Electric motors are the muscle of most Technic creations. While it’s perfectly fine to build mechanisms driven by hand, and some builders actually specialize in human-powered models, the most impressive constructions are motorized. Motors can be used for almost anything, from driving and steering to rotating, elevating, extending, and even controlling other electric components. In this chapter, we’ll explore which LEGO motors are best suited for which purposes.

LEGO has been making electric motors since 1965, and they can be classified into three general categories. The first motors were 4.5V motors, but they’re rare, old, and inferior when compared to the newer motors, so let’s move straight to the next category.

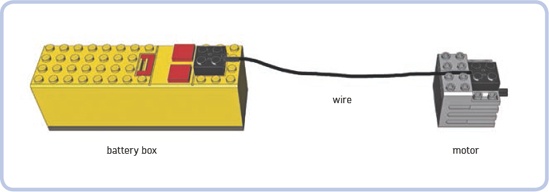

In 1990, LEGO introduced a second line of motors, running at 9V on six AA batteries (shown in Figure 12-1). These motors are considerably more powerful and convenient to use than their predecessors. The 9V line also has greater variation, including motors for boats with propellers and watertight housings. The 9V motors are widely available and highly popular. We’ll discuss this line of motors in this chapter, with the exception of some specialized ones, such as the Trains and Monorail motors, which are very difficult (or downright impossible) to use outside their intended applications.

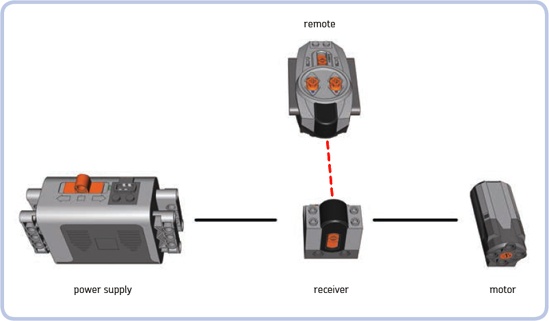

The third category of motors is the Power Functions (PF) line, introduced in 2007 (shown in Figure 12-2). These motors are designed to use a 9V power supply as well, but unlike the previous category, they are part of a carefully planned and currently developed system of motors and specialized parts. The Power Functions line includes just a few motors, which are designed to complement each other. Each motor is suited for different tasks, and the characteristics of the motors vary considerably. PF motors are well suited to studless building because they have odd widths and pin holes, and their torque is optimized for high-load applications. Additionally, they can be controlled remotely, while the motors in the other two categories can be controlled only with a wire connected to the power supply, which acts as a controller. Power Functions motors also allow more finegrained control, with more options than simply forward and reverse. We’ll explore the Power Functions system and its controls in Chapter 13.

The following list includes speeds of motors at both 9V and 7V whenever such data is available. (Rechargeable AA batteries and the rechargeable Power Functions battery provide a 7V power supply.) Also, note that motors are prone to wearing down over time; thus, the exact characteristics of any two motors of the same type can vary.

While there is no official technical specification for the LEGO motors, LEGO enthusiast Philippe “Philo” Hurbain has spent a lot of time performing many complex measures on these motors. This chapter’s measurements are derived from his work and used with his kind permission. (Read more about Philippe’s work at his site, http://www.philohome.com/motors/motorcomp.htm.)

No-load speed at 7V: 2000 RPM

No-load speed at 9V: 3300 RPM

The first motor in the 9V line, the 2838, is relatively large and has no internal gearing, which results in very high speed and low torque. It’s ineffective in high-load applications where it requires substantial gear reduction, often including one or more worm gears. This motor is also prone to overheating. The motor has a 1L axle protruding out of it and connects to the power supply through a 2×5 contact area in the middle of its bottom surface.

No-load speed at 7V: 160 RPM

No-load speed at 9V: 250 RPM

This 9V motor is popular due to its reasonable size and favorable characteristics. It’s a very quiet motor with substantial internal gearing, which creates noticeable inertia when the motor is stopped. The motor has a 1L axle and connects to the power supply through a 2×2 contact area on its top. Its upper surface is conveniently shaped, with one recess for the power plug and another for routing the wire backward. Its lower surface has a 1-plate-tall 2×2 bulge in the back.

