An ironworker connects a steel wide-flange beam to a column.

(Courtesy of Bethlehem Steel Company)

1

MAKING BUILDINGS

Sustainable Building Materials

Assessing Sustainable Buildings

The Work of the Design Professional

Construction Standards and Information Resources

The Work of the Construction Professional

Providing Construction Services

Trends in the Delivery of Design and Construction Services

Increasing Collaboration Among Team Members

Improving Efficiency in Production

Improving Information Management

LEARNING TO BUILD

This book is about the materials and methods of building construction. Throughout it, alternative ways of building are described: different structural systems, different methods of building enclosure, and different interior finishes. Each has characteristics that distinguish it from the alternatives. Sometimes a material is selected chiefly for its visual qualities, as in choosing one type of granite over another, selecting a particular color of paint, or specifying a special pattern of tile. Visual distinctions can extend beyond surface qualities. A designer may prefer the massive appearance of a masonry bearing wall building to that of a more slender exposed steel frame on one project, yet would choose the steel for another. Choices may be made for functional reasons, as in selecting a highly durable and water-resistant polished concrete instead of carpet or wood for a restaurant kitchen floor. Or, choices can be made on purely technical grounds, as, for example, in selecting a construction system that is noncombustible, so as to achieve a suitable level of building fire safety.

A building designer's choices are frequently constrained by regulations intended to protect public safety and welfare. Choices may be influenced by considerations of environmental sustainability. And frequently, selections are made on economic grounds. Sometimes one system is chosen over another because its first cost is less. Other times the full life-cycle costs—including first cost, maintenance, energy consumption, useful lifetime, and replacement—of competing systems are compared.

In describing the major systems of building construction, this textbook presents concerns that fall into two broad categories: building performance and building construction. Performance concerns relate to the inescapable problems that must be confronted in every building: fire; the flow of heat, air, and water vapor through the building enclosure; the small, but nonetheless important, movements of the building and its parts; water leakage; acoustical performance; aging and deterioration of materials; cleanliness; building maintenance; and so on.

Construction concerns relate to the practical problems of getting a building built safely, on time, within budget, and to the required standards of quality: sequencing of construction operations for maximum productivity; optimum use of building trades; division of work between the shop and the building site; convenient and safe worker access to construction operations; effects of weather; making building components fit together; quality testing of materials and components during construction; and much more. To the novice, these matters may seem of minor consequence when compared to the larger and often more interesting themes of building form and function. To the experienced building professional, who has seen buildings fail both aesthetically and functionally for want of attention to one or more of these concerns, these are issues that must be resolved as a matter of course to ensure a successful project outcome.

To gain a thorough knowledge of building construction, it is incumbent upon the student to go beyond what can be presented here—to other books, product literature, trade publications, professional periodicals, and especially the design office, workshop, and building site. One must learn how materials feel in the hand; how they look in a building; how they are manufactured, worked, and put in place; how they perform in service; how they deteriorate with time. One must become familiar with the people and organizations that produce buildings—the architects, engineers, materials suppliers, contractors, subcontractors, workers, inspectors, managers, and building owners—and learn to understand their respective methods, problems, and points of view. There is no other way to gain the breadth of information and experience necessary than to get involved in the art and practice of building.

In the meantime, this long and hopefully enjoyable process of education in the materials and methods of building construction can begin with the information presented in this textbook.

Go into the field where you can see the machines and methods at work that make the modern buildings, or stay in construction direct and simple until you can work naturally into building-design from the nature of construction.

—Frank Lloyd Wright, “To the Young Man in Architecture,” 1931

BUILDINGS AND THE ENVIRONMENT

In constructing and occupying buildings, we expend vast quantities of the earth's resources and generate a significant portion of its environmental pollution. Buildings account for 30 to 40 percent of the world's energy consumption and carbon dioxide gas (CO2) emissions. In the United States, buildings consume approximately 35 percent of this country's energy, 65 percent of its electricity, 12 percent of its potable water, and 30 percent of its raw materials. Building construction and operation together are responsible for roughly 40 percent of U.S. total greenhouse gas emissions and a third of its solid waste stream. Buildings are also significant emitters of particulates and other air pollutants. In short, building construction and operation cause many forms of environmental degradation and place a heavy burden on the earth's resources.

One simple definition of sustainability is building to meet the needs of the present generation without compromising the ability of future generations to meet their needs. By consuming irreplaceable fossil fuels and other nonrenewable resources, by building in sprawling urban patterns that cover extensive areas of prime agricultural land, by using destructive forestry practices that degrade natural ecosystems, by allowing topsoil to be eroded by wind and water, by generating substances that pollute water, soil, and air, and by generating copious amounts of waste materials that are eventually incinerated or buried in the earth, we have been building in a manner that will make it increasingly difficult for our children and grandchildren to meet their needs for communities, buildings, and healthy lives.

Sustainable building construction demands a more symbiotic relationship between people, buildings, communities, and the natural environment. Sustainable buildings—in both their operation and construction—must use less energy, consume fewer resources, cause less pollution of the air, water, and soil, reduce waste, discourage wasteful land development practices, contribute to the protection of natural environments and ecosystems, provide healthier interiors for building occupants, and minimize adverse social impacts.

The practice of sustainable design and construction, also called green building, continues to mature. The understanding of the interplay between buildings and the environment has deepened and standards for sustainability continue to evolve. Interest in and adoption of green building has broadened among public agencies, private owners, and building occupants. The design and construction industry has become more skillful at applying green practices, and sustainable building is becoming more integrated with mainstream practice. As a result, sustainable building performance is improving while the premium in cost and effort to design and construct such buildings in comparison to conventional buildings is declining or disappearing completely.

Sustainable Building Materials

Building sustainably requires access to information about the environmental impacts of the materials used in construction. For example, when selecting a material, the designer must ask: Does its manufacture depend on the extraction of nonrenewable resources, or is it made from recycled or rapidly renewable materials? Is additional energy required to ship the material from a distant location, or is it produced locally? Does the material contain toxic ingredients or generate unhealthful emissions, or is it free of such concerns? To enable meaningful decision making, reliable product information must be readily available to all the parties involved in the selection of materials for sustainable building design.

A series of international standards, designated as ISO 14020, distinguish three types of environmental labels that define expectations for comprehensiveness and reliability of sustainable materials and product information:

- Type I Ecolabels are independent, third-party certifications of environmental performance. Their accuracy and comprehensiveness are intended to ensure that the information provided is unbiased, relevant, and reliable.

- Type II Self-Declared Environmental Claims are provided directly by product manufacturers, without independent verification. They may also be more limited in scope than Type I labels. Type II labels may provide useful information, but users must employ their own judgment in evaluating the appropriateness of these products for a particular application.

- Type III Environmental Impact Labels provide the most comprehensive assessments of products and their environmental impacts on a comprehensive life-cycle basis. However, they do not in themselves provide environmental ratings or judgments—it is up to the user to interpret the data for this purpose. The information in Type III labels is independently verified, but the label itself may be prepared by the product manufacturer.

An example of a Type I Ecolabel is Green Seal Standard GS-11 for Paints and Coatings. Green Seal is a not-for-profit, independent organization that develops sustainability standards and certifications. For a paint or coating product to be certified to the GS-11 standard, it must:

- Meet minimum performance requirements, such as adhesion, ease of application, hiding power, washability, and fade resistance

- Be free of highly hazardous ingredients (for example, carcinogens)

- Not exceed permitted amounts for other less hazardous ingredients such as volatile organic compounds (a class of chemicals that contribute to air pollution and can act as irritants to building occupants)

- Be sold with instructions to the end user for safe application and responsible methods of disposal

By relying on this Green Seal certification, the paint specifier can easily and confidently identify environmentally responsible products from which to choose, without having to perform in-depth investigations of individual products.

Recycled materials content is an example of product information that is often provided in the form of a Type II Self-Declared Environmental Claim. That is, this information is usually reported directly by the product manufacturer, without third-party verification. This places more burden on the user of that information to determine its applicability. For example, the LEED¯ rating system (discussed later in this section) calculates recycled materials content as the sum of postconsumer content (materials recycled after use) plus one-half of preconsumer content (materials recycled during manufacturing). When relying on a Type II claim to determine recycled content for possible LEED credit, the designer must verify that the manufacturer's content claims accurately correspond to this standard's calculation method. At present, in North America, Type I and II environmental labels are the types in most common use.

