeter did not surge out of the ground all suddenly in response to the levée-en-masse of 23 August 1793. Only in March 1794, some five months into the year of the Terror, did the yield begin to materialize in any quantity. Before drafting the operative decree of 14 frimaire (4 December), Prieur and his scientific advisers in the Armaments Section had sought to prod the Régie des Poudres into expanding its possibilities. Among the last acts of the Constituent Assembly had been a law of 23 September 1791 nationalizing the munitions monopoly that had been a concession under Lavoisier’s leadership since 1775. The régisseurs, their headquarters still in the Arsenal of Paris, now reported to the Minister of Public Contributions (Finance) and were paid salaries instead of a share of the profits. They headed a considerable organization, beginning with a staff of twenty-two in Paris. Four inspectors-general oversaw the operations of another forty-seven refineries and powder mills of varying capacity throughout the country, each under the direction of a commissioner in one of three grades. All but eight subordinate members of the staff had worked under Lavoisier since before the Revolution, the mean time of service having been fifteen years.118

Piecemeal efforts began with a measure introduced by Carnot on 28 August 1793 lifting all restrictions on the operations of saltpetermen. Hence-forth they were authorized to enter and search all premises in any property whatever, without the owner’s permission. Especially to be exploited were ruined buildings and debris in the traitorous cities of Lyons and Toulon, demolished by order of the Convention after the defeat of their rebellious citizenry. The governing Committee added a fourth régisseur, Nicolas Leblanc, to the Régie des Poudres, exempted saltpetermen and powder-makers from military service, and requisitioned further workers to expand the corps. Representatives on mission spurred the search for saltpeter in regions where production lagged. Monge and a subcommittee of chemists in the Armaments Section were assigned funds to experiment with implementing the creation of artificial nitrification plants. It was recalled that in 1778 Lavoisier and his fellow régisseur, Clouet, had undertaken investigations of the Loire Valley downstream from Tours, and also of the Charente, and there discovered rich deposits that had never been exploited. Bypassing the Régie, Prieur enlisted the skills of a young chemist, Nicolas Vauquelin, Fourcroy’s former laboratory assistant and junior colleague. The assignment made his name. Appointed commissioner of the Committee of Public Safety on 31 August 1793, and given full powers to commandeer men, tools, and materials, Vauquelin and an associate, Joseph Jacotot, set up workshops for extracting crude saltpeter from the earths containing it throughout the region. 119

French victories in the autumn and early winter of 1793–94 may be thought to argue that these expedients and others like them, combined with a proportionate increase in size and number of powder mills, did in the event suffice to furnish the armies with the gunpowder needed to turn the tide of war. Such was not the view of Carnot, Prieur, and their scientific advisers. In what degree the further revolutionary saltpeter program was politically motivated, and in what degree logistically, it is impossible to say. The elements were inextricable. It appears likely, however, and Prieur’s report to the Convention on 14 frimaire suggests as much, that the quick and stunning success of the Vauquelin mission entered into the calculation in the decision of the Committee of Public Safety to transcend the capacities of the Gunpowder Administration, a holdover from the old regime after all, and to enlist the general public in augmenting the supply of raw material for munitions.

Initially the Régie des Poudres was to have been enlarged and supplemented, not supplanted. The decree of 14 frimaire enjoined private citizens to search everywhere for saltpeter save in locations reserved to the Saltpeter Corps. The Régie was to send one of its officials to every department in order to provide instruction to agents whom each district and municipality would name to organize the extraction of saltpeter locally. A common work-shop might be set up, or property owners might leach fruity deposits and evaporate the liquor on their own. In either case crude saltpeter was to be compensated at the fixed price of 24 sous a pound on delivery to the nearest installation of the Régie for refining.120

Distrustful of routine, however, and impatient for results, the Committee of Public Safety incrementally took control of munitions into its own hands. A decree of 4 nivôse (24 December 1793) divided France into eight regions for the purpose.121 An inspector in each exercised the authority of the Committee of Public Safety and reported directly to it. Henceforth certification of district agents pertained to them, not to officials of the Régie des Poudres, as did responsibility for stimulating the zeal of local authorities, extending the search for saltpeter, correcting procedures in workshops and powder mills, and instructing a team of young workers who might educate their fellows both by precept and example. The Gunpowder Administration continued to operate its own arsenals and powder mills, but had no part in the proliferating revolutionary operations.

Named to oversee ten departments in west central France was Vauquelin. His erstwhile collaborator, Jacotot, a Dijonnais lawyer and science teacher who had distinguished himself as a volunteer in the artillery, headed the neighboring ten departments in central France. François-Antoine-Henri Descroizilles, a pharmacist of Rouen turned chemical manufacturer, covered ten departments in the Northeast. A onetime consultant of Roland, he had been arrested as a federalist early in the Terror. Descroizilles had conducted successful experiments on artificial nitrification, however, and a memoir on the subject composed in prison won him release and appointment as inspector. It is an almost certain surmise that Guyton and Berthollet were the ones responsible for selecting the eight inspectors, all of whom were competent in chemistry, several as apothecaries.

The one they named first, Jean-Antoine Chaptal, had charge of the largest territory, eleven departments in Provence and Languedoc. A brilliant chemistry teacher in his youth and author of a successful textbook, Chaptal had become an enterprising chemical manufacturer in Montpellier.122 Participation in the revolutionary munitions program brought him to the fore, as it did Vauquelin, with the difference that his became a far more important presence on the national stage. In later years Chaptal published path-setting works on viniculture, on industrial and agricultural chemistry, and on French industry in general.123 Before that, as will appear, he served Bona-parte in the critical post of Minister of the Interior throughout the Consulate, during which term of office Chaptal in effect organized the Napoleonic administration of the country.

By February 1794 the flood of saltpeter began to outstrip the refining capacity of the Régie des Poudres, which was equally incapable of fabricating more than a fraction of the gunpowder it eventually made possible. Refining and powdermaking both required skills and a labor force as well as patriotism, however, and were none so easy to decentralize as was extraction from far-flung deposits. In the forefront of the action was another chemical manufacturer, Jean-Antoine Carny, rue du Harlay-au-Marais in Paris, to whom Berthollet had turned for industrial scale production of muriate powder in August 1793, and who on 12 April had already approached the first Committee of Public Safety with a proposal to fabricate the powerful new explosive.124 Questions about Carny’s honesty accompany his name in many of the archival records where traces of his activity remain. He was well thought of by Berthollet, Guyton, and Prieur, however, and there is no doubt about his enterprise. On 15 December 1793 Carny came forward with the design of what he claimed to be a new machine for fabricating gunpowder in a safe, speedy, and inexpensive manner—of which more in a moment. At or near the same time, Carny further proposed adopting a process for refining salt-peter more expeditiously than by the traditional method.

