Science and Technology in the Kitchen

In the past there were basically two scientific models for the study of food and its preparation: the medical/dietetic approach, practiced continuously from antiquity down to the present, and the more recent physical/chemical approach. From the end of the seventeenth century onward the physical/chemical model gave rise to many important experiments with raw materials and preservation processes, heat sources and cooking utensils. In the field of gastronomy, however, the concept of progress is often misleading. The correlation of ingredients, labor, and implements does not affect the food in any direct, uncomplicated way. The most archaic procedures may turn out to be superior to modern techniques. Today meat grilled over a wood fire is considered preferable to meat cooked with electricity. Similarly, polenta has more flavor when prepared in a deep pan over an open fire than when it is reconstituted by adding water to a packet of yellow powder. Taste is never simply a reflection of innovation.

There is an issue of continuity here: from one end of Italian culinary history to the other, from Bartolomeo Scappi to Pellegrino Artusi, the tin-lined copper pan was considered the most appropriate vessel for cooking directly over the open fire (a heat source that had to be continuously replenished), and it was filled with water that came first from the well, then from the aqueduct, and finally from the kitchen tap. In order to evaluate the level of progress attained in the management of heat sources and in the metal alloys used in cooking vessels and utensils, we must take into account some variable factors as well as some constants, including those of a social or demographic nature. Without the work of the scullery boy or maidservant, who habitually took care of the fire and kept an eye on the embers, carried in the logs and briars, and trimmed the branches, it would be impossible to explain the longevity of the ancient kitchen. Ippolito Nievo described this age-old space, which survived up to the beginning of the nineteenth century: “[It was] dark, almost black with ancient soot, in contrast with the bottoms of the pots, the dripping pans, and carafes that were hanging there on a nail, glinting like the eyes of the devil.”1 The modernization of the household kitchen, which took place over a long period of time, fought a difficult and sometimes losing battle with traditional practices and forms of resistance. The kitchen hearth in the castle at Fratta, where dripping pans are placed strategically under the skewer, evokes a sense of nostalgia—nostalgia for a tradition that, when confronted by novelty, underwent a transformation but died out in the process, along with so many recipes and flavors. Yet the dirt of this dark, unhealthy kitchen, which was freezing in some areas and very hot in others, evokes a very different sensation, inevitably alienating our modern taste and sensibility. The contradictions between hygiene and cooking, hearty flavors and good health are in fact worthy of a separate study.

The uneven pattern of progress witnessed in different aspects of culinary practice is another important historical factor in a country where, as we will see, energy sources, both public and private, privileged some forms of consumption and restricted others. In the nineteenth century there were ongoing efforts to perfect the production of domestic heat sources, but refrigeration did not become accessible in private homes until the subsequent century. This imbalance also affected cooking customs. When municipalities began to distribute gas to urban residents, cooking systems became increasingly homogeneous. At the same time, however, the seasonal fragility and perishability of food products, especially meats, could not be remedied even by storing them on ice. For decades the use of controlled refrigeration remained a luxury, while heat was available in the kitchens of all urban households. The industrial production of foods suited to this infrastructure (i.e., the availability of the gas stove and the inaccessibility of the refrigerator) is reflected in dishes such as pasta with tomato sauce, which involves two types of preserved foods, one dried and the other semiliquid. It was only in the 1950s that a balance was found between the two poles of energy supply, hot and cold. The refrigerator was thus installed in domestic kitchens alongside the stove, which had already been in place for a period of fifty years. The consequences were not merely a matter of individual convenience but involved the entire field of food consumption. We see this in the relationship between the production of frozen goods and the spread of preprepared dishes and meals. Frozen prebaked lasagna now replaced pastasciutta.

Although the history of food is closely linked to the infrastructures of domestic life, we will examine only the aspects of those infrastructures that have special relevance for us here. To evaluate individual discoveries and innovations, we must return to the space historically assigned to the cook, observe it in its intimate details, reexamine its structures and utensils, and imagine the men who worked there, comparing them to other men who repeated the same tasks in subsequent years—or were no longer obliged to repeat them thanks to the invention of a machine. Before bringing the scientist into the kitchen, we will first take a look at the kitchen par excellence, that of Bartolomeo Scappi. This will make it easier to appreciate mechanical innovations—the introduction of simple machines and new materials—and especially to observe the role of heat, which was first produced by human labor, then by combustible fuel, and finally by increasingly sophisticated equipment. The kitchen is in fact a laboratory for physical experiments. It provides a fire source and requires a significant supply of water. It produces hot edible objects that undergo transformation as the temperature changes from hot to lukewarm or from cold to freezing. Heat conduction, the control of steam, and above all the ability to calculate temperatures became part of the cook’s store of knowledge before science provided him with objective measuring tools. Yet it would be an error to contrast the cook’s empirical knowledge with the method of the scientist. Both practitioners repeatedly carry out experiments on the same raw materials, but their goal is different. For the scientist the primary concern is not the value or taste of an object but the process through which the ingredients are transformed into this object. This process can be observed by studying heat sources and conductors with thermometers and densimeters or by using chemical substances or creating mechanical devices. There are further analogies and discrepancies between practitioners of the mechanical arts and scientists. The distiller who produced spirits and the butler who created sugar concoctions were clearly alchemists, just as the carver who displayed his dexterity in slicing up a roasted carcass of meat was a worldly anatomist.

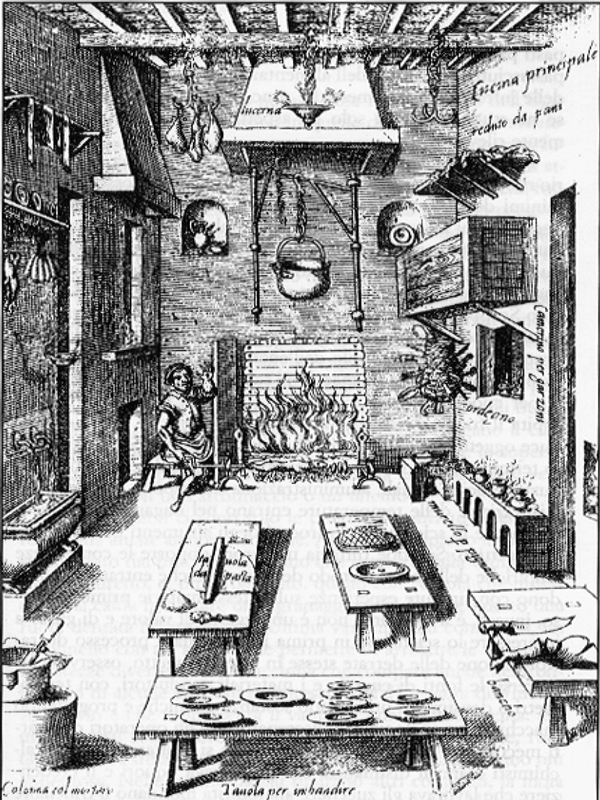

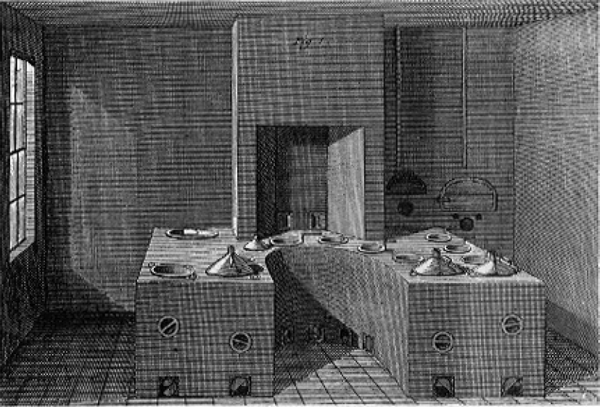

In the kitchen (engraving).

Source: Bartolomeo Scappi, Opera dell’arte del cucinare (Venice: Tramezzino, 1570).

