EXPERIMENTING WITH

GRIPPER DESIGNS

GRIPPER DESIGNS

The arm system detailed in Chapter 27 isn’t much good without hands. In the robotics

world, hands are usually called grippers (also end effectors) because the word more

closely describes their function. Few robotic hands can manipulate objects with the fine

motor control of a human hand; they simply grasp or grip an object, hence the name gripper.

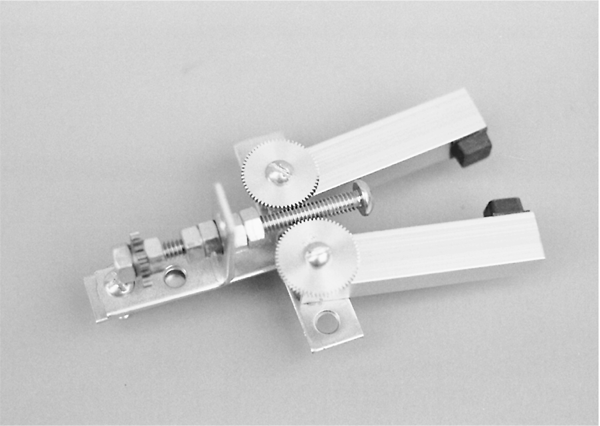

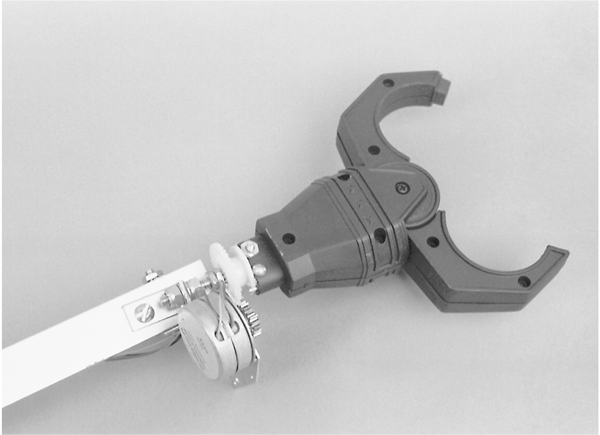

See Fig. 28-1 for an example.

Gripper designs are numerous, and no one single design is ideal for all applications.

Each gripper technique has unique advantages over the others, and you must fit the gripper

to the application at hand (pun intended). This chapter outlines a number of useful

gripper designs for your robots. Most are fairly easy to build; some even make use of inexpensive

plastic toys. The gripper designs encompass just the finger or grasping mechanisms.

The last section of this chapter details how to add wrist rotation to any of the gripper

designs.

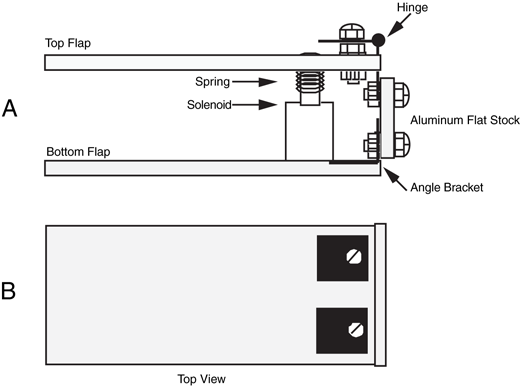

The clapper gripper is a popular design, favored because of its easy construction and simple

mechanics. You can build the clapper using metal, plastic, wood, or a combination of all

three. The parts list inTable 28-1 is for the parts used to build the metal and plastic clapper

shown in Fig. 28-2

2 |

1  -by-2 -by-2 -by- -by- -in thick acrylic plastic sheet -in thick acrylic plastic sheet |

2 |

1-by-  -in corner angle bracket -in corner angle bracket |

1 |

1  -by-1-in brass or aluminum hinge -by-1-in brass or aluminum hinge |

1 |

Small 6- or 12-vdc spring-loaded solenoid |

8 |

-in-by- -in-by- stove bolts, nuts stove bolts, nuts |

The clapper consists of a wrist joint (which, for the time being, we'll assume is permanently

attached to the forearm of the robot). Connected to the wrist are two plastic plates. The

bottom plate is secured to the wrist; the top plate is hinged. A small spring-loaded solenoid

is positioned inside, between the two plates. When the solenoid is not activated, the spring

pushes the two flaps out, and the gripper is open. When the solenoid is activated, the plunger

pulls in, and the gripper closes. The amount of movement at the end of the gripper is

minimal—about  in with most solenoids. However, that is enough for general gripping tasks.