By the end of January 1794 it became clear to Prieur and his colleagues that procurement of munitions and weapons must no longer be partitioned among the three ministries of War, the Navy, and Finance.125 On 1 February 1794 (13 pluviôse) the Convention centralized all operations under a new Commission des Armes et Poudres under the direct control of the Committee of Public Safety. To coordinate the proliferating activities in the capital, the Committee had already on 26 January (7 pluviôse) created an Administration Révolutionnaire des Poudres et Salpêtres for Paris.126 It was to have three administrators politically acceptable to the Commune and under the technical oversight of a commissioner of the Committee of Public Safety. On 3 February Carny was duly appointed to be munitions chief in Paris.127

Decisions about revolutionary installations were taken at the same juncture. The governing committee had already instructed Carny and an associate to scout out properties in which new powder mills might be installed. On 29 January it accepted his recommendation of the château of Grenelle beyond the Gros-Caillou quarter and an estate near the Porte des Ternes in what is now the seventeenth arrondissement.128 The section of Saint-Germain-des-Prés (Unité in patriotic parlance) stepped forward simultaneously, no doubt at Prieur’s prompting, with a solution to the problem of mounting a refinery for processing masses of crude saltpeter from all over France. Their revolutionary committee, ever distinguished by patriotism, offered for the purpose the nave and precincts of their Temple of Reason, the once and future abbey of Saint-Germain-des-Prés. In exchange they requested allocation of a smaller church in which to celebrate the cult of the Supreme Being. On 14 pluviôse (2 February), in a decree signed by Prieur alone, the Committee of Public Safety accepted the proposal, stipulating that the paintings in the ancient structure be transferred to the Louvre before refining began.129

At the end of February, Prieur and his consultants completed marginalization of the Gunpowder Administration. On the twenty-seventh the Committee of Public Safety extended the powers of the Administration Révolutionnairedes Poudres et Salpêtres from Paris to the entire Republic.130Henceforth the district agents overseeing the people’s extraction of crudesaltpeter all over France would report to the Revolutionary Administration.It would establish refineries and powder mills where it thought proper, alwayswith the approval of the Committee of Public Safety. It would place attheir head qualified artisans, giving preference to those who had followedthe revolutionary courses in Paris. In charge would be two expert commissioners.The side-tracked Gunpowder Administration, renamed Agence Nationaledes Poudres, would still run its own installations, but have no furtherpart in improvising new ones.

Prieur and his scientific consultants had already decided on the two commissioners who would head the national effort. Descroizilles, inspector for Normandy and the Northeast, accepted forthwith. Chaptal, inspector in the South, was in Carcassonne when he received a letter from Berthollet, dated 25 February, which informed him that “the wheel of the Revolution would be calling him to other functions.” Chaptal demurred. His enthusiasm for the Revolution had extended no further than the work of the Constituent Assembly. A patriot he supremely was, but of Carnot’s ilk, not Robespierre’s. If Republic there had to be, and clearly the Monarchy had failed, it should be an orderly Republic of talents and merit. For Chaptal’s was a provincial sensibility, nurtured in Montpellier and steeped in the culture of the Midi.

Though Chaptal was anything but a political activist by temperament, in early 1793 he was among the leaders of local Federalist resistance to Jacobin domination from Paris. As a consequence he was arrested and detained in the Citadel of Montpellier after expulsion of the Girondists from the Convention in June. Fortunately, the Revolutionary Tribunal had not yet extended its reach to Montpellier, and he was released after a few days. Thereupon he and his family took refuge in a remote village in the Cévennes. He kept a low profile high in the mountains until late December 1793, when the Committee of Public Safety appointed him Saltpeter Inspector in the Midi.

Two months later, summoned to a Paris ruled by Terror, Chaptal initially responded that he thought himself to be more useful to the Republic where he was. Attempting to take no for an answer, Berthollet sought to persuade the Committee of Public Safety to respect Chaptal’s reluctance. He failed. “Your refusal and your delay are very damaging,” Berthollet wrote, and sent a further word the next day: “Are you aware that the [Gunpowder] Agency with all its facilities cannot fabricate more than six million pounds a year, and that we require, and must make, thirty million? . . . You are going to compromise your reputation. The Committee of Public Safety will certainly put you under requisition.”

Still Chaptal held back. A final message from Berthollet urges: “The Committee of Public Safety will have none of your refusal. It knows that you are very useful in your present mission, but it needs you at the center of the action. . . . Come! You will have the backing of the Committee of Public Safety to do good work, and to resist any malevolence that manifests it-self. . . . I think that any further resistance will be interpreted badly.” Finally, on 23 March a direct letter from Carnot and Prieur themselves left Chaptal neither doubt nor choice. In Paris on or about 1 April, he met Robespierre for the first time, and went to work, conscious all the while of the fate that would await him if “malevolence” should prevail. It took the form of repeated denunciations that the Jacobin leadership in Montpellier forwarded to Fouquier-Tinville, prosecutor of the Revolutionary Tribunal.

Whatever Descroizilles’s contributions, his part was secondary, and Chaptal had overall charge of revolutionary production of munitions. Documents are lacking, but it must have been he who decided to concentrate all powdermaking in the château of Grenelle rather than setting up a second mill near the Porte des Ternes. Vats, troughs, stoves, and ovens were installed in the abbey of Saint-Germain-des-Prés, and refining masses of crude saltpeter began there in April, some weeks before the improvised powder mill was ready to combine the finished product with charcoal and sulfur. Serving as commissioner of the Committee of Public Safety under Chaptal, Carny had the job of designing both operations. His virtuosity was much more important in improving the technology of gunpowder than in refining saltpeter, however, and beginning in early May, he focused his attention on perfecting powdermaking at Grenelle.

It soon appeared that refining saltpeter and milling it into gunpowder posed problems of a very different sort from extraction of the raw material. Extraction was a nationwide voluntary effort, modestly compensated as piecework, motivated by patriotism, conducted in public, sustained by civic spirit. Crude saltpeter from all over France had to be shipped to Paris for processing and fabrication into gunpowder. Saint-Germain-des-Prés and Grenelle were in effect factory operations. They required, not merely technical virtuosity, but firm management backed by political authority. Under the circumstances nothing weaker than the authority of the Convention embodied in Representatives of the People would suffice. To direct Grenelle, the Committee of Public Safety named a naval engineer, Joseph Niou, deputy from Charente-Inférieue. To direct Saint-Germain-des-Prés it chose Augustin Frécine, deputy from the Loir-et-Cher.

The terms of their instructions make clear that the problems Niou and Frécine were expected to resolve were other than chemical. They were to see to the proper organization of the revolutionary powder mill and refinery and to maintenance of order. They were to dismiss employees who did not perform well, whether because of incompetence or lack of civic spirit. To replace the delinquents, they were to find citizens capable of good work. If necessary they might requisition any not already engaged in national service.131 Thus did Niou and Frécine, in company with their counterparts managing the fabrication of ordnance and small arms, encounter what Marxist historiography considers to be the fundamental contradiction of the French Revolution. The material interests of the working class were contrary to those of the government it had enabled to seize power.

On 23 prairial (11 June 1794) Frécine found himself obliged to address the following proclamation to his labor force:

I feel the most painful regret at finding myself forced even for a moment to drop the language of fraternity with you in order to make you hear only that of severe reason. I learn with surprise and sadness that there are individuals among you who obstinately want a raise in pay at the expense of the Republic. What then, citizens! Has the detestable spirit of greed that national justice has just annihilated among monopolists infected the pure soul of sans-culottes? Such a suspicion is too odious for me to be willing to entertain it, and you will not allow it to hang over your heads.

Did they not understand, continued Frécine, that price controls (the maximum enacted on 29 September 1793) entailed fixing the price of their labor? None among them was earning less than twice what he had in 1790. Let there be no more talk of raises. Let them remember that they are under requisition, and that the law of 13 pluviôse (2 February) prescribes arrest for whoever “impedes or delays the extraordinary fabrication of saltpeter and gunpowder.”132

In the event nothing was allowed to impede it. From mid-April until mid-June 1794, the Régie, renamed Agence Nationale des Poudres, ran its old installations while Chaptal’s Agence Révolutionnaire expanded the improvised ones. Finally, on 17 messidor (5 July 1794) the Committee of Public Safety, on recommendation of the overall Commission des Armes et Poudres, combined them into a single Agence des Poudres et Salpêtres.133 A triumvirate directed it: Champy from the Agence Nationale (the old Régie), Chaptal from the Agence Révolutionnaire, and François-Joseph Bonjour, formerly Berthollet’s laboratory assistant, employed since early 1794 in procurement of naval munitions.

