VC10 Takes Shape.

* Warning: Contains Graphic Technical Content

By early 1957, despite the strategic confusion created by the UK Government and BOAC, the State (in all likelihood, blind to its own airline strategy failings) took a decision to allow the funding for BOAC to order a large, four-engined British long-range airliner. BOAC would go on to say that it would have been happy to have a British version of the 707, or even a British, licencebuilt 707, but that government – BOAC’s accounting paymaster – insisted on a British-designed product. BOAC seemingly having conveniently forgotten that the political imperative for such a government decision had stemmed from the issue of BOAC itself ordering nearly 50 million pounds worth of Boeing 707s at a time of shortage of Sterling in the UK Exchequer!1

The de Havilland DH 118, Handley Page HP 97 (an HP 80 Victor derivative), Bristol 200 and the Vickers Avon powered Vanjet iterations, had come and gone – all on paper. And after the loss of an HP 80 Victor in July 1954 due to its T-tail design – the tail unit came off – Vickers had to prove that their T-tail was truly safe (the HP 80’s fin height was shortened for subsequent production). The key point, however, was that only Vanjet had morphed into a design specification that was the essence of the forthcoming airliner – which turned into the VC10 after much deliberation.

By now, despite its previous statements of needing an ever-increasing fleet of jets, BOAC now decided to order just twenty-five VC10 type machines to be deployed principally on the airline’s eastern and southern routes medium route empire – the ‘hot and high’, or ‘MRE’ network, with its difficult operating environment of high temperatures and (at that time) very short runways and minimal facilities – the old weight, altitude and temperature (WAT) limited, runways and airports of Imperial Airways.

BOAC mooted its transatlantic requirements and early thoughts of a larger or ‘Super’ type VC10 were discussed. But, if BOAC were to ‘swap’ orders for the MRE route Standard-type VC10s for Super VC10s (therefore reducing the number of Standard VC10s), then the loser would be Vickers, not BOAC. There seemed, however, to be strange BOAC and government attitude at play, Vickers would have to ‘prove’ that they could design and deliver the VC10 to very strict BOAC demands, before the airline might offer real and total commitment to the machine as orders. In the background, BOAC had a very large sword to wave over Vickers heads – the 707 and its potential Rolls-Royce Conway powered BOACspecific variant. The ability to carry a 35,000lb payload over a minimum 2,500 mile range at Mach .82 to Mach .88, and to have full, high temperature operating ability from un-lengthened runways, were the key demands. And out on the tropical eastern routes, a regular 35kt headwind would also have to be dealt with. Oh, and can you make it viable for the North Atlantic winter conditions to New York, Boston and Toronto as well, suggested BOAC.

The BOAC problem was to carry a good payload of 25,000lbs/40,000lbs for 2,500 miles from a hot temperature and/or high altitude runway, and reach the destination against headwinds and tropical weather – without offloading fuel, passengers, or cargo, and avoiding an unplanned refuelling stop.

The key issue of the VC10’s advantage over the 707 and DC-8 was its lesser take-off requirement for runway distance and carrying much more payload. That advantage was reduced by the longer runways soon built. But when looking at runway distances cited, we must remember that these often include not just the amount of runway needed to ‘rotate’ (‘Vr’) or ‘unstick’ the aircraft into the air, but the extra runway distance also required to include the ability to stop from a high-speed rejected take-off (for example, at 100kts+ due to engine failure). Such runway length requirements were set by British and American authorities. For example, a VC10 at typical passenger load, might actually lift off the ground in 4,000 – 5,500ft, but the (additional) required stopping distance might be another 2,000ft – thus giving a total runway requirement for lift off and a high speed ‘abort’ as a safe operation of 7,000ft. Rival Boeing and Douglas machines might need 10,000 – 11,500ft total runway distance requirements according to official figures.

The VC10’s first flight take-offs were in under 2,500ft (2,150ft!) actual distance to ‘unstick’ lift-off from the especially extended Brooklands 3,800 – 4,500ft runway that featured a high-speed taxiway bend. After departing, the newly manufactured VC10s and Super VC10s would land at nearby Wisely, at the Vickers test base. The in-service take-off weight for a Standard VC10 was up to 312,000lbs and for the Super VC10, 335,000lbs, but because the Wisely runway length of 6,000ft was insufficient for safe operation to the abandoned take-off runway length required at full load, a limited maximum take-off weight was applied, this being 260,000lbs. This still allowed test flights with a duration of over six hours. The first-flight from Wisley with a decent payload saw G-ARTA ‘unstick’ and fly in under 4,500ft and the landing of G-ARTA on the Wisely 6,000ft runway, saw G-ARTA stopped 3,600ft from the runway’s far end after a ground run of just 2,550ft.2 The brakes and tyres might have been a touch warm!

BOAC’s demanding routes required actual take-off distance to rotation (‘Vr’) and safe lift-off climb (‘V2’) that varied with aircraft weight and local temperatures. As some ‘runway distance required’ figures meant that combined total safe takeoff and emergency stopping distances, so some statistics also refer to a take-off distance to achieve a 35ft ‘screen’ height for obstacle clearance. But whatever the vagaries of the statistics quoted, the facts were clear, the VC10 – wait for it – took off in a shorter distance, at about a 25% slower speed, and did so with a full or almost-full max-range payload, all prior to climbing quickly and steeply to gain safety height. A VC10 required at least 2,000ft less runway than a (weight/payload limited) 707, but in really testing African ‘hot and high’ conditions, the 707 might need much more extra runway length than that with a load 10–20 tonnes below its maximum allowable normal take-off weight. Such airfields saw temperatures of 85º – 90ºF/30º – 35ºC or more, and altitude elevations of up to and over 5,000ft, and minimum runway lengths of 6000–8000ft. Until runway extensions were made, many of these runways were unusable by a 707 or DC-8 carrying any viable long-range load, or they would be unable to take-off at all.

Typical, ‘Difficult’ BOAC ‘Hot and High’ Airfields and Route Sectors 1962

Cited at the then dated runway lengths and the international standards (BCAR) runway temperature plus extra 15º Centigrade and with a/c payload fuel reserves at sixty minutes.

• Colombo to Cairo at 3,550 miles from 6,000ft runway

• Lagos to Kano 481 miles from 7,600ft runway and Kano to London at 2,750 miles from 8,610ft runway

• Kuala Lumpur to Calcutta at 1,610 miles from 6,000ft runway

• Mexico City to New York 2,080 miles from 13,500 runway at 7,350ft elevation

• Nairobi to Johannesburg from 8,000ft runway at 5,327ft elevation

• Salisbury to Nairobi from 6,000ft runway at 5000ft elevation

• Singapore to Karachi at 2,959 miles from 8,000ft runway

• Singapore to Sydney at 4,050 miles from 8,000ft runway

• Addis Abba (7,320ft elevation) to Nairobi from 6,000ft runway

To meet its demands, BOAC issued the toughest and most unfair large airliner specification ever issued to a manufacturer. The VC10 would have to lift a payload of 38,000–40,000lbs from a demanding tropical runway and have 2,500 miles range and be able to beat a 35kt headwind. Nevertheless, Basil Smallpiece and the newly Knighted Sir George Edwards signed the BOAC VC10 contract on 14 January 1958.

As we know, in hindsight, various claims about who said what and who demanded what in terms of orders have been made. BOAC ordered thirty-five Standard V1000 VC10s and Vickers reacted with a price of £1.5 million per airframe, with £1.75 million per airframe cited for the potential Super VC10. Thirty-five VC10s was, in 1958, likely to be more than BOAC then thought it wanted, yet did not BOAC very quickly say that such a number, even allied to its 707 orders, would not be enough for its 1960s predicted traffic growth plan? By the time the contract was signed, Vickers and its team got on with the job – using pre-existing Vanjet, Valiant and Vanguard experience to good engineering and fiscal effect. Between 1958 and 1960 there began ‘movement’ in the BOAC fleet requirements and the airline’s VC10 standpoint. Here began the ‘swap-shop’ between Standard and Super VC10 orders.

The VC10 contract was rewritten in 1960 and curtailed the Standard model order to fifteen and asked for thirty of the Supers. By 1961 the contract had changed to just ten Supers and thirteen Standards. Yet the next contract would be twelve Standards and seventeen Supers. BOAC seemed to be able to ‘play’ the order book at will. And Vickers had to bite on the medicine.

