TECHNOLOGICAL DEVELOPMENTS: 1000–1700

In the history of technology, it is often stated that, after a series of startling innovations, a phase of stagnation took hold in the western world during classical times and lasted for many centuries.

Around 2500 BC technological advance ground almost to a stop and during the next three thousand years rather little progress took place.... When compared with the revolution that preceded them, these three millennia constitute a technological stagnation.1

The Greco-Roman world, and especially the Roman world, while highly creative in other fields of human activity, remained, according to this point of view, strangely inactive in the technological field.2 As regards Rome, the classic example of the water mill and the anecdote about Vespasian are always cited. The Romans knew about the water mill, but built relatively few of them and continued to make far wider use of mills employing animal or human power.3 And it is said that when Vespasian was offered the plans of machines which would have saved on human labor, the emperor, though awarding a prize to the inventor, prohibited the construction of the machines “to allow the populace to make their living.”4

Starting from observations of this kind, historians have undertaken research into the possible reasons for the “failure” of the classical world, some pointing out the overabundance of slave labor, others the type of culture and prevailing sets of values. In all likelihood, the Greek and Roman technological “failure” has been exaggerated.5 All too often we tend to identify technology with mechanics, because our civilization is essentially mechanical. Political and administrative organization, military organization, architecture and road construction, even artistic products such as frescoes, bear the marks of technology, and in none of these fields could the Greeks and Romans be considered failures.

It remains true, however, that the Dark Ages ushered in a period in which technological innovations succeeded each other at a faster pace, and with an increasing emphasis on mechanical aspects. As Samuel Lilley wrote, “It was early in the Middle Ages that men began to find a way out of the [technological] impasse.”6 Lynn White put it this way:

The millennial span of the Middle Ages has the interest of being the period during which Europe built up the self-confidence and the technical competence which, after 1500, enabled it to invade the rest of the world, conquering, looting, trading and colonizing.7

Undeniably “modern technology is the extrapolation of that of the Western Middle Ages, not merely in detail but also in the spirit that infuses it.”8

A schematic inventory of the main technological developments of the West from the sixth to the eleventh century should include:

a. from the sixth century: spread of the water mill

b. from the seventh century: spread, throughout northern Europe, of the heavy plow.

c. from the eighth century: spread of the crop rotation system

d. from the ninth century: spread of the horseshoe and of a new method for harnessing draft animals

In relation to these developments three points should be made: First, the innovations just listed were not, properly speaking, inventions. The water mill, as previously noted, was known to the Romans. The heavy plow was of Slavic origin.9 The horseshoe seems to have been known to the Celts prior to the Roman conquests.10 The new methods for harnessing horses originated in faraway China and doubts have recently been raised about the productivity gains achieved by adopting this technique.11 What the Europeans displayed from the sixth to the eleventh centuries was not so much inventive ingenuity as a remarkable capacity for assimilation. They knew how to seize on good ideas and apply them to large-scale productive activity. Perhaps this attitude was influenced by the fresh outlook of the German invaders: the pride which drove the Romans and the Chinese to describe as barbarians all those who did not belong to their empires made them unreceptive to foreign ideas. Second, the innovations mentioned above were all linked to agricultural activity and, in combination, strengthened each other. As Lynn White noted,

The heavy plow, the open fields, the new integration of agriculture and herding, three field rotation, modern horse harness, nailed horseshoes and the whipple tree had combined into a total system of agrarian exploitation by the year 1100 to provide a zone of peasant prosperity stretching across Northern Europe from the Atlantic to the Dnieper.12

Finally, some of these innovations allowed for a more effective use of horse-power. The horseshoe increased the efficiency and therefore the value of the horse. At the end of the eleventh century, a road toll in the Angers region of France taxed a horse without horseshoes at one penny and a horse with horseshoes at two pennies. At the same time, throughout Europe the breeding of horses increased markedly, and efforts were made to improve breeds by importing horses from the Muslim countries. Increasingly, oxen were replaced with horses. In Picardy (France), from about 1160 onward, references to plowing with horses become more common and by the early thirteenth century references to plow-oxen had all but disappeared from the documents. On one manor belonging to Ramsey Abbey (England) the number of oxen halved while that of draft horses quadrupled between 1125 and 1160. “The horse costs more than the ox,” wrote Walter of Henley in his thirteenth-century treatise on practical husbandry. But the horse is stronger and faster than the ox and it can do more work than an ox before tiring, and in less time. Essentially the substitution of the horse for the ox meant the substitution of a more expensive but more efficient form of capital for a less expensive but less efficient one. The story of the horse was paralleled by that of iron. The amount of iron in agricultural equipment seems to have been extremely limited before the eleventh century. With the twelfth century, the more expensive but more efficient iron implements are mentioned more and more frequently in the documents.

In the barbarous West, it was certainly with an eye to greater effectiveness in battle that the technical innovations in iron working and horse breeding had been first promoted. Eventually, in the course of the twelfth century, both the use of the horse and that of iron were handed down from the squires to the peasants. It was in the twelfth century that the plow was improved, at least in the most thriving parts of Europe. Pieces of iron were added to the wood from which it was wholly constructed in Carolingian times, thus enhancing its ability to penetrate the soil.