The ultimate success of the munitions program virtually justified the rhetoric. By the time the Terror ended, in mid-summer 1794, some 6,000 workshops extracting crude saltpeter had sprung up throughout France, over sixty of them in Paris. In round numbers, the harvest of crude saltpeter in 1793 had fallen to just short of 2,718,000 pounds from an annual average of 3,500,000 during the preceding ten years. Prieur later claimed that in 1794 the revolutionary procedures had yielded 16,754,000. The most careful recent analysis of all the data, which at best are not precisely verifiable, reduces that estimate, though not drastically, to 14,750,000. What with the additional 4,830,000 pounds delivered to the former Gunpowder Administration, France produced 19,580,000 pounds of crude saltpeter from its own soil in 1794. The yield was less than the hyperbolic 30 to 40 million Prieur had called for in the report of 14 frimaire (4 December 1793) that launched the effort. Nevertheless, the achievement is no less remarkable in retrospect than it was at the time.

Refining would reduce the total to twelve million pounds of pure salt-peter. In theory that would have sufficed for fabricating 16 million pounds of military gunpowder, over five times the average annual production of explosives of all grades from 1775 through 1792. In practice powder mills were able to turn out seven million pounds of gunpowder in 1794—28. 6 percent from Grenelle, 20 percent from improvised mills elsewhere, and just over half from experienced installations of the former Régie des Poudres.134

What of the technology? Contemporary political commentaries echo Carny’s claim that he had invented the revolutionary procedures both for refining saltpeter and for fabricating gunpowder. The facts are otherwise. There is no doubt that he was a skilled manipulator of chemical apparatus, an effective manager, and a successful entrepreneur. He undoubtedly perfected and accelerated procedures on the factory floor both at Saint-Germain-des-Prés and at Grenelle. The principles were already known, however. With respect to saltpeter, the starting point was Lavoisier’s last chemical investigation.135

War was imminent when Lavoisier, having resigned from the Treasury, provisionally resumed his place in the Régie des Poudres.136 Still bedeviling procurement of munitions was the chronic dispute between the Régie and its suppliers, the saltpetermen of Paris, over estimating the quality, and thereby determining the price, of the crude saltpeter they dumped fort-nightly in the yard of the Arsenal.137 Manual laborers now had access to lawyers who knew how to make their grievances felt. “The Régie des Poudres,” they complained in a memoir to the National Assembly late in 1791, “had conceived the design, why it is difficult to say, of keeping the saltpetermen in entire dependence.”138 The one chemist of the Academy they trusted was Antoine Baumé, apothecary turned manufacturer, who looked at chemical operations from a practical point of view akin to their own. In 1788 he had served on an academic commission that investigated the assaying of crude saltpeter. The test they recommended was novel. It consisted of washing a sample of crude saltpeter with a saturated solution of saltpeter itself on the theory that impurities would be dissolved and carried off leaving a residue of the pure salt. In later years Baume claimed that the suggestion was his, though Lavoisier attributed it to Riffault des Hetres (Desestres in his spelling), the Régie’s commissioner at Tours.139 In either case, Baumé was party to the proposal, and the saltpetermen expressed willingness to abide by it on condition that their representatives be present every time a delivery was tested: “It makes little difference whether this procedure is or is not capable of improvement; the question here is not of the effect of salt-peter, but of the price the Administration ought to pay for it. This is no operation of chemistry, to be carried to the highest degree of precision; it is rather a rule of proportion, to be established between buyer and seller.”

On 14 May 1792, three weeks after the declaration of war, a decree of the National Assembly addressed the problem. The Minister of Public Contributions, Etienne Clavière, was to consult the Academy of Science and the Regie in order to find a formula that would resolve the issue. Clavière turned, inevitably, to Lavoisier. Ever intent on balancing whatever books, Lavoisier set to work. From mid-May through mid-August he labored virtually full-time on the problem of assaying crude saltpeter.

He experimented, not on a laboratory scale, but with randomized 5,000 pound samples shoveled out of the great mass of a normal delivery. This was the first time that a serious chemist, or any of the régisseurs, had refined saltpeter with his own hands, instead of merely studying the principles and overseeing the refinery. Lavoisier began with the test the saltpetermen were willing to accept—washing crude saltpeter with a saturated solution of the salt. Variations in temperature and concentration of other salts presented difficulties, but he thought to average out discrepancies by testing not one, but twelve samples from the first batch of crude saltpeter to be refined.

As always the saltpetermen had extracted their product by boiling the mixture of salts out of waste materials, throwing a bit of potash into the cauldron in order to convert the “eau-mère” (nitrates of calcium and magnesium) into saltpeter, and cooling the evaporated liquor to the point of crystallization. Lavoisier also carried out the traditional process of refining. It consisted of two further recrystallizations, after each of which the additional saltpeter washed out in the solvent water had to be recovered by further evaporation over high heat. Comparing the yield to what the assay had predicted, he discovered that up to 7 percent of the original saltpeter had boiled away with a portion of the liquid in these repeated firings. It followed that:

The saltpetermen were correct in saying that the crude saltpeter they delivered contained so much pure saltpeter, but that the Gunpowder Administration was no less right in holding that on refining the same material produced only some lesser amount.

From the moment that one perceives a truth that has been long sought and elusive, everything seems to join together to confirm and establish it.140

Lavoisier gave Baumé full credit, not for the idea of the test he had just used, but for imagining the application that immediately suggested itself: Might it be feasible to refine saltpeter cold by a similar procedure carried out on a large scale, and thus eliminate the loss to ebullition? Crude salt-peter could be washed in bulk with a saturated solution of itself that would dissolve and carry off impurities. Water alone would do as well, Lavoisier noted, since it would quickly become saturated in the process. Baumé had tried his notion, but only in the laboratory with a 100-ounce sample, and had reported positive results to the Academy of Science in a memoir read on 24 March 1792.141 He had been unaware of the effect of ebullition, which though it strengthened the case for trying the procedure, would still cause considerable waste since the “eau-mère” (solvent water containing nitrates of calcium and magnesium) would have to be treated with potash and evaporated before crystallization. A further large-scale experiment was the only way to test practicality.

Lavoisier proceeded to have a second 5,000-pound sample from the same randomized pile loaded into a large vessel. Over it his assistant poured a third of its weight of cold water—1,500 pints. After long stirring, he let the mixture settle before draining off the wash water. He then had the residue shoveled into large willow baskets placed in pans so that none of the drip should be lost. The saltpeter he obtained after this first lixiviation was grayish and looked rather like rock salt, of which it still contained a good deal. A second washing, this time with 2,400 pints of cold water (48 percent of the weight of the sample), left 2,593 pounds of saltpeter. Another 780 pounds precipitated out of the wash water and “eau-mère” on evaporation and cooling. The total yield from the cold process was thus 3,373 pounds, 128 more than he had obtained by the traditional method. The product was yellowish rather than pure white. It may still have contained up to 2 percent ordinary salt, but was certainly good enough for commercial use, especially in the manufacture of mineral acids. It would probably also have sufficed for fabrication of hunting-grade powder.

Whether cold refining was capable of yielding a usable saltpeter for the finest grade of military gunpowder, Lavoisier could not say. Before finishing the experiments he had planned, he had to abandon his laboratory. Un-nerved by the violent overthrow of the monarchy on 10 August, he and his wife moved out of the Arsenal on 15 August. They were none too soon. Three days later members of the revolutionary committee of the section, Les Piques, forced their way into the Arsenal, arrested his two colleagues, the Le Faucheux father and son, and jailed them in La Force. The elder Le Fau-cheux committed suicide in prison. After five days the son was released. Named to join him as régisseur was Fourcroy, who, ever adept at trimming his sails politically, had the prudence to refuse. Jacques-Pierre Champy, the second choice, accepted. Having been Gunpowder Commissioner for Burgundy, and a member of Guyton’s chemical circle in Dijon, Champy was admirably qualified.142 Less so was the one later named to the third place. A radical engineer, Louis-Pierre Dufourny was a member and for a time president of the revolutionary Commune of Paris. He took to signing himself simply “L’Homme Libre,” nothing more.