An example of Type III labeling is the Western Red Cedar Association's Typical Red Cedar Decking Product Declaration. This 10-page document describes this product's material characteristics and quantifies—in detail—the environmental impacts of the product throughout its life. For example, for every 100 square feet of decking harvested, milled, trucked to the construction site, installed, maintained through its useful life, and then disposed of at the end of its life, this declaration reports the following impacts:

- 2,500,000 BTU (2600 MJ) of energy consumed

- 0.1 gallons (0.3 liters) of fresh water consumed

- 180 lb (80 kg) of nonhazardous waste generated

Additional information in the report quantifies materials consumption, global warming potential (total contribution to global warming), smog production, ozone depletion, acidification and eutrophication potential, and more. Information about the standards to which this information is prepared and independent verification of the reported results are also included. This document does not, in itself, provide an environmental rating of the product. But it can be used, for example, in comparing Western red cedar to some other decking material, such as recycled plastic decking, to assess the relative environmental consequences of choosing one of these materials over the other.

Not all sustainable product information necessarily fits neatly into one of these three label types. But considerations of comprehensiveness, independence, and relevance of information are appropriate to the review of building materials data from any source.

The Material Life Cycle

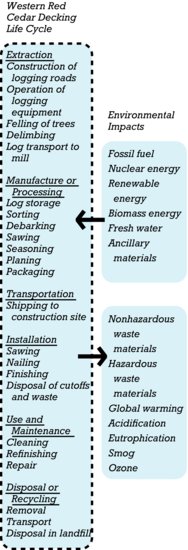

To most fully account for the environmental effects of a building material, its effects on the environment must be considered throughout its life cycle. This begins with raw materials extraction, continues with production and use, and finishes at end of life when a material is disposed of or put to an entirely new use. Such a life-cycle analysis (LCA) or cradle-to-grave analysis is considered the most comprehensive method for describing and quantifying environmental impacts associated with building materials. Through each life-cycle stage, environmental impacts are tallied: How much fossil fuel, electricity, water, and other materials are consumed? How much solid waste, global warming gasses, and other air and water pollutants are generated? The total of all these impacts describes the environmental footprint of the material. As noted earlier in this section, this type of comprehensive life-cycle analysis is an essential part of a Type III Environmental Impact Label (Figure 1.1).

Figure 1.1 Life-cycle analysis of Western red cedar decking. The underlined life-cycle stages (Extraction, Manufacture or Processing, etc.) are applicable to any building construction material LCA. The activities listed under each stage here are specific to the example of Western red cedar decking. For other materials, other activities would be listed. The right-hand column lists the types of environmental impacts associated with this material, both resources consumed (such as energy and water) and pollutants and wastes emitted (such as global warming gasses and nonhazardous waste). Though not included here, the LCA also quantifies these impacts so that one material can be readily compared with another.

The concept of embodied energy also derives from life-cycle analysis. Embodied energy is the sum total of energy consumed during the material's life cycle. Because energy consumption tends to correlate with the consumption of nonrenewable resources and the generation of greenhouse gasses, it is easy to assume that materials with lower embodied energy are better for the environment than others with greater embodied energy. However, in making such comparisons, it is important to be sure that functionally equivalent quantities of materials are considered. For example, a material with an embodied energy of 10,000 BTU per pound is not necessarily environmentally preferable to another with an embodied energy of 15,000 BTU per pound, if 2 pounds of the first material are required to accomplish the same purpose as 1 pound of the second. The types of energy consumed for each material, such as fossil, nuclear, or renewable, should be considered, as impacts differ from one energy source to another. Differences in the life span of materials must also be accounted for.

Embodied energy and other life-cycle effects may sometimes be calculated for only a part of the material life cycle. A cradle-to-gate analysis begins with materials extraction but extends only as far as when the material leaves the factory, excluding the effects of transportation to the building site, installation, use, maintenance, and disposal or recycling. In other cases, data may be reported from cradle to the construction site. Though less comprehensive, such analyses can in many cases still provide a useful basis for comparison between products. For example, for most materials, the difference in embodied energy between a cradle-to-cradle and cradle-to-construction site analysis is small, as most of the energy expenditure occurs prior to the material's installation, use, and disposal.

The concept of embodied effects can also be applied to any other measured input or output from a material life-cycle analysis. For example, embodied water refers to the fresh water consumed as a consequence of building with a particular material. Embodied carbon refers to the total carbon-related greenhouse gas emissions associated with a building material.

While life-cycle analysis represents the most comprehensive materials assessment method currently available, it does not necessarily address all environmental impacts. LCA of wood products, for example, does not capture the loss of biodiversity, decreased water quality, or soil erosion caused by poor forestry practices. These concerns are better addressed by sustainable forestry certification programs. As another example, although global warming potential is quantified in materials LCA, its ultimate consequences for ecosystems and wildlife populations are not described.

Unhealthy and Toxic Materials

Life-cycle analysis does not fully address human health impacts of materials used in the construction of buildings. For example, although LCA may describe a material's contribution to various forms of air pollution, it will not account for the increase in incidence of asthma or shortening of life expectancy that may result therefrom. To address such concerns, green building programs explicitly discourage the use of materials known to contain harmful ingredients or that generate such ingredients as byproducts of their manufacturing, use, or disposal.

As an example, historically, formaldehyde commonly has been used as an ingredient in binders and adhesives for many kinds of manufactured wood products. However, this chemical is now a recognized carcinogen and associated with a variety of additional adverse human health impacts. As a consequence, the use of materials with added formaldehyde in buildings is discouraged, and where such materials must be used, strict limits are set on acceptable formaldehyde emission levels. Lead, cadmium, and asbestos are other examples of once-common ingredients that are now discouraged or banned from use in building materials due to their toxicity. These and other examples are discussed in more detail throughout this book.

Assessing Sustainable Buildings

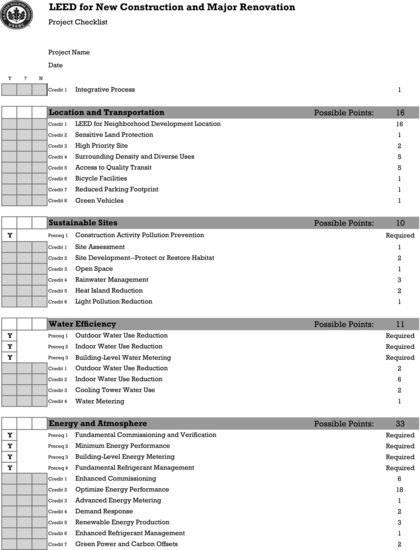

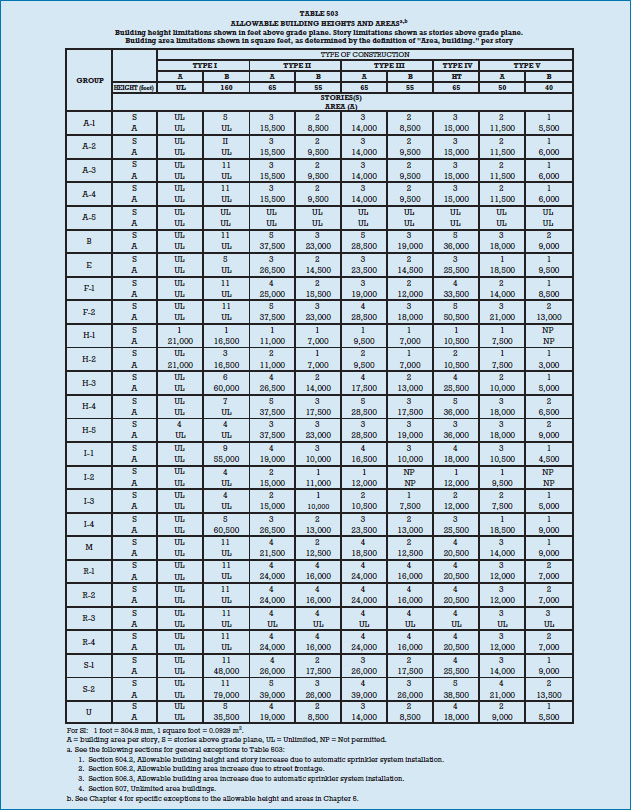

In the United States, the most widely applied system for evaluating building sustainability is the U.S. Green Building Council's Leadership in Energy and Environmental Design, or LEED¯, rating system. LEED for New Construction and Major Renovation groups sustainability goals into eight broad categories addressing areas such as site selection and development, energy efficiency, conservation of materials and resources, and others (Figure 1.2). Within each category are mandatory prerequisites and optional credits that contribute points toward a building's overall sustainability rating. Depending on the total number of points achieved, four levels of sustainable design are recognized, including, in order of increasing performance, Certified, Silver, Gold, and Platinum. The LEED rating system is voluntary. It is used when adopted by a private building owner or mandated by a public building agency.