When we enter the kitchen illustrated in Scappi’s work, we find ourselves in a place that looks as though it belongs in Sleeping Beauty’s castle. Although there must be great deal of commotion and smoke here, the characters seem to have been stuck in the same place for four hundred years, waiting to be brought back to life. Work spaces are located in the middle of the kitchen, and fireplaces, stoves, and sinks are placed against the walls at an appropriate distance from where dishes are prepared or completed. The engravings in Scappi’s book suggest the array of utensils used here, and information on the materials these are made of is provided in the inventory of equipment found at the beginning of the volume. Knives, spoons, skewers, stands, trivets, and frying pans are made of iron. All the pots are of tin-lined copper. The other materials are of little importance. Paddles and pins for rolling and stretching out the dough are made of wood. Mortars are made of bronze and marble. The tubular syringes used in making butter and the containers for vinegar are made of tin. In the battery of kitchen utensils iron and copper are the most common materials, and they would continue to dominate for a very long time. These metals conduct heat well. The saucepan lids not only protect the contents of the pans but also reflect back the heat, browning the top of the food. For this reason the lids were not equipped with handles (which isolate heat) but with soldered rings that could be grasped with the help of a rag or a hook.

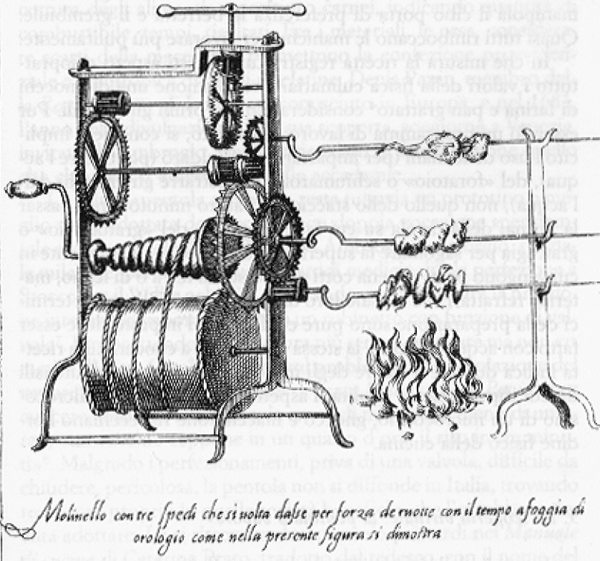

In the ancient kitchen we find pans that can be placed directly over the fire. We also find some machines. There are three versions of the spit: the first was rotated manually by a man who stood on the other side of a low, protective wall in order to shield himself from the flames. A more advanced type of skewer involved a fan that, when set in motion by the hot air rising above the flames, caused a cylindrical cogwheel to rotate; this in turn moved the serrated wheel attached to the rod. The third, more complex variation is a “machine with three skewers” that allowed for the roasting of foods on three different levels. This instrument, which reflects the advantage of a large kitchen, also appears in the frontispiece of some seventeenth-century editions of Vincenzo Cervio’s Il trinciante (The carver): here, with the help of the heat alone, the food is allowed to cook slowly, with prized meats, the most appetizing of ingredients, rotating around each other on the spit. In the papal kitchens these implements also included a grindstone, a pulley for the sink, a lever to raise pots from the fire, and a peasant instrument, the zagola, but all of these were dependent on muscle power. The spit alone reveals that there was a potential energy source in those kitchens—heat—and hence a future laboratory of innovation.2

The objects made in the kitchen are above all manufactured products. Kneading, mixing, chopping, whipping, pulverizing, and pounding are all actions entrusted to human hands. Only in the nineteenth century was such effort supplemented with machines. Sixteen people, assigned to different tasks, worked in contact with food. Given this number and the amount of dishes that were prepared in the kitchen, the availability of labor was not the principal worry of the master cook. His greater concern was managing the heat source and adapting it to the work under way. It was no accident that Scappi compared himself to an architect.3 Heat and cold occupy opposite poles not only in dietary science but also in the layout of the kitchens, where they are organized according to a system of gradual progression: first there is the open fire, then the stove, then the little brick wall that holds the burning fuel, the tongs, and so on, and finally the plate warmers. In an antechamber we find the cold dishes or those of delicate color: fresh milk, whipped fior di latte, and honeyed milk. The circulation of air, which is regulated by various means—high ceilings, windows, stove hoods, and chimneys—allows these polar opposites to complement each other, diffusing or eliminating smoke, odors, dust, ashes, and flour particles. In the nineteenth century this was the aspect of the culinary process that fell under the iron rule of hygiene, interpreted as the need for fresh air and meticulous cleanliness. The designation of different spaces for cooking, kneading, working with chilled or cold foods, steeping fish in brine, plucking poultry, and skinning animals (the coal shed, the woodpile, and the employees’ lavatory are elsewhere) is part of a type of organization that supervised both food and refuse. Each employee had a specific task in an assigned space. One would turn the spit. Another, working at the opposite side of the kitchen, would take care of the biancomangiare, and another would work with milk products in a cold room. The assignment of separate tasks did not necessarily mean individual professional freedom for each employee. The apprentices lived and worked together, as their sleeping quarters were in an adjacent room.

Spit for cooking meat (engraving).

Source: Bartolomeo Scappi, Opera dell’arte del cucinare (Venice: Tramezzino, 1570).

The kitchen is a microcosm. None of its copper utensils would appear on the dining table, and none of the iron knives would be used to slice the meat in front of the prelate. The pans gave their shape to food that was eventually transferred to other containers. Even the most delicate creations could emerge from hell to be served in heaven, without revealing a trace of the sweat and heat endured in their preparation. There was, however, an intermediate space—the small dining room, the tinello, where the dining-room officers ate meals with their guests—but this was a private, restricted space, and it was not always located next to the kitchen. If anything, its existence reinforced the idea of a hierarchy among those whose supreme goal was to serve the needs of their noble masters. Scappi attributed an intrinsic dignity and a specific form of attire to individual roles: dishwashers worked bareheaded, their arms uncovered. Those who handled food were expected to wear a cap and an apron. Almost all of them rolled up their sleeves in order to work as cleanly as possible.

How are these details, especially the concerns of culinary physics, reflected in the recipes? Let us take the example of a recipe for flour gnocchi and grated bread,4 starting with the utensils. Although Scappi’s recipe provides a detailed plan of work, there is also an implicit need for manual labor (for kneading the dough), for a large pot (to boil the water), and for a slotted spoon or strainer (to extract the dumplings from the water), not to mention a sieve to sift the flour, a table for kneading, and a grater for shaping the surface of the gnocchi. The bowl into which the cooked gnocchi were placed had to be made of pottery or wood, materials that prevented the dumplings from sticking to each other. The temperatures appropriate to the preparation of this dish are also clear: the dough had to be made with boiling water and would be cooked in boiling water. The recipe thus indicates the heat of the ingredients and the utensils on which the quality, appearance, and consistency of the dish depend. As a microcosm of a microcosm, dumplings and noodles reflect the physical order of the kitchen.

A Virtual Discovery: The Pressure Cooker

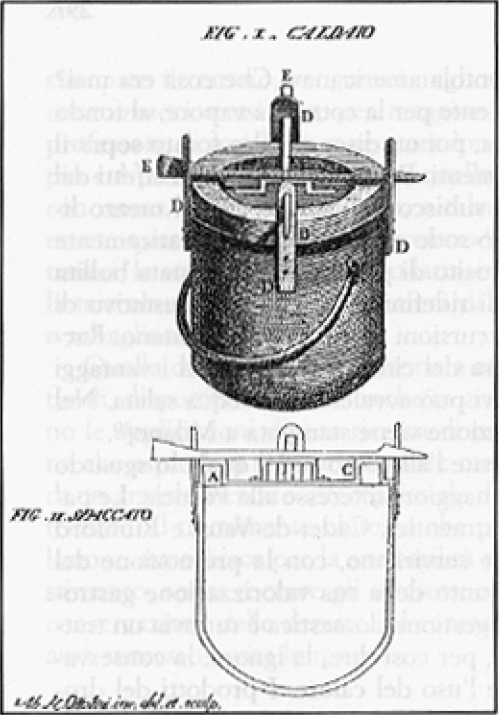

The history of inventions that had lasting effects on culinary labor has paradoxical aspects. We will discuss two that are particularly relevant to physics: artificially produced heat and its convection in food preparation. As we have seen, the importance of these issues was fully recognized long before new forms of production were studied and made available. Denis Papin’s invention of a type of saucepan that controlled the use of steam was undoubtedly the first instrument responsive to the dual necessity of reducing cooking time and consuming a lesser amount of combustible fuel. Instructions for its use are found in La manière d’amolir les os et de faire cuire toutes sortes de vivandes en fort peu de temps & à fort peu de frais (How to soften bones and cook all kinds of dishes in a short time and at minor cost).5 This is a log of experiments carried out with a “machine” that consisted of a double cylinder made of iron—the lower part for boiling water, the upper part for steaming food—sealed hermetically with screws and rods. There is a chapter dedicated to instructing cooks on the use of this apparatus, which was especially suited to cooking meats, indicating the quantities of fuel needed, cooking times, and results. Among the ingredients that could be cooked this way, we find bones, which had been regarded as waste. Cooking bones allowed for the creation of broths and gelatins for charitable, philanthropic purposes. Denis Papin, a member of London’s Royal Society and a well-known personality in Europe, was living in Venice as a guest of Ambrogio Sarotti in 1681, the year in which the news of his invention became widespread. A scientist of fame, he introduced his discovery, which he called a “digester,” to the scientific academies.