Further horrified by the September massacres, Lavoisier decided to leave his temporary lodging and escape Paris for the relative shelter of his manor of Freschines. He and his wife remained there until November, returning to take up his forlorn defense of the Academy in 1793. While in the country he wrote up his incomplete experiments on cold refining of saltpeter.

I am far from proposing to make so great a change lightly. I did not intend to suggest it at all until I should be able to demonstrate the possibilities and advantages by repeated and more developed experiments. Indeed, I mention it in this memoir only because, being no longer provided with the same means to pursue the large-scale experiments that I had intended in the matter, I thought it my duty to transmit the results of my observations to the Ministry and to my successors.143

Lavoisier published his memoir in two installments in the October 1792 and January 1793 issues of Annales de chimie.144 It concludes with an exact description of the apparatus he would have set up and the procedures he would have followed in order to verify the advantages and minimize the disadvantages of cold refining of saltpeter. The arrangement would have been simplicity itself. Two lead-lined trenches, one and a half to two feet deep, six feet wide, as long as space permitted and sloping slightly end to end, would have been lined with lead. A bed of crude saltpeter up to eigh-teen inches deep would be spread in each. Over it would be poured 25 to 30 percent of its weight of water. After long stirring and soaking, the wet salt-peter would be heaped into a pile at the upper end of the trough, and the liquid drained from the lower end through one of two taps. That would carry off all the “eau-mére” (calcium and magnesium nitrate) and much of the salt. A second washing of the residue, with 35 to 45 percent of its weight in water, would remove the rest of the salt and be drained through a second tap into a separate container. Potash would be added to the rinse water from the first washing in order to recover saltpeter on evaporation. The solution from the second rinsing would simply be evaporated in order to recover the salt.

What followed on the ground was cruder and more complicated. Du-fourny, now a successor in the Régie des Poudres, drafted the official instructions circulated throughout France by order of the Committee of Public Safety in implementation of the decree of 4 December 1792 calling for the popular extraction of saltpeter. The phrasing is suited to the readership and devoid of chemical terminology. Whether or not Dufourny had read Lavoisier’s final memoir, he certainly consulted with people who had. So far as it goes, the procedure he outlines for extraction of saltpeter by washing the materials containing it with cold water is similar in the essentials to Lavoisier’s proposal for refining.

Instead of lead-lined troughs in the refinery, washtubs or wine tuns are to be split lengthwise. The half-cylinder tubs, fitted with taps, are arranged in sets of three. All three in each set are filled with the earth or pulverized debris to be leached. Water poured into the first is to cover the contents to a depth of two fingers. After three hours of soaking, the mixture is stirred vigorously, and allowed to soak another three hours. The water drawn off is then passed in the same way through the second tub, and set aside to be evaporated to crystallization. A second charge of water is passed in succes-sion through all three tubs. The first tub is then filled with new earth or rubble and becomes the third for the next sequence, in which a third charge of water is passed in reverse order through all three tubs. The process con-tinues back and forth in such wise that the solution to be evaporated will have passed through three tubs, of which the last is filled with new earth after every third washing.

Evaporation then consists in simmering the liquor in a large boiler or cauldron. At the end of the first stage, the solution is sufficiently concen-trated for the saltpeter to crystallize on cooling. That point has been reached when crystals form in a test spoonful. The solution is next poured into earthenware, copper, or iron vessels and left to cool and settle for three or four days, in which time crystals of saltpeter form all along the sides and bottom. The liquor is then poured off and the saltpeter allowed to drain into it. That liquor contains further saltpeter in solution along with impurities, of which common salt predominates. In the course of a further evaporation, gobbets of salt are skimmed off the surface as they appear. When the volume is reduced by about half, a saltpeter bonus crystallizes out on cooling. There is, finally, still more saltpeter to be obtained from the remaining “eaux-mères,” but recovering it requires potash or wood ashes and the specialized skills of professional saltpetermen. The ordinary citizen will do better to collect this last liquid and hand it over to the nearest refinery. Such were the layman’s instructions for the revolutionary saltpeter program.

The next contemporary document consists of the program of the Revolutionary Course on the Fabrication of Saltpeter and Gunpowder.145 It was completed on 30 ventôse (20 March 1794), some four to six weeks before refining got under way at Saint-Germain-des-Prés. Except for the exordium “Mort aux Tyrans,” the language is that of chemistry, not of the streets. The level was the same as it would have been a little later in the elementary chemistry course in one of the educational institutions of which the revolutionary courses were a precursor. Although purporting to describe how salt-peter is extracted and refined, the account is really of how things should be done.

The third lecture deals with extraction. The process it describes is the same in principle as that called for in the Instruction (above) circulated throughout the country in December 1792. Instead of sets of three impro-vised troughs, however, the proper atelier is now said to be furnished with at least thirty-six barrels, preferably fitted with false bottoms for filters as well as machined taps. They are arranged twelve to a rack on three levels. A system of pumps, conduits, and pipes facilitates circulating the wash waters. After leaching, crude saltpeter is recovered from solution by evaporation in egg-shaped copper vessels set into wood-burning brick ovens. It would be preferable to substitute shallow copper basins since rate of evaporation is proportional to surface area. Finally, the most extensive discussion in the lecture on extraction treats the theory of specific gravity in liquids. The hydrometer invented by Baumé is to be used to measure the relative concen-trations of the various salts mingled in solution with saltpeter, and evaporation is to be controlled accordingly.

None of this can have had any but a coincidental bearing on the revolutionary saltpeter patriotically extracted in village squares and in workshops cobbled together in the Place Maubert and other places like it throughout Paris. The reference workshop (if not hypothetical) must have been some installation, unidentified, of the Régie des Poudres.

The fourth lecture, on refining crude saltpeter, is even more theoretical. It opens with a method that is of interest merely in illustration of chemical properties. Saltpeter may be refined simply by exposing it to the air. In a humid atmosphere the impurities, which are deliquescent, slowly dissolve out and may be drained off. That is feasible only on the laboratory scale, however, and the main subject of this lecture is a detailed account of the standard procedure for refining crude saltpeter by two further recrystallizations together with a description of the apparatus and an explanation of the underlying theory. The auditor is told that this is what happens in refineries, though with no mention of the Régie des Poudres, which still ran them. Only at the end, almost as an afterthought, did the lecturer devote two paragraphs to an outline of the more rapid method of cold refining that the “Revolutionary Genius” had required and created, and that could take the place of the old process. That was in February and March 1794.

Six months later the new process had replaced the old one. In October Chaptal drew up full instructions for the treatment of crude saltpeter that “national factories,” by which he meant Saint-Germain-des-Prés, had developed. 146 Henceforth the method was to be standard in refineries throughout the country. Leavening the workforce that developed it, first under Carny’s direction and later under Frécine’s, were artisans (unfortunately nameless) who had followed the Revolutionary Course all jammed together on the benches of the amphitheater in the Jardin des Plantes. The equipment was far more elaborate than the lead-lined troughs Lavoisier had imagined. Experience also led to certain modifications in the procedure he had suggested. The recipe now prescribed three rounds of rinsing instead of two, each time with proportionally less water than he had called for, and Chaptal specified shorter intervals of soaking. Also the residue after the third washing was dissolved in boiling water and filtered to screen out insoluble impurities before final crystallization. Nevertheless, it was Lavoisier, Chaptal acknowl-edged (though only later in a textbook account), who had first carried out cold refining, and Carny who implemented and perfected the process in the emergency production of 1794.