The use of more efficient capital led to gains in productivity. In turn, progress in productivity made it possible to adopt more costly but more efficient types of capital. At the same time there were developments in human capital with the emergence of technicians trained in the new technologies. Studies have been made of the spread of the village blacksmith in Picardy. Until the early twelfth century, no trace is found. Then thirty blacksmiths appear at random in the sources between 1125 and 1180. By the end of the twelfth century there was a smith at work in ten of the thirty villages belonging to the priory of Hesdin.13

To maintain the fertility of the land despite the severe scarcity of fertilizers, the people of the Middle Ages and of the Renaissance resorted to a very primitive form of rotation. Until modern times between a third and a half of all arable land of Europe lay fallow – a constraint which was particularly severe if one considers that the fields that were under cultivation did not yield more than three to six times the seed sown. Fitting new crops into the rotation was the technical innovation which made it possible to reduce or abandon the fallow year. When and where the innovation was first put into practice we do not know. When Philippe de Commines arrived in Lombardy with the French army of Charles VIII at the end of the fifteenth century, he remarked that some of the land he saw “never rests.” A common rotation was publicized by Richard Weston, an English traveler in Flanders in 1652; it consisted of rotating grain, turnips, and clover. These practices, however, spread only very slowly and throughout the preindustrial period land remained largely under-exploited. The Europeans of the Middle Ages and of the Renaissance proved much more innovative and successful in other fields.

Until the tenth century, mills were used in the West for milling grain. In contrast, early information on water mills in China suggests they were used not for turning simple millstones, but for the more complicated job of blowing bellows in metal work. The difference should not surprise us: in the Dark Ages the West was essentially agrarian and was both poorer and less developed than China. But as cities, trade, and manufacturing expanded in Europe from the tenth century onward, motive power derived from hydraulic energy was applied to an increasing variety of productive processes (Table 6.1). Water mills became more complicated and powerful. Perhaps as early as 822, and certainly by 1088 in Picardy and Normandy, water mills were used to prepare the malt necessary for the manufacture of beer. The adaptation of the mill to this and other types of operation involved the introduction of new mechanisms, in particular a series of vertical hammers set in motion by cams inserted on one of the axes of the mill.

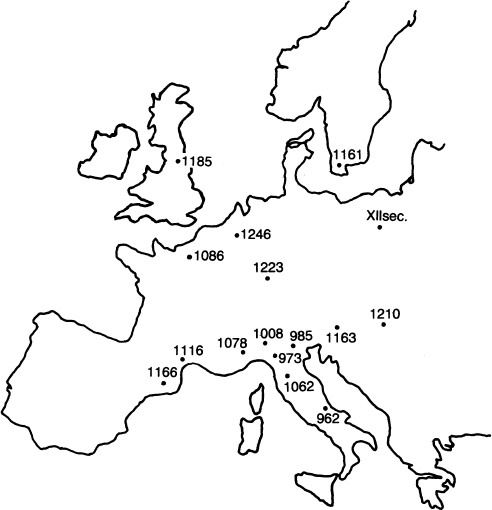

Between about 950 and about 1050, water mills were applied to cloth fulling in Parma, Milan, and Florence. By the end of the eleventh century, the new technology had reached Grenoble and Lérin and would soon reach the rest of France and arrive in England and Germany also. Water mills were used for fulling cloth in 1161 in Sköna (Sweden), at least since 1185 in England, in 1223 and 1246 respectively at Spier and Trier in Germany. The adoption of the new process revolutionized the textile industry of the time to such an extent that Carus-Wilson, describing these developments in England, labeled them “An Industrial Revolution of the Thirteenth Century.” In France the adoption of the mills sparked off violent protests among workers who maintained that the new technology was detrimental not only to the quality of the product but also to employment. These were the earliest instances of protest by labor against the adoption of labor-saving mechanical devices. In England the new technology caused the manufactures to relocate. Until the thirteenth century they had been mainly concentrated in the southeastern areas of the country; then they moved into the northwestern areas, where the availability of adequate flows of water made it possible to construct mills.14

Table 6.1 Emergence of new industrial applications of the vertical water wheel to c. 1550

| Type of mill | Date of first occurrence | Location |

| Beer | 861 | N.W. France |

| Hemp | 990 | S.E. France |

| Fulling | 962 | Italy |

| 820? | Switzerland? | |

| Iron | 1025? | S. Germany |

| 1197 | S. Sweden | |

| Oil | c. 1100 | S.E. France |

| Ore-stamping | 1135 | N. Italy |

| Tanning | 1138 | N.W. France |

| Sugar | 1176? | Sicily? |

| Cutlery (grinding and polishing) | 1204 | N.W. France |

| Saw | 1204 | N.W. France |

| Mechanical bellows | 1214 | Styria |

| Mustard | c. 1250 | S.E. France |

| Poppy | 1251 | N.W. France |

| Paper | 1276 | N. Italy |

| Mine-pumping (chain type) | 1315 | Moravia |

| Mortar | 1321 | S. Germany |

| Turning (lathes) | 1347 | S.E. France |

| Pigment (paint) | 1348 | N.W. France |

| Blast furnace | 1384 | Belgium |

| Pipe-boring | c. 1480 | S. Germany |

| Rolling and slitting | 1443 | Cent. France |

| Wire | 1351? | S. Germany |

| 1489 | S. Germany | |

| Gem-polishing | 1534 | N.W. France |

Source: Bradford B. Blaine, “The Application of Water-Power to Industry during the Middle Ages” (Ph.D dissertation, University of California, Los Angeles, 1966).

There is evidence of the use of water mills in the production of iron in Styria in 1135, in Normandy in 1204, in Southern Sweden in 1197, and in Moravia in 1269. In Normandy, in 1204, a mill was used to drive wood saws. Mills were used in the manufacture of paper at Fabriano in 1276, at Troyes in 1338, and at Nuremberg in 1390. By the late fifteenth century any large western European city could be pictured much as a mid-sixteenth-century traveler described Bologna (Italy). He told of a sluice from the river Reno that provided water power

The spread of the fulling mill in various regions of Europe. Paolo Malanima.

Source: The Economist, London.

to turn various machines to grind grain, to make copper pots and weapons of war, to pound herbs as well as oakgalls [for dyeing], to spin silk, polish arms, sharpen various instruments, saw planks.15

By the thirteenth century water mills in the West had wheels 1 to 3.5 meters in diameter with a corresponding 1 to 3.5 horsepower. By the seventeenth century it was possible to make wheels 10 meters in diameter. The Italian water mills used in the production of silk thread were not only extremely complicated but also monstrously large pieces of machinery. However, the majority of the mills were still built with wheels 2 to 4 meters in diameter. Builders preferred to increase the number of wheels rather than deal with all the complicated technological problems involved in the concentration of energy on one single wheel.