Figure 1.2 The LEED-NC v4 Project Checklist. (Courtesy of U.S. Green Building Council.) You can download a PDF of this figure at http://www.wiley.com/go/aflblce6ne.

The process of achieving LEED certification for a building begins at the earliest stages of project conception, continues throughout the design and construction of the project, and involves the combined efforts of the owner, design team, builder, subtrades, and materials suppliers. Its successful implementation requires a high level of cooperation among all of these parties. During this process, the achievement of individual credits is documented and submitted to the Green Building Council, which then makes the final certification of the project's LEED compliance after construction is completed.

The Green Building Council has also developed related rating systems for other types of construction, including existing buildings, commercial interiors, building core and shell construction, schools, retail building, healthcare facilities, homes, and neighborhood development. Through affiliated organizations, LEED is also implemented in Canada and other countries.

A second sustainability standard, the International Living Building Institute's Living Building Challenge™, sets a more ambitious standard for sustainable building. The Living Building Challenge aspires to move society beyond making buildings that do less environmental harm, to constructing buildings that do no harm at all, or even provide benefit, to the natural environment. For example, a building constructed and operated to this standard will (when considered on an annualized basis) generate all its own energy from on-site renewable resources, consume no fresh water, and have no net carbon greenhouse gas emissions.

The Living Building Challenge consists of 20 imperatives (e.g., net zero energy or appropriate sourcing of materials), grouped into 7 broad categories, called Petals, such as Site, Water, Materials, Social Equity, and so on. For a new building to meet this standard, it must meet all 20 imperatives. There are two certification levels: “Living,” for buildings that fully meet the standard; and “Petal Recognition,” for buildings that meet minimum partial requirements. Certification occurs after a building has been operational for at least one year, when its real-life performance can be assessed.

With regard to construction materials and methods, the most relevant imperatives in this standard are found in the Materials category, including:

- Red List: Materials considered toxic or highly detrimental to the environment are entirely excluded from buildings.

- Embodied Carbon Footprint: Considered on a life-cycle basis, the building must not be a net emitter of carbon greenhouse gasses.

- Responsible Industry: Materials must meet responsible third-party sustainability standards.

- Appropriate Sourcing: Depending on material density, materials must be manufactured within certain distances of the building construction site.

- Conservation and Reuse: Materials waste must be minimized throughout all project life phases.

The Living Building Challenge can also be applied to neighborhoods, landscape and infrastructure projects, and building renovations. It is a testament to the progress of the sustainable building industry that buildings meeting this ambitious standard and achieving Living certification are now a reality.

Other green building programs and standards offer a variety of pathways to sustainable building construction, suitable to various building types, building owner objectives, and markets. The U.S. National Green Building Standard addresses residential building types, from single-family homes to multistory apartment buildings and hotels. The International Green Construction Code is a model code that puts green building standards into a legally enforceable format, useful for municipalities that wish to make sustainable construction mandatory. CALGreen is the sustainable construction code for the state of California. A variety of professional organizations and government agencies offer programs to support sustainable building, such as the 2030 Challenge, ASHRAE's high-performance building standards, and the U.S. EPA's green programs. Green Globes certifies new and existing commercial buildings in the United States, Canada, and other countries. The Building Research Establishment Environmental Assessment Method, or BREEAM, is an environmental assessment system for buildings constructed in the United Kingdom and other European countries.

Sustainable building practice is producing measurable, positive results in building performance. An evaluation of sustainable facilities completed by the U.S. General Services Administration in the first decade of this century showed reductions in energy consumption and greenhouse gas emissions in the range of 25 to 35 percent in comparison to conventional building stock. Meaningful improvements in other sustainability metrics were achieved as well. Sustainable buildings being designed to meet today's best practices are capable of even higher performance levels.

Along with its tangible success, sustainable building also presents new challenges and risks to the design and construction industry. Reformulated or entirely new materials may prove to be less durable than those they replace. Products from unique sources may be susceptible to supply shortages or price instability. Buildings constructed with more airtight enclosures may become vulnerable to problems of indoor air quality or moisture accumulation within exterior walls and roofs. Green roofs may be more vulnerable to leakage, and if they do leak, more expensive to repair. Inexperience with green building technologies may lead to design or construction errors. Completed buildings may not meet the performance goals to which they were designed or the heightened expectations of their owners. Uncertainties regarding the costs of green building design, construction, or operation may create financial uncertainty for the parties involved.

It is incumbent upon those involved with sustainable building to recognize and minimize these risks. All parties must collaborate effectively, to ensure that the broad goals of sustainability are understood and effectively implemented. Designers and builders must adequately educate themselves so that they properly apply new technologies. The selection of green materials and systems must be done with care, and without losing sight of traditional concerns such as durability, practicality, and safety. Further, the contractual agreements between designers, builders, and owners must appropriately set expectations and fairly balance risks.

Considerations of sustainability are included throughout this book. In addition, a sidebar in nearly every chapter describes the major issues of sustainability related to the materials and methods discussed in that chapter. For more information on sustainable design and construction resources, see the references listed at the end of this chapter.

THE WORK OF THE DESIGN PROFESSIONAL

A building begins as an idea in someone's mind, a desire for new and ample accommodations for a family, many families, an organization, or an enterprise. For any but the smallest buildings, the next step for the owner of the prospective building is to engage, either directly or through a hired construction manager, the services of building design professionals. An architect helps to organize the owner's ideas about the new building while various engineering specialists work out concepts and details of foundations, structural support, and mechanical, electrical, and communications services.

[T]he architect should have construction at least as much at his fingers' ends as a thinker his grammar.

—Le Corbusier, “Towards a New Architecture,” 1927

This team of designers, working with the owner, then develops the scheme for the building in progressively finer degrees of detail. Drawings, primarily graphic in content, and specifications, mostly written, are produced by the architect–engineer team to describe how the building is to be made and of what. These drawings and specifications, collectively known as the construction documents, are submitted to the local government building authorities, where they are checked for conformance with zoning ordinances and building codes before a permit is issued to build. A general contractor is selected, who then plans the construction work in detail. Once construction begins, the general contractor oversees the construction process and hires the subcontractors who carry out many portions of the work, while the building inspector, architect, and engineering consultants observe the work at frequent intervals to be sure that it is completed according to plan. Finally, construction is finished, the building is made ready for occupancy, and that original idea—which may have been initiated years earlier—is realized.

Zoning Ordinances

The legal restrictions on buildings begin with local zoning ordinances, which govern the types of activities that may take place on a given piece of land, how much of the land may be covered by buildings, how far buildings must be set back from adjacent property lines, how many parking spaces must be provided, how large a total floor area may be constructed, and how tall the buildings may be. In larger cities, zoning ordinances may include fire zones with special fire-protection requirements, neighborhood enterprise districts with economic incentives for new construction or revitalization of existing buildings, or other special conditions.

Building Codes

In addition to their zoning ordinances, local governments regulate building activity by means of building codes. Building codes protect public health and safety by setting minimum standards for construction quality, structural integrity, durability, livability, accessibility, and especially fire safety.

Most building codes in North America are based on one of several model building codes, standardized codes that local jurisdictions may adopt for their own use as a simpler alternative to writing their own. In Canada, the National Building Code of Canada is published by the Canadian Commission on Building and Fire Codes. It is the basis for most of that country's provincial and municipal building codes. In the United States, the International Building Code¯ (IBC) is the predominant model code. This code is published by the International Code Council, a private, nonprofit organization whose membership consists of local code officials from throughout the country. It is the basis for most U.S. building codes enacted at the state, county, and municipal levels. The International Building Code is the first unified model building code in U.S. history. First published in the year 2000, it was a welcome consolidation of a number of previous competing regional model codes.