in with most solenoids. However, that is enough for general gripping tasks.

in with most solenoids. However, that is enough for general gripping tasks.

in with most solenoids. However, that is enough for general gripping tasks.Cut two  -in-thick acrylic plastic pieces to 1

-in-thick acrylic plastic pieces to 1 by 2

by 2 in. Attach the lower flap to two

1-by-

in. Attach the lower flap to two

1-by- -in corner angle brackets. Place the brackets approximately

-in corner angle brackets. Place the brackets approximately  in from either side of the flap. Secure the pieces using

in from either side of the flap. Secure the pieces using  -by-

-by- -in bolts and

-in bolts and  nuts. Cut a 1

nuts. Cut a 1 -in length of 1

-in length of 1 -by-

-by-  -in aluminum bar stock. Mount the two brackets to the bottom of the stock as shown in

the figure. Attach the top flap to a 1

-in aluminum bar stock. Mount the two brackets to the bottom of the stock as shown in

the figure. Attach the top flap to a 1 -by-1-in (approximately) brass or aluminum miniature

hinge. Drill out the holes in the hinge with a #28 drill to accept

-by-1-in (approximately) brass or aluminum miniature

hinge. Drill out the holes in the hinge with a #28 drill to accept  bolts. Secure the hinge

using

bolts. Secure the hinge

using  bolts and nuts.

bolts and nuts.

-in-thick acrylic plastic pieces to 1

-in-thick acrylic plastic pieces to 1 by 2

by 2 in. Attach the lower flap to two

1-by-

in. Attach the lower flap to two

1-by- -in corner angle brackets. Place the brackets approximately

-in corner angle brackets. Place the brackets approximately  in from either side of the flap. Secure the pieces using

in from either side of the flap. Secure the pieces using  -by-

-by- -in bolts and

-in bolts and  nuts. Cut a 1

nuts. Cut a 1 -in length of 1

-in length of 1 -by-

-by-  -in aluminum bar stock. Mount the two brackets to the bottom of the stock as shown in

the figure. Attach the top flap to a 1

-in aluminum bar stock. Mount the two brackets to the bottom of the stock as shown in

the figure. Attach the top flap to a 1 -by-1-in (approximately) brass or aluminum miniature

hinge. Drill out the holes in the hinge with a #28 drill to accept

-by-1-in (approximately) brass or aluminum miniature

hinge. Drill out the holes in the hinge with a #28 drill to accept  bolts. Secure the hinge

using

bolts. Secure the hinge

using  bolts and nuts.

bolts and nuts.The choice of solenoid is important because it must be small enough to fit within the

two flaps and it must have a flat bottom to facilitate mounting. It must also operate with

the voltage used in your robot, usually 6 or 12 V. Some solenoids have mounting flanges

opposite the plunger. If yours does, use the flange to secure the solenoid to the bottom

flap. Otherwise, mount the solenoid in the center of the bottom flap, approximately  in

from the back end (nearest the brackets), with a large glob of household cement. Let it stand

to dry.

in

from the back end (nearest the brackets), with a large glob of household cement. Let it stand

to dry.

in

from the back end (nearest the brackets), with a large glob of household cement. Let it stand

to dry.

in

from the back end (nearest the brackets), with a large glob of household cement. Let it stand

to dry.Align the top flap over the solenoid. Make a mark at the point where the plunger contacts

the plastic. Drill a hole just large enough for the plunger; you want a tight fit. Insert the

plunger through the hole and push down so that the plunger starts to peek through.

Align the top and bottom flaps so they are parallel to one another.

Using the mounting holes in the hinges as a guide, mark corresponding holes in the aluminum

bar. Drill holes and mount the hinge using  -in-by-

-in-by- bolts and nuts.

bolts and nuts.

-in-by-

-in-by- bolts and nuts.

bolts and nuts.Test the operation of the clapper by activating the solenoid. If the plunger works loose,

apply some household cement to keep it in place. You may want to add a short piece of rubber

weather stripping to the inside ends of the clappers so they can grasp objects easier.