That is not the end of the saltpeter story, though it is as far as we shall follow it. In 1810 Bottee and Riffault describe an industry transformed by the interpenetration of chemistry and technology throughout a further fif-teen years of wartime.147 Cited are subsequent researches by Berthollet, Gay-Lussac, Vauquelin, and Bérard concerning the chemistry of nitrates, potash, sulfates, and other salts.148 Still more striking, however, is the sophistication of the language, the instrumentation, and the procedures. The operators clearly knew the behavior of their materials from experience and had learned their chemical properties by studying the science. Neither extraction nor refining were now carried out in cold solution. Instead, temperatures were carefully controlled to avoid ebullition, and concentrations regularly titrated to determine the amount of each impurity at every stage. Treatment was modified accordingly in order to recover the last grains of saltpeter from recrystallization, now reduced to one operation, and subsequently from the several wash waters. The very scale was on another order of magnitude. By Chaptal’s account, 500 to 600 pounds of crude saltpeter went into each vat. In 1810 the amount was ten times as great—3,000 kilograms. The restored Administration of Saltpeter and Gunpowder, in short, was running an oper-ation of modern quantitative chemistry on a fully industrial scale.

Converting other nitrates, mainly of calcium and magnesium, into po-tassium nitrate required stirring potash (potassium carbonate) into solution both during extraction and refining of saltpeter. Potash (Vegetable alkali) was obtained from wood ashes and the incineration of plants and under-brush.149 The need for it in the production of revolutionary saltpeter failed to elicit a comparably patriotic response. Housewives were unwilling to sacrifice the ashes from hearth and stove that they mixed with fat to serve as soap. Though urged, they largely failed even to carry their buckets of dirty wash water to the nearest saltpeter workshop. Chaptal’s successor as Inspec-tor of Saltpeter and Gunpowder in the Southwest, Raymond, was partic-ularly severe: “Ashes are in some sense the property of women citizens, not all of whom are Republicans. For most of them that stuff is more precious than liberty.” They think only of the laundry, not of their sons and hus-bands at the front. “Free and enlightened Men, about this you will hear only the voice of the Fatherland. You will not allow the avarice of a sex, incapable by itself of sensing the price of the small sacrifice asked of it, to compromise for a single moment the security of our country.”150 Unable to rely on volun-teers, he and his fellow inspectors, reinforced by deputies on mission, had to compel local authorities to requisition working parties for incinerating brush, herbaceous plants, weeds, and the lies of wineries, all of which yielded “salin,” or crude potash in varying measure.

The Committee of Public Safety sought further to encourage the production of synthetic sodium carbonate in order that artificial “mineral alkali” might be substituted for potash in the textile industry and in manufacture of soap and glass. The main source of natural soda in the eighteenth century had been certain seashore plants that convert sodium chloride from sea water into organic salts and yield sodium carbonate on incineration and lixiviation. The best quality, known as barilla, came from the beaches around Alicante in Spain. The supply was inelastic. Growing demand in the 1780s, combined with obvious mercantilist considerations, had led the Bureau du Commerce under Tolozan’s direction to promote efforts already under way to find a practical method for converting sea salt directly into commercial soda. By the time of the Revolution, at least eleven such processes had been proposed, by Carny and by Guyton de Morveau among others, and several were in operation. Chaptal’s chemical works at Montpellier produced soda from the action of brine on litharge (lead oxide). The partnership of Mal-herbe and Athénas in Brittany made it from the action of Glauber’s salt (sodium sulfate) on sodium chloride in the presence of iron scrap and char-coal. The glass factory at Muntzthal and the bleaching plant at Javelle used other methods. Nowhere, however, could artificial soda be made as cheaply as barilla, and none of these processes survived commercially.

The one that eventually did, and that became the main basis of the alkali industry in the nineteenth century, exploited the reaction discovered by Nicolas Leblanc. He succeeded in converting sodium sulfate into soda by fusion in the presence of limestone and charcoal. A surgeon in the retinue of the duc d’Orléans, Leblanc made the discovery sometime in the latter half of 1789. Lacking any capital, he formed a partnership with the Duke himself and two others, the Duke’s agent, Henri Shée, and J.-J. Dizé, Darcet’s laboratory assistant at the Collège de France. They chose a site near Saint-Denis for their factory, La Franciade. On 25 September 1791 Leblanc received the fourteenth patent issued under the patent law of 7 January 1791.151 La Fran-ciade never came on line to reach its theoretical capacity of 275,000 pounds of soda annually. Throughout 1792 and the first half of 1793 its operation consisted merely of large-scale experiments performed to perfect the several stages of the process. In July 1793 the impossibility of obtaining sulfuric acid amid wartime shortages forced Leblanc to shut down. Throughout the year of the Terror, he worked with revolutionary saltpeter in Paris. On 29 December 1793 (9 nivôse an II) the Committee of Public Safety named him to the Régie des Poudres to assist Champy, LeFaucheux, and Dufourny as fourth régisseuer. In the meantime his plant was visited and its procedures inspected, also by order of the Committee of Public Safety. A decree of 28 January 1794 (8 pluviôse an II) ordered that the revolutionary mode of war production be extended to the manufacture of alkali, and Prieur appointed a commission headed by Jean Darcet to examine, evaluate, and publish all procedures and to make recommendations. Their clear and thorough report is our main source of information for the state of the industry.152

The legend of Leblanc, spread upon the annals of invention by himself and his descendants, features the patriotic innovator of a flourishing enter-prise destroyed by the Committee of Public Safety’s order to publish his discovery. He thus becomes the innocent victim of the Revolution, his rights sacrificed to the war effort, he himself compromised and excluded from his own factory because of tainted capital provided by the Duc d’Orléans. Betrayed by his scientific colleagues, he is ruined by competitors who take advantage of his patriotism to secure a commanding lead in exploiting his own process. The benefactor of his country, broken by its ingratitude, he dies by his own hand in 1806, having won for his pains only a pathetic place in the martyrology of inventive genius.

Leblanc did commit suicide, but the story has no other substance. He was a clever chemist but nothing of an entrepreneur. Berthollet and Fourcroy made every effort to protect his interest and to enable him to reopen his plant. His conduct assured their failure. He made impossible conditions: forgiveness of debts, huge subsidies, a monopoly on all the sodium sulfate produced in France. Leblanc finally managed to regain title from his credi-tors in 1801, but failed to make a profit from his process. Nor did anyone else for over twenty years. Artificial soda was manufactured by that and other methods in the interval, but succeeded economically only as a by-product. Until well into the nineteenth century it could not compete as a principal object of manufacture with the importation of natural soda from Spain and the Natron Lakes of Egypt.153

Gunpowder is what finally counts in any assessment of the material effect of the revolutionary munitions program. Acceleration of production, expan-sion of yield, and modification of the physical character of the product were its main features, all pertaining rather to persons versed in the technology than to consultation of scientists, intervention of politicians, or participation by the general public. Guyton, Carny, and Berthollet did, however, give the three lectures devoted to fabrication of gunpowder that concluded the revo-lutionary course. The first lecture ended with a warning: “The effects of gunpowder can never be too terrible when it is employed against wild beasts or tyrants, but it can be fatal to those working on it if they commit the slightest imprudence, so that for their own protection discipline in the workshop must be very strict.”154

Powder mills of the Régie des Poudres fabricated their product in the classic proportions of 75 percent saltpeter, 12.5 percent charcoal, and 12. 5 percent sulfur. The machinery consisted of batteries of twelve mortars and pestles arranged six on either side of a camshaft run by water power. Weighing eighty pounds each, the pestles were fitted at the foot with shoes of copper sheathing. They delivered fifty to fifty-five strokes a minute dropping a distance of fourteen inches into mortars hollowed out of a solid block of hardwood. The charge in each consisted of a twenty-pound batch of the ingredients, which had been separately pulverized and stirred together man-ually. The composition was moistened with a pint of water before starting the mill. Pounding lasted twenty-one hours. At the end of the first hour, and every three hours thereafter, the clutch was thrown to stop the cam-shaft, and the pestles were lifted in order to allow the charge in each mortar to be stirred, transferred to the next, and remoistened. Compacting finished, the powder was spread out to dry for several days, during which it hardened to the consistency of a flat pastry. Broken into pieces manually, it had then to be crumbled and grained or corned by pressing the powder gently with a small wooden pestle through a succession of two sieves made of sheep-skin stretched on a wooden frame. The holes punched in the first were about an eighth of an inch in diameter, and smaller in the second. The granulated gunpowder was then further dried and the dust sifted out by shaking on a strainer of cloth. The dust, which might amount to 20 percent or 30 percent of the original weight of powder, had to be collected, compacted, and recycled through the graining stage. Depending on the weather, which deter-mined the time for drying, fabricating a batch of gunpowder in the classic manner required up to a week.