The first “pressure cooker” was, however, only a prototype and was adopted for both experimental and commercial objectives. From 1750 Ambrogio Sangiorgio, a Milanese spice merchant, used it to extract concentrates and medicinal broths.6 Wilke perfected its design in Stockholm in 1773, using the internal pressure of the steam to create a seal and inventing a kind of tap that functioned as a valve.7

Looking for a simpler way of sealing the pot, which was secure but not hermetic, Abbot Ottolini revisited the problem of regulating the steam. Timing the process with his watch, he was the first to claim that he had cooked beef “in less than an hour,” “an aged capon in a quarter of an hour,” and “rice in three minutes” in “Papin’s digester.”8 In spite of improvements the saucepan was dangerous and difficult to close without a valve. It was not widely adopted in Italy, meeting with resistance even in the charitable organizations for which it was intended. A full century later it reappeared, bearing the name of its inventor, in Caterina Prato’s Manuale di cucina (Cooking manual), which was translated from German into Italian. In addition to economical advantages, other motives were added in promoting its use: “It improves the texture and aroma of the foods, and the liquid does not overflow.”9

The history of the pressure cooker is a perfect illustration of the gap between invention and commercialization, and by examining it in detail we can understand why it was so difficult to introduce this type of utensil into domestic kitchens. In fact, it was not used on a broad scale until the twentieth century, when energy supply became more stable and reliable and when long cooking periods and the need for protracted supervision of the stove became problematical. It would be an error, however, to consider the pressure cooker independently of the larger picture of energy planning and heat supply. As the open hearth—which remained a primary source of heat only in peasant society—was gradually abandoned and gas lines were installed for widespread domestic use, heat became the subject of several studies with the objective of producing clean, economical, and readily available energy. More than a century after Papin, Count Rumford relaunched research on cooking systems in a series of projects on kitchen equipment, steam convection, the improvement of chimney flues, and the preparation of economical soups. In a climate of secular philanthropy and organized charity, what had originally been conceived as a project for constructing a machine that would produce broth or bone gelatin economically was now reformulated and relaunched in a more complex way. With financial support from the public sector, Rumford, an American physicist, organized an entire chain of production—from combustible fuel to heat source, from soup to consumer—in several European cities, including Munich, Paris, and Verona, where “the kitchen of the Pietà Hospital is the best I have ever created.”10 No detail escaped his attention: when he discovered that barley tended to stick or burn in the cooking process, he designed a double-bottomed saucepan with an insulating function.11 Once he had planned the practical details, he dedicated himself to the study of foods, particularly the preparation of meals for the poor, exploring various ingredients and recipes for what would become known internationally as “Rumford soup.”

Though his initial interest was in managing and transmitting heat in the preparation of balanced, nutritional food, Rumford was soon confronted with the problem of flavor. Ingredients such as potatoes, which were ideal from the economic perspective, met with resistance from his impoverished consumers. He devised a way to overcome this by adding appetizing elements such as dry bread, which offered a pleasant contrast to the thick but still liquid meal, and encouraged chewing. Though working on a basis of individual commissions, Rumford considered nutritional formulas to be exportable since, like steam, they could pass unhindered through borders. Hence he undertook the study of less costly national dishes, for which he planned an international system of distribution. Inspired by the popular consumption of pasta in Naples, he created recipes for macaroni, and the popularity of this dish throughout Europe at the beginning of the nineteenth century demonstrates a successful alliance of philanthropic and gastronomic values.12

The study and production of artificial refrigeration have different implications. Sixteenth-century treatises on beverage temperatures trace the ancient origins of chilled drinks and praise their civilizing values. The use of snow, stored in ice pits and mountain trenches and transported to the city by night during the summer season, was a pleasure enjoyed by the ancient Romans and a small luxury that never went out of fashion. At the conclusion of the Trattato della natura de’ cibi et del bere (Treatise on the nature of foods and drink), by Baldassarre Pisanelli, a physician of the sixteenth century, we find a chapter on the “effects of cold drinks” that discusses the flavor, digestive properties, and ability of chilled beverages to lower feverish body temperatures.13 Considering the consumption of cold drinks to be an environmental necessity, Pisanelli suggests the use of water, wine, and chilled fruits, secure in the conviction that he is voicing a common social aspiration: “Today every poor tradesman wants Bread, Wine, and Snow.” More than the well and possibly the wine cellar, snow beds furnished the raw material for cold drinks. Pisanelli declared that the use of saltpeter was “of little use” and fit “for sailors only,”14 thus dismissing the value of chemical processes—saltpeter is hypothermic—which were regarded as an inferior device.

It was, however, the chemical study of salt that led to the boom in chilled beverages and ice-cream products in the eighteenth century with the production of artificially generated refrigeration. Filippo Baldini, the author of the first Italian tract on sorbets (De’ sorbetti) wrote: “Having examined the value of salts, Monsieur Réaumur, his thermometer in hand, found that almost all of them caused a slight level of freezing, except for sea salt. See the Memorandum of the Academy of Sciences, 1732. Wishing to economize, one could use sodium, which is ash of alica, as this chills almost all liquids in a much more efficient way than sea salt.”15

Baldini prescribes the exact amount of salt, ice, and sugar used in making sorbets, offers a disquisition on citric acids (from citron, lemon, and orange), and introduces a new type of fruit recently arrived from America: the pineapple. With this treatise he succeeded in popularizing a chemical procedure that had culinary applications by weighing its value from the perspective of flavor and nutrition. This scientific information was tacitly circulated among ice-cream manufacturers (Naples, the city where the treatise was printed, was the home of the best ice-cream makers in Europe) and consumers. The consumers in turn consulted Baldini, a medical professor, for further information, asking his opinion on a number of things, including chocolate sorbet, the most sought after concoction of all, “made of cocoa powder, cinnamon, sugar, and sometimes vanilla, especially when it has to be frozen.”16 The sorbet maker was part of the equipment used in making preserves and was suited to the processing of fruits and flowers, coffee and zabaglione. It was made of iron or tin and was submerged in a tub of refrigerating solution.17

The history of refrigeration is unique. The availability of natural snow and ice in summer, even in areas with a hot climate, delayed the application of scientific research to new production processes, which began to boom in the field of food preservation with the creation of a huge international meat market in the second part of the nineteenth century. The chemical procedure that prolonged freezing temperatures took hold because of its simplicity and low cost without affecting broader, collective interests, particularly the preservation of products. Unlike the pressure cooker, it would enjoy success and longevity.

Appert in Italy: The Flavor of Preserved Foods

Up to the eve of the French Revolution, the diffusion of these scientific concepts was entrusted for the most part to physicians; they were addressed exclusively to the elite and were accepted as a phenomenon whose social role could be recognized at a distance. In 1765 Voltaire had pointed to the existence of red currant sorbet and ice creams as tangible signs of progress,18 but on the question of natural, chemical, or artificial ice few were capable of expressing an opinion. Steam and saltpeter still had the status of trade secrets. Toward the end of the eighteenth century, however, a new climate developed among scientists, public authorities, and citizens, and a series of innovations is reflected in gastronomic literature. Count Rumford, an expert on fireplaces, ovens, and kitchens, was one of the individuals who contributed to the reconceptualization of cooking in terms of energy and heat conservation. His soups, recommended by Parmentier,19 became popular in Italy. But Rumford was not the only one concerned with cooking equipment. Parmentier had in fact already perfected the “American saucepan,” which was a simple pan for steaming food. Water was placed in the bottom of this receptacle, and the food was then arranged on a disk of perforated tin and placed over the water. Parmentier studied the effects of heat on ingredients that do not dissolve in liquid but remain firm while retaining their color. Starting with the intention of boiling a potato that would not fall apart, he redefined the taste standard of cooked vegetables and fruits, completing experiments that brought him far afield. Among other things he recommended rice prepared in the Chinese manner. Parmentier’s work also showed the advantages of a type of cooking that could be carried out with salt water when traveling at sea. His report was published in Milan in 1787.20

Italians had a great interest in the way the French treated potatoes. Parmentier’s comments on the potato, along with those of Cadet-de-Vaux and Rumford, were frequently translated into Italian.21 These texts would help to promote the consumption of potatoes and enhance their culinary appreciation. Nevertheless, the scientific process that genuinely revolutionized household management—the practice of applying heat to foods sealed in glass jars in order to preserve them—virtually ignored the potato.