The story of the water mill runs parallel to that of the windmill. When the windmill first appeared in Persia, possibly in the seventh century AD, it was mounted on a vertical axle and appears to have been used mostly for irrigation purposes. The Chinese became acquainted with the Persian mill in the course of the thirteenth century AD and soon adopted it. As far as we know, the windmill first appeared in Europe at the end of the twelfth century in Normandy and in England. Windmills are mentioned in 1204 in Picardy, in 1237 in Tuscany, in 1269 in Burgundy, in 1259 in Denmark, in 1274 in Holland. The tradition persists that the windmill was brought back to Europe by the Crusaders. The European windmill, however, displays some originality. While the oriental mill had sails mounted on a vertical axis, the European mill had sails mounted on a horizontal one. It appears that someone brought back from the Middle East not a description of the local windmills, but the idea of harnessing wind energy and that the European craftsmen then devised a totally new contraption. Originally the western windmill was mounted on a heavy post and the mill had to be turned to face into the wind. This limited the size of the mills. By the fourteenth century, however, the tower mill had been developed; in this type of mill the building and the machinery remain stationary; only the top rotates to face the sails into the wind. This innovation allowed the erection of much larger and more powerful units. The sails had to be turned into the wind manually, but this job was later made easier by the introduction of cranks and gears. Finally, in 1745, Edmund Lee invented the fantail, a device which held the sails into the wind automatically, probably the earliest example of automatic control in machinery.

The Winged Mill. An engraving by Johannes Stradanus (1523–1605). The caption reads “The winged mill which now wants to be driven by the winds is said to have been unknown to the Romans.” In this Flemish setting are shown both types of windmills, the post mills and the tower mills. New York Public Library.

Many tower mills could generate as much as 20 or 30 horsepower. Thus the windmill was a more powerful motor than the water mill. But its spread was severely restricted by geography and climate. This explains why, although windmills became characteristic landmarks in some areas, they never became as numerous or as widespread as water mills. But like water mills, windmills, originally built for grinding grains, were later employed in an increasing variety of productive processes. In Amsterdam in 1578, there were windmills used in throwing silk, printing ribbons, fulling and calendering cloth, dressing leather, extracting oil, making gunpowder, and rolling copper plates.16

The proliferation and increasing power of water mills and windmills, like the increased use of horses, made available more energy for productive uses. Unlike horses, however, the mills supplied inanimate energy. Their widespread use marked the beginning of the breakdown of the traditional world in which man had to depend for power on animal or vegetable sources of energy.17 It was the distant announcement of the Industrial Revolution.

The use of the mill in manufacturing signalled a new trend: thus far innovations had occurred only in the agricultural sector; now they increasingly began to occur in the manufacturing and service sectors. This trend was both a consequence and evidence of the expansion of these two sectors.

About the middle of the eleventh century the vertical loom was introduced in Flanders, and possibly in Champagne. In comparison with the traditional horizontal loom, it was claimed that the new loom increased labour productivity by three to five times and also made possible substantial improvements in the quality of production.

A Chinese reference to a magnetic pointer floating in a bowl of water dates from about AD 1040. In the late twelfth century an English Augustinian monk described a magnetized needle which he said sailors used for locating the North Star in bad weather. Somewhere in the Mediterranean region, in about 1300, the transition was made from the primitive needle-and-bowl to a self-contained instrument, the compass. The perfecting of the gyroscopic compass, the adoption of the waterclock for measuring the movement of the ship, the drawing up of naval charts with related instructions, the compilation of trigonometric tables for navigation, and the adoption of the stern rudder on the central line of the ship, made possible instrumental or mathematical navigation, which in turn made possible a greater utilization of the ship as capital. Frederic C. Lane has shown that during the thirteenth century the idle period of ships in winter was gradually shortened and that, by the last quarter of the century, a ship could complete two round trips a year throughout the Mediterranean, traveling even in winter.18

The contemporaries of Dante (1265–1321) felt that they lived in a period of great technological change. In 1267 Theodoric, Bishop of Bitonto, wrote that “quotidie instrumentum novum et modus novus solertia et ingenio medici invenitur” (“owing to the laboriousness and ingenuity of the physicians, every day a new instrument and a new technology are invented”). In a sermon delivered in Florence in 1306, Father Giordano da Pisa declared “Every day new arts are discovered.” Among the innovations of the period one should mention the spinning wheel and spectacles. About the latter, in the sermon mentioned above, Father Giordano had the following to say:

It is not twenty years since there was discovered the art of making spectacles which help you to see well, and which is one of the best and most necessary in the world. I myself saw the man who discovered and practiced it, and I talked with him.19

At the beginning of the fourteenth century came the first clocks and the first firearms. The fourteenth century also saw the invention of canal locks.