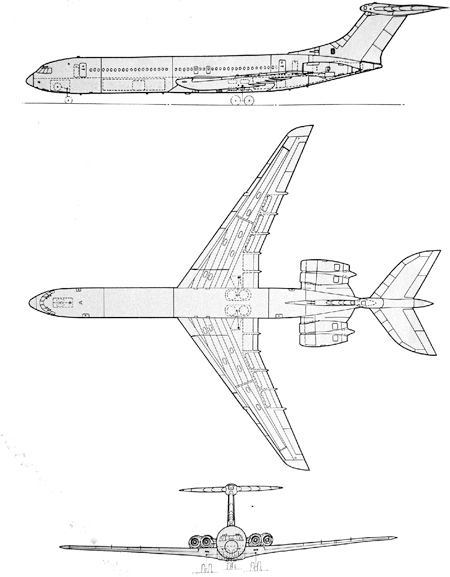

At great cost, Vickers built two vast new assembly factory ‘halls’ at Brooklands to cope with the VC10’s size, notably the fin height, but early fabrication of the airframe took place at the Brooklands Assembly Line Hangar ‘W1’ (now a housing estate). The ‘Wing Shop’ was adjacent to this main ‘W1’ hangar. With the VC10 parts in jigs and frames, the main fuselage body structure was mated together minus the tail fin and wings and engines. Then the airframes were taken on special wheeled trailers or cradles over to the so-called ‘Cathedral’ large assembly ‘shop’ or hall – where all the final assembly was carried out by fitting the fin (road-freighted in from the Hurn factory), rudder, tailplane, engines and undercarriages.

As the design process proceeded, fiscal and time savings could be made by Vickers by using its prior experience (notably of Vanjet), but greater expense in time and money would be required from Vickers own purse as the design development and BOAC operating requirements were firmed up with the airline supplying its actual airfield operating figures for tough locations like Nairobi, Karachi, Lusaka and Salisbury.

Max-payload for the VC10 would be 39,769lbs/18,039kgs in BOAC specification. Super VC10 would lift 50,406lbs/22,860kgs as a type 1151 for BOAC (the East African passenger/cargo Super VC10 would lift 60,231lbs/27,360kgs). The payload range would approach 4,700 miles+.

The original Vanjet-Vanguard costing basis using existing jigs and toolings, but this would have to be leapfrogged as the design developed and we have to state that this was Vickers own affair and not BOAC’s responsibility. But this was how the design process evolved to meet the airline’s requirements. By discarding earlier designs as evolving Vanjet proposals, the VC10, like the V1000/VC7, had become a true long-haul machine. In the Viscount, Vanguard and Valiant, Vickers had pioneered new ideas and new techniques, notably in structural terms and in ‘fail-safe’ and double ‘fail-safe’ structural load and stress pathway design to reduce airframe fatigue from flight, ground, and pressurisation loadings.

So VC10 offered not just ‘spare’ structural load paths, but a double redundancy with extra load paths all designed to take up the load if a principal structural member was damaged and another invoked. This technique ensured that the VC10, which would be subject to some pretty rough conditions on basic tropical runways, would not suffer from structural weakness. We can opine that like the entire industry, Vickers benefited from the structural lessons of the Comet 1 tragedies, however, Vickers had, prior to those tragic events, decided to make a tougher (if heavier) structure and use more reinforcement than de Havilland had. From 1948, the Viscount had used curved elliptical shapes for all fuselage cut-outs such as doors, windows and panels – before, de Havilland’s used the riskier, square cornered cut-outs for such items on their new Comet 1. So the men at Weybridge knew their stuff. The VC10 would also bring multiple, protective, fail-safe dual flight-control designs, which would create new standards in this design area. An ‘Iron duck’ nickname was latterly attached to the ship-like construction of the VC10 – Vickers once being great shipbuilders.

The Team

Sir George Edwards operated a truly integrated team of experts and artisans. Under Edwards, a real team spirit existed at Vickers. The resultant quality of their designs and products were, of course, world-class and world-beating. It is not possible herein to mention every employees name, but between the men of the advanced projects design office, the engineering projects teams, and the vital shop floor workers (or ‘associates’ as collegiate corporate speak might now call them), we can, for the record, cite vital VC10 project contributors. Any omissions herein are accidental or the result of the author, fifty years down the line, being unable to further research a detailed employee list.

Ernest E. Marshall led the Vickers design function under Sir George Edwards leadership, Basil Stevenson was Assistant Chief Designer. Hugh Hemsley was Assistant Chief Engineer and VC10 project engineering leader, Hugh Tyrer was Vickers Chief Metallurgist. Jack Swanson and Ted Chivers were the Senior Draughtsmen. Frank Ward, Sammy Walsh, Maurice Wilmer and John Davis were lead contributors in the advanced projects team.

The aerodynamics team, the VC10s ‘aero’ men under Ken Lawson as Chief Aerodynamicist, saw John Hay as Assistant Chief Aerodynamicist, Mike Salisbury as Assistant Lead Aerodynamicist, Roger Back and Heinz Vogel as aerodynamicists. Dieter Kuchemann was a project contributor via his RAE role.

The engineering team was David McElhinney as Chief Stress Engineer, David James as Chief Structures Engineer, John Davies as Chief Weights Engineer and Jim Richards was Deputy Chief Stressman, while David Findlay was Leader Wing Stress. Albert Kitchenside was a Structural Engineer on the wing stress team. The fuselage Project Manager was Maurice Wilmer and Alec Paterson was fuselage build leader. N.W. Boorer (latterly a BAC chief project engineer) worked on fuselage and pressurisation systems.

The engineering systems team covering the innovative flight controls, and electrical systems men, included: Ted Petty as Chief Project Engineer, Harry Zeffert as Leader Electrical Engineering, Jack Ratcliffe, Colin Jehu, and Gerry Hitch, as Senior Electrical Engineers. Gordon Howells was the Senior Engineer on the flight controls. George Aylesbury was Lead Mechanical Engineer. G.W. Webber was the lead autopilot project Design Engineer. One of the youngest men to work on the VC10 was A.R. Walker, who, aged twenty-two, started his Vickers career as a young engineering apprentice in 1957 and worked on VC10, BAC 1-11, and TSR2 up to 1965.

The VC10 prototype (G-ARTA) build production was overseen by Bill Potter as production manager, Ken Keenan as his assistant, with Wally Chapman, Cyril Redman and Harry Welton as senior foremen at Vickers Weybridge. Ivor Tinker and Ron Storey were two well-known members of the VC10 engineering/ manufacturing team that created G-ARTA. Edward Read was chief draughtsman at Vickers Hurn on the tail control surfaces.

The flight-test teams for the VC10 and Super VC10 were: G.R. ‘Jock’ Bryce, Brian Trubshaw, Bill Cairns, John Cochrane, Eddie McNamara, Doug Howley, Roy Mole, Chris Mullen, Roy Holland, Ian Muir and Peter Diss. Later Super VC10 and RAF development airframe flight crews included R. Radford and P. Baker. Vickers training pilots to BOAC and VC10 customers were D. Hayley-Bell and L. Roberts, with D. Ackery in the flight test department.

The vital VC10 (and Super VC10) ground crews, who also travelled overseas with the flight test and route proving flights, included: Ron Bennett, Eddy Capell, Denis Collier, Joe Lindsey, Ken Norridge, Bill Oldfield, Jack Pulfer, John Randell, Toby Tobias, Maurice Ungless, Denis Wells and Bob Wright.3

The above lists are not intended to be definitive and many more unnamed and unrecognised men (and women) contributed to the design and build of the VC10.

Design Issues

The key VC10 design issue was not one just of principal power, but of lift and runway ability as en route airfield flexibility – to which power was not the sole story. Anyone could create a rocket ship with power and it might have very high take-off speeds, require a 10,000ft runway length, and more critically, have very high landing speeds and high wing loadings. And what good was a high Mach number cruising speed if the aircraft behaved like a pig near the ground – with safety implications? So power, or more appropriately, thrust, was not the only asset to be valued.

Lift and lifting ability were the crucial factors and they would come firstly from wing design. Thus were set the VC10s key ‘aero’ design parameters. Then came the new fail-safe split-systems control design philosophy, the electrical and service systems innovations, and then the structural design ingredients. All of these advanced airframe and systems developments combined to create a ‘next-step’ in large airliner design and many of the VC10s features and achievements can now be seen in recent Boeing and Airbus airframes. If the 707 was, in design terms, the ‘best practice’ in 1958, then the VC10 advanced the arts in 1962.