You can also use stick-on rubber feet squares, available at most hardware and electronics

stores.

The two-pincher gripper consists of two movable fingers, somewhat like the claw of a lobster.

The steps for constructing one basic and two advanced models are described in this

section.

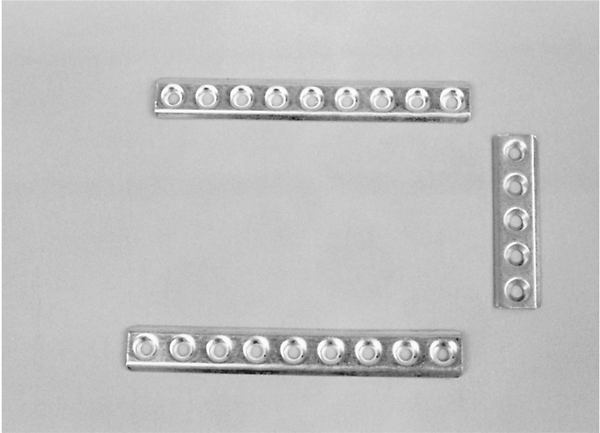

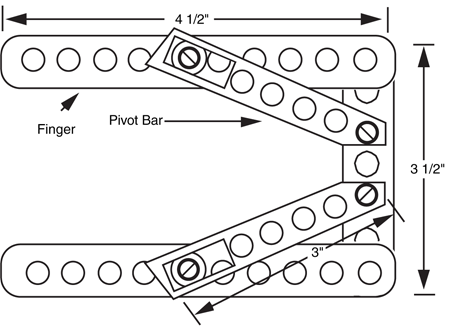

For ease of construction, the basic two-pincher gripper is made from extra Erector set

parts (the components from a similar construction kit toy may also be used). Cut two metal

girders to 4  in (since this is a standard Erector set size, you may not have to do any cutting).

Cut a length of angle girder to 3

in (since this is a standard Erector set size, you may not have to do any cutting).

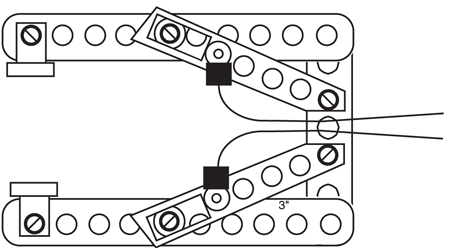

Cut a length of angle girder to 3  in, as shown in Fig. 28-3 (refer to the parts list in

Table 28-2). Use

in, as shown in Fig. 28-3 (refer to the parts list in

Table 28-2). Use  -by-

-by- -in bolts and nuts to make two pivoting joints. Cut two 3-in

lengths and mount them (see Fig. 28-4). Nibble the corner off both pieces to prevent the

two from touching one another. Nibble or cut through two or three holes on one end to

make a slot. As illustrated in Fig. 28-5, use

-in bolts and nuts to make two pivoting joints. Cut two 3-in

lengths and mount them (see Fig. 28-4). Nibble the corner off both pieces to prevent the

two from touching one another. Nibble or cut through two or three holes on one end to

make a slot. As illustrated in Fig. 28-5, use  -by-

-by- -in bolts and nuts to make pivoting

joints in the fingers.

-in bolts and nuts to make pivoting

joints in the fingers.

in (since this is a standard Erector set size, you may not have to do any cutting).

Cut a length of angle girder to 3

in (since this is a standard Erector set size, you may not have to do any cutting).

Cut a length of angle girder to 3  in, as shown in Fig. 28-3 (refer to the parts list in

Table 28-2). Use

in, as shown in Fig. 28-3 (refer to the parts list in

Table 28-2). Use  -by-

-by- -in bolts and nuts to make two pivoting joints. Cut two 3-in

lengths and mount them (see Fig. 28-4). Nibble the corner off both pieces to prevent the

two from touching one another. Nibble or cut through two or three holes on one end to

make a slot. As illustrated in Fig. 28-5, use

-in bolts and nuts to make two pivoting joints. Cut two 3-in

lengths and mount them (see Fig. 28-4). Nibble the corner off both pieces to prevent the

two from touching one another. Nibble or cut through two or three holes on one end to

make a slot. As illustrated in Fig. 28-5, use  -by-

-by- -in bolts and nuts to make pivoting

joints in the fingers.