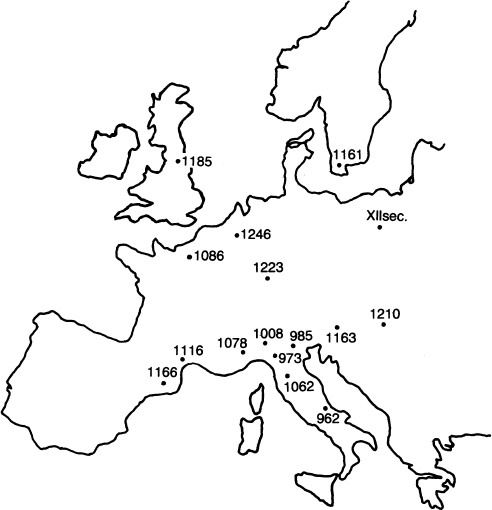

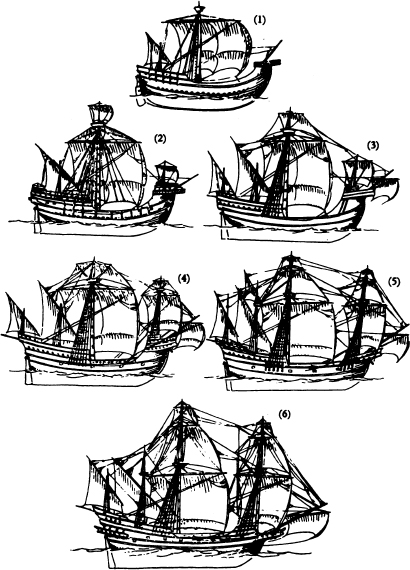

The shipwrights of ancient Greece, of ancient Rome, and of the Vikings would build a hull by attaching each plank laboriously to the plank below it; only after the shell was complete were ribbing and braces inserted. By the later Middle Ages, European shipwrights were building ships skeleton-first, making a vast saving in both time and labor. Exactly when and where the transition first took place we do not know. It was, in any case, just the first in a remarkable series of technological innovations. In the course of the fifteenth century the full-rigged ship was developed. This type of ship combined the best of both the northern and the southern European traditions. The hull was carvel-built, but the greatest innovation was in the rigging. By the ninth century the problem of shifting the sail spar over the mast during tacking, which had prevented the Romans from building larger ships using fore-and-aft rigging, had been solved, and larger merchant ships were fitted with lateen sails. Thus equipped, a ship could sail 60–65 degrees off the wind. This marked a major advance in ship performance. A full-rigged ship carried three masts, the fore- and mainmasts with square sails and the mizzenmast with a lateen (triangular) sail. With this combination, the square sails could be made large, while the lateen sail made sailing close to the wind possible. As time went on, more sails were added, and the big, bulging mainsail which was characteristic of the early caracks was divided into several smaller square sails – a change that made the canvas stand flatter and the ship better able to beat to windward. To understand fully the importance of these developments, one must see them against the background of the chronic shortage of energy which thwarted the activity of preindustrial people. The full-rigged ship enabled the Europeans to harness the energy of the wind over the seas to an extent inconceivable in previous times.

The development of ships’ rigging, 1430–1600. (1) c. 1430, (2) c. 1450, (3) c. 1500, (4) c. 1530, (5) c. 1560, (6) c. 1600.

Source: Unger, The Ship in the Medieval Economy.

Eighteenth-century English merchant vessel. This type of ship generally ranged in size from 150 to 250 tons: the crew would vary from 15 to 25 men, plus the captain. The ships might be armed with anything from 15 to 20 cannon. This was the most common type of vessel in the merchant navies of seventeenth-century Europe.

| vela latina: lateen sail | gabbia: topsail |

| bonetta: stun-sail | maestra: mainsail |

| albero di mezzana: mizzenmast | parrochetto: fore-topsail |

| cassero di poppa : poop deck | trinchetto: foresail |

| casseretto: deck cabin | scialuppa: lifeboat |

| ponte di coperta : upper deck | alloggi: quarters |

| pala del timone: rudder blade | stiva principale: main hold |

| cabina principale: main cabin | albero di trinchetto: foremast |

| ruota del timone: helm | coltellaccio: studding sail |

| cambusa: galley | bompresso: bowsprit |

| DOTAZIONl DI BORDO: SHIP’S OUTFIT | vela a tarchia: spritsail |

| albero di maestra: mainmast | |

| rostro: cutwater |

The economic consequences were immediately felt. Full-rigged ships no longer had to wait for only the most favorable breeze, and consequently the elapsed time of voyages diminished. Since the sail area could be increased and more energy exploited, the size of vessels grew and their carrying capacity rose until the middle of the sixteenth century,20 and costs were correspondingly reduced. Eventually the development of the Dutch fluyt (see p. 258) brought to a stop the growth in size of cargo ships, well below the technically feasible maximum of over 2,000 tons. The fluyt showed that the optimum tonnage for intra-European and for many extra-European trades in the seventeenth and eighteenth centuries was in the range of 300 to 500 tons. Ships in Europe did not grow much above that tonnage until after 1800.

While naval construction was progressing, more sophisticated techniques of open-seas navigation were being developed. By 1434, the Portuguese, who had succeeded in rounding the formidable and feared Cape Bojador on the west coast of Africa, had developed systematic knowledge of the winds in the Atlantic. Before 1480 they learned to calculate latitude by converting, with the help of declination tables, the heights of the sun or the North Star over the horizon. The quadrant for measuring latitude must have come into use in about 1450, and by 1480 the astrolabe was also in use.

Navigation was anything but a peaceful occupation in those days, and ships carried ordnance for both defensive and offensive purposes. Traditionally, naval guns were made of bronze, and in the course of the sixteenth and seventeenth centuries noticeable progress was made in the casting of bronze. Beginning in the middle of the sixteenth century, however, England first, and then Holland and Sweden, developed the technique of casting iron guns, which were much less expensive than bronze cannon. Thus it became possible to put more guns aboard ships at lower expense.