Building-code-related information in this book is based on the IBC. The IBC begins by defining occupancies for buildings as follows:

- A-1 through A-5 Assembly: public theaters, auditoriums, lecture halls, nightclubs, restaurants, houses of worship, libraries, museums, sports arenas, and so on

- B Business: banks, administrative offices, college and university buildings, post offices, banks, professional offices, and the like

- E Educational: schools for grades K through 12 and some types of child day-care facilities

- F-1 and F-2 Factory Industrial: industrial processes using moderate-flammability or noncombustible materials, respectively

- H-1 through H-5 High Hazard: occupancies in which toxic, corrosive, highly flammable, or explosive materials are present

- I-1 through I-4 Institutional: occupancies in which occupants under the care of others may require assistance during a fire or other building emergency, such as 24-hour residential care facilities, hospitals, nursing homes, prisons, and some day-care facilities

- M Mercantile: stores, markets, service stations, salesrooms, and other retail and wholesale establishments

- R-1 through R-4 Residential: apartment buildings, dormitories, fraternity and sorority houses, hotels, one- and two-family dwellings, and assisted-living facilities

- S-1 and S-2 Storage: facilities for the storage of moderate- and low-hazard materials, respectively.

- U Utility and Miscellaneous: agricultural buildings, carports, greenhouses, sheds, stables, fences, tanks, towers, and other secondary buildings.

The IBC's purpose in describing occupancies is to establish different levels of life-safety hazard in buildings. For example, a hospital, in which patients are bedridden and cannot escape a fire without assistance from others, must be designed to a higher standard of safety than a hotel or motel occupied by able-bodied residents. A large retail mall building, containing large quantities of combustible materials and occupied by many users varying in age and physical capacity, must be designed to a higher standard than a warehouse storing noncombustible masonry materials and occupied by relatively few people who are all familiar with their surroundings. An elementary school requires more protection for its occupants than a university building. For a theater, with patrons densely packed in dark spaces, more attention must be paid to emergency egress provisions than for an ordinary office building.

These occupancy classifications are followed by a set of definitions for construction types. At the head of this list is Type I construction, made with highly fire-resistant, noncombustible materials. At the foot of it is Type V construction, which is built from combustible light wood framing—the least fire-resistant of all construction types. In between are Types II, III, and IV, with levels of resistance to fire falling between these two extremes.

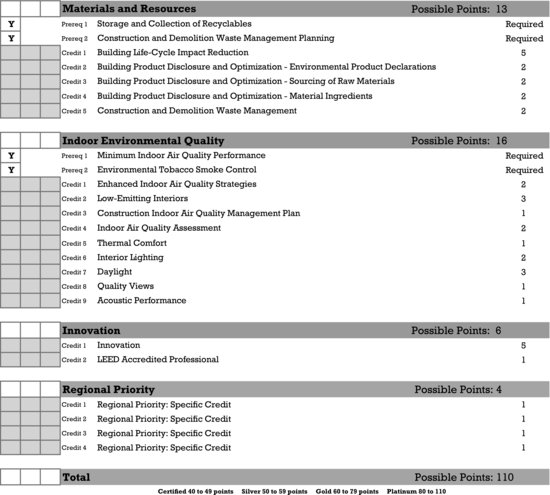

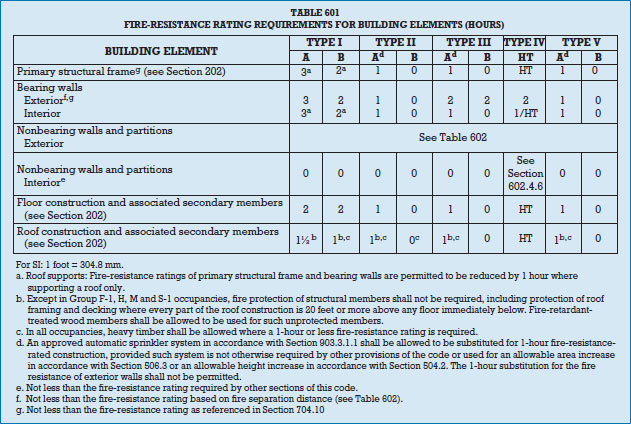

With occupancies and construction types defined, the IBC proceeds to match the two, stating which occupancies may be housed in which types of construction, and under what limitations of building height and area. Figure 1.3 is reproduced from the IBC. This table gives starting values for the maximum building height, in both feet and number of stories above grade, and the maximum area per floor for every possible combination of occupancy and construction type. Once the values in this table are adjusted according to other provisions of the code, the maximum permitted size for a building of any particular use and type of construction can be determined.

Figure 1.3 Height and area limitations of buildings of various types of construction, as defined in the 2012 IBC. These base values are modified according to various code provisions to arrive at the final allowable height and area for any particular building. For the purposes of this book, many of these modifications are simplified or ignored. (Table 503 excerpted from the 2012 International Building Code, Copyright 2011. Washington, D.C.: International Code Council. Reproduced with permission. All rights reserved. www.ICCSAFE.org)

Consider, for example, an office building. Under the IBC, this building is classified as Occupancy B, Business. Reading across the table from left to right, we find immediately that this building may be built to any desired size, without limit, using Type I-A construction.

Type I-A construction is defined in the IBC as consisting of only noncombustible materials—masonry, concrete, or steel, for example, but not wood—and meeting requirements for resistance to the heat of fire. Looking at the upper table in Figure 1.4, also reproduced from the IBC, we find under Type I-A construction a listing of the required fire resistance ratings, measured in hours, for various parts of our proposed office building. For example, the first line states that the structural frame, including such elements as columns, beams, and trusses, must be rated at 3 hours. The second line also mandates a 3-hour resistance for bearing walls, which serve to carry floors or roofs above. Nonbearing walls or partitions, which carry no load from above, are listed in the third line, referring to Table 602, which gives fire resistance rating requirements for exterior walls of a building based on their proximity to adjacent buildings. (Table 602 is included in the lower portion of Figure 1.4.) Requirements for floor and roof construction are defined in the last two lines of Table 601.

Figure 1.4 Fire resistance of building elements as required by the IBC. Types I and II construction allow the building structure to be made only of noncombustible materials, that is, steel, concrete, and masonry. Type V construction allows any material, including wood. Types III and IV allow combinations of internal wood structure surrounded by noncombustible exterior walls. (Tables 601 and 602 excerpted from the 2012 International Building Code, Copyright 2011. Washington, D.C.: International Code Council. Reproduced with permission. All rights reserved. www.ICCSAFE.org) You can download a PDF of this figure at http://www.wiley.com/go/aflblce6ne.

Looking across Table 601 in Figure 1.4, we can see that fire resistance rating requirements are highest for Type I-A construction, decrease to 1 hour for various intermediate types, and fall to zero for Type V-B construction. In general, the lower the construction type numeral, the more fire-resistant the construction system is. (Type IV construction is somewhat of an anomaly, referring to Heavy Timber construction consisting of large wooden members that are relatively slow to catch fire and burn.)