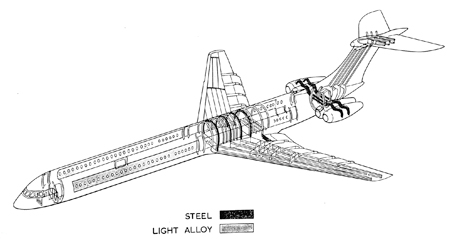

The VC10 needed to be stronger and more fatigue and distress resistant than the Comet or an airliner designed for easier routes. Rough runways in Africa would demand a very tough structure that would resist fatigue. Over fifty-five per cent of the VC10’s structure (by weight) was machined from high quality, solid lumps or slabs (billets) of metal. This delivered safe sections of very strong, and large, aircraft parts in the wings, fuselage and inner chassis structure which were of consistent metallurgical quality, and had uninterrupted stress pathways or patterns. A superior, smoother exterior finish (aerodynamically beneficial) was also a benefit of the expensive machining process for the alloys used: the VC10s skin – ‘smoothness criteria’ – was the best in the world and better than that to be found on a 707 or DC-8. And with a reduced panel and parts count, construction was easier and torsional rigidity higher – with fewer joints to flex or fail or corrode.

The main wing skins were machined from single bits of metal 35ft long– much stronger than a multiple panel skin. The VC10’s main wing had only seven main panels – ensuring great consistency of strength. Upper wing surfaces were made of a zinc-rich alloy (DTD 5050) and the lower surfaces of an aluminium copper alloy (ST24). The three-part wing structure was therefore very strong indeed, and so too was the central wing box that carried many loadings. Wing-skin milling was overseen by Harry Welton – senior foreman.

From a corrosion resistance standpoint, the VC10 used the best moisture reduction and corrosion inhibition systems ever seen on a civil airliner (arguably never bettered to date) and proved their worth in protecting the VC10s structure in the humid conditions of its main operating arenas. This also made the VC10 less likely to defect and repair than its rival. Any airliner constantly being heated, wetted, and then deep frozen at high cruise level, needed real and effective anticorrosion treatment – like a Swedish car for example. The VC10 was painted inside and out – ‘all over’ – and with all hidden cavities treated where required and several layers of corrosion inhibition paints applied throughout the structure. It was, in a sense, rustproofed. These coatings added weight – but they reduced corrosion, and the needs and costs for regular replacement of corroded parts. The 707 did not feature such advanced corrosion protection techniques – so saving build costs and weight – thus creating more likelihood of renovation and replacement costs after purchase to be borne by the customer airline.

The proof was in the pudding, and it was proved early on when BOAC sold the three early VC10 airframes that had spent a decade in the corrosive humid skies of Africa. These machines were actually sold to Boeing, who in 1976 chopped them up in-situ at London Heathrow Airport – an act of deliberate commercial vandalism according to some observers. Ripped apart with their hidden, inner cavities and secrets exposed for the first time since construction, no structural corrosion was found at all and no ‘fatigue distress’ discovered; noteworthy corrosion would have been normal and expected in any airliner, especially a tropical route operating machine. But the early VC10s were nearly ‘as new’ under their slightly soiled skins and yellow anti-corrosion paint.

Of course, later in the VC10 and Super VC10 life, after decades of service and years of adverse storage prior to conversion to RAF tankers, some corrosion and fatigue was encountered in structural components – twenty or thirty years into airframe life in a fifty year story.

Supersonic Valiant and the T-Tail Origins of the VC10

Of singular significance was the decision to employ a T-tail configuration – and not just any boring, short, stubby T-tail, but a grand, elegantly swept piece of design with an outrageously stylish sculpted bullet firing atop the fin.

The advantages of the (Multhopp-created) T-tail included better (increasing) control authority than a low-set tail at high incidence angles, a beneficial ‘endplate’ effect upon fin drag, and helpful effects in critical Mach numbers with a better ability to balance increased main-wing chord. The high fin also removed the tailplanes from the issues of engine exhaust flow plumes and engine pod flow, and compressibility and interference effects in rear-mounted engine configurations. Only the spectre of the ‘deep-stall’ or ‘super-stall’, with its potential for loss of elevator authority and resulting ‘locked in’ irrecoverable total airframe stall, haunted the T-tail as a design philosophy. Most manufacturers relied on a control stick-pusher to avoid a too nose-high attitude, the VC10 had one by legislative order, but its T-tail was unique in avoiding the worst aspects of the T-tail stall behaviours and characteristics due to its sweep and height, allied to massive elevators that were properly powered. There was never a VC10 deep-stall accident, unlike other airframes.

Many assume that the T-tail stemmed from the need for the ‘clean’ unencumbered wing design, and that this choice was made during the Vanjet studies. However, as early as 1952 – before the Caravelle’s swept, rear-engined shape – Vickers were drawing up a T-tailed, elegantly swept, Valiant derivative. This was the supersonic variant of the Valiant – to a proposed Ministry specification and first drawn in January 1952 with discussion of an informal nature with the RAF’s senior air staff. A highly swept main wing, and further swept tailplane, worked to keep the critical Mach numbers in tune at supersonic speeds. Interestingly, Vickers proposed that this Mach 1.38 capable airframe should be Rolls-Royce Conway powered (using existing Valiant ducting, but revised, aft-spar engine mountings). Of particular note, it was in this Valiant Mk2 supersonic design that we see the first use by the Vickers design team of a tall, elegant, swept, T-tailed fin, and of real design interest, highly swept, curved shaped tailplanes atop the empennage.4 We can see clear origins of the fin and tailplane designs of the later VC10 in this 1952 design by Ken Lawson and colleagues.

VC10 Takes Shape.

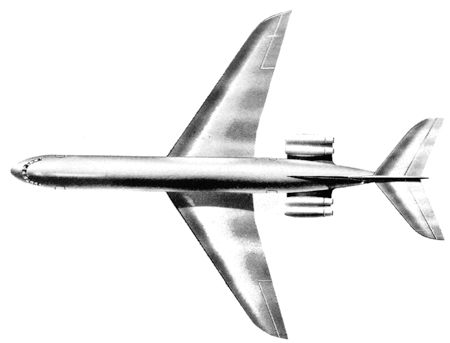

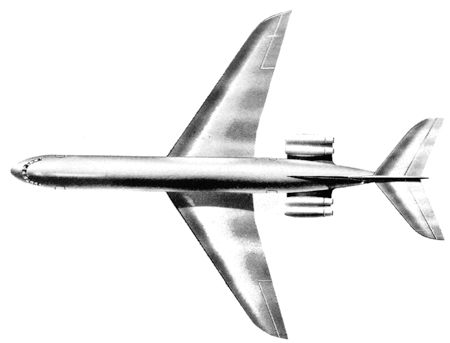

Who ‘designed’ the VC10? The above mentioned men all designed or engineered the VC10, and it is very hard to ascribe to one person the actual shape, or for want of a better word, ‘styling’. The Valiant and Vanjet works heavily influenced the shape or style of the VC10, and Ken Lawson’s aerodynamics input had an effect on the shapes chosen – notably that fin. But there is a riddle in the tale, because we know that it was Sir George himself who actually sat down and made rough sketches of the aircraft’s configuration and basic shape. He might not have fully formed the final touches or the exact form of that ‘sculpted’ iconic tail, but the reality is that Edwards drew the initial design sketches, by hand at home with a pencil.5

‘Aero’ Issues and Wing Design

Vickers had, via the Vanjet studies, decided on the ‘clean’ wing, with nothing hanging off it. Rear engines ensured an efficient, ‘clean wing’ airflow. Yet paradoxically, this aerodynamic advantage removed a structural advantage – known as ‘wing bending relief ’ upon the wing structure from the engines – when the weight of an engine(s) hanging below the wing, offers an opposing force (downwards) to the created ‘lift’ force that is trying to bend the wing upwards. Engines under the wing – in opposing bending moment – therefore offer a benefit to the wing structure, as less wing reinforcement and strength (incurring weight in the wing) is required to counteract the lift force upon the wing structure. With no such engines on the wing, the ‘clean’ wing has to be stiffer, stronger, and heavier. This is one of the reasons that the VC10 is more expensive to operate than a 707, because the VC10’s wing structure is slightly heavier for the same number of passengers accommodated, with figures of 25.7% of Maximum Take-Off Weight (MTOW) as opposed to the 707-320s 24.6%. It may not seem much, but it had a cost in terms of fuel consumption.

For the VC10, the wing loading was intended to be a low 80lbs/ft2/394.4kg/m2, but the penalty of the heavily reinforced VC10 structure saw that figure heading towards 99lbs/ft2. The Super VC10 had a minimum wing loading of 80.08 lbs/ ft2/394.5kg/m2, but a maximum weight wing loading of over 101lbs/ft2 and a max take-off weight wing loading of a not inconsiderable 114.3lb/ft2/558.1kg/m2. This was not dissimilar to the wing loadings of the big Boeing and Douglas jet variants, but was ameliorated by the VC10/Super VC10 high lift devices, lower aerodynamic drag and extra thrust. The VC10’s wing area was initially set at 2,800ft2/264.8m2. When the prototype’s wing was changed to improve its operating characteristics the wing area increased to 272.4m2.