The combination of innovations and progress in the techniques of naval construction, navigation, and armament production provided a basis for Europe’s expansion overseas. And that changed the course of world history. As Lynn White put it: “The bursting of Europe’s oceanic boundaries at the end of the fifteenth century is one of the central events in history. It was made possible by a long and ingenious series of Medieval and Renaissance improvements in shipbuilding and the nautical arts which were entirely empirical. The majestic result is the measure of the effectiveness of such empiricism.”21

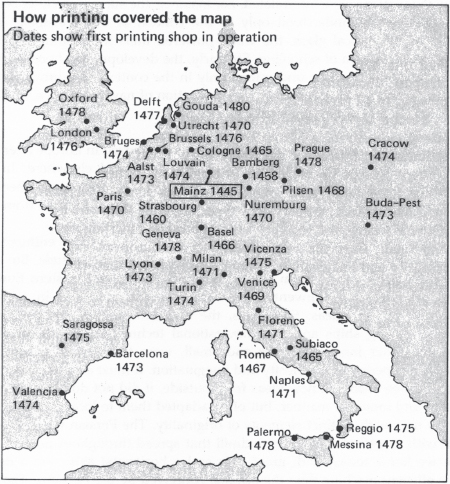

Another revolutionary technological innovation of the fifteenth century was heralded by Gutenberg’s printing of the Bible with movable characters. Before that event books were so expensive that only a few wealthy people could afford to own them. In Spain in around 800, a book cost about as much as two cows. In Lombardy between the end of the fourteenth and the end of the fifteenth century the average price of a medical book equaled the living costs of an average person for about three months, and a law book cost as much as such a person’s maintenance for one year and four months.22 This helps to explain why in 1392 the Countess of Blois, wife of the Baron of Castellane, on bequeathing to her daughter a parchment manuscript of the Corpus Juris, expressly stipulated that the daughter should marry a jurist so that the valuable treasure would come into the right hands. As long as books remained so outrageously expensive it was unlikely that literacy would become widespread. The introduction of movable type marked a new era. As the full-rigged ship opened up vast new geographical horizons to the Europeans, so the press with movable characters opened up vast new horizons and opportunities in the fields of knowledge and education. The new invention spread rapidly through Europe and beyond (see map opposite).

Source: The Economist, London.

The spinning wheel was known in China as early as the eleventh century. In Europe it appeared in the course of the twelfth century. The spinning wheel is the earliest known application of belt-driven transmission. Its use in the production of cloth in western Europe raised productivity by a factor of two or possibly three.

These were a few of the innovations that emerged during the Middle Ages and the Renaissance. They formed part of a broader process of innovation. More often than not the process of innovation advanced in small steps and through numerous minor experiments, by the gradual accumulation of small improvements rather than by sudden eruptions of invention. The approach was always empirical and unsystematic. It was only after the Industrial Revolution, with the emergence of modern science and the controlled experiment, that the essential character of this process changed. Many innovations were interrelated. For instance, the success of Gutenberg’s invention can be understood only in the context of the availability and spread of the optical glass, the water-powered mills for pulping rags for paper, and a system of schooling. Similarly, the development of ocean navigation techniques can be understood only in the context of improved shipbuilding technology, advances in the production of naval ordnance, and the spread of literacy among sea captains.

As noted above, many of the innovations which occurred in Europe after the eleventh century were adaptations of ideas developed elsewhere. In all likelihood the windmill was a Persian invention; the spinning wheel, a Chinese invention; the Europeans learned how to use the compass from the Arabs; gunpowder, in all probability, was a Chinese invention.

Europe always proved extraordinarily receptive, and the enthusiastic curiosity of a Marco Polo is evidence of this open-minded attitude. But this is not the whole story. From the twelfth century onward, western Europe developed an original inventiveness which manifested itself in a rapid crescendo of new ideas. Spectacles, the mechanical clock, artillery, new types of sailing ships and new navigational techniques, together with a thousand other innovations big and small, were the original product of European experimental curiosity and imagination. It must also be noted that when Europe absorbed new ideas from outside, it did not do so in a purely passive and imitative manner, but often adapted them to local conditions or to new uses with distinct elements of originality. The Persian windmill was built with a vertical axis. The windmill that spread throughout Europe, the type we know today, with great sails and a horizontal axis, was a much more efficient machine than the original conceived by the Persians. Though the Chinese invented gunpowder, they used it mostly for fireworks. The adoption of gunpowder by Europeans was accompanied by the manufacture of firearms, the construction of which rapidly improved, so much so that, at the beginning of the sixteenth century, when the Europeans arrived in China aboard their galleons, the Chinese were astounded and terrified by western guns. Paper was invented in China, and its manufacture spread to the Muslim Empire in the course of the eighth century, probably after the Arabs conquered the city of Samarkand in AD 753. In about AD 793 the first paper factory was set up in Baghdad and by AD 1000 bound books made of paper circulated widely in different parts of the Muslim Empire. The Byzantines, typically conservative, never learned how to manufacture paper. The Europeans learned the technique during the thirteenth century. The appearance of the first paper factories at Xátiva and at Fabriano represented the transplantation into Europe of an idea born elsewhere. But while the production of paper outside Europe remained at the level of manual production, it is typical that, in the West, the pulp was processed by machines driven by water mills. Printing was invented by the Chinese, but by the end of the twelfth century the Europeans had turned it into an extremely efficient mass production process.

One of the original features of western technological development after the twelfth century was the increasing emphasis placed on the mechanical aspects of technology. There was a real passion for the mechanization of all productive processes. In the Forez by 1251, there existed a mill to grind mustard, and by the end of the Middle Ages mechanical clockwork had been successfully applied to the roasting of meats. The basic reason for this attitude is not easy to grasp. One may argue that the shortage of labor brought about by repeated epidemics favored the adoption of labor-saving devices, but a phenomenon by its nature so complex can scarcely be reduced to naïve and simplistic determinism.

Necessity explains nothing; the crucial question is why some groups respond in a particular way to needs or wants which in other groups remain unformulated and unfilled. The case of the mechanical clock is particularly instructive.

From earliest antiquity man had created a variety of devices to solve the problem of measuring time. The sundial was the first solution, followed by the clepsydra, or water clock. Occasional use was also made of sticks of combustible material (incense or wax), properly calibrated, which marked the passage of time while burning. The Europe of the Dark Ages inherited these techniques without adding new ones. But at least from the thirteenth century onward, there were people in Europe who sought a mechanical solution to the problem. In 1271, Robertus Anglicus reported such efforts but acknowledged that the solution had not yet been found. A few decades later, however, mechanical clocks rang the hours on the bell towers of St Eustorgio and St Gottardo in Milan, and of the Cathedral of Beauvais. About the middle of the fourteenth century Giovanni De’ Dondi produced a mechanical masterpiece which marked the passing of the days, the months, the years, and the revolutions of the planets.