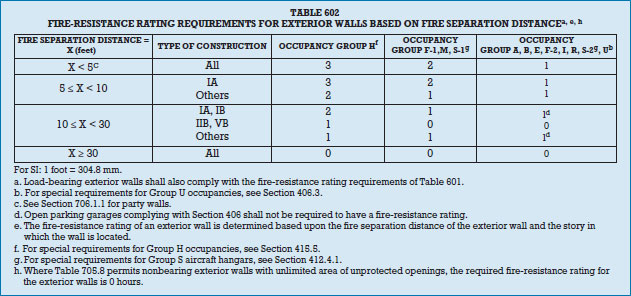

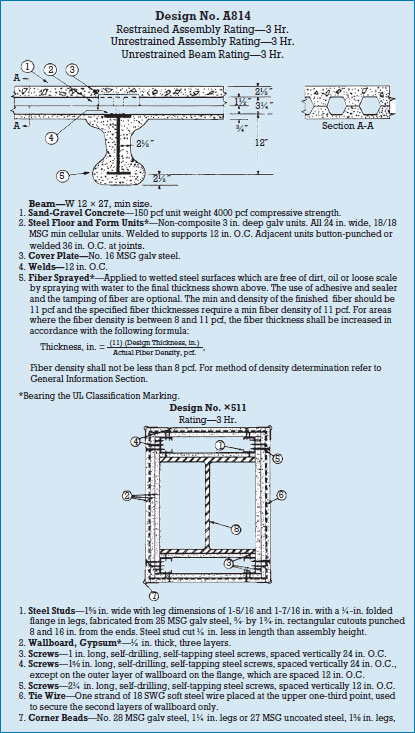

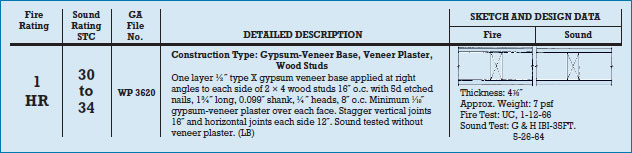

Once fire resistance rating requirements for the major parts of a building have been determined, the design of these parts can proceed, using building assemblies meeting these requirements. Tabulated fire resistance ratings for common building materials and assemblies come from a variety of sources, including the IBC itself, as well as from catalogs and handbooks issued by building material manufacturers, construction trade associations, and organizations concerned with fire protection of buildings. In each case, the ratings are derived from large-scale laboratory tests of building components carried out in accordance with an accepted standard protocol to ensure uniformity of results. (This test, ASTM E119, is described more fully in Chapter 22 of this book.) Figures 1.5 and 1.6 show examples of how such ratings are commonly presented.

Figure 1.5 Fire resistance ratings for a steel floor structure (above) and column (below), taken from the Underwriters Laboratories Fire Resistance Directory. In the floor assembly, the terms “restrained” and “unrestrained” refer to whether or not the floor is connected to its supporting structure in such a way that it is, or is not, prevented from expanding longitudinally when subjected to the heat of a fire. (Reprinted with permission of Underwriters Laboratories Inc.)

Figure 1.6 A sample of fire resistance ratings published by the Gypsum Association, in this case for an interior partition consisting of wood studs and fire-resistant gypsum wallboard. (Courtesy of the Gypsum Association.)

In general, when determining the level of fire resistance required for a building, the greater the degree of fire resistance, the higher the cost. Most frequently, therefore, buildings are designed to the lowest level of fire resistance permitted by the building code. Our hypothetical office building could be built using Type IA construction, but does it really have to be constructed to this high standard?

Let us suppose that the owner desires a three-story building with 30,000 square feet per floor. Reading across the table in Figure 1.2, we can see that in addition to Type I-A construction, the building can be of Type I-B construction, which permits a building of 11 stories and unlimited floor area; or of Type II-A construction, which permits a building of 5 stories and 37,500 square feet per floor. But it cannot be of Type II-B construction, which allows a building of only 3 stories and 23,000 square feet per floor. It can also be built of Type IV construction but not of Type III or Type V.

Other factors also come into play in these determinations. If a building is protected throughout by a fully automatic sprinkler system for suppression of fire, the tabulated area per floor may be tripled for a multistory building or quadrupled for a single-story building. The rationale for this permitted increase is the added safety to life and property provided by such a system. A one-story increase in allowable height is also granted under most circumstances if such a sprinkler system is installed. If the 3-story, 30,000-square-foot office building that we have been considering is provided with such a sprinkler system, a bit of arithmetic will show that it can be built of any construction type shown in Figure 1.2 except Type V.

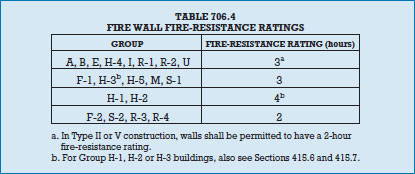

If more than a quarter of the building's perimeter walls face public ways or open spaces accessible to firefighting equipment, an additional increase of up to 75 percent in allowable area is granted in accordance with another formula. Furthermore, if a building is divided by fire walls having the fire resistance ratings specified in another table (Figure 1.7), each divided portion may be considered a separate building for purposes of computing its allowable area, which effectively permits the creation of a building many times larger than Figure 1.2 would, at first glance, indicate. (For the sake of simplicity, additional considerations in determining allowable building height and area in the IBC have been omitted from these examples.)

Figure 1.7 Fire resistance requirements for fire walls, according to the IBC. (Table 706.4 excerpted from the 2012 International Building Code, Copyright 2011. Washington, D.C.: International Code Council. Reproduced with permission. All rights reserved. www.ICCSAFE.org)

The IBC also establishes standards for natural light; ventilation; means of egress (exiting); structural design; construction of floors, walls, and ceilings; chimney construction; fire protection systems; accessibility for disabled persons; and many other important aspects of building design. In addition to the IBC, the International Code Council also publishes the International Residential Code (IRC), a simplified model code addressing the construction of detached one- and two-family homes and townhouses of limited size. Within any particular building agency, these codes may be adopted directly in their model form. Or, as is more common, they may be adopted with amendments, adjusting the code to better suit the needs of that jurisdiction while still retaining its overall structure and intent.

The building code is not the only code with which a new building must comply. Energy codes establish standards of energy efficiency for buildings, affecting a designer's choices of windows, heating and cooling systems, and many aspects of the construction of a building's enclosing walls and roofs. Because of the significant environmental impacts associated with building energy consumption, the development of higher-performance energy codes that require buildings to consume less energy is one of the most important contributors to improving building sustainability.

Health codes regulate aspects of design and operation related to sanitation in public facilities such as swimming pools, food-service operations, schools, or healthcare facilities. Fire codes regulate the operation and maintenance of buildings to ensure that egress pathways, fire protection systems, emergency power, and other life-safety systems are properly maintained. Electrical and mechanical codes regulate the design and installation of building electrical, plumbing, and heating and cooling systems. Some of these codes may be locally written, but, like the building codes discussed earlier, most are based on national models. In fact, an important task in the early design of any major building is determining what agencies have jurisdiction over the project and what codes and regulations apply.

Other Constraints

Other types of legal restrictions must also be observed in the design and construction of buildings. Along with the accessibility provisions of the IBC, the Americans with Disabilities Act (ADA) makes accessibility to public buildings a civil right of all Americans, and the Fair Housing Act does the same for much multifamily housing. Together, these access standards regulate the design of entrances, stairs, doorways, elevators, toilet facilities, public areas, living spaces, and other parts of many buildings to ensure that they are usable by physically handicapped members of the population. The U.S. Occupational Safety and Health Administration (OSHA) controls the design of workplaces to minimize hazards to the health and safety of workers. OSHA sets safety standards under which a building must be constructed and also has an important role in the design of industrial and commercial buildings.

Conservation laws protect wetlands and other environmentally sensitive areas from encroachment by buildings. Fire insurance companies exert a major influence on construction standards. Through their testing and certification organizations (Underwriters Laboratories and Factory Mutual, for example) and the rates they charge for building insurance coverage, these companies offer financial incentives to building owners to build hazard-resistant construction. Federal labor agencies, building contractor associations, and construction labor unions have standards, both formal and informal, that affect the ways in which buildings are built. Contractors have particular types of equipment, certain kinds of skills, and customary ways of going about things. All of these affect a building design in myriad ways and must be appropriately considered by building designers.

Construction Standards and Information Resources

The tasks of the architect and the engineer would be much more difficult to carry out without the support of dozens of standards-setting agencies, trade associations, professional organizations, and other groups that produce and disseminate information on materials and methods of construction, some of the most important of which are discussed in the following sections.

Standards-Setting Agencies

ASTM International (formerly the American Society for Testing and Materials) is a private organization that establishes specifications for materials and methods of construction accepted as standards throughout the United States. Numerical references to ASTM standards—for example, ASTM C150 for portland cement, used in making concrete—are found throughout building codes and construction specifications, where they are used as a precise shorthand for describing the quality of materials or the requirements of their installation. Throughout this book, references to ASTM standards are provided for the major building materials presented. Should you wish to examine the contents of the standards themselves, they can be found in the ASTM references listed at the end of this chapter. In Canada, corresponding standards are set by the Canadian Standards Association (CSA). The International Organization for Standardization (ISO), an organization with more than 160 member countries, performs a similar role internationally.