No-load speed at 7V: 140 RPM

No-load speed at 9V: 219 RPM

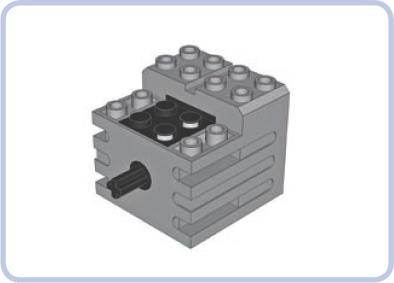

Externally identical to the 9V 71427 motor (shown previously), this motor is almost one-third lighter at the expense of slightly reduced speed. The difference in weight makes it more sought after than the original 71427 motor, so it sells for significantly higher prices. The motor has a 1L axle and connects to the power supply through a 2×2 contact area on its top. Its upper surface is conveniently shaped with one recess for the power plug and another for routing the wire backward. Its lower surface has a one-plate-tall 2×2 bulge in the back. Just like the 71427 motor, this motor can be mounted on rails using the two slots on its sides (shown in Figure 12-3).

No-load speed at 7V: 210 RPM

No-load speed at 9V: 315 RPM

This motor is similar to the 71427 motor, except that it has a higher speed and is louder. It’s 1 plate taller than the 71427 motor and comes with a completely flat bottom. The motor has a 1-stud-deep axle hole and connects to the power supply through a 2×2 contact area on its top.

No-load speed at 9V: 16 RPM

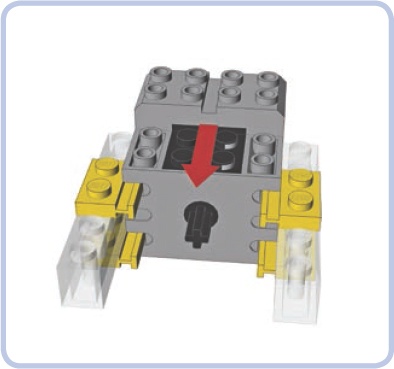

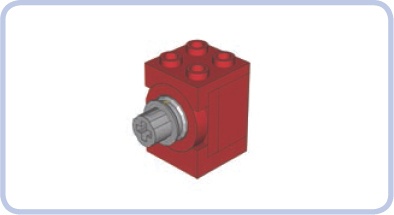

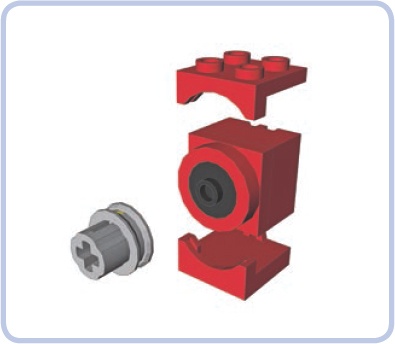

This 9V motor is exceptional for its small size. It’s rare, highly sought after, and expensive. Its speed is so slow that it doesn’t usually need external gear reduction, while its torque is quite high for a motor this size (higher than the 2838 motor’s torque, for example). A complete Micromotor consists of four individual pieces: an upper and lower brace, a “Micromotor pulley,” and the motor itself. The motor is rarely used without these pieces, although it can be operated without the braces if it is connected to something by its power plug. The motor connects to the power supply through a 2×2 contact area at its back. Figure 12-4 shows an exploded view of the Micromotor and its parts.

Figure 12-4. An exploded view of the Micromotor, showing its upper and lower brackets, pulley, and motor

The Micromotor’s specially designed pulley has a 1-stud-deep axle hole and a belt groove for a rubber band. The pulley allows the motor to be connected to an axle. The pulley also works like a slip clutch, preventing the motor from stalling.

No-load speed at 7V: 82 RPM

No-load speed at 9V: 117 RPM

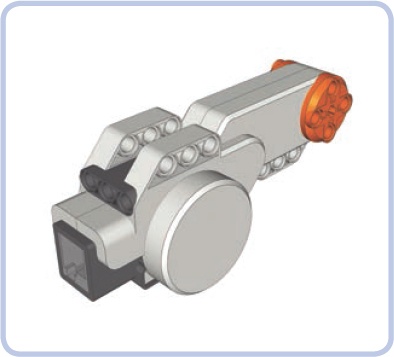

This motor was designed specifically for the MINDSTORMS NXT set. It has the highest torque of all existing electric LEGO motors and high power consumption. It includes a rotation sensor with a one-degree resolution, which is useful when designing robots that require precise control.

However, its shape and size are a disadvantage when one is using it outside MINDSTORMS constructions, and it connects to the power supply through a MINDSTORMS-type plug, which means that a special converter cable is required to connect it to regular 9V or Power Functions power supplies. Unlike other motors, its output is a 3-stud-wide ring (orange in the figure above) with four 1-stud-deep pin holes around the center. It also has an empty axle hole in the center through which any axle longer than 3 studs can be inserted.