The VC10 had a slightly higher aspect ratio than the 707, being set at 7.5 aspect ratio. It was the VC10’s advanced aerofoil and more efficient flaps and slats that improved the slow speed handling and the airfield performance of the VC10 in comparison to other machines such as the 707 and DC-8. This slower, low speed handling was a major safety factor benefit to the VC10.

The sweep of a wing is usually measured at the quarter-chord (width) line and a swept-back wing has a higher critical Mach number than a non-swept-wing. The VC10 wing was to be a 35º sweepback wing, but much debate over a 32.5 º sweepback took place. The final VC10 wing sweep figure was therefore just slightly below that 35º ideal formula of 1940s German advanced wind tunnel provenance that Boeing (but not Douglas) followed in their jets. The maximum operating Mach number (MMO) for the VC10 was set at 0.886 for 31.000 feet and above. Later built RAF VC10s were cleared to Mach 0.925 speed cruise (and sometimes operated above that figure). The designed maximum speed (MD) is Mach 0.94. Later on in the life of the RAF VC10s (as tanker conversions) the MMO was adjusted to 0.866, putting less stress on the ageing structures that were in their fourth decade.6

In terms of overall aerodynamic performance, the VC10 was very smoothly finished in comparison to its two main rivals, had more curvaceous nose window design to the 707, and better sealing than any of its rivals. The general finish of the aircraft was exemplary in terms of reducing localised surface issues and airflow degradations and drag triggers. The lack of a ridged cabin window ‘belt line’ offered significant smoothness criteria advantages over the rival airframes and much lower aerodynamic noise too. Fokker aped the technique for its F28; a mini Vanjet/VC10 if ever there was one.

Such VC10/Super VC10 overall advantages stemmed from forensic work by the aerodynamics team.

However, it was soon obvious in testing that two drag issues were extant – that of confused airflow around the engine exhausts, and that the wing tip vortex was stronger than was anticipated from the wind tunnel tests. The prototype aircraft seemed to produce more drag than predicted, and in some cases buffet (localised flow separation) was encountered; localised flow reversal under the engine nacelles was even suggested by observed tuft testing in flight. So, in original prototype configuration the VC10 had a small drag related performance issue and quick changes to the design had to be made – at Vickers expense. This was all part of the expected experimentation with such a new design. At prototype stage, such findings and changes are normal, and as such should not be perceived or reported as a VC10 design failure: experimentation, observation, and correction are what prototypes are for! The 707, and notably the DC-8, both underwent wing design modifications (in service), with the DC-8 family requiring a continuing series of 1960s aerodynamic redesigns to wing, pylons and engine pods.

To counter the VC10’s small drag problem at the rear of the engine nacelles, the famed ‘beaver’ tail shaped carvings were added – fine tuning exhaust and local airflow patterns – and then further reshaped for the Super VC10. The VC10 engine nacelles had featured a ‘Seddon’ airflow step between each of the two engines, this consisted of a number of angled steps that produce vortices and thereby ‘fill in’ the gap area between the two tail pipes. Photos taken from a Canberra of tufted engine nacelles on VC10 prototype G-ARTA showed that this feature was not working as conceived, and to correct this a number of alterations were made to it. The engine exhaust ‘beaver tail’ nacelle extensions were implemented as a result of these studies, and were constructed and tested prior to final selection and application as a production tooling. Ron Storey oversaw this part of the VC10’s development work. For the Super VC10 design, the engine mount stub wing was widened by 15in to reduce boundary layer airflow interference over the pod junction, and the angle of the engine mountings slightly altered – all as a result of ongoing research improvement and taking into account the longer fuselage and its resultant effects on local airflow near the engines.

An Area-Ruled VC10?

One potentially very expensive drag reduction measure that was considered was an ‘area rule’ aerodynamic application to the rear fuselage-wing and engine stubwing interaction. This was recalled by VC10 test and development ground crew engineering technician Maurice Ungless (who had worked on the VC10’s fuel systems during G-ARTA’s construction) in his VC10 memoirs as published at VC10.net.7 Ungless described the rarely referenced prototype application to the VC10 of ‘area ruling’ of the airframe for drag peaks and troughs in cross sectional areas throughout the aircraft’s length. Ungless recalled that to combat localised drag flows at the back end, two blister fairings were manufactured in the shape of a ‘Sting Ray’, in plain view and installed on each side of the fuselage over the two rear cabin doors, between the wing and engine nacelles. Apparently, these 6ft x 4ft panels protruded out from the fuselage to a maximum (depth) of approximately 8 inches, then faired into the fuselage aerodynamically at the edges. They were built and tuft-tested and filmed during flight trials, but it was considered that the drag reduction was small and the benefit was not enough to incorporate what was an expensive modification.

Out on the VC10’s wing tips, original squared off tips were exchanged for socalled ‘Kuchemann’ tips (a seen on Vanjet prototypes). These revised-flow tips featured a large radius curve from the leading edge to a sharp corner at the trailing edge in planform – increasing total wingspan by 6ft. Also, the slat housings were realigned to provide for a slightly different slat position when extended. G-ARTA was flown in a large number of different configurations to find out what would have the most beneficial effect on the VC10’s cruise drag. G-ARTA had first flown on 29 June 1962, Chief test pilot G.R. ‘Jock’ Bryce (who would go on to head BAC’s operational sales department) undertook the test flying with E.B. Trubshaw (Second pilot) as handling flight crew and R. Holland (Assistant Flight Test Manager), C. Mullen and I. Muir as official technical observers. Soon, there were fifteen tons of technical equipment and fifty miles of cabling on board the test airframe, and over a year of test flying ensued.

Peak Performance

The VC10 wing aerofoil had a new shape – with a flatter top and more cambered lower profile at the wing root – in direct contrast to the 707’s ‘old’ style top-curved aerofoil. The VC10 had a new design of aerofoil tagged as ‘peak’, or ‘peaky’ – because it created a peak in the performance graph of lift pressure and induced drag formula upon the wing – that was designed to be more efficient. This ‘peaky pressure’ distribution was so new it required development. Some have asked, did it lead to the over optimistic initial performance guarantees to BOAC? Subsequent changes to the aerofoil, notably to the Super VC10 design, indicate that this was less of an ‘error’ by Vickers, and more of a case of discovery during the design of a new theory upon which the VC10 was the first airliner for which this wing profile was specifically designed. For this, Vickers worked together with the National Physical Laboratory (NPL), the Royal Aircraft Establishment (RAE) and also the Aircraft Research Association (ARA) for over six months, and together they designed a wing with a ‘peaky’ pressure distribution (chordwise). This was so named as the aerofoil produced a low pressure peak over the leading edge as opposed to the previous theory of a fairly constant low pressure section over a significant portion of the wing’s aerofoil chord.

Much of the work on this wing must be credited to H. Pearcy at the NPL and B. Haines (ARA), as they came up with the idea for the peaky wing and developed it for the VC10. The result was a wing that was tuned to be ‘super-critical’ in that it maintained its flow by not only delaying the conventional flow separation upon the aerofoil’s lifting surface, but by moving that point of separation from its usual location on the aerofoil. This allowed localised boundary layer airflow tuning to an unheard of level. A two-dimensional transition between supersonic and subsonic flow without creating a shock wave lay behind their ‘peaky’ aerofoil’s behaviour. Transferring such to real-life three-dimensional reality required much research. Little credited in the VC10 story was the work of a Dr J. Weber, who via her RAE work with Dieter Kuchemann, provided a complementary theory framing the accurate determination of pressure distribution over a definitive wing section. This provided reverse-engineered knowledge transfer about wing airflow effects as the VC10 was designed – notably using an early analogue super-computer (Pegasus). The super-efficient lift mechanism was tailored to avoid compression drag by deliberately creating an airflow expansion wave (a moving localised airflow layer zone) over the leading edge and providing space for the air to act or move within it. Kuchemann and Weber were both German experts given new lives in Britain post-1945. So there was some degree of German advanced knowledge filtered down into the VC10. But we can say that the wing was of Vickers – albeit with some ‘borrowed’ knowledge – like much of UK and US aerodynamics developments post-1945.

The new aerofoil shape delayed the onset of shock waves which normally degrade the subsonic flow and thereby determine the critical Mach number. Boundary layer work was also relevant to the effect gained. The end result was a wing which was very efficient at the top of its speed range, but also worked well at the low speed end with flaps and slats extended. The VC10s slats only had one position – fully open, as opposed to fully closed.