A grocer named Nicolas Appert sold his highly appreciated products—legumes preserved in fresh condition, without added salt, vinegar, or sugar—to Parisians long before he decided to divulge the secret of their preparation. Peas, artichokes, asparagus, and fruit of all kinds were thus available out of season. A vegetable farm and processing plant in Massy and a store in Paris constituted the basis of Appert’s system of production and distribution, and he promoted his products in a catalog and in newspaper advertisements. His discovery became widely known in 1810, when he won a substantial prize from the Ministry of the Interior. The same year, the Italian translation of L’art de conserver pendant plusieurs années toutes les substances animales et végétales (The art of preserving for several years all animal and vegetable products) was published in Siena, and a German translation of the same work appeared in Koblenz. The English version appeared two years later.22

Before Appert’s discovery, the usual procedures for preserving food were either physical or chemical. They involved primarily the use of cold or heat. Meats and fish were smoked, dried, or kept on ice. These methods had many inconveniences. If foods had been dried, they needed to be rehydrated before use. To keep them cold, it was necessary to secure a freezing environment or the appropriate quantity of ice (which was expensive in temperate climates). There was also the possibility of using additives: brine and salt were used for pickling cucumbers and herrings and curing pork meat. Other options were oil or vinegar or, for fruit, liquor and even honey and sugar. Obviously the cost varied according to the method employed, and the use of additives could be expensive but had the advantage of being very appetizing. Sometimes the food product itself provided material for its own preservation: goose or duck fat, having congealed in the cooking process, could be placed in jars along with pieces of the cooked meat. The substance to be preserved could undergo one or two procedures at varying cost, but these treatments had one element in common: the alteration of the natural properties of the fresh product. The color and texture of fish would change, for example, as each additive brought about different modifications. Fruits gradually lost their color when submerged in alcohol; smoke pierced the surface of hardened meat. Preserved foods also had a specific taste that seemed desirable in its peculiarity—the sharpness typical of salt, the pungency of vinegar, the inebriating nuances of liquor, or the rich properties of animal fats (goose, for example) and vegetable oils. Each edible substance, when desalted or rehydrated, drained or wiped off, retained the unmistakable flavor of a condiment along with the vague aftertaste of its original properties. The original aroma, however, was inevitably absent, replaced by a distinct odor of the sort that prevailed in food stores. It was possible to adjust excessively strong flavors not only through cooking but also through judicious combinations. Wine could dissolve and eliminate salty residues in the mouth, just as it was used to wash down mouthfuls of food in which the concentration of juices was too intense. The art of drinking was fundamental for the full enjoyment of preserved foods, dissolving their harshness at a very visceral level.

Clearly, dried and rehydrated peas could never pass for fresh products. Appert’s procedure, however, provoked a different result, and it was surprisingly simple and repeatable: parboiled root vegetables and fruits were placed in bottles, carefully sealed, and boiled in a bain-marie for a period of time that varied according to the ingredients. At the end of this process the contents were sterile, and the jars could be stored on shelves for months or years before being sold. When opened, the peas seemed naturally green and still a little crisp, with a familiar fragrance, appearance, and taste. The claim made by the Societé d’encouragement pour l’industrie nationale was quite clear: the new method “does not add any foreign body to the substance intended for preservation.” Appert understood none of the scientific reasons for this outcome, a fact that presented no difficulty to him from a commercial perspective. His method of production, which he carried out on a small scale, was adapted for industrial development and was also suitable for domestic use. This led to its immediate success all over Europe.

In Italy Appert’s discovery became known through the publication of manuals translated from the French. L’arte di conservare gli alimenti, which appeared in Italy in 1824, presented his method of sterilizing and sealing food in jars—along with more traditional procedures—and publicized the recent development of containers with tin lids in England.23 To appreciate the diffusion of Appert’s procedure in cookbooks that described its applications around the middle of the nineteenth century, we have only to consult the writings of Agnoletti, a cook and food preserver who worked in Rome, in Tuscany, and at the court of Maria Luigia of Parma. In 1814, when his Nuovissima cucina economica first appeared, he was unaware of the new methods. Here, for bottling tomatoes, he suggests sealing the jars carefully and placing them in a cool place or drying the tomatoes out in the sun or on the stove. In the Manuale del cuoco e del pasticciere (Manual for the cook and the pastry cook), which was published in 1832, by contrast Agnoletti reveals that he has caught up with the trend: “For better preservation, boil the sealed bottles in a bain-marie for sixteen minutes, and allow them to cool in the same liquid.” He may have learned of Appert’s method sometime between 1821 and 1826 when he lived in Parma, where French cooks plied their trade, or at a later date.24 Either way, thanks to the testimony of the book he published in 1832, we know that the new method of preserving tomatoes was integrated into elite cuisine by that juncture. Developments within the domestic environment would have occurred at a later stage.

ABOVE The pan (engraving).

Source: Girolam Ottolini, Il digestore di Papino (Milan, 1770).

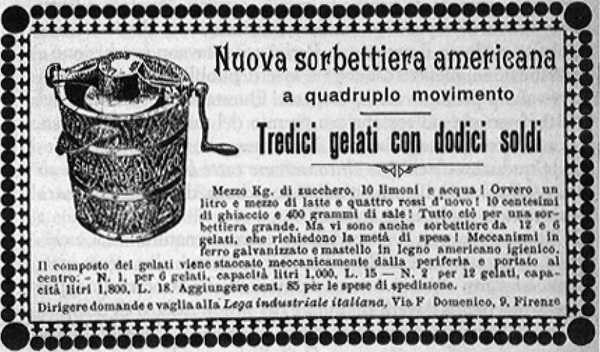

BELOW: Newspaper advertisement for a “new American sorbet maker” from the late nineteenth century.

We must underline a dual aspect of Appert’s system: pulses were preserved without additives—salt, vinegar, or oil—that would have altered their flavor. When cooking a product preserved in this way, it could be treated as though it were fresh, and it might even pass as fresh. It was thus in cooking—with peas, asparagus, beans, and artichokes—that the advantages of this procedure were most evident, though in the case of potatoes the results were disappointing and costly. Fruit, or other foods served cold on the sideboard, did not yield similar results: red currants were resistant to this mode of preservation, and strawberries lost consistency and fragrance, requiring the addition of sugar. To limit these drawbacks, ripening, harvesting, and processing had to follow each other in quick succession. A different kind of advantage is achieved in the preparation of various sauces. In the case of the tomato, which was used above all as a condiment, the new method guaranteed constant availability at a steady cost, summer and winter, without waste. In Italy this would be the preserved food par excellence, spreading to all parts of the country and becoming an aspect of national identity. Italy’s canning industry was created after national unification, consistent with the level of progress achieved elsewhere in Europe, and the labels attached to the cans were adorned with the image of this fine red fruit.

The widespread use of preserved foods had profound consequences for taste. The market value of products dropped, reducing the difference between early and later seasonal varieties. Costs became more moderate, and flavors were standardized. There was a big difference between the appearance, and especially the color, of these preserves and the results obtained with traditional methods of dehydration. The new method could be applied to game, which now became available at times of the year when it would otherwise be impossible to find, thus allowing consumers to have constant access to woodcock and pheasant, roasted or jugged, after they had been heated in saucepans and stored in jars. Common pulse vegetables and prized meats were subject to the same techniques. Always available, preserved vegetables enjoyed growing favor in restaurants, where they were used, openly or surreptitiously, as substitutes for dishes or side plates prepared from fresh foods. Eternally fresh spring vegetables traveled everywhere in cans and were widely welcomed. We have only to read the menus to find that “Argenteuil asparagus” was served at the Grand Hôtel d’Italie in Florence for Christmas dinner in 1900 and at the Hotel Continental in Moscow during the month of January 1901.25 These vegetables kept their name, their prestige, and even their place of origin. The fact that they were accepted even by diners who dictated culinary taste led to the posthumous transfiguration of the grocer Nicolas Appert into a master cook and pastry expert.