Our most detailed contemporary account of the technology comes from two officials who had served under Lavoisier and whose careers in the Gun-powder Administration spanned the entire revolutionary and Napoleonic era.155 While Bottée and Riffault pay tribute to the élan of popular involvement in the munitions crisis of 1793–94, their tone is deprecatory with respect to the techniques improvised in the emergency. They leave the unin-tended impression that it was the push of an oversupply of saltpeter rather than the pull of supplying the armies that motivated adoption of expe-ditious methods of fabricating gunpowder.

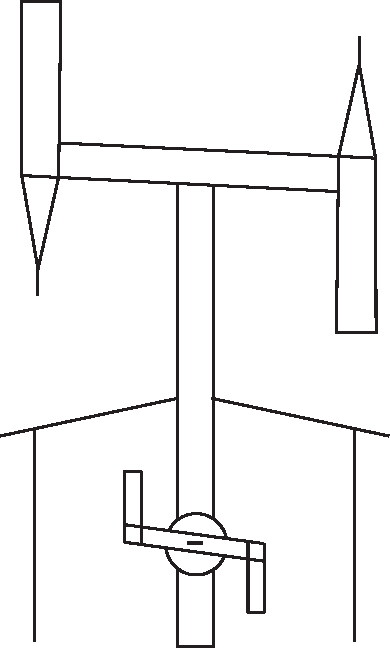

However that may have been, the established arsenals of the Régie des Poudres continued to work with the machinery at hand while the “revolutionary” procedure that Carny introduced at Grenelle dispensed with stamping mills altogether. Instead, he composed gunpowder in a centrifuge. A barrel thirty-two inches long by sixteen inches in diameter and pierced by a horizontal axle rested on two sawhorses with a crank handle at either end. The charge consisted of seventy-two pounds of separately pulverized saltpe-ter, charcoal, and sulfur in the standard proportions. With the ingredients were loaded two hundred copper balls just under an inch in diameter. Two men in two-hour shifts whirled the barrel as fast as might be for twelve hours.

The result was not the compacted composition produced by a stamping mill, but a uniform mixture of loose powder. After a little moistening it could be compressed into sheets at once. The press consisted of a pile of thirty trays, two feet by eighteen inches, with tongue-in-groove rims. A quarter-inch deep layer of powder was spread evenly onto each. A vise and lever arrangement permitted squeezing the pile hard enough to compress the layers into “galettes” or press cakes a sixteenth of an inch thick. Graining could be carried out in one of two ways. The press cakes could be spread inside a sheet folded over them and crumbled under a rolling pin. Or, and this was more efficient, a piece of coarse canvas could be placed on each tray before the powder was layered onto it. The threads would be squeezed into the press cake and grain the powder into roughly cubic morsels of close to the right size for military gunpowder. Neither method of graining left ap-preciable dust to be recycled. The whole process required a couple of days.

Carny proposed the elements of just such a system to the Committee of Public Safety as early as 15 December 1793, well before the powder mill at Grenelle had even been imagined. A commission consisting of Monge, Has-senfratz, and Berthollet reported favorably.156 Carny later put it about that, even like refining saltpeter in cold solution, the idea of dispensing with stamping mills was his own. In fact, powder mills in England had been composing gunpowder by use of millstones since the middle of the century.157 In 1781 a French engineering officer, Joseph-François Charpentier de Cossigny, on duty in the Ile de France (now Mauritius), had tried the centrifu-gal technique successfully in a colonial powder mill. His repeated attempts to break the monopoly of the Régie des Poudres and interest a succession of Ministers of the Navy and of War fell on deaf ears in the late 1780s and early in the Revolution. In April 1794 he approached Berthollet, who in-formed the Committee of Public Safety but returned a noncommital answer. At the same time Cossigny, a former nobleman, was obliged by the law of 16 April (27 germinal) to quit Paris for the provinces, whence he returned after the fall of Robespierre to win the attention of Chaptal and Champy.158

Champy, a veteran of the Régie des Poudres, developed the last of the procedures deriving from revolutionary techniques, although he perfected it only in 1796, two years after the levée-en-masse had run its course. Swiss gunpowder had long had the reputation of being the finest anywhere pro-duced. Its superior quality was thought to be a function of the physical form of the grains, which were spherical rather than angular and irregular in form. Private craftsmen, mainly in the canton of Berne, produced it in small quantities. Where known at all, their jealously guarded procedures were thought to be inapplicable to large-scale exploitation.

Champy hit upon a method of fabricating just such spherical grains. In April 1795 two powdermakers in the Agence des Poudres et Salpêtres, Barthélemy and Paillart, gave a demonstration in the new powder mill in Vincennes of a method the former had invented for compressing loose powder composed centrifugally. Instead of transferring it to a press, they moistened it and ground the paste by means of two vertical millstones turning in a wooden trough. After eight minutes, it took on sufficient consistency to be granulated by shaking it through the sieve in a brass sizing drum. Quite unexpectedly the gunpowder grains that thus formed were perfectly round, albeit too humid. There was the further, seemingly insurmountable, diffi culty that the millstones and the drum were so gummed up that they had to be laboriously cleaned after every operation.

Champy was present at the demonstration. He knew that the Swiss procedures involved a rotary method of graining, and it occurred to him that substituting a second round in the rotating barrel for the milling and sieving of the Barthélemy experiment might avoid the inconvenience of the latter while emulating the success of the former on an industrial scale. So it proved. Slightly different proportions of saltpeter, charcoal, and sulfur—75 percent saltpeter, 16 percent carbon, 9.0 percent sulfur—were mixed in the rotating barrel for about three and a half hours. The loose powder was then slightly moistened in a kneading pan with a saturated solution of saltpeter to make up the small initial deficit. Passing the pasty mixture through a sieve reduced it to globules which, and here was the original feature, were then reloaded into the barrel, without the copper balls this time around, and whirled dry for roughly half an hour. The grains of powder that emerged from this, the earliest mechanical method of corning, were perfectly spher-ical.

The advantages were considerable. Mechanical graining saved a third to a half of the time and labor required for manual processing; dampened pow-der was safe to handle; and round grains held up better during storage and shipment than did angular ones. Also, and this was apparently important, they were easier to recognize as stolen if a shipment was hijacked. The only disadvantages appeared to be that getting the degree of moisture right was pesky and that round powder, while comparable in force to ordinary powder when proved in mortars and artillery pieces, was less suitable for small arms. In October 1796 a blue ribbon commission consisting of François-Marie d’Aboville, presiding General of the Central Artillery Committee, and two members of the newly established Institut de France, Borda and Pelletier, reported enthusiastically on both the fabrication and tests of round powder run in the proving grounds at La Fère. They recommended that it replace traditional black powder and become standard issue for the armed forces. In May 1797, the government ordered fabrication of 100,000 pounds for fur-ther tests on a still larger scale.159