No-load speed at 7V: 300 RPM

No-load speed at 9V: 420 RPM

This unusual Power Functions motor was designed for LEGO Education sets. It has low internal gearing, which allows it to be easily driven and to act as a power generator. However, its large size and poor speed and torque performance make it practically useless when compared to other Power Functions motors. The motor has a 1-stud-deep axle hole and an integral wire.

No-load speed at 7V: 185 RPM

No-load speed at 9V: 275 RPM

With a diameter of only 3 studs, this popular Power Functions motor takes up little space and fits studless constructions exceptionally well while offering very good torque. The only downside to this motor is that it’s 6 studs long; other than that, it’s easy to use, powerful, and versatile. This motor has a 1-stud-deep axle hole and an integral wire. It can be mounted either from the front using some of its four pin holes or from the bottom using studs.

No-load speed at 7V: 203 RPM

No-load speed at 9V: 272 RPM

Introduced in 2012, the L motor works where the Medium motor is too weak and the XL motor is too big. At 3×4×7 studs it’s only slightly larger than the Medium motor, while delivering nearly 180 percent of Medium’s torque. It’s a little slower than Medium motor though, and its power consumption is higher (see understanding the speed control feature in basic remote for details). This motor has a 1-stud-deep axle hole and an integral wire. It can be mounted from the front or back, or from two of its sides using pin holes—it has 14 of those, including 2 at the back.

No-load speed at 7V: 100 RPM

No-load speed at 9V: 146 RPM

This is the most powerful Power Functions motor. It shares some essential internal parts with the NXT motor but has lower torque and higher speed. The XL motor is popular because it’s extremely powerful, and it’s more prevalent and easier to use than the NXT motor. Still, its large size makes coupled Medium motors a better choice in many cases. This motor has a 1-stud-deep axle hole and an integral wire.

This motor cannot be connected via studs. It has six axle holes on its front and four on its sides, which allow it to be firmly braced in a construction against considerable output torque.

Introduced in 2012, the Servo motor is designed for steering systems. It can’t rotate continuously—instead, it rotates 90 degrees clockwise or counterclockwise from its central position. Its low speed allows it to be used with most steering systems directly, with no gearing in between, while its huge torque makes sure it won’t be easily stalled.

When used with a basic PF remote, the Servo motor rotates 90 degrees in one direction or the other when the remote’s lever is pushed, and it returns to the central position when the lever is released. When used with the speed control PF remote or directly with the rechargeable PF battery, the motor follows the rotation of the speed dial, meaning that it provides proportional steering with 7 steps in either direction and 1 neutral position (which it returns to after the remote’s stop button is pressed). In other words, it uses the PF speed control feature to break its 180 degrees of total rotation range into 15 steps, 12 degrees each, while its speed remains constant at all times.

This motor measures 3×5×7 studs, and it has a bulge on its bottom with a 1-stud-deep axle hole on the front and another on the back. Thus, the motor can be inserted between two axles; it will keep them 1 stud apart and rotate them as one in the same direction. It also has an integral wire and can be mounted from the front or from two of its sides using pin holes.

Torque (inner output/outer output): 1.83 N•cm/2.48 N•cm

No-load speed at 7V (inner output/outer output):

| 906 RPM/670 RPM |

No-load speed at 9V (inner output/outer output):

| 1245 RPM/920 RPM |

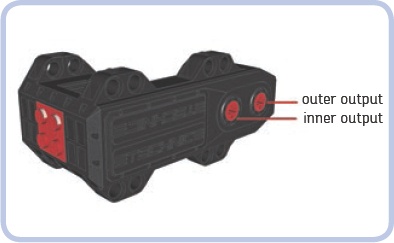

This 9V motor was originally designed for a discontinued series of fast radio-controlled cars. As such, it has an unusual shape, good torque, and very high speed. Unfortunately, it is also very noisy and has extremely high power consumption; in fact, some power supplies can’t even let it run at full power. In theory, its speed and torque make it the most powerful electric LEGO motor, and with efficient external gearing, it can perform better than XL or NXT motors. It does, however, tend to become overheated under high loads, which causes its internal electronic protection to shut the power off until the motor cools down.

The RC motor is unique because it has two outputs. Both are empty axle holes running in the same direction, but the motor’s internal gear ratio is different for each of them. Because of this, the inner output runs faster at lower torque than the outer one.