-in bolts and nuts to make pivoting

joints in the fingers.

2 |

4  -in Erector set girder -in Erector set girder |

|

1 |

3  -in-length Erector set girder -in-length Erector set girder |

|

4 |

-in-by- -in-by- stove bolts, fender washer, tooth lock washer, nuts stove bolts, fender washer, tooth lock washer, nuts |

|

Misc. |

14- to 16-gauge insulated wire ring lugs, aircraft cable, rubber tabs,

-by- -by- -in corner angle brackets (galvanized or from Erector set) -in corner angle brackets (galvanized or from Erector set) |

|

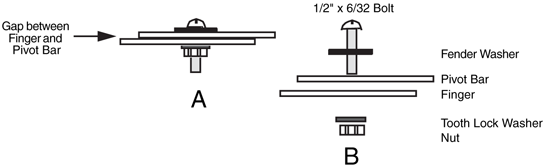

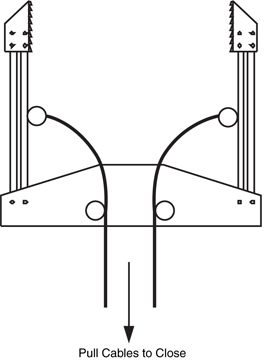

Figure 28-5 Hardware assembly detail of the pivot bar and fingers of the two-pincher

gripper. a. Assembled sliding joint; b. exploded view.

The basic gripper is finished. You can actuate it in a number of ways. One way is to

mount a small eyelet between the two pivot joints on the angle girder. Thread two small

cables or wire through the eyelet and attach the cables. Connect the other end of the cables to a solenoid or a motor shaft. Use a light compression spring to force the fingers apart

when the solenoid or motor is not actuated.

You can add pads to the fingers by using the corner braces included in most Erector set

kits and then attaching weather stripping or rubber feet to the brace. The finished gripper

should look like the one depicted in Fig. 28-6.

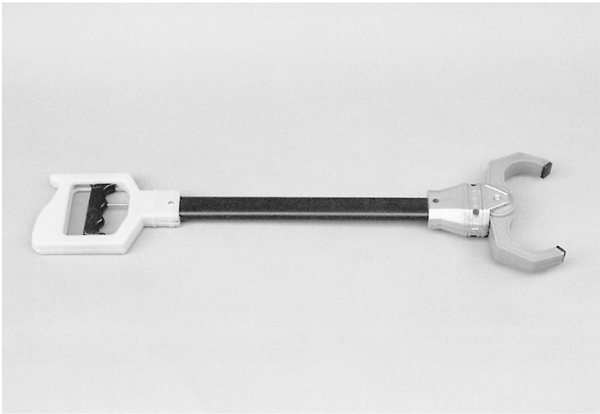

You can use a readily available plastic toy and convert it into a useful two-pincher gripper

for your robot arm. The toy is a plastic extension arm with the pincher claw on one end and

a hand gripper on the other (see Fig. 28-7). To close the pincher, you pull on the hand gripper.

The contraption is inexpensive—usually under $10—and it is available at many toy

stores.

Figure 28-7 A commercially available plastic two-pincher robot arm and claw toy. The gripper

can be salvaged for use in your own designs.

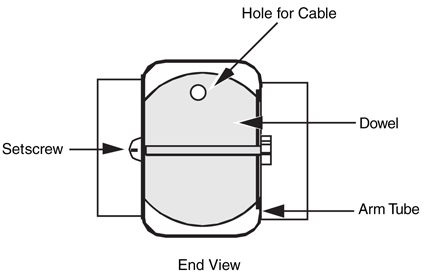

Chop off the gripper 3 in below the wrist. You'll cut through an aluminum cable. Now

cut off another 1 in of tubing—just the arm, but not the cable. File off the arm tube until

it's straight, then fashion a 1

in of tubing—just the arm, but not the cable. File off the arm tube until

it's straight, then fashion a 1 -in length of

-in length of  -in-diameter dowel to fit into the rectangular

arm. Drill a hole for the cable to go through. The cable is off-centered because it attaches

to the pull mechanism in the gripper, so allow for this in the hole. Place the cable through

the hole, push the dowel at least

-in-diameter dowel to fit into the rectangular

arm. Drill a hole for the cable to go through. The cable is off-centered because it attaches

to the pull mechanism in the gripper, so allow for this in the hole. Place the cable through

the hole, push the dowel at least  in into the arm, and then drill two small mounting holes

to keep the dowel in place (see Fig. 28-8). Use

in into the arm, and then drill two small mounting holes

to keep the dowel in place (see Fig. 28-8). Use  -by-

-by- -in bolts and nuts to secure the

pieces.