That never happened. The urgency of the year II was long past. Carny had returned to private industry attempting to exploit, not his own process for converting marine salt to soda, but Leblanc’s. Chaptal had gone home to Montpellier, where he accepted the chair of chemistry in the reformed med-ical faculty, the École de Santé. The Directory had replaced the Committee of Public Safety while exercising nothing like comparable authority. Munitions were again the monopoly of the Agence Nationale des Poudres et Salpetres, the old Régie redux. Bureaucratic infighting and obstruction de railed Champy’s invention and delayed the introduction of round powder until his procedures were perfected by his son fifteen years later. Meanwhile, Bottée’s colleague and co-author, Riffault, had devised modifications in the stamping mill that permitted fabricating gunpowder more speedily than by the revolutionary centrifugal method. It was a near thing, and fortunate in Bottée’s view, that Prieur had intervened to prevent junking the stamping mills in favor of rotating barrels amid the flush of enthusiasm for the latter at Grenelle.160

For production ended at Grenelle on 31 August 1794. On that day 300 of the 1,800 laborers perished in an explosion that destroyed the mill. One of them, according to contemporary accounts, had taken his pipe out of his mouth before entering and put it in his pocket with the tobacco still smol-dering. New mills using the same procedure, and separated for safety, were installed in four nearby locations, a former convent in the Bois de Vin-cennes, a onetime abbey in the Forest of Saint-Germain-en-Laye, a her-mitage in the forest of Senart near Corbeil, and a monastery close by Es-sonnes. It was months before they could be in production, however. An accident twelve days earlier had stemmed the flow of saltpeter. On 19 Au-gust, three weeks after the fall of Robespierre and the end of the Terror, an overheated drying oven started a conflagration that raced through the refin-ery of Saint-Germain-des-Prés, consuming all the stocks of saltpeter on the floor. Refining resumed after a few weeks, and continued at a reduced pace through 1795, but the zest had gone up in smoke.161

There is no dispute but that the emergency programs both of saltpeter and gunpowder met the needs of the armies in 1793–94. There is also no doubt that the example of its success, the brief stimulus of competition, and the exposure to scientific scrutiny forced a restored establishment to acceler-ate and modify its own procedures. The problem of the chemical role of the constituents in producing the detonation of gunpowder had preoccupied chemists for at least a century. Lavoisier, Berthollet, and Gay-Lussac all ad-dressed it, albeit in a somewhat peripheral manner, without successfully deriving the properties of the phenomenon from their respective theoretical standpoints. The earliest comprehensive research was the work Joseph-Louis Proust carried out in Spain. Between 1785 and 1806 he served as professor of chemistry at the Royal Artillery School in Segovia and munitions adviser to the Spanish Government. In 1812 Bottée and Riffault annotated a separate printing of the seventh in the series of nine memoirs on gunpowder that Proust published in the Journal de physique between 1810 and 1814. The chapter that concludes their 1811 treatise is a discussion of potential improvements in the technology of gunpowder. They there cite appreciatively his experiments on measuring the volume of gas produced by burning saltpeter in the presence of varying proportions of sulfur and charcoal.162

The phenomenon of detonation thus presented chemistry with problems, but so far at least chemical theory had nothing to offer the technology of gunpowder. Modifications were empirical in nature deriving, not from the chemistry of the ingredients, but from increasingly detailed scrutiny of the physical properties of gunpowder—its shape, density, the size of grains—and the relation of these variables to the design of ordnance and small arms. The influence of science in modernizing the technology of gunpowder was real but indirect, as it was in the intimately linked instance of saltpeter. In the aftermath of revolutionary exposure to the scrutiny of scientists, technicians became better educated than formerly. They conducted their work in a far more scientific fashion than they had done. They understood what they were doing in a more sophisticated manner. Scientific knowledge and behav-ior penetrated industry. Theory no doubt entered here and there, but it did not transform practice. Not quite yet.

What, finally, of the weapons to be fired by revolutionary gunpowder? On 3 November 1793 Carnot reported to the Convention on the installation of the Manufacture Extraordinaire d’Armes of Paris pursuant to the levée-en-masse of 23 August.163 The goal was to turn out 1,000 muskets a day in a city where none had ever been made and a country where the annual production had averaged a mere 50,000. Already, in just over two months, hammers were clanging on anvils and fashioning cast-iron strips into barrels in the first of 258 open-air forges, 140 to be installed on the esplanade of the Invalides, 54 in the Luxembourg garden, and 64 in the Place de l’Indivisibilité (now the Place des Vosges). The Committee of Public Safety had commandeered forges and blacksmiths from the departments of the Cher, the Allier, the Nièvre, the Haute-Saone, the Haute-Marne, and the Côte-d’Or, the nearest regions in which ironwork of good quality was produced. The strips being forged, however, had to be shipped from foundries around the country. The cost of moving trip-hammers for flattening bars at the foundry would have been prohibitive.

Moored in the Seine, five large barges held sixteen gun lathes and reaming apparatus for calibrating the bore. Alongside were millstones and grinding tools for removing spurs and polishing surfaces. All were to have been driven by water power, but the river was so low that hydraulic machines had to be supplemented by a manually operated mill in the cloister of Saint-Germain-des-Prés and by steam power on the Ile Louviers and in several suburban locations. Installed in former convents, town-houses of émigrés, and halls of the university, and hence less in evidence, were seventeen work-shops for boring priming holes, fashioning stocks, fabricating flintlocks, and finally assembling and testing muskets. Already 240 fabricators of flintlocks from the armory of Maubeuge, occupied by the enemy, were lodged in the cells of the former Charterhouse near the Observatory and at work in the cloister. Bayonettes and ramrods, however, were contracted out to private workshops.

When fully organized in the winter of 1794, the administration of the Manufacture d’Armes de Paris was staffed by bureaucrats who had run pro-curement in the former ministries of War and the Navy. They reported through the overall Commission des Armes et Poudres to Prieur and the Committee of Public Safety. By a decree of 24 August 1793, the Committee itself had already selected eight accomplished ironworkers in Paris and sent them to the armory in Charleville to learn the trade of gunsmith, and fast. They were to follow and practice every step in the fabrication of muskets and to bring back to Paris samples of all the parts at each stage in their fashioning. They would thus be prepared to direct the revolutionary workshops.

In addition the Committee requisitioned all laborers who could be spared from existing arsenals throughout the country. The sections of Paris were required to take a census of ironworkers and an inventory of their tools. Common laborers were to hire themselves out to the public workshops. Artisans who had the equipment and wished to work in their own shops under contract were encouraged to do so. The most accomplished cohort consisted of clockmakers and watchmakers in Paris, a company “known for their patriotism,” who resolved to suspend their own work and devote themselves to making the parts for which their skills were best adapted.

Piece-work was the basis of payment for all but unskilled laborers. Prices and wages had been fixed by an arbitration commission consisting of representatives of the Paris sections, of the municipality, of workers from the armory at Maubeuge, of the War Ministry, and of the Administration of the Manufacture de Paris. The chairman was Hassenfratz, whom the Commit-tee of Public Safety named on 12 November 1793 to be its commissioner and liaison with the whole enterprise.164 The manual he undertook to produce on fabrication of muskets never reached publication, however, and iron-workers from other trades had to learn the art of making guns as best they might on the job.

In the old regime, Maubeuge and Charleville in the North, Saint-Etienne in central France, and Liège in Belgium were the centers for manufacture of small arms and sporting guns. At the outset the Manufacture de Paris was to follow procedures long established there. The Committee intended, how-ever, to create incentives for inventive artisans to simplify, rationalize, and improve techniques throughout. Carnot recognized that difficulties were bound to arise and errors to occur in organizing so enormous and novel an enterprise. Persons hostile to the Revolution had denigrated the effort from the start and sought to hobble it in all sorts of ways—by bidding up the raw materials, by harassing the cadre of skilled workers, by subjecting them to conscription, by inciting in them avaricious pretentions to higher wages. For Carnot was not immune to the strain of political paranoia infecting the revolutionary leadership.