It is very likely that the mechanical solution to the problem of how to measure time was discovered in northern Italy. It has been argued that the invention of the mechanical clock came in response to the European climate because in winter the water in the clepsydras froze and overcast skies often rendered sundials useless. Such an explanation exemplifies the kind of simplistic determinism criticized above. The earliest mechanical clocks kept time so imperfectly that they had to be continually adjusted, the corrections being made by “clock governors” who turned the hour hand (the minute hand appeared only a good deal later) backward or forward precisely on the basis of sundials and water clocks. The first mechanical clocks cannot therefore be regarded as substitutes for sundials and water clocks.

Why Europeans produced the mechanical clock is much more subtle. Some years ago P.G. Walker wrote:

Because we see the machine reshaping society and changing man’s habits and ways of life, we are apt to conclude that the machine is, so to speak, an autonomous force that determines the social superstructure. In fact, things happened the other way around.... The reason why the machine originated in Europe is to be found in human terms. Before men could evolve and apply the machine as a social phenomenon they had to become mechanics.23

The men of the thirteenth century thought of measuring time in mechanical terms because they had developed a mechanical outlook of which mills and bell ringing mechanisms were clear evidence. Clocks spread rapidly throughout Europe, but production was not limited to clock faces, hands, and motors. On public buildings, as in Basel and Bologna, or inside churches, as in Strasbourg and Lund, extremely complicated clocks were constructed. Often, telling the time was almost incidental, accompanied as it was by the revolutions of the stars, and by the movements and pirouettes of angels, saints, and Madonnas. These contraptions were both the result and the evidence of an irrepressible taste for mechanical achievements. This taste took extreme forms during the Renaissance and had practical results. Efforts were directed at replacing factors of production (e.g. labour) that were in short supply while at the same time increasing productivity. In 1402 the managers of the Fabbrica del Duomo in Milan studied proposals for a stone-cutting machine which, with the help of a horse (costing 3 shillings a day), would do work for which four men (at a wage of 13½ shillings per man per day) would otherwise be needed. A few years later, the same managers studied the plans for another machine – to transport marble – which was also designed to reduce the labor force normally required.24

The constant and generalized preoccupation with machines and mechanical solutions had a duel series of consequences. On the one hand, clear productivity gains were achieved in a number of productive sectors. On the other hand, a cumulative process was set in motion whereby the more the machine was studied the more it reinforced people’s mechanical outlook. Books on mechanics proliferated in the course of the sixteenth and seventeenth centuries. More significant than that, a mechanical outlook began to pervade such improbable fields as art and philosophy. While the artists of the Far East delighted in painting flowers, fish, and horses, Leonardo da Vinci and Francesco di Giorgio Martini were obsessed with machinery. Philosophers came to regard the universe as a great piece of clockwork, the human body as a piece of machinery, and God as an outstanding “clock-maker.”

If, at the time of the Scientific Revolution, the leading branch of learning was mechanics, if the very characteristic of the Scientific Revolution was, as has been said, the “mechanization of the world view,” all this was not a new development unrelated to previous events; on the contrary, it was the logical consequence of a mental outlook which had taken centuries to develop. And we, with our obsession for computers, mechanical gadgetry and mathematical models, represent the final outcome of a centuries-long development.

The dominant theme of the Greco-Roman and the oriental conceptions of the world was that of harmony between man and nature – a relationship that presupposed the existence of irresistible forces in nature to which man was compelled inevitably to submit. The myths of Daedalus, Prometheus, and the Tower of Babel clearly indicated the fate of those who attempted to reverse the man-nature relationship by asserting man’s predominance. When the inhabitants of Cnidus asked the oracle of Delphi for its opinion on the timeliness of digging a canal bisecting the isthmus of their peninsula, the oracle replied: “Jove would have created an island instead of a peninsula if that had been his wish.” Technological progress was thought likely to bring more or less dubious material benefits but it was also feared as a possible source of dangerous disturbances to existing political, social, and natural equilibria. It might be a force for good but it might equally well turn out to be a force for evil. The position of the Greeks and Romans was to favor the defensive use of technai in relation to technai itself. This involved caution, restrictions, and fear, and it made the bearers of techne socially vulnerable.

The medieval world somehow managed to break with this tradition. Still too technically backward to dominate nature to any appreciable degree, the Europeans of the Middle Ages found refuge in the world of dreams. The “animism” of the ancients and of the orientals was replaced by the cult of the Saints. The saints were not devils or demons; they were men – men in the grace of God, but still men whose features everyone could see on the portals of, or inside, the churches. Their features were like those of all other men. The saints did not recline in the hieratic immobility of oriental holymen, nor did they find amusement like the Greek gods in punishing men for their audacity. On the contrary, they were always at work to overcome the adverse forces of nature: they conquered diseases, calmed stormy seas, saved harvests from storms and locusts, softened the fall for anyone who leapt into a ravine, put out fires, buoyed up the drowning, and guided ships in danger. The saints practiced what the commoners dreamed of: they harnessed nature and, far from being condemned for doing so, they lived pleasantly in Paradise in the company of God. Harnessing nature was not regarded as a sin; it was a miracle. A belief in miracles is the first step toward making them possible. Inadvertently, medieval man moved in the direction of making miracles less the result of the action of saints and more the result of his own actions.

Easy explanations of complex historic phenomena charm people, precisely because they are easy and, therefore, reassuring. The explanation pleases, the problem irritates. And yet the explanation is often unattainable, while the problem remains the only valid thing.