-in bolts and nuts to secure the

pieces.

in of tubing—just the arm, but not the cable. File off the arm tube until

it's straight, then fashion a 1

in of tubing—just the arm, but not the cable. File off the arm tube until

it's straight, then fashion a 1 -in length of

-in length of  -in-diameter dowel to fit into the rectangular

arm. Drill a hole for the cable to go through. The cable is off-centered because it attaches

to the pull mechanism in the gripper, so allow for this in the hole. Place the cable through

the hole, push the dowel at least

-in-diameter dowel to fit into the rectangular

arm. Drill a hole for the cable to go through. The cable is off-centered because it attaches

to the pull mechanism in the gripper, so allow for this in the hole. Place the cable through

the hole, push the dowel at least  in into the arm, and then drill two small mounting holes

to keep the dowel in place (see Fig. 28-8). Use

in into the arm, and then drill two small mounting holes

to keep the dowel in place (see Fig. 28-8). Use  -by-

-by- -in bolts and nuts to secure the

pieces.

-in bolts and nuts to secure the

pieces.

Figure 28-8 Assembly detail for the claw gripper and wooden

dowel. Drill a hole for the actuating cable to pass through.

You can now use the dowel to mount the gripper on an arm assembly. You can use a

small  -in U-bolt or flatten one end of the dowel and attach it directly to the arm. The gripper

opens and closes with only a

-in U-bolt or flatten one end of the dowel and attach it directly to the arm. The gripper

opens and closes with only a  -in pull. Attach the end of the cable to a heavy-duty solenoid

that has a stroke of at least

-in pull. Attach the end of the cable to a heavy-duty solenoid

that has a stroke of at least  in. You can also attach the gripper cable to a

in. You can also attach the gripper cable to a  -in round

aircraft cable. Use a crimp-on connector designed for 14- to 16-gauge electrical wire to

connect them end to end, as shown in Fig. 28-9. Attach the aircraft cable to a motor or

rotary solenoid shaft and activate the motor or solenoid to pull the gripper closed. The spring built into the toy arm opens the gripper when power is removed from the solenoid

or motor.

-in round

aircraft cable. Use a crimp-on connector designed for 14- to 16-gauge electrical wire to

connect them end to end, as shown in Fig. 28-9. Attach the aircraft cable to a motor or

rotary solenoid shaft and activate the motor or solenoid to pull the gripper closed. The spring built into the toy arm opens the gripper when power is removed from the solenoid

or motor.

-in U-bolt or flatten one end of the dowel and attach it directly to the arm. The gripper

opens and closes with only a

-in U-bolt or flatten one end of the dowel and attach it directly to the arm. The gripper

opens and closes with only a  -in pull. Attach the end of the cable to a heavy-duty solenoid

that has a stroke of at least

-in pull. Attach the end of the cable to a heavy-duty solenoid

that has a stroke of at least  in. You can also attach the gripper cable to a

in. You can also attach the gripper cable to a  -in round

aircraft cable. Use a crimp-on connector designed for 14- to 16-gauge electrical wire to

connect them end to end, as shown in Fig. 28-9. Attach the aircraft cable to a motor or

rotary solenoid shaft and activate the motor or solenoid to pull the gripper closed. The spring built into the toy arm opens the gripper when power is removed from the solenoid

or motor.

-in round

aircraft cable. Use a crimp-on connector designed for 14- to 16-gauge electrical wire to

connect them end to end, as shown in Fig. 28-9. Attach the aircraft cable to a motor or

rotary solenoid shaft and activate the motor or solenoid to pull the gripper closed. The spring built into the toy arm opens the gripper when power is removed from the solenoid

or motor.

