REACHING OUT WITH

ROBOT ARMS

ROBOT ARMS

Robots without arms are limited to rolling or walking about, perhaps noting things that

occur around them, but little else. The robot can't, as the slogan goes, "reach out and

touch someone," and it certainly can’t manipulate its world.

The more sophisticated robots in science, industry, and research and development have

at least one arm to grasp, reorient, or move objects. Arms extend the reach of robots and

make them more like humans. For all the extra capabilities arms provide a robot, it's interesting

that they aren't at all difficult to build. Your arm designs can be used for factory

style, stationary “pick-and-place" robots, or they can be attached to a mobile robot as an

appendage.

This chapter deals with the concept and design theory of robotic arms. Specific arm projects

are presented in the next chapter. Incidentally, when we speak of arms, we will usually

mean just the arm mechanism minus the hand (also called the gripper). Chapter 28,

"Experimenting with Gripper Designs," talks about how to construct robotic hands and how

you can add them to arms to make a complete, functioning appendage.

Take a close look at your own arms for a moment. You’ll quickly notice a number of important

points. First, your arms are amazingly adept mechanisms. They are capable of being maneuvered into just about any position you want. Your arm has two major joints: the

shoulder and the elbow (the wrist, as far as robotics is concerned, is usually considered part

of the gripper mechanism). Your shoulder can move in two planes, both up and down and

back and forth. As well as moving your arm up and down and back and forth, you can

rotate your shoulder as well. The elbow joint is capable of moving in one plane; it can be

thought of as a simple hinge, and the bone connected to it can be rotated.

The joints in your arm, and your ability to move them, are called degrees of freedom.

Your shoulder provides three degrees of freedom in itself; shoulder rotation and two-plane

shoulder flexion. The elbow joint adds a fourth and fifth degree of freedom: elbow flexion

and elbow rotation.

Robotic arms also have degrees of freedom. But instead of muscles, tendons, ball and

socket joints, and bones, robot arms are made from metal, plastic, wood, motors, solenoids,

gears, pulleys, and a variety of other mechanical components. Some robot arms provide

but one degree of freedom; others provide three, four, and even five separate degrees

of freedom.

Robot arms are classified by the shape of the area that the end of the arm (where the gripper

is) can reach. This accessible area is called the work envelope. For simplicity's sake, the

work envelope does not take into consideration motion by the robot’s body, just the arm

mechanics.

The human arm has a nearly spherical work envelope. We can reach just about anything,

as long as it is within arm's length, within the inside of about three-quarters of a

sphere. Imagine being inside a hollowed-out orange. You stand by one edge. When you

reach out you can touch the inside walls of about three-quarters of the peel.

In a robot, such a robot arm would be said to have revolute coordinates. The three other

main robot arm designs are polar coordinate, cylindrical coordinate, and Cartesian coordinate.

You’ll note that there are three degrees of freedom in all four basic types of arm

designs.

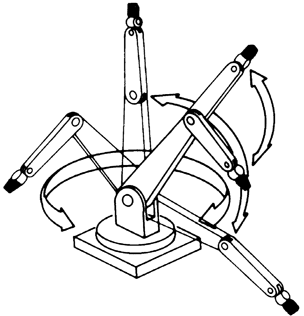

Revolute coordinate arms, such as the one depicted in Fig. 26-1, are modeled after the

human arm, so they have many of the same capabilities. The typical robotic design is somewhat

different, however, because of the complexity of the human shoulder joint.

The shoulder joint of the robotic arm is really two different mechanisms. Shoulder rotation

is accomplished by spinning the arm at its base, almost as if the arm were mounted on

a record player turntable. Shoulder flexion is accomplished by tilting the upper arm member

backward and forward. Elbow flexion works just as it does in the human arm. It moves

the forearm up and down. Revolute coordinate arms are a favorite design choice for hobby

robots. They provide a great deal of flexibility, and they actually look like arms.

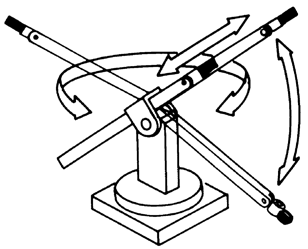

The work envelope of the polar coordinate arm is the shape of a half sphere. Next to the

revolute coordinate design, polar coordinate arms are the most flexible in terms of the ability

to grasp a variety of objects scattered about the robot. Fig. 26-2 shows a polar coordinate

arm and its various degrees of freedom.