The new VC10 wing avoided the need for major ‘washout’ twist, or either negative or positive formula (or both) on the aerofoil – camber alterations were minimal, even so, a lot of fine mathematical work went into blending each zone of effect across the aerofoil and to avoid unwanted local aerodynamic disturbances.8

The VC10s large trailing edge flap area of sixty-five per cent was greater than its rivals, and of significance, that flap area was uninterrupted by gaps because no wing-mounted engine exhaust efflux flows existed. The similarly uninterrupted leading edge slats curved out and downwards to a higher degree than any slat before it, and only Boeing’s later 727 leading edge matched it. This gave rise to the VC10’s ‘ground effect’ cushion of air upon landing – aiding the famous soft touchdown.

Still with the wing design, over at Teddington in the NPL, and at the RAE – also nearby at Farnborough – experts were consulted and several modifications were tried out. In one of the suggested ‘tweaks’, two inboard slats on each wing were locked outwards by three degrees and then taped and layered over with liberal amounts of balsa wood, hessian cloth and adhesive – thus filling in the gaps. In this configuration the VC10 prototype, G-ARTA, performed several flights from Boscombe Down with tuft testing and in-flight photography and measurements. The leading edge changes seemed to produce beneficial results, so the aerodynamicists designed a new leading edge which could lower the VC10’s cruise drag. The costs of this modification might be very high indeed, as would the required changes to the ‘setting’ of the wing via a change to the wing torsion box spar junctions. This would have meant building completely new wings and changing a lot of the jigs on the wing production line at vast expense and Sir George told the team to find a cheaper way. The consequent design worked almost as well as the fine-tuned, but structurally expensive predecessor, but which was far easier to manufacture – requiring no changes to the wing incidence setting and torsion box structure. This leading edge was eventually fitted to the 1102 and later models, as well as the Super VC10s.

The only real early design ‘battle’ in the design office over VC10 wing design was to be the wing’s thickness/chord ratio. This parameter could be seen as a challenge between the aerodynamicists and the structural engineers – as the ‘aero’ men would like the thinnest wing possible while the structures men needed depth for strength. With the custom-designed profile of the VC10, a large part of this fight was over before it started, as the wing design was already fixed by the stringent airfield performance demands. For the 1101 type this ratio was 13% at the root and 9% at the tips. Later in the development process this ratio was changed to 17% at the root when the wing chord was increased on the inboard section.

On the VC10 prototype wing in 1962, photos of this event show a very clean wing with one (almost full-chord length) wing fence at approximately threequarters span to control the spanwise tip flow which without such fence, would otherwise spread decaying air and lift flow towards the ailerons, rendering them less effective and adversely effecting tip stall issues. The original wing tips were squared, but revised to Kuchemann standard – adding to the total span, and then a new, tall, inboard, wing fence would be added to control spanwise flow near the stall speed and benefit engine intake flow – all at minor cost to the lift coefficient from the minuscule reduction in the wing’s upper surface area. The tall inboard fence was insisted upon by the Vickers test pilots and was the subject of some debate. Its main benefits (a the cost of a tiny amount of wing lifting surface area) were to stabilise airflow at low speed near the wing root-to-fuselage area, deliver better airflow to the engine intakes, and very interestingly, provide a major airflow effect resulting in an enhanced nose-down pitch at the stall. The VC10 had to be proven deep-stall safe and risky testing took place – but the wing performance was benign and soon finalised.

Removing the new, tall fence, was found to increase the risks of spanwise flow and (the adverse) nose-up pitch. Along with the engine-stub wing aerodynamic effect in acting like an elevator surface (beneficial downwards pitch), the new wing fence greatly aided the VC10s low speed and stall regime handling. No other rear CG, rear-engined T-tailer exhibited the beneficial, classic nose-down auto-recovery pitch at the stall. Here was another unique VC10 designed-in safety factor. It is worth repeating that no VC10 was ever lost in a deep-stall in testing or commercial service. This cannot be said of the other major T-tail airliner designs. Indeed, even BOAC’s British airline associate, BEA, lost a Trident and all its passengers in a deep stall and had close calls on numerous other occasions. A BAC 1-11 also suffered a deep stall tragic loss.

Few people realise that the VC10s stall speed with flaps and slats deployed was below 100kts; an astounding speed for a large four-engined airliner. In fact in airline stall tests, crews would take the VC10 up to the onset of the stick-push (with accompanying klaxon warning) at a remarkable 97kts and then heave the nose down quickly. Beyond the onset of stall, the VC10 had the extra safety-measure of the unique, natural, nose-down pitch behaviour that its design delivered. However, the deep stall was not to be trifled with at low power settings and, if the VC10 got to 19º or 20º nose-up at low speed with flaps and gear dangling, it would need very decisive action to avoid trouble. Any ‘pitch-up’ would be fatal.

A particular ‘aero’ design challenge was to create a low drag engine pod and stub wing strut installation that was in tune with the wing airflow behaviour and wake. The strut needed to be thin, and yet strong. The ‘stepped’ swept strut design fed air to the ‘dead’ air region and tuned the wake flow off the back of the strut, reducing drag. For the Super VC10 the angle of this strut was further refined with a mild infilled twist applied. Another aspect of the engine mounting cradle and stub wing and fin interface was to tune the vibration levels so that they did not adversely interact with each other and tear the structure apart; as had recently happened with the Lockheed Electra’s engine mounting-to-wing design interaction. All these efforts were typical of the perfectionist and forensic engineering that went into the VC10 underneath that glamorous profile.

On the elegant tail fin, it was vital that shock wave formations at the join of fin and tailplane were tuned down to low values, so the maximum thickness section of the tailplane was moved forwards relative to the outboard sections – hence the great sweep angle seen in the design and the swan-like ‘bullet’ fairing atop the fin.

For the main wing, expensive, and heavy, double slotted flaps were considered, but the simpler and lighter Fowler-type was settled upon, but these were subject to a great deal of lift/drag effect work by the Vickers team. Despite the Fowler type flap requiring as much rearwards extension as possible to be effective, the flaps were made to travel to a set angle or value, yet with as much lift as a higher value chord design: a thicker flap panel profile regained any lift losses from decreased flap angle travel. Flaps at 40º on the VC10 provided excellent approach behaviour.

The achievements of the Ken Lawson led VC10 aerodynamics team should always be credited for this airliner’s excellence in aerodynamics and handling.

Test pilot Brian Trubshaw took over the stall test regime flying and carefully explored over 2,000 possible stall profile parameters. He said that the VC10 was a machine that pilots could trust, even if they might sometimes forget that they were not flying a fighter jet – such were the VC10s reserves.9

From the 1102 series Standard-model VC10 onwards, a revised wingtip design was also incorporated. This saw a bulbous and slightly drooped shaping to the leading edge and wingtip curve, and improved local lift number and better airflow at the tips (lessening the risks of a wing drop) and allowed a wider safety margin at high altitudes. A VC10 could now cruise at 41,000–43,000ft, near what pilots call ‘coffin corner’ – the thin air regime where lift and speed margins between flight or stall are very small indeed, sometimes less than ten knots depending on the aircraft’s weight at the time. The new slightly lobed wingtip is quite noticeable in photographs of the Ghana Airways and BUA machines. A small vortex fence was added to the under surface of the leading edge, a sharp strip appeared on a portion of leading edge and some reshaping added to aid airflow aided matters for the 1102–1103 series. The Super VC10 did not need these lobed wingtips as its aerofoil had been revised along the span. Of note, the outboard wing fence was deleted and two short, mini-vortex flanges added; on the leading edge only.

The use of a specially designed supercritical aerofoil profile was a huge step in aerodynamics knowledge and use, as at the time, such aerofoil profiles were limited – a theoretical gain not yet proven in flight. The designers of the VC10 were breaking new ground, and during the thousands of hours flown on the prototype and the development airframes, they were learning every day. From this they developed the wing. The BOAC ‘early wing’ VC10 Type 1101variants were slightly less economical than their latterly modified brothers, but BOAC had declined to include the various improvements that were suggested – although incorporating the changes would have delayed delivery. The BOAC specification VC10 still managed to fulfil all the promises made with regard to the hot-and-high runway performance that were requested by BOAC – contrary to some erroneous later claims. And the Super VC10’s developed supercritical wing theory is now all the rage in advanced wing design.

The VC10 had low aerodynamic drag in all parameters – notably in terms of its self-created lift induced drag coefficient, and in terms of its profile/parasitic drag – the faired-in nose, smooth fuselage contours and skin, smoothed window ‘belt line’ (or lack thereof), and the removal of wing-pylon and engine pod interactions, creating an advantage, as did the unencumbered ‘clean’ wing design; all offered significant advantages over the opposition. The highly swept fin and tailplane lowered the Mach numbers and the curved and sculpted bullet fairing atop the fin was an ultimate piece of aerodynamic design.