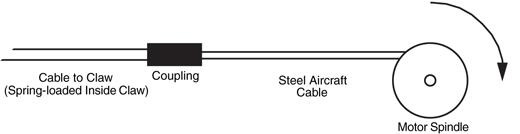

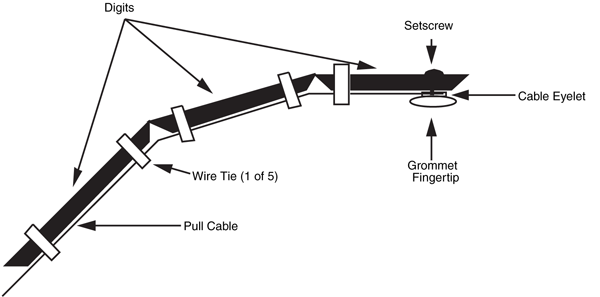

Figure 28-9 One method for actuating the gripper: attach the solid aluminum

cable from the claw to a length of flexible steel aircraft cable. Anchor the cable to a

motor or rotary solenoid. Actuate the motor or solenoid and the gripper closes. The

spring in the gripper opens the claw when power to the motor or solenoid is

removed.

This gripper design (Fig. 28-1) uses a novel worm gear approach, without requiring a hard-to-

find (and expensive) worm gear. The worm is a length of  -in 20 bolt; the gears are standard

1-in-diameter 64-pitch aluminum spur gears (hobby stores have these for about $1

apiece). Turning the bolt opens and closes the two fingers of the gripper. Refer to the parts

list in Table 28-3

-in 20 bolt; the gears are standard

1-in-diameter 64-pitch aluminum spur gears (hobby stores have these for about $1

apiece). Turning the bolt opens and closes the two fingers of the gripper. Refer to the parts

list in Table 28-3

-in 20 bolt; the gears are standard

1-in-diameter 64-pitch aluminum spur gears (hobby stores have these for about $1

apiece). Turning the bolt opens and closes the two fingers of the gripper. Refer to the parts

list in Table 28-3

-in 20 bolt; the gears are standard

1-in-diameter 64-pitch aluminum spur gears (hobby stores have these for about $1

apiece). Turning the bolt opens and closes the two fingers of the gripper. Refer to the parts

list in Table 28-32 |

3-in lengths  -by- -by- -by- -by- -in aluminum channel -in aluminum channel |

|

2 |

1-in-diameter 64-pitch plastic or aluminum spur gear |

|

1 |

2-in flat mending T |

|

1 |

1  -by- -by- -in corner angle iron -in corner angle iron |

|

1 |

3  -by- -by- -in 20 stove bolt -in 20 stove bolt |

|

2 |

-in 20 locking nuts, nuts, washers, tooth lock washers -in 20 locking nuts, nuts, washers, tooth lock washers |

|

2 |

-in-by- -in-by- stove bolts, nuts, washers stove bolts, nuts, washers |

|

1 |

1-in-diameter 48-pitch spur gear (to mate with gear on driving motor shaft) |

|

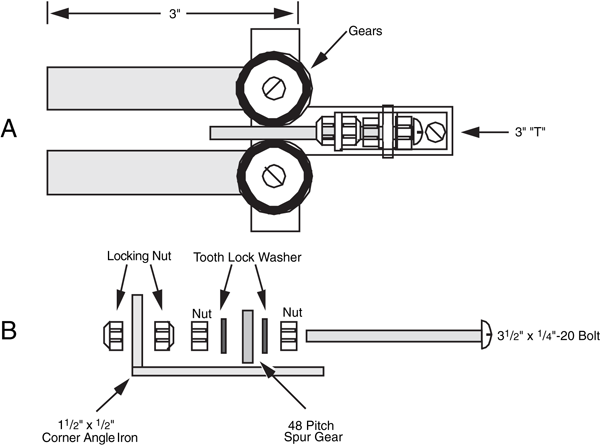

Construct the gripper by cutting two 3-in lengths of  -by-

-by- -by-

-by- -in aluminum channel

stock. Using a 3-in flat mending T plate as a base, attach the fingers and gears to the T as

shown in Fig. Fig. 28-10. The distance of the holes is critical and depends entirely on the diameter

of the gears you have. You may have to experiment with different spacing if you use

another gear diameter. Be sure the fingers rotate freely on the base but that the play is not

excessive. Too much play will cause the gear mechanism to bind or skip.