It is tempting to say that the Greco-Roman world failed to develop technologically because there were too many slaves, and that medieval and Renaissance Europe produced notable technological developments in reaction to the scarcity of labor caused by epidemics. But the factors at play were much more numerous and complex. What has been mentioned here, albeit briefly, regarding mental attitudes and aspirations should serve to warn against easy explanations, though it does not pretend to offer alternative solutions. Europe’s receptive attitude, the substitution of the cult of the Saints and the faith in miracles for animism, the rise and spread of a mechanical outlook – these and similar things are not explanations but only problems in a wider and more intricate context. Why was western Europe so receptive and favorable to change? Why did medieval Europe obsessively dream of mastering nature? Why was it looking for mechanical solutions? We do not know.

So far we have referred to western Europe as a single entity, but at various periods some areas were more innovative than others. From the twelfth to the fifteenth century the Italians were in the forefront not only of economic development but also of technological progress. In the sixteenth and seventeenth centuries this primacy passed to the English and the Dutch. A key focus for analysis, then, is the diffusion of technological innovations from their area of origin to other areas, and the migrations of technicians.25

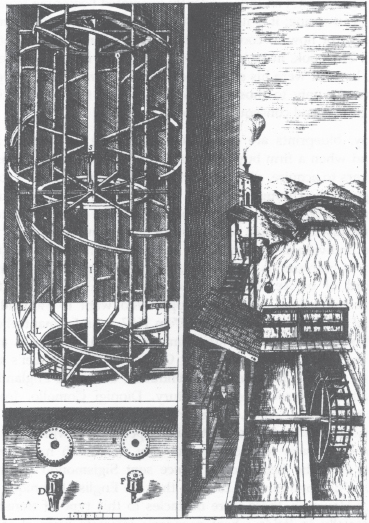

In 1607 Vittorio Zonca published in Padua his Nuovo Teatro di Machine et Edificii, which included, among numerous engravings of various contraptions, the description of an intricate water-powered machine for throwing silk in a large factory. Zonca’s book went into a second edition in 1621 and a third in 1656, and still the details of the mill were considered a state secret. In Piedmont (Italy), where silk production played a major economic role, law regarded “the disclosing or attempting to discover” anything relating to the making of the said engines a crime punishable by death. G.N. Clark has shown that a copy of the first edition of Zonca’s book had been on the open-access shelves of the Bodleian Library from at least as early as 1620. Yet it was not until nearly one hundred years later that the English succeeded in building a mill for the throwing of silk, and then only after John Lombe, during two years of industrial espionage in Italy, “found means to see this engine so often that he made himself master of the whole invention and of all the different parts and motions.”26 Critics of this story have pointed out that John Lombe’s journey was really unnecessary because the silk-throwing machines could have been constructed with the help of Zonca’s book. They are perfectly right when they point out that Zonca’s engravings are in fact more revealing than Lombe’s own patent specification. But they miss the point. The point is, as Oakeshott wrote:27

A water-powered throwing mill. Engraving from Vittorio Zonca’s Nuovo Teatro di Machine et Edificii published in 1607. The machine was used to twist filaments of raw silk into long threads that were strong enough to weave. Master throwers owned the machine, employed eight to ten journeymen, and worked for silk merchants on a piece-rate basis.

It might be supposed that an ignorant man, some edible materials and a cookery book compose together the necessities of a self-moved activity called cooking. But nothing is further from the truth. The cookery book is not an independently generated beginning from which cooking can spring; it is nothing more than an abstract of somebody’s knowledge of how to cook: it is the stepchild, not the parent of the activity. The book, in its turn, may help to set a man on to dressing a dinner, but if it were his sole guide he could never, in fact, begin: the book speaks only to those who know already the kind of thing to expect from it and consequently how to interpret it.

Even today, blueprints are considered inadequate to transmit full information, and when a firm buys new and elaborate machinery it sends some of its workers to acquire, directly from the manufacturers, the knowledge of how to operate it. Through the ages, the main channel for the diffusion of innovations has been the migration of people. The diffusion of technology has been mostly the product of migrations of human capital.

Cases of individuals who migrated temporarily in order to acquire information about innovations and to bring it back to their own countries were not unheard of before the Industrial Revolution. Nicolaes Witsen, in a passage quoted below, mentions people who went to Holland to study “economical building in the dockyards.” In 1657, John Fromanteel of London went to Holland to learn the art of making pendulum clocks as recently invented by Huygens and made by Coster: on Fromanteel’s return his family firm was the first to make pendulum clocks in England.28 In the second half of the seventeenth century, Dionigi Comollo, from Como, according to his own words, “spent many a year in Amsterdam and other main towns of Holland where, at [his] expense and with great care [he] learned how to make woollens in the way the Dutch had newly developed.”29 In 1684 the Republic of Venice sent Sigismondo Alberghetti, Jr, gunsmith, to England in order to learn the new English technique of casting ordnance.30 However, there were obstacles to this type of transmission of skills. Especially in fields where economic interests were at stake, communities and guilds were intractably jealous of their technologies and usually sought to prevent their secrets from being divulged.

Innovations spread chiefly through the migration of skilled craftsmen who settled in foreign countries. For the sixteenth and seventeenth centuries there is plenty of literature about the French Huguenots and the Flemish Protestants who brought advanced technologies to England, Sweden, and other parts of Europe and set up new trades. The dramatic story of the religious refugee has such an appeal that one is often inclined to forget that not all migrations of skilled workers and innovations in the sixteenth and seventeenth centuries can be ascribed to religious intolerance. A number of the Walloons who took to Sweden the new techniques of casting iron cannon in the first part of the seventeenth century were Catholic, and they were for a time allowed to retain their faith as well as maintain priests in their communities.31 Although most of the French clockmakers who moved to London in the course of the seventeenth century were Huguenots, John Goddard, of Portsoken Ward, was known as a “papist.”32 The Swedish and Flemish craftsmen who moved to Russia in the seventeenth century and introduced the technique of casting iron guns were certainly not motivated by religious preoccupations.33 Paul Roumieu, who reintroduced the art of watchmaking into Scotland, was traditionally supposed to have been one of the refugees driven out of France as a consequence of the Edict of Nantes. It has now been established that he had moved to Edinburgh at least eight years before the persecution of 1685.34

This brings us to the question of the forces behind the mobility of skilled labor in preindustrial Europe. As is customary in such cases, one can distinguish between “push” forces and “pull” forces. On the “push” side there was the long, grim list of misfortunes that made life unbearable for the preindustrial craftsman: famines, plagues, wars, taxes, job shortages, and political and religious intolerance. For the average worker life was pretty miserable at best. A small extra dose of misfortune was more than enough to make it unendurable. The attachment of preindustrial workers to a given place was directly proportionate to the quality of their living conditions.