The advanced aerofoil wing offered major drag reductions and the trailing or wake drag was minimal. Worth citing again as a very noteworthy feature was the natural ‘nose-drop’ at the stall, a very rare feature indeed for a rear-biased, rear CG, rear-engined T-tail aircraft design. Again, wing design, tail design (tall and highly swept), and the beneficial aerodynamic ‘pitching’ effect of the engine ‘stub’ wing combination, all helped created this rare, safety enhancing stall recovery characteristic. Unlike most other rear-engined, T-tailed airliners, the VC10 did not suffer from a nose-up pitch at the worst moment of high incidence and rearbiased CG and centre of lift and pressure, which could all combine to attempt to tip a T-tailer over backwards as it reared up. Auto-ignition would keep the engines turning too.

Control systems

Another lead example of the VC10’s second generation design approach was in the nature and action of its electro-mechanical-hydraulic flight and airframe control systems, notably an automatic function.

All the main flying controls were fully powered and there was not the cheaper spring or servo tab mechanical effect used. Lessons about control surface effect and reliability had been learnt by Vickers on the Valiant, V1000 and Vanjet studies, and these were transferred into the VC10 main flight control mechanisms. No manual reversion was required. A split-system double redundancy design was used, so if a component in the system failed, the other system picked up the required mechanism of action. Systems of two halves, each with a separate drive from a separate engine power supply source, ensured great safety and fail-safe action. Each half of the system could operate simultaneously and each could act as an emergency standby to the other. So, system A is operated by engines 1 and 3, while system B (powering the same controls) is run from engines 2 and 4 – so a system, or engine failure does not mean that the aircraft ‘loses’ any or all of its systems. Each part of each system is driven by separate electro-hydraulic power units. The VC10 had four electrical generation sources, the 707 had three.

A total of eleven identical power units provide cross-referenced dual feed to the whole VC10 control system. If all four engines (and thus their respective separately powered systems) should fail, the VC10 had a drop-down electrical ram air turbine (ELRAT) – a ‘windmill’ electrical generation device designed by Harry Zeffert (and a rarely specified optional hydraulic system turbine HYRAT) in which an airflow-driven windmill of mini-turbine design can be deployed to power the vital flight control systems. Again, this was a VC10 first and not seen on the 707 and DC-8. The ELRAT saved the Super VC10 on two occasions in service and was not an ‘allowable defect’ if it was unserviceable – a VC10 and Super VC10 could only be flown if the ELRAT was signed off as functional.

Many of the components on the VC10s new systems designs came from established components already used in military and civil aircraft, so they were reliable from the word go, and not likely to suffer developmental reliability glitches. Some of these components, of electro-hydraulic nature, were shared under joint UK-USA licence agreements.

All the main ‘primary’ flying controls could be operated normally, or by their ‘brother’ system, if one part failed – albeit it at a slightly reduced rate of action. By using such a continuously ‘live’ system or mechanism, the VC10 did not rely on a redundant emergency back-up system that would normally lie dormant for years and itself having inbuilt risk factors for its reliability when rarely needed. Weight was saved by not completely duplicating the entire system, but instead creating a split system. The hydraulic system ran at 3,000psi and required steel and alloy pipes of the highest quality where the fluid, a fire retardant ‘Skydrol 500’ formula, would run. Special seals had to be developed that would not be degraded by the fluid itself. And you could not put Skydrol in your car’s braking system!

The electrics were 200volts DC, driven from four separate engine-driven generators and featuring Westinghouse brushless generators – unaffected by high altitude conditions and temperatures. A Ferranti transformer provided the 28volt output of 150 amperes. Any unlikely ‘runaway’ control surface could be overruled or countermanded by its split system ‘mate’. There were four elevator sections and a three section rudder. All of the VC10 control runs were direct physical linkages of mechanical, rod, lever and cable, with a ‘Hobson’ artificial feel unit adding a carefully graded hand-to-control yoke ‘feel’ reflective of surface, and speed related aerodynamic loadings being fed back to the pilot. ‘Feel’ force was proportional to control surface deflection, speed and height. The system was advanced in that it had an altitude related sensing parameter – taking into account reducing air pressure at height, so no false sensations or information was given to the pilot. The complexity and success of this artificial feel system was not matched for many years in aviation or automotive application.

As well as applying to actual moving flight control surfaces, the spilt-system pervaded the hydraulics, electrics, cabin air system, and other functions, thus providing a very reliable total aircraft operating system. So the VC10 flight controls were accurate, superbly safe and reliable. The Plessey Company were behind much of the VC10s electrical superiority. Aspects of this split-system or double redundancy fail-safe design appeared in the later Boeing 747 electrical system power designs, no doubt aided by the presence of former Vickers/BAC electrical design engineers in new job at Boeing’s Renton offices in the 1960s. The VC10’s new way of systems being double powered, and having a live back-up to its major mechanical systems was new, and marked it out from its competitors.

In terms of function, more new technical feats were established by the VC10 in addition to the new fail-safe control surface operational design because each (separate) section of the control surfaces was driven or activated by a separate power control unit – signalled by duplex autopilots – each of which ‘read’ or monitored the other. This meant that flight control had multi-function ability and safety, leading to a combination of automatic control, auto throttle, auto flare and a pilot ‘hands off’ automatic landing ability with a failure rate so low that it was unique. The VC10 was thus, a pioneer (along with Trident) of reliable, consistent, CAT 1 automatic landing, although the Trident took it to Category IIIA runway visibility level on more often occluded European runways. From 1968, the Super VC10 offered full category, in-service auto-land. Using BAC/Elliot signalling technology and autoland/auto-coupled approaches became the norm in bad conditions. At that time, only five runways on the BOAC Super VC10 route network offered instrument landing systems (ILS) to match the Super VC10’s own in-built capabilities. By the late 1970s the Super VC10 systems were removed – having been less often used than planned, and offering a weight and money saving option by their removal. No issues with the systems lay behind such an economic decision.

For the flight crew, the Vickers engineers also designed a new, quick-reference way of controlling all the new split-systems with what was an early form of flight management system – a diagrammatic systems control panel in an electromechanical display and control device depicting the shape of the aircraft, and systems locations therein, and the actual in-flight position of that surface – the ‘baby aeroplane’ as the Vickers men called it. This was made by Sangamo Weston Ltd.

VC10’s Reinforced Structure.

The flight deck was also spacious, well laid out, deeply windowed, and, as even admitted by Boeing 707 pilots, much easier to sit in and manage than their cramped, narrow, control post.

Fuselage and Wing Strength

The VC10 was a monocoque type fuselage structure, but was one that featured extra reinforcements in critical areas. Like a Saab, Volvo, or Mercedes car of the era, the VC10 body was a self-supporting monocoque type, yet one which benefited from over-engineered, extra stiff, localised reinforcements and strengthening to a degree not seen in simpler or cheaper (and lighter) mainstream structures. Of note, the VC10 design was the first time large jet engines had been paired at the rear of an airframe – requiring novel engineering solutions. Overall, throughout the VC10, a multiple load path network was built in – so if a part failed, other elements could absorb the failure and defuse any local fractures or cracks. The central cabin wing box and tail were incredibly strong, cabin and body apertures reinforced – milled from solid panels – and that central keel rail ran forwards to a nose/cockpit section of heavy duty formers, frames, and castings. The door frames were also heavily over-gauged and built up with massive support frames. The more usual practice of multi riveted, multi-welded, multi-panel work was avoided where possible. Huge chunks cut from solid metal alloys, and large machined skins, engendered high torsional rigidity. The wing was multi-spar with four main spar units and a massively strong centre box. This was a wing and hull without compromise. And it paid the price in weight – being several tonnes heavier than the 707 – for the VC10 was built like a proverbial (Vickers) battleship! Such construction saved the day and many lives in service.

Copper rich aluminium alloys and titanium alloys were used – at great expense. Panels were larger than those used by Boeing – so were stiffer and had fewer rivets and joints. The Vickers designers reduced the traditionally deployed numbers of lap joints, splices and seams along the window line – instead, using a machined from solid panel along the entire length of the window belt line. The window line panels were 34ft by 6ft and ¾ in thick. There were fewer crack-raising points and stiffening was integral – not add-on. Diagonally located load support beams, torque boxes, and massive cleating, all created a really strong structure. The additional skin cleats at each frame station would restrict any failure to one frame bay. Channel frames were doubled up with overlapping edges and the fuselage panels were laid transversely over their frames and with circumferential straps over them.