-in aluminum channel

stock. Using a 3-in flat mending T plate as a base, attach the fingers and gears to the T as

shown in Fig. Fig. 28-10. The distance of the holes is critical and depends entirely on the diameter

of the gears you have. You may have to experiment with different spacing if you use

another gear diameter. Be sure the fingers rotate freely on the base but that the play is not

excessive. Too much play will cause the gear mechanism to bind or skip.

-by-

-by- -by-

-by- -in aluminum channel

stock. Using a 3-in flat mending T plate as a base, attach the fingers and gears to the T as

shown in Fig. Fig. 28-10. The distance of the holes is critical and depends entirely on the diameter

of the gears you have. You may have to experiment with different spacing if you use

another gear diameter. Be sure the fingers rotate freely on the base but that the play is not

excessive. Too much play will cause the gear mechanism to bind or skip.

-in aluminum channel

stock. Using a 3-in flat mending T plate as a base, attach the fingers and gears to the T as

shown in Fig. Fig. 28-10. The distance of the holes is critical and depends entirely on the diameter

of the gears you have. You may have to experiment with different spacing if you use

another gear diameter. Be sure the fingers rotate freely on the base but that the play is not

excessive. Too much play will cause the gear mechanism to bind or skip.

Figure 28-10 A two-pincher gripper based on a homemade work drive system. a. Assembled

gripper; b. worm shaft assembly detail.

Secure the shaft using a 1 -by-

-by- -in corner angle bracket. Mount it to the stem of the T

using an

-in corner angle bracket. Mount it to the stem of the T

using an  -by-1-in bolt and nut. Add a #10 flat washer between the T and the bracket to

increase the height of the bolt shaft. Mount a 3

-by-1-in bolt and nut. Add a #10 flat washer between the T and the bracket to

increase the height of the bolt shaft. Mount a 3 -in-long

-in-long  -in 20 machine bolt through the

bracket. Use double nuts or locking nuts to form a free-spinning shaft. Reduce the play as

much as possible without locking the bolt to the bracket. Align the finger gears to the bolt

so they open and close at the same angle.

-in 20 machine bolt through the

bracket. Use double nuts or locking nuts to form a free-spinning shaft. Reduce the play as

much as possible without locking the bolt to the bracket. Align the finger gears to the bolt

so they open and close at the same angle.

-by-

-by- -in corner angle bracket. Mount it to the stem of the T

using an

-in corner angle bracket. Mount it to the stem of the T

using an  -by-1-in bolt and nut. Add a #10 flat washer between the T and the bracket to

increase the height of the bolt shaft. Mount a 3

-by-1-in bolt and nut. Add a #10 flat washer between the T and the bracket to

increase the height of the bolt shaft. Mount a 3 -in-long

-in-long  -in 20 machine bolt through the

bracket. Use double nuts or locking nuts to form a free-spinning shaft. Reduce the play as

much as possible without locking the bolt to the bracket. Align the finger gears to the bolt

so they open and close at the same angle.

-in 20 machine bolt through the

bracket. Use double nuts or locking nuts to form a free-spinning shaft. Reduce the play as

much as possible without locking the bolt to the bracket. Align the finger gears to the bolt

so they open and close at the same angle.To actuate the fingers, attach a motor to the base of the bolt shaft. The prototype gripper

used a  -in-diameter 48-pitch spur gear and a matching 1-in 48-pitch spur gear on the drive motor. Operate the motor in one direction and the fingers close. Operate the motor

in the other direction and the fingers open. Apply small rubber feet pads to the inside ends

of the grippers to facilitate grasping objects.

-in-diameter 48-pitch spur gear and a matching 1-in 48-pitch spur gear on the drive motor. Operate the motor in one direction and the fingers close. Operate the motor

in the other direction and the fingers open. Apply small rubber feet pads to the inside ends

of the grippers to facilitate grasping objects.

-in-diameter 48-pitch spur gear and a matching 1-in 48-pitch spur gear on the drive motor. Operate the motor in one direction and the fingers close. Operate the motor

in the other direction and the fingers open. Apply small rubber feet pads to the inside ends

of the grippers to facilitate grasping objects.