The American National Standards Institute (ANSI) is another private organization that develops and certifies North American standards for a broad range of products, such as exterior windows, mechanical components of buildings, and even the accessibility requirements referenced within the IBC itself. Government agencies, most notably the U.S. Department of Commerce's National Institute of Science and Technology (NIST) and the National Research Council Canada's Institute for Research in Construction (NRC-IRC), also sponsor research and establish standards for building products and systems.

Construction Trade and Professional Associations

Design professionals, building materials manufacturers, and construction trade groups have formed a large number of organizations that work to develop technical standards and disseminate information related to their respective fields of interest. The Construction Specifications Institute, whose MasterFormat™ standard is described in the following section, is one example. This organization is composed both of independent building professionals, such as architects and engineers, and of industry members. The Western Wood Products Association, to choose an example from among hundreds of trade associations, is made up of producers of lumber and wood products. It carries out research programs on wood products, establishes uniform standards of product quality, certifies mills and products that conform to its standards, and publishes authoritative technical literature concerning the use of lumber and related products. Associations with a similar range of activities exist for virtually every material and product used in building. All of them publish technical data relating to their fields of interest, and many of these publications are indispensable references for the architect or engineer. In some cases, the standards published by these organizations are even incorporated by reference into the building codes, making them, in effect, legal requirements. Selected publications from professional and trade associations are identified in the references listed at the end of each chapter in this book. The reader is encouraged to obtain and explore these publications and others available from these various organizations.

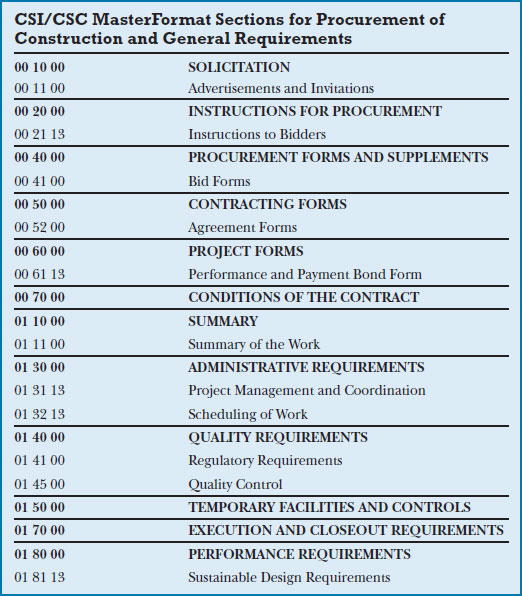

MasterFormat and Other Systems of Organizing Building Information

The Construction Specifications Institute (CSI) of the United States, and its Canadian counterpart, Construction Specifications Canada (CSC), have evolved over a period of many years a comprehensive outline called MasterFormat for organizing information about construction materials and systems. MasterFormat is used as the outline for construction specifications for the vast majority of large construction projects in these two countries. It is frequently used to organize construction cost data, and it forms the basis on which most trade associations' and manufacturers' technical literature is cataloged. In some cases, MasterFormat is used to cross-reference materials information on construction drawings as well.

MasterFormat is organized into 50 primary divisions intended to cover the broadest possible range of construction materials and buildings systems. The portions of MasterFormat relevant to the types of construction discussed in this book are as follows:

These broadly defined divisions are further subdivided into sections, each describing a discrete scope of work usually provided by a single construction trade or subcontractor. Individual sections are identified by six-digit codes, in which the first two digits correspond to the division number and the remaining four digits identify subcategories and individual units within the division. Within Division 05—Metals, for example, some commonly referenced sections are:

Every chapter in this book gives MasterFormat designations for the information it presents to help the reader know where to look in construction specifications and other technical resources for further information.

MasterFormat organizes building systems information primarily according to work product, that is, the work of discrete building trades. This makes it especially well suited for use during the construction phase of building. For example, Section 06 10 00—Rough Carpentry specifies the materials and work of rough carpenters who erect a wood light frame building structure. However, finish carpentry, such as the installation of interior doors and trim, occurs later during construction, requires different materials, and is performed by different workers with different skills and tools. So it is specified separately in Section 06 20 00—Finish Carpentry. Defining each of these aspects of the work separately allows the contractor to most efficiently and accurately manage the work's costing and execution.

In contrast to MasterFormat, the UniFormat™ standard organizes building systems information into functional groupings. For example, Uniformat defines eight Level 1 categories:

- A Substructure

- B Shell

- C Interiors

- D Services

- E Equipment and Furnishings

- F Special Construction and Demolition

- G Building Sitework

- Z General

Where greater definition is required, these categories are subdivided into so-called Level 2 classes, Level 3 and 4 subclasses, and even Level 5 or higher-numbered sub-subclasses, each describing more finely divided aspects of a system or assembly. For example, wood floor joist framing can fall under any of the following UniFormat descriptions:

- Level 1: B Shell

- Level 2: B10 Superstructure

- Level 3: B1010 Floor Construction

- Level 4: B1010.10 Floor Structural Frame

- Level 5: B1010.10.WF Wood Floor Framing

- Etc.

UniFormat provides a more systems-based view of construction in comparison to MasterFormat and is most useful where a broader, more flexible description of building information is needed. This includes, for example, description of building systems and assemblies during project definition and early design, or the performance specification of building systems, such as discussed later in this chapter for design/build project delivery. UniFormat is also well suited to organizing construction data in computer-aided design and building information modeling systems, which naturally tend to aggregate information into functional groupings. (Building information modeling is also discussed at greater length later in this chapter.)

The OmniClass™ Construction Classification System is an overarching scheme that attempts to incorporate multiple existing building information organizational systems, including MasterFormat, UniFormat, and others, into one system. OmniClass consists of 15 Tables, some of which include:

- Table 13: Spaces by Function

- Table 21: Elements

- Table 22: Work Results

- Table 23: Products

- Table 31: Phases

- Table 32: Services

- Table 35: Tools

- Table 41: Materials

- Table 49: Properties

For example, Table 13—Spaces by Function merges a number of existing systems for the management of information about rooms and spaces within buildings, useful to building owners and facilities managers. Table 21—Elements is based on UniFormat, and Table 22—Work Results is based on MasterFormat. OmniClass is an open standard that is described broadly by its authors as “a strategy for classifying the built environment.” It is based on an international standard for organizing construction information, called “ISO 120006-2,” and it continues to undergo active development.

The increasing attention given to organizational systems like UniFormat and OmniClass reflects the building industry's need to manage increasingly complex sets of data and efficiently share that data between disciplines, across diverse information technology platforms, and throughout the full building life cycle, from conception to extended occupancy. For more information on MasterFormat, UniFormat, and OmniClass, see the references at the end of this chapter.

THE WORK OF THE CONSTRUCTION PROFESSIONAL

Providing Construction Services

An owner wishing to construct a building hopes to achieve a finished project that functions as required, meets expectations for design and quality, costs as little as possible, and will be completed on a predictable schedule. A contractor offering its construction services hopes to produce quality building, earn a profit, and complete the project in a timely fashion. Yet, the process of building itself is fraught with uncertainty: It is subject to the vagaries of the labor market, commodity prices, and the weather; despite the best planning efforts, unanticipated conditions arise, delays occur, and mistakes are made; not infrequently, requirements change over the course of the project; and the pressures of schedule and cost inevitably minimize the margin for miscalculation. In this high-stakes environment, the relationship between the owner and contractor must be structured to share reasonably between them the potential rewards and risks.

Construction Project Delivery Methods

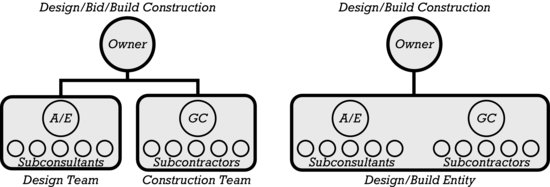

In conventional design/bid/build project delivery (Figure 1.8), the owner first hires a team of architects and engineers to perform design services, leading to the creation of construction documents that comprehensively describe the facility to be built. Next, construction firms are invited to bid on the project. Each bidding firm reviews the construction documents and proposes a cost to construct the facility. The owner evaluates the submitted proposals and awards the construction contract to the bidder deemed most suitable. This selection may be based on bid price alone, or other factors related to bidders' qualifications may also be considered. The construction documents then become part of the construction contract, and the selected firm proceeds with the work. On all but small projects, this firm acts as the general contractor, coordinating and overseeing the overall construction process but frequently relying on smaller, more specialized subcontractors to perform significant portions or even all of the construction work. During construction, the design team continues to provide services to the owner, helping to ensure that the facility is built according to the requirements of the documents as well as answering questions related to the design, changes to the work, verification of payments to the contractor, and similar matters.