The crucial wing box and centre section, leading back to the very heavily reinforced tail area, was where the VC10s real heavy metal and strength was to be found. All this was new and required much design and testing, but it produced a very strong fuselage with no issues relating to potential pressurisation-cycle induced fatigue, and few of load and impact distress. With its strong spars machined from solid skins and thick skin panels, the elegantly swept and very smooth VC10 wing offered immense strength. All the inspection hatches in the wing had milled from solid frames – another exquisite and expensive engineering solution unique at the time to the VC10. The wing design was strength tested and passed a sixty per cent overload – a figure higher than many airliner wing structures ever achieved, including recent large composite structures– and the VC10 was also subjected to an asymmetric wing deflection test – 7ft on the tip and 6ft the other way at the opposite tip. Even at these loadings, across these tests, the brilliance of the VC10 wing design was proven, no actual test ‘failure’ in terms of structural (spar) breakage took place, instead, the wing flex and cracking reached a peak loading (at sixty per cent overload) that was deemed as a test limiting ‘fail’ reading – but not a broken wing – unlike certain other airframes old and current.

Intriguingly, the VC10 had American cabin windows – a product named Oroglas 55 created by the Lenning Chemical Company from a Rhom and Hass (USA) reputedly German-originated process; each window had three sheets of glass and the external pane was larger than its aperture so it self sealed itself into its hole, and added structural strength once glued in place.

The VC10 featured a lightweight, noise absorbing composite floor covering – end grain balsa wood with steel sandwich construction made by the Mallite Company. One VC10 also used a test section composite-type glass fibre reinforced rudder (as 1 of 3 sections), and was the basis of an early Ciba-Geigy composite rudder experiment from which a great deal was learned about such structures. Although it is unlikely that Vickers would have considered using the now deployed, Airbus- type composite fin with its controversial and much debated composite-tocomposite and composite-to-metal, asymmetric fin-to-fuselage mounting design that does not use fuselage frames taken up as a chassis bearer into the fin. Issues of composite rudder degradations (notably from hydraulic fluids), rudder failures, composite delaminations and structural failures – allegedly resulting in events such as the Air Transat Airbus ‘Havana incident’ – reflect the very slow pace of composite fibre design, development and testing mechanisms since the 1960s when a composite fin was tested on the VC10.

Because so much of the VC10 chassis, fuselage, and wings, was made from single pieces of metal, and had much fewer rivets, joints and panels than normal, the resulting structure was very stiff, fatigue-distress resistant, corrosion proof, and had in-built load-paths to carry stresses on more routes in the structure than was normal: A true fail-safe principal.

Low Stress Levels

Key stress levels in the VC10’s airframe structure were cited by Vickers at 11,000lbs per square inch compared to 17,000–20,000lbs per square inch in the rival machines. Lower stress meant longer structural life! Cracks in the structure could be lessened and an early estimate of 30,000 flight hours or 10,000 landings (a decade’s typical airline usage) before any such cracking might be expected, was soon upped beyond 60,000 hours – testament to the VC10 structure, which was stiff but not brittle.

The fuselage reinforcing hoops were thickened at the point where they intersected the floor – providing extra reinforcement at that crucial junction. In the wing area, massive gauge alloy hoops ran around the cabin and into the wing box. Anti-tear straps and oversized corner fillets all added to a fuselage that was the strongest, most rigid, and most tear resistant yet devised. Around the doors there was further heavy gauge reinforcement. Under the floor, Vickers fitted a 20in wide central keel (another shipbuilding idea!) the entire length of the airframe as a longitudinal torsion box type structure that reinforced the traditional cross beams. Advanced metal extrusion processes were also deployed – the VC10 was solid, but as light as it could be whilst retaining that solidity.

Down at the back, the four giant engines (and their thrust) were held in place by not just massively strong engine mountings beams, but a complex, almost geodetic, ‘basket’ network of supports, braces, beams and panels that tied the whole tail unit, the engines, and the vertical fin and its loads, into what was probably the strongest piece of airframe structure then seen anywhere.

Designing a structure to hold four Rolls-Royce Conways, absorb their thrust/ torque into a safe mounting and letting their effect work, was no easy task. To attach the Conways and their 45+ tonnes of thrust output, safely to an airframe, particularly in closely coupled rear-mounted configuration, was a very considerable engineering challenge. Get it wrong and the engines would either tear themselves away from the airframe, or tear the airframe apart. So, the two main engine beams were very expensive, drop-forged alloy structures, and were the mounting point for the four, 10ft long, external, curved ‘spectacle’ shaped engine support bearers which had three thrust load-bearing pick-up points for each engine. The downwards acting stress loadings of the four engines upon the engine beams and support frames – notably upon landing – required extensive engineering solutions to ensure long life and safety.

The need to make sure the tall tail fin and its very large horizontal tail surfaces would stay attached and not fail in extremis due to bending and twisting stresses, as well as normal in-flight loadings, was paramount. The fin had vertical spars that grew from deep within the fuselage tail structure and vertical stringers and a very thick skin sheeting all combined to resist twist and failure.

The large tailplane’s (bigger than some military jets main wingspans) loads had to be passed down into the fin structure and much local reinforcement was applied. The tailplane was mounted from the its fin-support box via two roller bearings (allowing pivot of incidence setting), with a third mount via the screwtype actuator that connected the fin top to a forward reaching arm on the main fin structure.10

Of note, this tailplane incidence screw-jack device featured a safety rod to stop it running away with itself – which could lead to loss of control. A certain other T-tailed airliner did not have a screw-jack safety stop and eventually mass fatalities resulted in a screw-jack runaway accident due to alleged maintenance failures. Still in the tail, the steel and alloy support sleeves carried the main loadings to and from the tailplane ribs and castings. The combination of all this Vickers design work saw the VC10 survive three major tailfin overload events and several engine-related incidents in service – whereas other airliners similarly afflicted, have not.

The famous South American turbulence-related incident that befell a VC10, surely proved that this work served its purpose; the tail stayed attached and the aircraft flew home to London – subsequent inspection revealed a failed fin support, but the fail-safe back up structure had carried that failure and its loads.

The tail fin and tailplanes were heated by ducting for anti-icing and used Boulton and Paul built power control units. If one of the four elevators should fail to work, the others could counteract its adverse effects.

A Barnes Wallis Legacy?

Where did Edwards and his team get the VC10’s quality of construction ethos from? Where did that hewn from solid, extra-safe structural integrity start? We can cite the Vickers tradition and the effect of Barnes Wallis’ obsession with geodetic structures upon Edwards when he worked under Wallis. However difficult Wallis may have allegedly been to work for, his focus on strength, failsafe design and allied efficiency, can only have manifested in Vickers later, nongeodetic structures. From the Viking, as the company’s first airliner, onwards, the all-metal alloy monocoque of Vickers fuselages was reinforced and much stronger than the norm. Just as the geodetic Vickers Wellington had saved lives in wartime RAF service with its multi-load path structure, so too, would the non-geodetic VC10 in airline life. Looking up inside the VC10s tail and rear end, we can see an almost-geodetic network of reinforcing metal work.

The VC10 fin and tailplane – one of the largest structures in the airframe building world at that time, were manufactured at the Bournemouth Hurn plant. There, a dedicated team of time-served aviation industry artisans constructed this complex structure.

Typical of such men was Edward ‘Ted’ Read as chief draughtsman on the VC10 tail control surfaces. Read had worked on Horsa gliders in the war, worked for de Havilland on the Vampire and Comet, contributed to building the Airspeed Ambassador, and then spent time in the Vickers design office before moving to the south coast to work for the Vickers Hurn factory.

Edward Read’s son, the ex-RAF photographer and industrial film maker, Michael, says: ‘My father was so proud to have worked on so many important British aircraft – including the D-Day gliders – but the massive VC10 tail at Hurn was, for him and his co-workers, a major jet age achievement. He would bring the VC10 drawings home and lay them out on mum’s pastry table and check and double check everything. Ensuring that the big beautiful tail – which was one of the VC10s’ most crucial and complicated components – was correctly built as designed, was a vital contribution to what was then Europe’s biggest airframe.’11

The VC10’s main undercarriage allowed a very soft landing – minimising the shock loading upon the engine bearers and the entire tail structure. The main undercarriage was rearwards swept by 10º and had cranked main beams. The rear of the four main wheels per bogie touched down first and the two-stage shock absorbers took the shock out of the impact forces. A VC10’s landings were the smoothest of any airliner and once mastered, flattered the pilot.

Engine development

Rolls-Royce had taken to naming their new jet engines after famous rivers, and their largest jet engine to date, in 1955, was aptly named after the powerful and reliable River Conwy – as ‘Conway’. Not only was this engine the largest Rolls-Royce jet design, it was the first viable large turbofan, as opposed to pure turbojet – a big stepping stone in jet engine history. By creating an outer, or surrounding ‘bypassed’ envelope of unburnt airflow through and from the jet engine, more efficient thrust was created with lower noise levels being delivered by such managed exhaust airflow. A large fan, mounted on the front of the engine, or in an intake with first stage guide fans, could be driven by ‘free’ energy from the main combustion process and fan, and allow cool flow of airflow around the hot part of the jet mechanism. Some turbofans used an aft-fan, rear mounted and driven, but the front fan was deemed more efficient.