The diffusion of preservation and its application to the market sectors of highest demand (soups, fish, pulse vegetables, fruit with syrup, jams, and so on) led to the democratization of elite values. Based on the premise that each basic foodstuff was theoretically suitable for Appert’s method of processing, advertisers began to claim that the freshest and most natural vegetables were those in a can. The place of origin now became part of the brand name: the San Marzano tomato functions as the symbol of a national industry, the Cirio Company, based in Naples. After World War I the canning industry monopolized the publication of educational texts on cooking as well as communication with homemakers. Cirio was Italy’s best-known culinary publisher up to the 1960s, producing recipe books by acknowledged authors that were organized according to specific themes (particularly the tomato), household notebooks, coloring books for children, and albums with competitions. Among the individuals who wrote prefaces for these books was Lidia Morelli, known for her contribution to the field of domestic science.26 An element common to all these books was the insertion of at least one canned or preserved product and one fresh product among the ingredients listed in each recipe while underscoring the recipe’s cost advantage, speed of execution, and uniformity of taste. The main promotional theme was not convenience, however, but rather the natural, sensory aspect of food. Color is regarded as a compelling feature: the greenness of peas and string beans and the redness of tomatoes are the marks of an evolutionary continuity, from garden to can to dish. The preserved product thus becomes a universal value in a can. Its ingredients and recipes and even its container do not vary. By combining peeled tomatoes and dried pasta, one obtains a pasta dish that, thanks to a distinctive mode of preservation, is identical from one end of the country to the other. This canning policy, which was identical to Fascist policy, had obvious implications. By proliferating maps of Italy showing the location of processing plants and depots, reflecting regional and local traditions in recipe titles, and combining typical ingredients from different areas with the famous peeled tomatoes, a culturally diverse country became unified through its gastronomic values.

The Oven, the Sorbet Maker, and Simple Machines

Cookbooks reflect innovations in the field of preservation primarily from the perspective of application. In their concern for the infrastructures of cooking, the authors place greater importance on the invention of new dishes than on the introduction of new utensils. Yet knowledge and experience allowed the home cook to master the use of ancient stoves and enabled the professional cook to supervise his staff in controlling heat and cold. The cookbook does not concern itself with physical location except on a purely theoretical level, highlighting only two related concerns: the choice of ingredients and the equipment needed for cooking. The use of open fireplaces and brick containers of live coals to provide heat gave way in time to cookers that regulated heat in a more uniform way. From the second half of the eighteenth century to the twentieth, the greatest problem implicit in heat sources—the regulation of low and high temperatures—underwent several stages of development.

Among the items that reflected this evolution was the oven, which in the early nineteenth century was heated by controlling the quantity of firewood and evaluating the temperature with empirical methods. Only the pastry cook’s complete familiarity with the heat source guaranteed good results, and all advice offered to the public was of necessity approximate. Vialardi suggested placing “a damp rag at the tip of a long stick” in the oven and withdrawing it five minutes later to see if it had burned (in which case the oven was too hot) or simply browned (in which case the temperature was right for pastry dough and meat dishes with grated cheese topping). When Trattato di cucina pasticceria moderna (Treatise on modern pastry making) was published in 1854, German and French ovens, which provided constant heat, were already available and were recommended by Vialardi “for private kitchens.”27 The fate of domestic pastry making, including its most delicate applications such as soufflés, depended on the progressive refinement of this resource, both in homes and restaurants, which had developed over time from a simple bell-shaped structure, to the country range, to this new model. The introduction of the cast-iron, charcoalfueled kitchen range meant that as many as eight burners could be accommodated on the same surface, and underneath this there was room for two ovens, two stoves, a tank for hot water, and two broilers with a spit.28 By opening and closing the doors of the range, the cook could access the desired compartment without coming in contact with hot ashes, excessive smoke, or live flames. The advent of municipal gas would refine the process of heat regulation without overheating the environment surrounding the stove, fulfilling one of the main objectives of a functional appliance: a clean, cool kitchen. One must not exaggerate the changes, however. Taking into account the simplicity of contemporary domestic arrangements, Pellegrino Artusi suggests cooking a chocolate soufflé in a Dutch oven or on a simple burner between two heat sources.

Natural ice was still used in the preparation of sorbets and ice creams. The techniques suggested by Baldini were still in fashion in Vialardi’s time, though the freezing mixtures were now more effective, as they consisted of water and ammonia nitrate, which could make the temperature rise above or fall below –10°C to –15°C, depending on the proportions applied. When the tin sorbet maker was submerged in this mixture, the cook could still stir the ice cream in the container. The problem presented by the production of cold temperatures evolved in a specific way. In the nineteenth century the commitment to freezing mixtures, and hence to the transportation of natural ice, still prevailed. This custom began to decline in the southern part of the USA after 1890 with advances in the refrigeration industry.29 Refrigerators and refrigerated warehouses did not make their appearance in Italy until the twentieth century, with the advent of World War I. Examination of the monthly magazine L’industria italiana del freddo (The Italian refrigeration industry) shows that by 1928 there was already a broad national network of private and state-run factories for the processing of chilled food, preserving it with artificial ice.30 Since there was no cooling network available to private homes, which were still without refrigerators, those who made ice cream at home continued to practice the older techniques, though some mechanical improvements were added: Artusi recommends the “American sorbet maker” with its triple-action mechanism, as it allowed the user to freeze the mixture in a faster and more uniform manner than other devices.31 Moreover, the artisans who specialized in making ice cream lacked the capital to invest in costly appliances. Between the publication of Grifoni’s Trattato di gelateria in 1911 and Hoepli’s manual in 1922 there is no evidence of any evolution. Both recommend the use of a tub for the ice and salt, with a cylinder in the middle and a handle to turn the rods inside. Giuseppe Ciocca, the author of the Hoepli manual who was one of the best-known experts on ice cream in the 1930s, and Amedeo Pettini, the famous cook who wrote the preface, both noted the empirical aspect of the sorbet-making process, while consoling themselves in their status as heirs to a time-honored tradition: “We can easily foresee that one day the mechanical preparation of frozen mixtures will be carried out with different methods than those used today. But whatever the technical procedure might be in the future, the historical fact is that we were the first to introduce ice cream to civilization, and Italians were for centuries the foremost ice-cream makers in the world.”32

More noticeable advances were made in the simple appliances used in establishments without a fireplace, but these correspond in many ways to a more ancient concept. Comparing Scappi’s battery of utensils in 1570 to that of Giovanni Nelli in Il re dei cuochi in 1868, we find gridirons and fish kettles, stewpots and mortars in both. The saucepan used for steaming green vegetables is of more recent origin, as we have seen, and so is the tool for fashioning vegetables known as the presse julienne. By pressing a lever, this utensil can mold and slice long, thin strips of vegetables (such as carrots) into the shape desired. Among the appliances introduced into the home, many had a hand-operated screw mechanism, such as the meat grinder, which Artusi soon replaced with the lunette. In Caterina Prato’s Manuale we also find a mill for grating stale bread. The potato masher is fairly widespread, but the tool for removing the stones in plums much rarer. During the Fascist era, some modest progress could be observed in the kitchen with the introduction of a machine for cutting green beans, the juicer,33 the vegetable strainer, and the handle-operated eggbeater (electric beaters were seen only in dairy shops). The list can be extended, though not by much, if we include hotel kitchens, where there were juice extractors (for fruit as well as for the carcasses of game birds), slicers, and pureemaking machines, reflecting the needs of a more complex system of service.34

These minor inventions were not intended to function with electrical power, but this did not prevent women from dreaming of the possibility of powering them with automatic batteries. The modesty of the utensils was supplemented by their users’ genuine pleasure in being part of an up-to-date domestic economy. Sponsored by the major industrialists from Borletti to Ginori, ENIOS, the National Office for the Scientific Organization of Labor, was established in Italy in 1926. One of its tasks was to promote the efficiency of domestic labor.35 This meant adopting the American model in the hope of encouraging private investments. Its initial project—the remodeling of the domestic space—was assigned to the architect, and the housewife was called on to imagine the furnishings, the tables (for dining, working, and ironing), and the dresser on which each dish would be assigned its proper place. As the kitchen walls filled up with various items, it became clear that even the smallest details had a symbolic value. A scale and a clock were present in every kitchen, since recipes specified cooking times and the quantities of ingredients in numeric terms, as though their transmission anticipated a collective memory loss, with a simultaneous loss of confidence in experience and analogical intuition. With its white tiles and white wood furniture, the kitchen now looked like a laboratory, and the careful organization of plates, dishes, pots, and pans also bore tribute to the cult of personalized practicality.