The structural fault lines proved to be real, however. A thorough and original recent study exhibits how deeply they ran both into the body politic of the labor force and into the technical problems encountered in mass-producing muskets.165 At the height of the effort in the late spring of 1794 the Manufacture de Paris employed over 5,000 workers. They had little in common, not even their grievances. Locksmiths from Maubeuge and Liège, many separated from their families and all badLy lodged, detested Paris.They evinced impatience bordering on scorn for thE clockmakers, instrument makers, and other skilled artisans assigned to learn the trade by working under them. Experts normally turned out five flintlocks in a ten-day work ueek. Novices did well to make one or two. The inequity of payment by the piece left the latter far worse off than they had ever been in their proper trades, and they demanded a daily wage.

The largest contingent of workers engaged in calibrating and finishing barrels and assembling muskets were masters, journeymen, or apprentices from the metal trades in the capital—swordsmiths, ordinary locksmiths, ornamental ironworkers, cutlers, scissor-grinders, jewelers, goldsmiths, watchmakers, machinists, and so on. Their skills were as varied as their experience. Used to their own shops, many now spent long days in impro-vised factories under the direction of armorers requisitioned from the old arsenals. Casual laborers from the sans-culotte seedbeds of the capital per-formed the merely manual tasks. None at any level were more content than working people in general to rest one day in ten instead of every Sunday.

One other thing all had in common. They could not feed their families with the revolutionary patriotism attributed to them by the governing Committee. Like laborers in the saltpeter refinery of Saint-Germain-des-Prés, they soon demanded better pay. Prices were rising despite the maximum. As early as December 1793 a riot in the Capucins workshop and walkouts in two others slowed production. The Committee of Public Safety ordered the arrest of six Maubeuge armorers responsible for the former. Late in the month Hassenfratz found that a majority of workers were absent after an attempted mutiny in a flintlock atelier at Marché-aux-Puces. Again its direc-tor went to prison. The Committee proceeded to invoke the LeChapelier law of 1791 that forbade trade associations, and decreed that all instigators of collective action among armaments workers would be jailed in irons for two years. Discontents nonetheless simmered, and rumors circulated of a general strike in the Manufacture d’Armes. Whatever their revolutionary zeal in the early months of Jacobin governance, armament workers shared with others a gathering alienation from the ruling party. Execution of leading Hébertists in March 1794 exacerbated mutual mistrust.

Despite all this, production of muskets surpassed 500 a day for most of the time between March and December 1795. The goal of 1,000 was reached briefly in September. True, about 10 percent of the output consisted of repairs to old muskets, and quality was another matter. There was nothing like the rigorous verification of calibers and testing on the range imposed by procurement officers in the old regime. Proving the completed musket con-sisted of a single firing in the ditch alongside the Arsenal. Fabrication of flintlocks, however, was the limiting bottleneck. Forging the barrel was a comparatively simple and straightforward task. The flintlock was a work of precision consisting of nine finely machined principal parts. By April 1794, the revolutionary ateliers were managing to deliver a mere handful, at most eighty a day, a fifth of the rate of production at the end of the old regime, and at an exorbitant price. Even so, repairs to old weapons accounted for most of the output.

In order to break out of the impasse, Prieur and his advisers acted on the Committee’s intention to encourage innovation. Scholars who frequent tech-nical reaches of the archives have long been tantalized to come upon fragmentary records of the revolutionary Atelier de Perfectionnement, in effect a research and development laboratory. From those papers it immediately ap-pears that Eli Whitney was by no means the first to imagine the advantage that interchangeability of parts would entail in the production of muskets. Now Alder in his recent study of revolutionary arms production has discov-ered that the notion was nothing novel by the end of the eighteenth century.166 Standardization was already a desideratum in Gribeauval’s reform of the French artillery after defeat in the Seven Years War. Honoré Blanc, designer of the musket adopted in 1777, standardized flintlocks on an experimental scale at Saint-Étienne, only to be frustrated by resistance amounting to po-tential mutiny among the established gunsmiths, each in his own small shop. In the traditional practice of their trade, master locksmiths aided by one or several journeymen fabricated all the parts for each flintlock individ-ually. They produced one at a time, adjusting the pieces to each other as they worked along. The general design was the same, but the tumbler of one might or might not fit into another.

Late in the 1780s the artillery high command installed Blanc in a laboratory workshop located in the security of the dungeon of Vincennes. In No-vember 1791 he was ready to go public and staged a demonstration in front of the Invalides. A gunsmith there assembled a number of flintlocks from parts taken at random from a bin holding enough to equip 500 muskets. Commissions of the Academy of Science and of the Artillery verified his success. The artillery officers worried, however, about the impact of such a system on the old armories, and about the social desirability of replacing skilled craftsmen with low-paid workers stamping out gun parts by rote. Whether for that reason, or out of inertia, the government took no action. Blanc ultimately elected to go into business for himself, but did not get into production in the factory he established at Roanne before 1797.167

Prieur and his scientific advisers, most immediately Vandermonde and Hassenfratz, thought to emulate and enlarge on Blanc’s achievement when the Committee of Public Safety created the Atelier de Perfectionnement by an order of 4 May 1794.168 Situated in the former townhouse of the Mont-morency family, virtually a palace at 169 rue Marc, it was a considerable undertaking. Installed were drop hammers, a rolling mill, drill presses, a stamping machine, and machine tools of various sorts. Twenty of the best locksmiths were transferred from the Manufacture de Paris, and a famous mechanic, one Glaësner, was requisitioned from Lyons. At the height of activity, in January 1795, the personnel consisted of ninety-five people. In charge was Vandermonde, who had directed the collection of machines that had been built around the legacy of Vaucanson and maintained by the Academy of Science. Assisting was Hassenfratz, who had busied himself in armaments from the time he served, first under Pache in the Ministry of War, and then under Monge in the Ministry of the Navy. At the outset, the foreman on the shop floor, with the title of Inspector, was Pierre-Bernard Mégnié, Mégnié le Jeune, who with Fortin and Lenoir was one of the three leading instrument makers of Paris.169

The initial purpose was to speed up the production of muskets and, in the words of Hassenfratz, “to simplify it in such a manner that any type of citizen can henceforth perfectly well fabricate separate pieces of muskets.”170 Mégnié describes his attempt to divide the labor of producing tumblers, hammers, springs, triggers, pans, vises, and so on by means of a proto-assembly line:

We began installing the flintlock workers by making various experiments [essais] on the labor going into the parts of a flintlock, such as passing the same piece through several hands in the sequence of the different stages in its fabrication in order to find out whether time would be saved or quality improved by restricting each worker to han-dling the same tool for the same task. But the French temperament, especially in a town like Paris, is ill suited to such regimentation [con-centration], so that our experiments did not have the result we ex-pected of them. Accordingly, since then the locksmiths are following the usual procedures until such time as we can complete the machines that will save time and improve quality by use of lathes, dies, stamping machines, screw presses, and so on.171

As in the pioneering work of Honoré Blanc, the experiment was a techni-cal success and for the time being a practical failure. The Atelier de Perfectionnement did succeed in fabricating a handful of flintlocks made of inter-changeable parts. The artisans followed the new system only under duress, however, and reverted to traditional methods there and throughout the Manufacture de Paris for most of their output, which did increase in the late spring and summer of 1794.

After Thermidor discontent was rife and discipline in the Atelier a problem. Mégnié quarreled with the administrative director, a bureaucrat called Anthelmy, and vanished under a financial cloud, as indeed he had done once before in his career. Appointed to succeed him was Francois-Philippe Charpentier, a noted machinist who had designed a horse-powered mill for boring six cannon at once, and whom Thomas Jefferson had engaged to construct a portable press. For the Thermidorean Committee of Public Safety, on which Guyton and Fourcroy served along with Prieur and Car-not, believed in the promise of research and development. The Atelier de Perfectionnement broadened its mission to making machine tools and stan-dard weights and measures for the metric system. It survived liquidation of the Manufacture de Paris. In the end, reinstitutionalization of science and technology under the Directory combined the Atelier de Perfectionnement with Vandermonde’s collection of machines in the new Conservatoire National des Arts et Métiers.