Governments and administrators were perfectly aware of the situation and knew that the loss of able craftsmen had grave consequences for the economy. Decrees forbidding the emigration of skilled workers were quite common in the late Middle Ages as well as in the sixteenth and seventeenth centuries. Special attention was given to certain categories of workers whose activity was considered either essential for the safety of the state or particularly important for the economy. The Venetian government, for instance, strictly prohibited the emigration of caulkers, and from a document of 1460 we learn that a caulker who left Venice risked six years in prison and a 200-lire fine if apprehended.35 In those days, however, the effectiveness of governmental control was, of necessity, rather tenuous. The repetitious insistence with which the governments issued decrees threatening penalties for workers who fled the country and refused to return provides conspicuous evidence of the inefficiency of control over emigration. Typically enough, impotence bred ferocity. In 1545 and 1559 the Grand Duke of Florence decreed that workers in the brocade trade who had left the town should return to it. Special favors were announced for those who would comply with the order, and penalties were threatened for those who did not. But in all likelihood the results were unsatisfactory: in 1575 the Grand Duke authorized “any person to kill with impunity any of the above-mentioned expatriates” and posted a reward of 200 scudi for each expatriate craftsman who could be brought back “dead or alive.”36

The circumstances which “pulled” craftsmen into a given area ranged from employment opportunities to political peace or religious tolerance. Quite often there was also a conscious policy on the part of governments. Administrators not only threatened emigrants but also devised ways to attract foreign craftsmen, especially those who could bring them new industries or new techniques. In the twelfth and thirteenth centuries the champions of the Drang nach Osten attracted Dutch peasants into eastern Europe with generous grants of good virgin land. As mentioned above,37 in 1230–31 the Commune of Bologna (Italy) attracted 150 artisans with their families and assistants, granting them all kinds of privileges and aid in order to develop the woollens and silk industries. In 1442 the Duke Filippo Maria Visconti brought to Milan (Italy) a Florentine craftsman who was supposed to start “some special work of silk.” The Duke paid a monthly subsidy, exempted the craftsman and all his employees from tax and waived import duties on all raw materials required by the enterprise.38 Colbert was generous in granting privileges, land, and titles to Abraham and Hubert (Jr) De Beche, when he invited them to France to set up an iron industry on the model of that of Sweden.39 On occasion, it was considered legitimate to resort to force, and craftsmen were literally kidnapped. An inquiry by the Bergskollegium in the 1660s into the emigration of Swedish iron masters revealed that a number of workers sailed from Nyköping believing that they were being taken to some other part of Sweden. Instead they were brought to Lübeck, from there to Hamburg, and finally to France, where Colbert was determined to start an iron industry on the Swedish model. A few workers escaped; one of them, Anders Sigfersson, returned to Sweden in 1675.40

Of course, it is one thing to lead a horse to water; it is quite another to make it drink. The fact that a person or group of persons with knowledge about an innovation moves into a geographic area does not ensure that the innovation will actually take root in the new environment. It depends on a number of circumstances. The personality of the migrants has to be taken into account as well as their number in relation to the size of the host society. No less important is the nature of the host environment. Many Italian technicians moved to Turkey in the course of the fifteenth, sixteenth, and seventeenth centuries, taking techniques and ideas with them. Yet no appreciable innovations took root in Turkey. The refugees who moved to England, on the other hand, found extremely fertile ground. The Huguenot clockmakers who taught the English the art of clock- and watchmaking, the refugees from the Low Countries who brought the techniques of the “new drapery” to Norwich, the French glassmakers who established the manufacture of window glass in England41 soon encountered ingenious local imitators who, by pursuing their ideas along original lines, further developed the foreign techniques and opened the way to more innovations. What makes an environment responsive or not is difficult to determine. At first sight the problem of transplanting an innovation into an alien environment might appear to be merely one of introducing new methods of production and the instruments, tools, or machines appropriate to them. But what is really involved is a particular and more profound condition which can be understood and assessed only in human and social terms.42 This notion was glimpsed centuries ago by the Dutchman Nicolaes Witsen, who wrote in his great treatise on shipping, published in Amsterdam in 1671:

It is surprising that foreigners, though they may have studied economical building in the dockyards of this country, can never practice it in their own land.... And this in my opinion proceeds from the fact that they are then working in an alien environment and with alien artisans. From which it follows that even if a foreigner had all the building rules in his head, they would not serve him, unless he had learned everything here in this country by experience, and still that would not help him, unless he should find a way to inculcate in his workmen the thrifty and neat disposition of the Hollander, which is impossible.43

As good old Nicolaes Witsen observed, it all depends on disposition. And this allows one to end this chapter, for a change, on a cheerful note. Down the centuries, those countries where intolerance and fanaticism prevailed lost to more tolerant countries that most precious of all possible forms of wealth: good human minds. The qualities that make people tolerant also make them receptive to new ideas. The influx of good minds and a receptiveness to new ideas were among the main sources of the success stories of England, Holland, Sweden, and Switzerland in the sixteenth and seventeenth centuries.