A turntable rotates the entire arm, just as it does in a revolute coordinate arm. This function

is akin to shoulder rotation. The polar coordinate arm lacks a means for flexing or

bending its shoulder, however. The second degree of freedom is the elbow joint, which

moves the forearm up and down. The third degree of freedom is accomplished by varying

the reach of the forearm. An “inner” forearm extends or retracts to bring the gripper closer

to or farther away from the robot. Without the inner forearm, the arm would only be able

to grasp objects laid out in a finite two-dimensional circle in front of it. The polar coordinate arm is often used in factory robots and finds its greatest application as a stationary device.

It can, however, be mounted to a mobile robot for increased flexibility.

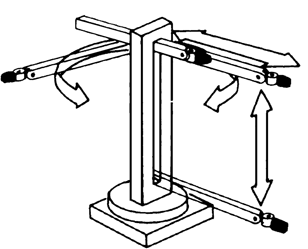

The cylindrical coordinate arm looks a little like a robotic forklift. Its work envelope resembles

a thick cylinder, hence its name. Shoulder rotation is accomplished by a revolving base, as in

revolute and polar coordinate arms. The forearm is attached to an elevatorlike lift mechanism,

as depicted in Fig. 26-3. The forearm moves up and down this column to grasp objects at various

heights. To allow the arm to reach objects in three-dimensional space, the forearm is outfitted

with an extension mechanism, similar to the one found in a polar coordinate arm.

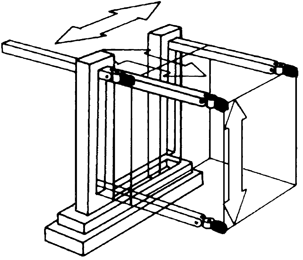

The work envelope of a Cartesian coordinate arm Fig. 26-4) resembles a box. It is the arm

most unlike the human arm and least resembles the other three arm types. It has no rotating parts. The base consists of a conveyer belt-like track. The track moves the elevator column

(like the one in a cylindrical coordinate arm) back and forth. The forearm moves up

and down the column and has an inner arm that extends the reach closer to or farther away

from the robot.

There are three general ways to move the joints in a robot arm:

- Electrical

- Hydraulic

- Pneumatic

Electrical actuation is done with motors, solenoids, and other electromechanical devices.

It is the most common and easiest to implement. The motors for elbow flexion, as well as

the motors for the gripper mechanism, can be placed in or near the base. Cables, chains,

or belts connect the motors to the joints they serve.

Electrical activation doesn't always have to be via an electromechanical device such as a

motor or solenoid. Other types of electrically induced activation are possible using a variety

of techniques. One of particular interest to hobby robot builders is shape-memory alloy, or

SMA, as discussed previously.

Hydraulic actuation uses oil-reservoir pressure cylinders, similar to the kind used in earthmoving

equipment and automobile brake systems. The fluid is noncorrosive and inhibits

rust: both are the immediate ruin of any hydraulic system. Though water can be used in a

hydraulic system, if the parts are made of metal they will no doubt eventually suffer from

rust, corrosion, or damage by water deposits. For a simple home-brew robot, however, a

water-based hydraulic system using plastic parts is a viable alternative.

Pneumatic actuation is similar to hydraulic, except that pressurized air is used instead

of oil or fluid (the air often has a small amount of oil mixed in it for lubrication purposes).

Both hydraulic and pneumatic systems provide greater power than electrical actuation,

but they are more difficult to use. In addition to the actuation cylinders themselves, such

as the one shown in Fig. 26-5, a pump is required to pressurize the air or oil, and values

are used to control the retraction or extension of the cylinders. For the best results, you

need a holding tank to stabilize the pressurization. For small robot arms, the Lego Technics

pneumatic cylinders, controls, and tanks can make the task of actuating an arm quite

easy.

Figure 26-5 One of the many available sizes and styles of pneumatic cylinders. This one has a

bore of about  in and a stroke of three in.

in and a stroke of three in.

in and a stroke of three in.

in and a stroke of three in.An interesting variation on pneumatic actuation is the Air Muscle, an ingenious combination

of a small rubber tube and black plastic mesh. The rubber tube acts as an expandable

bladder, and the plastic mesh forces the tube to inflate in a controllable manner. Air Muscle

is available premade in various sizes; it is activated by pumping air into the tube. When filled

with air, the tube expands its width but contracts its length (by 25 percent). The result is that

the tube and mesh act as a kind of mechanical muscle. The Air Muscle is said to be more

efficient than the standard pneumatic cylinder, and according to its makers it has about a

400:1 power-to-weight ratio.

|

To learn more about . . . |

Read |

|

Building a robotic revolute coordinate arm |

Chapter 27, "Build a Revolute Coordinate Arm" |

|

Creating hands for robot arms |

Chapter 28, "Experimenting with Gripper

Designs" |

|

Endowing robot arms and hands with the sense of touch |

Chapter 29, "The Sense of Touch" |