Among the many virtually useless machines found in this laboratory-theater, only one gives us reason to pause—the “mechanical mixer” designed for preparing sheets of pasta dough that Lidia Morelli had mentioned in 1935.36 This contraption, made of metal cylinders operated by a handle, raises complicated questions: is it additional proof of the alienation of a new generation of women from domestic work, or does it rather bear witness to the diffusion of pasta making outside its geographical and anthropological area? In the eyes of the culinary experts, the machine’s success was synonymous with the increasing rarity of the art of the rolling pin and symptomatic of a diminishing respect for the quality of the kind of dough that could only be produced by hand. In reality the pasta maker flourished just as shops selling fresh pasta were becoming widespread in the major cities, and more than a call to revive traditions it suggests support for their conservation. The abandonment of certain fundamental elements and the replacement of handmade pasta with dried pasta were already under way in 1935, along with the commercialization of regional pasta specialties.

A complex evaluation of small domestic appliances supports the claim that the manual labor of the woman of the house was still important. The convenience offered by the new gadgets was of minimal importance when considered in relation to the overall length of time needed to prepare a meal. The preparation of foods continued to be carried out by hand, from basic ingredients to the final presentation of the dish. What began to increase on a modest scale was the market for partially prepared foods (such as stock cubes or preserved items) and food that was ready for cooking (such as fresh pasta). And yet there were some major innovations. Ovens, stoves, and sinks were renovated in the space of twenty years, bringing about a significant labor-saving advance. From 1880 onward the homes of Italy’s major cities were connected to the municipal gas supply, and by 1930 electric stoves had already begun to appear.37 The imbalance between country and city before the spread of the gas cylinder grew more marked, and no one questioned what was seen as an innovation of enormous importance. “The miracle starts early in the morning: we no longer begin the day by setting the fire but by placing something on the fire!”38 In the modern kitchen the air is clean, the temperature is cooler, and the age-old polarization of hot and cold disappears. Water and fire, at opposite ends of the kitchen in Scappi’s engravings, now appear side by side. Electricity, or heat without flames, followed the availability of gas. Once running water became available, so too did hot and cold water, which could be mixed at will. The electrical boiler made its appearance during the Fascist period, taking over yet another of the basic functions of the hearth. Water was no longer placed in a pot on the burner but was heated in a container and became available with the turn of a faucet. The handling of new elements, inflammable gases, and electric wires was certainly not more difficult to master than the earlier arrangements, but it implied a different awareness of movements and gestures, and often, as a result of the reduced need for domestic staff, there was a sense of loneliness that had not been experienced in the kitchen in previous times. The economy of combustible fuel depended on the turning of handles or knobs and the calculation of abstract parameters, and it was the woman of the house who gave direct instruction to the maid on its consumption.

The energy potential meant there was an increase in the number of hot points in a self-regulated house. The electric stove had three or four burners and an oven that could be used without long delays since it involved minimal supervision and presented few demands for intervention. Tasks such as adding liquid to a pot, turning the food, rotating it, removing it from the heat, uncovering it, and covering it up again were automatically eliminated by regulating the oven. One could even avoid the possibility of liquid bubbling over or food sticking to the bottom of the pan. In addition to the stove-top burners, one could also use an electric hot plate for the coffee maker. Where? Near the electrical outlet, on top of any table. All this could be achieved by connecting a plug, turning switches, and pressing buttons, without firewood or coal. The old pots and pans are replaced in accordance with the new energy sources, which are clean, safe, and temperature-controlled. Copper pans suddenly seem antiquated. They are difficult to polish on the outside and to coat on the inside. Iron survives only in frying pans. The ancient kitchen of the past now faces its demise. For slowcooked dishes, stews, and thick soups, cast iron prevails, which is excellent to use and easy to clean. The thick aluminum pan with an insulated handle dominates the battery of pots and pans because of its lightness and affordability. In 1899 Dr. Formenti, following a visit to Switzerland and Germany, announced the success of this pan and anticipated the use of aluminum in the manufacture of stockpots, saucepans, stewpots, skimmers, small shovels, ladles, and so on.39 Within a few decades a revolution had taken place, as aluminum became the material that was universally adopted by refectories and mess halls, hotels and patrician residences. This new pale metal lent itself to all kinds of uses and prompted the housewife to develop a real interest in materials. Nickel, though costly, offered all the advantages of copper but did not need to be lined with tin and polished. The enamel pan also appeared, though it seemed delicate. But the marvel that captured everyone’s imagination was the pirofila, a Pyrex casserole dish produced by Ginori. Bright, transparent, and lightweight, the pirofila brought a distinctive design to ovenware. It was nonetheless a fragile object and would have to be replaced in the long run, unlike copper pans, which last forever. After World War I these were the kinds of cookware that broke a sacred taboo, since they did not make a sharp distinction between kitchen pots and serving dishes or between the realm of the servants and that of their employers. The Pyrex dish allowed the food cooked in the oven or on top of the stove to be placed directly on the dining table. As attractive as a soup tureen, it could be handled and cleaned with greater ease. None of these artifacts, which were high on the list of wedding gifts, precluded competition in the middle-class household. If aluminum was light, solid, and conducted heat well, enamel and Pyrex were fragile, washable, and attractive to look at. All seemed equally necessary, including even the ancient earthen stewpot used for cooking beans.40

La cucina elegante, a recipe collection for the most refined sector of Milanese society, immediately adopted this new style. A porcelain container capable of withstanding the heat of the stove was judged to be indispensable for “Beef au gratin,” “Mushroom-stuffed tomatoes,” and “Fish soufflé.” Modernization makes some recipe titles sound outdated or inappropriate, such as “partridges in a stewpot,” which are now cooked in a Pyrex dish, transferred from the oven to the stove top for deglazing, and then placed directly on the dining table.41 In bourgeois homes the arrival of the new kitchenware signaled the triumph of the woman of the house, who was responsible for structural investments and for obtaining the kinds of equipment that would involve the expenditure of small amounts of capital. Such purchases foreground the value of domestic work and can be exhibited to guests with pride, as a sign of hospitality. Since objects of this kind are designed for the family meal, they are clearly distinguishable from the tableware used in restaurants, designed for serving individual portions. There was also the advantage of time saving, since time could be used in a more concentrated, efficient way. Three or four burners could be used simultaneously for the same meal. Cooking procedures that seemed to last forever became mere memory when everything could be achieved in a quicker fashion. Canned and preserved foods were successfully integrated into these transformative processes: a can of peas or peeled tomatoes needed only brief contact with the heat, since they were already preboiled or blanched. Legumes requiring lengthy cooking procedures, such as beans and lentils, could now be removed from the jar and placed in a saucepan for just a short interval before the heat was turned off. Food could be acquired precooked (in the case of beans) or preroasted (in the case of peppers), and the goal was to finish off a process that was begun elsewhere and to beautify the final presentation. In addition, a cube of meat concentrate could supplement a stew or fortify a broth, and boiled meat, which was mainly used as the basis for soups, sauces, and fillings, took on an increasingly prestigious role, becoming tantamount to a fine course in itself. Energy, electrical appliances, preserves, and canned foods thus altered the tempo of meal preparation, with ever-increasing recourse to external sources of food and energy.

The housewife of the Fascist period had a space to fill in her kitchen, the space still occupied by the icebox, a large, enamel-plated container. For Rina Morelli, writing in 1935, the secret aspiration of replacing it still seemed too farfetched: “Electrical refrigerators are now available, most of them imported from America. Not only is it unnecessary to place ice inside them, but they themselves produce ice cubes. Unfortunately, the cost prohibits their widespread accessibility.”42

The icebox was filled with blocks of ice that were delivered to the home on summer mornings. Its natural extension was the moscarola, an aerated safe that was often placed on the balcony and used to keep foods cool. In homes without a cellar—the coolest indoor space available—food was exposed to variations in temperature and soon lost its chill. Milk spoiled, butter melted, and fish had to be cooked no more than six hours after purchase. But the middle-class housewife armed herself against the climate and was ready for disaster. The importance given by lexicons of home cooking to ice-cream making, with reference to such techniques as loading the ice-cream maker, softening the mixture, surrounding the molds with ice, and blending the mixture over ice, seems surprising today. This domestic art—or rather this special fascination with coldness—would soon be rendered obsolete with the introduction of a freezing compartment for popsicles, sorbets, and ice creams. But in the 1930s it had a signal importance. Since few could own a refrigerator, the Electrolux seemed like a magical ice factory, the dream of an automatically functioning icebox.