Figure 1.8 In design/bid/build project delivery, the owner contracts separately with the architect/engineer (A/E) design team and the construction general contractor (GC). In a design/build project, the owner contracts with a single organizational entity that provides both design and construction services.

Among the advantages of design/bid/build project delivery are its easy-to-understand organizational scheme, well-established legal precedents, and relative simplicity of management. The direct relationship between the owner and the design team ensures that the owner retains control over the design and provides a healthy set of checks and balances during the construction process. With design work completed before the project is bid, the owner starts construction with a well-defined scope of work, a fixed price bid, and a high degree of confidence regarding the project schedule and final costs.

In design/bid/build project delivery, the owner contracts with two entities, and design and construction responsibilities remain divided between these two throughout the project. In design/build project delivery, one entity ultimately assumes responsibility for both design and construction (Figure 1.8). A design/build project begins with the owner developing a conceptual design or program that describes the functional or performance requirements of the proposed facility but does not detail its form or how it is to be constructed. Next, using this conceptual information, a design/build organization is selected to complete the remainder of the design and construction of the project. Selection of the designer/builder may be based on a competitive bid process similar to that for design/bid/build projects, on negotiation and evaluation of an organization's qualifications for the proposed work, or on some combination of these. Design/build organizations themselves can take a variety of forms: a single firm encompassing both design and construction expertise; a construction management firm that subcontracts with a separate design firm to provide those services; or a joint venture between two firms, one specializing in construction and the other in design. Regardless of the internal structure of the design/build organization, the owner contracts with this single entity throughout the remainder of the project, and this entity assumes responsibility for all remaining design and construction services.

Design/build project delivery gives the owner a single source of accountability for all aspects of the project. It also places the designers and constructors in a collaborative relationship, introducing construction expertise into the design phases of a project and allowing the earliest possible consideration of constructability, cost control, construction scheduling, and similar matters. This delivery method also readily accommodates fast track construction, a scheduling technique for reducing construction time that is described later in this chapter.

Other delivery methods are possible: An owner may contract separately with a design team and a construction manager. As in design/build construction, the construction manager participates in the project prior to the onset of construction, introducing construction expertise during the design stage. Construction management project delivery can take a variety of forms and is frequently associated with especially large or complex projects (Figure 1.9). In turnkey construction, an owner contracts with a single entity that provides not only design and construction services, but financing for the project as well. Or design and construction can be undertaken by a single-purpose entity, of which the owner, architect, and contractor are all joint members. Aspects of these and other project delivery methods can also be intermixed, allowing many possible organizational schemes for the delivery of design and construction services that are suitable to a variety of owner requirements and project circumstances.

Figure 1.9 In its traditional role, a construction manager (CM) at fee provides project management services to the owner and assists the owner in contracting directly for construction services with one or more construction entities. A CM at fee is not directly responsible for the construction work itself. A CM at risk acts more like a general contractor and takes on greater responsibility for construction quality, schedule, and costs. In either case, the A/E design team also contracts separately with the owner.

Paying for Construction Services

With fixed-fee or lump-sum compensation, the general contractor or other construction entity is paid a fixed dollar amount to complete the construction of a project regardless of that entity's actual costs to perform the work. With this compensation method, the owner begins construction with a known, fixed cost and assumes minimal risk for unanticipated cost increases. In contrast, the construction contractor assumes most of the risk of unforeseen costs, but also stands to gain from potential savings. Fixed-fee compensation is most suitable to projects where the scope of the construction work is well defined when the construction fee is set, as is the case, for example, with design/bid/build construction.

With cost plus a fee compensation, the owner agrees to pay the construction entity for the actual costs of construction—whatever they may turn out to be—plus an additional amount to account for overhead and profit. In this case, the construction contractor is shielded from most cost uncertainty, and it is the owner who assumes most of the risk of added costs and stands to gain the most from potential savings. Cost plus a fee compensation is most often used with projects for which the scope of construction work is not fully known at the time compensation is established, a circumstance most frequently associated with construction management or design/build contracts.

Cost plus a fee compensation may also include a guaranteed maximum price (GMAX or GMP). In this case, there is a maximum fee that the owner is required to pay. While the contractor's compensation remains under the guaranteed amount, compensation is made in the same manner as with a standard cost plus a fee contract. However, once the compensation reaches the guaranteed maximum, the owner is no longer required to make additional payments and the contractor assumes responsibility for all additional costs. This compensation method retains some of the scope and price flexibility of cost plus a fee compensation while also establishing a limit on the owner's cost risks.

Incentive provisions in owner/contractor agreements can be used to more closely align owner and contractor interests. For example, in simple cost plus a fee construction, there may be an incentive for a contractor to add costs to a project, as these added costs will generate added fees. To eliminate such a counterproductive incentive, a bonus fee or profit-sharing provision can provide for some portion of construction cost savings to be returned to the contractor. In this way, the contractor and owner jointly share in the benefits of reduced construction cost. Bonuses and penalties for savings or overruns in costs and schedules can be part of any type of construction contract.

Surety bonds are another form of legal instrument used to manage financial risks of construction, most frequently with publicly financed or very large projects. The purpose of a surety bond is to protect an owner from the risks of default, such as bankruptcy, by the construction contractor. For a fixed fee, a third party (surety) promises to complete the contractual obligations of the contractor if that contractor should for any reason fail to do so. Mostly commonly, two separate bonds are issued, one for each of the general contractor's principal obligations: a performance bond to assure completion of the construction and a payment bond to assure full payment to suppliers and subcontractors.

With competitive bidding and fixed-fee compensation, the owner is assured of competitive pricing for construction services and the contractor assumes most of the risk for unanticipated costs. With a negotiated contract and simple cost plus a fee compensation, the risks of noncompetitive pricing and unanticipated costs are shifted mostly to the owner. By adjusting projecting delivery and compensation methods, these and other construction-related risks can be allocated in varying degrees between the two parties to best suit the requirements of any particular project.

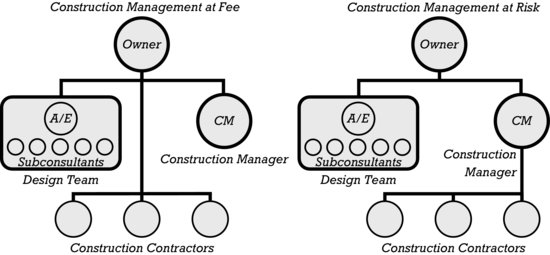

Sequential versus Fast Track Construction

In sequential construction (Figure 1.10), each major phase in the design and construction of a building is completed before the next phase begins, and construction does not start until all design work has been completed. Sequential construction can take place under any of the project delivery methods described previously. It is frequently associated with design/bid/build construction, where the separation of design and construction phases fits naturally with the contractual separation between design and construction service providers.

Figure 1.10 In sequential construction, construction does not begin until design is complete. In phased construction, design and construction activities overlap, with the goal of reducing the overall time required to complete a project.

Phased construction, also called fast track construction, aims to reduce the time required to complete a project by overlapping the design and construction of various project parts (Figure 1.10). By allowing construction to start sooner and by overlapping the work of design and construction, phased construction can reduce the total time required to complete a project. However, phased construction also introduces its own risks. Because construction on some parts of the project begins before all design is complete, an overall cost for the project cannot be established until a significant portion of construction is underway. Phased construction also introduces more complexity into the design process and increases the potential for design errors (for example, if foundation design does not adequately anticipate the requirements of the not yet fully engineered structure above). Phased construction can be applied to any construction delivery method discussed earlier. It is frequently associated with design/build and construction management project delivery methods, where the early participation of the construction entity provides resources that are helpful in managing the complex coordination of overlapping design and construction activities.

Construction Scheduling

Constructing a building of any significant size is a complex endeavor, requiring the combined efforts of countless participants and the coordination of myriad tasks. Managing this process requires an in-depth understanding of the work required, of the ways in which different aspects of the work depend upon each other, and of the constraints on the sequence in which the work must be performed.