Expanded from experience on the Avon engine, the Conway was a pioneer, the original design of two-spool compressor jet with a larger static vaned front end jet mouth with a revolving turbine that streamed off an amount of intake air and wrapped it over and around the jet core shafts and exhaust flow – as opposed to a distinct large, single ‘fan’ front mounted entry section turbine later seen as an add-on to the Pratt and Whitney JT3C design. Conway went through numerous iterations from a 9,000lbs thrust device up to its final 22,000lbs rating. The Conway, at an early 13,500lbs thrust, was mooted to be a possible developed Vickers Valiant (to replace Avons) and a V1000 powerplant choice, and then developed CO.10 engines were seen on the early BOAC 707s, but the long gestation period of the Vanjet and VC10 allowed time for the refinements that led to the very powerful VC10-specific Conway 42 and 43 iterations.

Early Conways had 0.3 bypass airstream ratio, then upped to 0.6 and 16,500lbs static measured thrust. This was soon uprated to 18,000lbs, then 20,370lbs, and then to 21,800lbs thrust in the Conway 42 and 43 models respectively. Improvements in Conway thrust came from a larger low-pressure stage and scaled-up stages and components, each by smaller degrees rather than simply bolting on a large intake fan at the front. This avoided excessively higher engine shaft rpm and resultant higher temperatures in the engine’s core. Rolls-Royce concentrated on improving the CO.10 and CO.12s’ vanes, turbine blades, airflow, and low pressure stages.

The Conway had a fixed intake vane, quite a narrow intake mouth and a slender profile in the engine pod – meaning reduced frontal area and less drag. Intake air is taken in via static guide vanes before hitting the first compressor that had a central core built into a titanium lined duct. Air pressure is more than doubled (x 2.25) before being passed along into the main chamber. There, 38% of that flow is streamed off from the core into the bypass function – the remaining entering the combustor area. At the exhaust end, the bypass air forms a sheath of airflow over the hot exhaust gas flow via re-streaming at near supersonic velocities – hence the noise! The combustor air enters the process at over fifteen times the intake value. Nimonic coated alloy igniter, or flame tubes, ignite the combined air/fuel mixture; the resultant force delivering the thrust to rotors that drive the shaftdriven compressor stages.

Previous Conway experience had revealed areas of high wear in certain valves and nozzles, so for the revised variant engines, hardened coatings, enhanced design and oil system improvements were all implemented. Major CO.12 to CO.42 differences included: larger low pressure turbine, by-pass ratio increased and an increased capacity low pressure turbine. An extra intermediate stage compressor was added to the CO.43 from the CO.42. The CO.43 runs at slightly higher temperatures to the CO.42, but not to a level likely to induce fatigue. The first CO.42 was powered up in June 1960, but it would be 1963 before it was fully tested and certificated. Soon afterwards, the idea of an underwing ‘spare’ engine carrying pylon for the VC10 was mooted – utilising a lightweight composite bullet-shaped fairing that had minimal effects on airframe trim.

With the VC10’s engines mounted from a stub wing from the fuselage, rather than wing pylon, the VC10 Conway application required a new way of mounting components to or from it – using a central mounting ‘carrier’ beam. Being mounted close to the fuselage airflow meant that special crosswind and localised airflow issues all had to be carefully studied for the VC10’s engine intake airflow characteristics and to avoid stalled air causing the engine to ‘cough’. The opportunity was taken to expand the ‘gap’ between the engines and fuselage with an 11in span extension to the Super VC10s engine stub wing mounting design.

Advanced vibration metering was applied to the VC10’s Conways with a graphical display at the flight engineer’s station – allowing very fine monitoring of any engine vibration issues, be that actual specific-engine vibration, or comparative vibrations levels across all four power units. A second set of throttles were also mounted at the engineer’s control desk on the flight deck – again allowing extra vigilance to power settings.

The dangers of turbine or rotor ‘burst’ in closely paired jet engines was of concern because, in the close-coupled configuration, escaping blades and heavy rotor components could penetrate and damage the adjoining engine or the hull. As with the wing-root mounted engine configuration of the Comet, such paired engines needed careful design to protect each engine and the surrounding area with armour plating (Comet’s engines were uncomfortably close to the main fuel tanks). In the VC10’s use of paired engines, the powerplants were (unlike in the Comet and the V1000) kept away from the fuselage, fuel tanks and wing structure. For the VC10, a compressor casing capable of containing explosive blade events was designed. The large low pressure fan was wrapped in a flanged steel case and the Stage 4 engine core zone saw a thickened magnesium-rich cladding. Any turbine over speed is countered by an emergency shut-off control that selfactuates in under one second of a turbine burst. Each engine pod is divided into two sections, separated by a fireproof bulkhead, attached to the aforementioned flanged bulkhead. So the ‘hot’ combustion zone is separated from the cool air zone. Fuel and hydraulic lines are mounted ahead of the bulkhead. The design of the protective barriers between the VC10’s paired engines was proven to work on the rare occasion when an engine suffered an explosive failure – fires did not spread, and in most cases, escaping components did not disable the neighbouring engine, nor penetrate the fuselage; and the engine bearers held – although on one occasion bending spectacularly.

Thrust reverse were initially fitted to all four VC10 engines – but reduced to the two outer engines after fin buffet distress from the inboard reversers was discovered. The big benefit of the uprated Conway was that the VC10 entered service with a ‘new’ engine, but one that had been previously proven in service in its early incarnations. Engine reliability was therefore high from launch.

With a two, as opposed to a three core design, the Conway’s engine length and pod could offer aerodynamic advantages over longer and ‘fatter’ engines.

Conway CO12/540 Details:

Max Thrust at take-off: 20,370lbs/9,240kgs x4

Max Continuous thrust: 16,560lbs

Cruise Thrust: 4,500lbs at 35,000ft with specific fuel consumption of 0.823lbs per hour

Max Pressure Ratio: 15:1

Dry Weight: 5001lbs

Length: 54 in

Engine Diameter: 51 in

Note* Super VC10 and RAF VC10 used Conway 550B (21,825lbs/988kgs) x4. 24,000lbs thrust version not manufactured.

Test Flying and Route Proving

The VC10 and Super VC10 fleet both underwent extensive ‘Tropical Trials’ flight test development periods on the very routes in African and Asia that they had been designed for. The VC10’s first flight in 1962 meant that it had two years of development flying before entering BOAC service, and prior to certification the VC10 flew 4,230 hours of test flying. Somewhat surprisingly, all twelve BOAC VC10s had been manufactured by October 1963 – to the point where several airframes sat new and un-flown as development flying continued with G-ARTA and then the BOAC G-ARVA, G-ARVB and G-ARVF airframes starting the BOAC test period. G-ARVF flew most of the African and Asia route test flying. The Super VC10 followed the VC10 quickly, and first flew on 7 May 1965 – only one month after the standard model entered commercial service, G-ASGA and G-ASGD doing much of the test and route proving flying from spring 1965 onwards.

Of interest, much of the VC10 early ‘hot and high’ trials were conducted closer to home than might be imagined: rather than flying all the way down to Africa for every such test, Vickers secured use of a high altitude and high temperature runway at the military airfield at Torrejon in Spain. There, on 12 August 1963, the Standard VC10, G-ARVB, left Wisley under the command of Bill Cairns – who performed much of the flight testing of the VC10 in Africa (Peter Baker was co-pilot). G-ARVB flew to Madrid, and then at Torrejon began the harsh testing regime that included heavy landings, go-arounds, and high-speed rejected takeoffs likely to cause brake and tyre overheats. Every combination of speed, weight, flap and slat setting, temperature, and engine power, were tried out to frame the performance rule book and flight manuals. Notably, the very high weight, high speed abandoned take-off tests resulted in the brakes overheating and the tyres ‘popping’ their fuse-plugs as designed in order to avoid explosion by making the tyres deliberately deflate. G-ARVB crawled its way off the Torrejon runway, hobbled by deflating tyres, and much was learnt from such a testing regime.12

Clearly, the proximity of the Spanish locations made it quicker and easier to gain experience, but both Johannesburg airport and the Lanseira runway made for actual African operating experience. It was during such testing that the early issues of brake and tyre performance were revealed – leading to modifications and improvements prior to service entry. In cold weather and wet testing, Vickers and Dunlop also noted that a specially flanged or ‘chined’ nose wheel tyre design could reduce water spray off the undercarriage and reduce the flow of such spray into the engines.