This “compression” machine is responsive to the capacity of some gases, particularly anhydrate sulfur, to produce cold by evaporation after they have been compressed and liquefied. The use of the refrigerator in large establishments, on ships, in meat storage, and in storehouses of perishable goods goes back to the late nineteenth century. It spread rapidly in the United States and England and slowly and laboriously in Latin countries. Shown at all the universal exhibitions held at the end of the nineteenth century, the refrigerator was installed in maritime warehouses and railway depots by the end of World War I. In geographical terms it spread first in north-central Italy, which is cooler than all other parts of the nation. Created to meet the needs of the community at large, it was installed in large hotels in the form of chambers and in more modest lodging houses in the shape and size of a simple cupboard. Gas, electricity, and artificial refrigeration were first tested and installed in the largest hotels, then in smaller ones, and down the scale in terms of size until they reached private homes. The Manuale dell’industria alberghiera (Manual of the hotel industry) published by the Touring Club Italiano in 1923 takes this situation for granted. Here we observe ten pages of advertisements for refrigerators, almost all of them placed by German-owned outlets.43 This is an indication of the progress already achieved in the technology of refrigeration and its belated availability for domestic use.

Many understood that the refrigerator was used to preserve food, but few had experienced its capacity directly. It was nonetheless evident to all that this magic box produced water in a solid state. The symbol of the refrigerator is the ice cube, obtained by placing little metal trays filled with drinking water in the freezer. The refrigerator was one of the marvels of the hotel bar, where all utensils for making drinks were in evidence, including the shaker and the ice shaver. But was ice ever served at home? Almost never, given the backwardness of the infrastructures and the types of beverages consumed. Even water was artificially gaseated with the addition of powder before it was placed on the table. The practice of mixing drinks met with open hostility from the gourmets: “It is really disgusting to see some individuals drinking a cocktail before meals.”44 And yet the “little block of pure ice” was featured in all promotion campaigns, in the advisories issued to users, and in magazines or newspaper sections devoted to the ideal home. It even made an appearance in a recipe book, without it being clear to the reader whether this object was to be purchased or produced in the home. Il talismano della felicità, the Quattrova illustrato, and books instructing readers on how to receive guests all reserve a chapter for ice cubes and appetizers. In fantasies of the home that one might wish to have, there was even a furnished corner consisting of a domestic “American bar” or, lacking that, a piece of furniture on wheels on which glasses and bottles were placed.45 The cocktail, like the ice cube, evokes America, its contradictions (Prohibition was repealed in 1933), and its extravagance. The Accademia d’Italia, alarmed by its success, suggested replacing the word “cocktail” with “arlecchino” (Harlequin), while Filippo Tommaso Marinetti suggested “polibibita” (polydrink) instead.

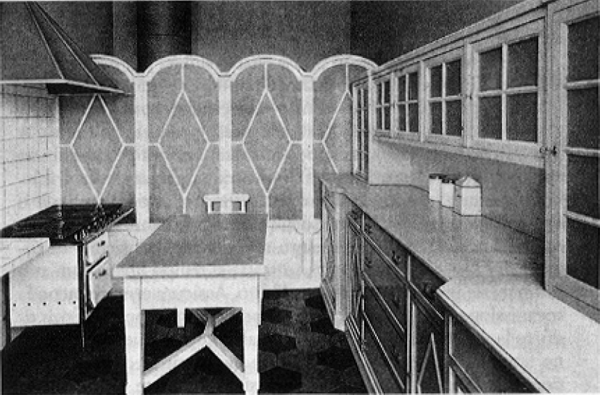

ABOVE: The kitchen of Baron Lerchenfeld of Munich.

Source: Benjamin Rumford, Essais politiques, économiques et philosophiques (Paris, 1802).

BELOW: Ideal kitchen.

Source: Lidia Morelli, La casa che vorrei avere (Milan: Hoepli, 1931).

In photographs from the 1930s we see that all kitchens are equipped with a clock. This is the household god presiding over culinary work, allowing one to calculate the labor of the housewife against the cost of the machine. The revolution in cooking materials and food preserves, in utensils and heat sources is increasingly legitimized by a gain in time. This would be underlined with even greater emphasis in the project of universal electrification that took place in the 1950s. And yet in praising the value of time lies the ambiguity of modernity. The relationship among edible objects, manual labor, and machines, far from being simplified, becomes increasingly complex. This is due primarily to the increasing rarity first of home cooks and later of maids, and hence the end of a dream: since machines were not capable of producing food on their own or, in other words, since they could not provide a service equal to the input of a cook or a maid, almost any cooking project meant for the woman of the house a burden that was not much lighter than the previous one. The refrigerator and the electric stove were dreams of an assisted domestic life. Without assistance they are containers to be filled and emptied mechanically. Semiprepared foods and preserved foods that were ready to eat became increasingly available as the refrigerator grew larger and as heat sources became progressively more powerful, instituting an ever greater connection between the microcosm of the domestic space and the macrocosm of the hypermarket.

How were recipes and dishes transmitted in this setting, which was cleaner and more efficient than the traditional space? This is difficult to assess, insofar as the updating of domestic infrastructures coincided with the growing availability of semiprepared products ready for consumption. As family cooking was carried out with a growing battery of equipment, the importance traditionally attributed to experience began to diminish. Was it industry that created the crisis in manual work, or was it manual work that abandoned industry? Over the past thirty years, in the midst of contemporary urban life, the work carried out in the kitchen has taken on an increasingly varied aspect, representing both an accumulation of “overtime” hours snatched from one’s leisure time and a refined art to be practiced during one’s spare moments. The everyday transmission of a gastronomic legacy is no longer guaranteed, though the demand for traditional dishes—especially those that that require time and patience—has remained steady. The utopian ideas that presided over the modernization of the kitchen have turned against their beneficiaries. Hygiene, functionality, safety, speed, economy, and the very notion of progress today seem generic ideals, not necessarily compatible with gastronomical values.

A slow and profound transformation of foods accompanied the alteration of the kitchen space brought about by clean energy and electrical equipment. The shift from an artisanal product, an object made by hand, to something produced with steam, boilers, and motorized power represents the first phase of industrialization. The most important consequences of applied scientific research are noted, however, at the moment when new nutritional principles are patented and foods are reconstituted. Gastronomy drives this process through the consumption of new products, but at the same time it submits to the effects of chemicals that guarantee convenience, hygiene, and moderate cost. One of the consequences of this is the presence in apparently traditional foods of ingredients that are not perceptible to the human senses or conceivable to the gastronomic sensibility. This hidden, indirect effect of research is manifest in cooking at a time when the transformation of the culinary environment is still in process. Yet unlike electricity or pots and pans these novelties are less evident to sense perception, and advertising minimizes the structural evolution of the nutritional object. Behind this procedure lies the suspicion of falsification in a society that is anchored by education to the humanistic myths of the good and industrious countryside. The originality of the new industrial culture is its use of technology for the creation of foods, both old and now, as we will briefly outline below.