Figure 1.11 captures one moment in the erection of a tall building. The process is led by the construction of the building's central, stabilizing core structures (in the photograph, the pair of concrete towerlike structures extending above the highest floor levels). This work is followed by construction of the surrounding floors, which rely, in part, on the previously completed cores for support. Attachment of the exterior skin can follow only after the floor plates are in place and structurally secure. As the building skin is installed and floor areas become enclosed and protected from the weather, further operations, such as the roughing in of mechanical and electrical systems, and eventually, the installation of finishes and other elements, can proceed in turn. This simple example illustrates considerations that apply to virtually every aspect of building construction and at every scale from a building's largest systems to its smallest details: Successful construction requires a detailed understanding of the tasks required and their interdependencies in time and space.

Figure 1.11 In this photo, the construction sequence of a tall building is readily apparent: A pair of concrete core structures leads the construction, followed by concrete columns and floor plates and, finally, the enclosing curtain wall. (Photo by Joseph Iano.)

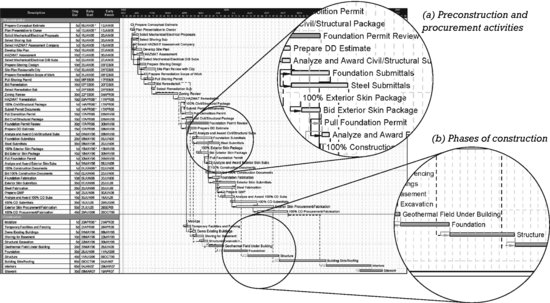

The construction project schedule is used to analyze and represent construction tasks, their relationships, and the sequence in which they must be performed. Development of the schedule is a fundamental part of construction project planning, and regular updating of the schedule throughout the life of the project is essential to its successful management. In a Gantt chart or bar chart, a series of horizontal bars represents the duration of various tasks or groups of tasks that make up the project. Gantt charts provide an easy-to-understand representation of construction tasks and their relationships in time. They can be used to provide an overall picture of a project schedule, with only a project's major phases represented (Figure 1.10), or they can be expanded to represent a larger number of more narrowly defined tasks at greater levels of project detail (Figure 1.12).

Figure 1.12 In a Gantt chart, varying levels of detail can be represented. In this example, roughly the top three-quarters of the chart is devoted to a breakdown of preconstruction and procurement activities such as bidding portions of the work to subtrades, preparing cost estimates, and making submittals to the architect (a). Construction activities, represented more broadly, appear in the bottom portion (b).

The critical path of a project is the sequence of activities that determines the least amount of time in which a project can be completed. For example, the construction of a building's primary structural system is commonly on the critical path of a project schedule. If any of the activities on which the completion of this system depends—such as design, shop drawing production and review, component fabrication, materials delivery, or erection on site—are delayed, then the final completion date of the project will be extended. In contrast, other systems not on the critical path have more flexibility in their scheduling, called float, and delays (within limits) in their execution will not necessarily affect the overall project schedule.

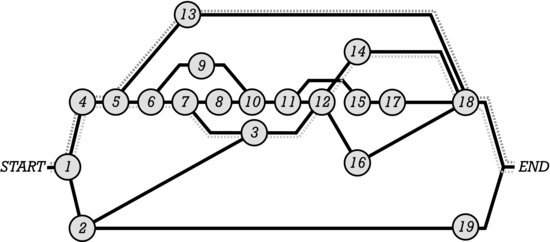

The critical path method is a technique for analyzing collections of activities and optimizing the project schedule to minimize the duration and cost of a project. This requires a detailed breakdown of the work involved in a project and the identification of dependencies among the parts (Figure 1.13). This information is combined with considerations of cost and resources available to perform the work, and then analyzed, usually with the assistance of computer software, to identify optimal scenarios for scheduling and worker and resource allocation. Once the critical path of a project has been established, the elements on this path are likely to receive a high degree of scrutiny during the life of the project, as delays in any of these steps will have a direct impact on the overall project schedule.

Figure 1.13 The critical path method depends on a detailed analysis of work tasks and their relationships to generate an optimal construction schedule. Shown here is a schematic network diagram representing task dependencies. For example, task 6 cannot begin until tasks 1, 4, and 5 are completed, and tasks 7 and 9 cannot begin until task 6 is finished. The dashed lines on the diagram trace two of many possible paths from the start to the end of the diagram. To determine the critical path for this collection of tasks, all such paths must be identified and the time required to complete each one calculated. The path requiring the most time to complete is the critical path, that is, the sequence of activities that determines the least time in which the collection of tasks as a whole can be completed.

Managing Construction

Once a construction project is underway, the general contractor assumes responsibility for day-to-day oversight of the construction site, management of trades and suppliers, and communications between the construction team and other major parties, such as the owner and the designer. On projects of any significant size, this may include responsibility for filing construction permits, securing the project site, providing temporary power and water, setting up office trailers and other support facilities, providing insurance coverage for the work in progress, managing personnel on site, maintaining a safe work environment, stockpiling materials, performing testing and quality control, providing site surveying and engineering, arranging for cranes and other construction machinery, providing temporary structures and weather protection, disposing or recycling of construction waste, soliciting the work of subtrades and coordinating their efforts, submitting product samples and technical information to the design team for review, maintaining accurate records of the construction as it proceeds, monitoring costs and schedules, managing changes to the work, protecting completed work, and more.

TRENDS IN THE DELIVERY OF DESIGN AND CONSTRUCTION SERVICES

Increasing Collaboration Among Team Members

The design and construction industry continues to evolve, testing innovative organizational structures and project delivery methods in which designers, builders, and owners assume less adversarial and less compartmentalized roles. Such approaches share characteristics such as:

- Contractual relationships and working arrangements that foster collaboration between project members

- Participation of the construction contractor during the design phases of a project

- Overlapping of design and construction activities to reduce the “time to market”

- Expanded definitions of project services to more fully recognize the full life cycle of a project—from its original conception, through planning, design and construction, to postconstruction occupancy—to best serve the needs of the building owner

The growth of design/build in the construction marketplace is one example of this trend: Between 1980 and 2010, the share of private, nonresidential construction work performed as design/build construction increased from roughly 5 percent of the total market to 40 percent.

The current state of the art in collaborative project delivery is integrated project delivery (IPD). In IPD, the key parties—including at least the design team, construction team, and owner agency—share mutually the responsibilities, decision making, and financial risks and rewards of the project. In its purest form, all major parties to the project share one agreement, binding them all to the same goals and outcomes. In other cases, a shared joining agreement may be used to mutually bind parties contracted under separate agreements. The goal of IPD is to increase project efficiency, improve project outcomes, and reduce conflict and litigation. In every case, IPD project delivery depends on a high level of collaborative and open communication, respect, and trust between the parties involved.

Improving Efficiency in Production

Other efforts within the construction industry focus on improvements in the efficiency of construction methods themselves. Unlike factory production, most building construction takes place outdoors, is performed within constrained and often physically challenging work areas, and is executed by a highly fragmented workforce. Despite the differences in these production environments, the construction industry is looking to lessons learned in factory production for approaches to improving its own processes. Such so-called lean construction methods attempt to:

- Reduce complexity

- Eliminate wasteful activities

- Structure the supply of materials and methods of production to achieve the quickest and most reliable workflow

- Decentralize information and decision making, to put control of processes into the hands of those most familiar with the work and most capable of improving it

A typical home may be made of more than 100,000 separate pieces, assembled by as many as 1000 workers. Estimates of labor inefficiency in building construction in general run as high as 35 to 40 percent, and of materials wastage, 20 percent or more. The challenge of lean construction is to restructure all aspects of construction—its design, materials manufacturing, product transport, component assembly, and workforce integration—to reduce these inefficiencies and deliver a finished product of the highest possible quality.

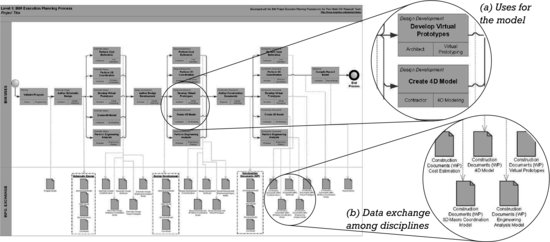

Improving Information Management