First published in 1891, Artusi’s La scienza in cucina promoted a rational gastronomy with specific attention to physiology and hygiene. The term “science,” accompanied by the qualifier “applied,” was synonymous with industry, but Artusi himself proved to be a modest user of industrial conveniences and products. His book mentions the pickled foods that he purchased in Reggio. Here he also bought cheeses, such as Parmesan, and dried pasta—spaghetti and macaroni—but he chose to process his preserves at home, sterilizing them in sealed jars. He consumed beet sugar and drank coffee and beer. He did not avoid using Liebig meat extract as an alternative to broth.46 This product, which he describes as “one of the few food preparations recommended by scientists,” was produced in Uruguay from 1863 onward. Prepared from beef gristle, salt, and water, it was shipped to Munich and sold from there to the world at large. It had a shelf life of up to fifteen years.47

Italy’s two best-known industrial products, which were exported all over the world, were pasta and tomato preserves. Three machines were essential for the production of pasta: the mixer, which amalgamates flour and hot water; the kneader, either hand-operated or motorized, which completes the mixing process by incorporating all the tiny grains of semola into the dough; and finally the trafila, or press, which compresses the dough and gives it a particular shape before it is submitted to the process of artificial dehydration. At the beginning of the twentieth century all these phases were mechanized. Contents are shown on the packaging in different languages, along with the seal of inspection (for glutinated pastinas) and cooking instructions. Taking into account the possibility of export, the recipes for macaroni are written in French or in English. The instructions stipulate the quantities of water and pasta but not the boiling times, which are shorter in the south and longer as one travels north. The accompanying sauces are described in English, French, and Italian with a series of recipes that range from the fastest and simplest to the most complex, emphasizing the value of pasta as a complete meal (and not only as a side dish). According to the information on one label:

When boiled, [macaroni] can be served in different ways:

1. With grated cheese sprinkled on top and a few dashes of pepper;

2. With fresh butter, grated cheese, and additional butter according to taste;

3. With tomato sauce, meat sauce, or ragout, specially prepared each time, and grated cheese on top.48

Renato Rovetta, son of an industrialist from Brescia, compiled L’industria del pastificio (The pasta industry), the Hoepli manual dedicated to the production of pasta. He also produced Il pomodoro (The tomato), another manual by the same company. Tomato processing required a strainer and a crusher, a boiler for cooking, and equipment for concentrating the tomato pulp in a vacuum. Metal cans were then filled either by hand or by machine. Prepared for export, tomato sauce and tomato concentrate also included a recipe on the packaging label.

The Hoepli manuals describe all phases of the modernization of the Italian food industry from 1890 to 1940, providing information on planning, equipment, canning, and even tasting instructions. The commercialization of food production facilitated the development of an Italian gastronomic model that was compatible with the resources and taste preferences of foreign countries (for example, butter was the only fat used in cans of tomato sauce bound for France). The recipes attached to the manual on rice (Tecnologia del riso) are as detailed and as thorough in their instructions as any of the pamphlets produced for domestic use. The recipes take into account not only the ways in which rice can be served (including soups and sweet fritters) but also the various regions where it is consumed (from the area around Milan to the Veneto, from Naples to Sicily).49 The function of the recipe is threefold: to confirm the continuity between manual and mechanical forms of production, to demonstrate the suitability of the industrial product for traditional culinary use, and to offer simple and widely applicable models of preparation.

Naturally some products, such as Liebig extract used to make broth, did not simply replace other foods but functioned as integrators without the consumer being aware of their specificity. For example, powdered milk was used in 1929 in the manufacture of biscotti and chocolates, in luxury cakes and pastries, and in many products for children.50 The use of instant chocolate had anticipated this trend. With this type of ingredient there is no longer any continuity between handmade and industrial products. What we see instead is an exclusively industrial reformulation, with results that are difficult to assess from the standpoint of taste as well as gastronomy. Milk was a special focus of experimentation in Italy and in other, advanced countries. Its use in fermented drinks, yogurt, and lowfat cheeses such as quartirolo and, to an even greater degree, in caseine, which was destined for the manufacture of plastic, demonstrates how scientific applications were expanded within and beyond the food sector.

Industrial preparations enjoyed a remarkable degree of success in the pastrymaking sector during the 1930s. Beginning with a small packet of yeast and another of vanilla-flavored sugar (the basis of all sweet baked goods), the idea developed of creating packaged desserts of both Italian and foreign origin that could be assembled by the consumer with minimal domestic outlay (eggs, butter, and milk). The immediate availability of a stove or an icebox thus made possible the creation of a ciambella (ring-cake) or a sweet pudding. Bertolini, Elah, Royal, and Maizena, all respected brand names, soon published their own recipe collections for desserts, as Cirio had done for canned products. Artusi’s chocolate pudding was suddenly outdated, but it did not die out. This revival of recipes, now dedicated to milk and sugar, has a traditional aspect. Here the cook is implicitly a mother, the consumer a child, and her preparations are inevitably served at home. These values could be enhanced with the addition of special nutritional properties, as in the creation of baby foods and soups—along the lines of the project sponsored by the Dahò company—fortified with oats, tapioca, refined flour, and carefully trimmed legumes. There was a strong demand for healthy industrial products among the middle classes from the beginning of the twentieth century onward, and this would become more widespread with the rise in living standards.

Thanks to these “magic” packets, the food industry asserted its power in terms of speed and ease of execution. It promised success yet allowed the able consumer to claim the credit. The range of packaged items soon multiplied, as products became available for leavening, sweetening, and flavoring or as a substitute for eggs (Ovocrema). Containers of bicarbonate of soda could be used for cooking dried legumes, preparing desserts, preserving broth, making sparkling drinks, and even for footbaths. This chemical magic was easily accepted since it was integrated into the culinary craft of the home. The housewife’s relationship with industrial processes, however, remained ambivalent. On the one hand she was optimistic, since she had faith in yeast and in the pasteurized milk produced by central dairies. On the other she felt confused. Although milk inspires confidence, it is difficult to assess the quality of butter. Manuals appeared to protect the consumer from some of the products in daily use: “Butter is one of the most falsified food products. Theoretically one could say today that truly genuine butter can no longer be found commercially.”51 The presence of greater quantities of water than allowed or the use of unlawful colorants or inferior fats such as margarine and coconut oil is not often perceptible to taste and smell. What was the consumer to do in these circumstances? Trust the brand name was the advice given by the director of the municipal chemical laboratory of Milan.52 This is how self-certification became common practice.

The war years in Italy (from 1917 to 1918 and again from 1940 to 1944) also brought a sense of ambivalence to the relationship between public authorities and the food industry. Obligatory food rationing followed the outbreak of war, and this resulted in the recourse to substitutes (such as saccharine, chicory, barley coffee, and synthetic oil), “poor” cooking (vegetable broth and chestnut meal), the practice of making-do (with recycled fats, for example), and the deliberate falsification of rationed products. In response to the pressures of need and availability, culinary creativity flourished in this climate, with a special emphasis on ritual and on the possibilities offered by leftovers. These extraordinary times eliminated all free markets other than the black market and turned the consumer back in the direction of the countryside, where it was still possible to buy food, even if prices were high. The food industry suffered during this period almost as much as the consumers. Yet it reemerged unblemished in the postwar years with growing supply and demand. The publication of promotional recipe collections was then resumed by Carli olive oil and the Cirio canning company, barometers of middle-class dining.

But changes were even more evident beyond the domestic sector. A look at the dessert industry at this juncture is illuminating. In 1950 “Algida and Motta placed ice cream on the market; in 1951 Motta invented sticks [ice lollipops or popsicles], and in 1955 Pavesi and Motta brought out crackers.”53 At a time when the refrigerator was becoming widely available and the food industry was attempting to invent new ways to fill it, homemade ice cream disappeared, and the production of crackers and breadsticks began to compete with bread making. Sachets of yeast now seemed dated, and the expression “homemade” was less and less applicable to common foods. Ice creams and crackers in fact became snacks consumed independently of mealtimes. Eaten purely for pleasure, they are symbols of a new industrial trend that emerged in response to the decrease in domestic baking and the simultaneous increase in consumption outside the home.

The capitalism of food and agriculture instigated the synthesis of domestic modernization (from the refrigerator to the microwave oven), the increasing tendency to delegate culinary operations elsewhere, the trend toward occasional consumption, and the need to salvage a culinary identity. It produced long-lasting items (such as frozen lasagna) as well as products suited for quick cooking (spaghetti). Successive layers of industrial history peacefully coexist. By concentrating on the wide-ranging craft of pasta making, the Barilla Company triumphed, without tomato canning companies being swallowed up. The dairy sector grew, following the pattern of product differentiation already embarked upon and capturing consumers from all age groups. The most successful food and agriculture groups, however, are those that combine different product sectors and guarantee their international distribution. To what extent were gastronomic culture and practices affected by this phenomenon?

The food industry quietly insinuates itself into recipes through the requirement of specific ingredients and domestic equipment, but it does not dictate the law for the basic food model. It offers a finished product (frozen pizza) or ensures convenient assembly (a box of pizza ingredients) without bringing an end to the domestic production of the kind of pizza dough that is first leavened and then covered with the necessary flavorings. It encourages exotic experiments. In the area of public and private distribution it also teaches ways of consuming food that are foreign to Artusi’s gastronomy: eating without knives and forks (fried potatoes), spreading substances on bread (mayonnaise or Nutella, a chocolate-hazelnut spread), licking (an ice-cream cone), and throwing away beverage containers.