-in-diameter 48-pitch spur gear and a matching 1-in 48-pitch spur gear on the drive motor. Operate the motor in one direction and the fingers close. Operate the motor

in the other direction and the fingers open. Apply small rubber feet pads to the inside ends

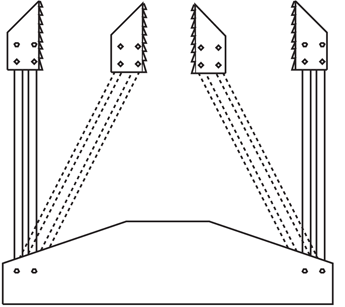

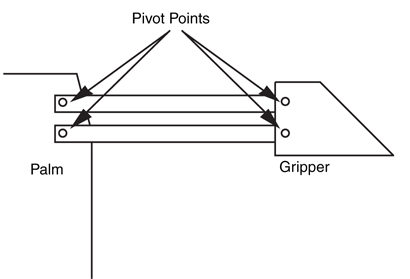

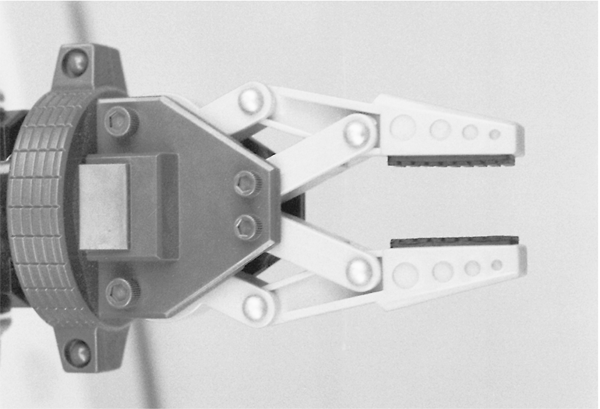

of the grippers to facilitate grasping objects.Figs. Fig. 28-11 through Fig. 28-14 show another approach to constructing two-pincher grippers.

By adding a second rail to the fingers and allowing a pivot for both, the fingertips

remain parallel to one another as the fingers open and close. You can employ several actuation

techniques with such a gripper. Fig. Fig. 28-15 shows the gripping mechanism of the

Radio Shack/Tomy Armatron. Note that it uses double rails to effect parallel closure of the

fingers. You can model your own gripper using the design of the Armatron or amputate an

Armatron and use its gripper for your own robot.

Figure 28-11 Adding a second rail to the fingers

and allowing the points to freely pivot causes the fingertips

to remain parallel to one another.

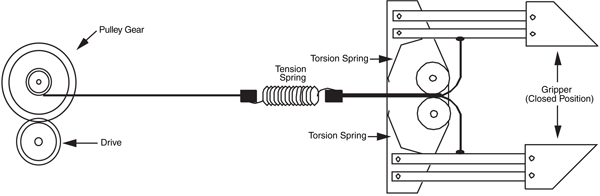

Figure 28-13 A way to actuate the gripper.

Attach cables to the fingers and pull the cables with a

motor or solenoid. Fit a torsion spring along the fingers

and palm to open the fingers when power is

removed from the motor or solenoid.

Figure 28-14 Actuation detail of a basic two-pincher gripper using a motor. The tension spring prevents undo pressure on the object being

grasped. Note the torsion springs in the palm of the gripper.

Figure 28-15 A close-up view of the Armatron toy gripper. Note the use of the dual-rail finger

system to keep the fingertips parallel. The gripper is moderately adaptable to your own designs.

Clapper and two-pincher grippers are not like human fingers. One thing they lack is a compliant

grip: the capacity to contour the grasp to match the object. The digits in our fingers

can wrap around just about any oddly shaped object, which is one of the reasons we are

able to use tools successfully.

You can approximate the compliant grip by making articulated fingers for your robot. At

least one toy is available that uses this technique; you can use it as a design base. The plastic toy arm described earlier is available with a handlike gripper instead of a claw gripper.

Pulling on the handgrip causes the four fingers to close around an object, as shown in Fig. 28-16. The opposing thumb is not articulated, but you can make a thumb that moves in a

compliant gripper of your own design.

Figure 28-16 Commercially available plastic robotic arm and hand toy. The gripper can be

salvaged for use in your own designs. The opposing thumb is not articulated, but the fingers have a

semicompliant grip.

Make the fingers from hollow tube stock cut at the knuckles. The mitered cuts allow the

fingers to fold inward. The fingers are hinged by the remaining plastic on the topside of the

tube. Inside the tube fingers is semiflexible plastic, which is attached to the fingertips. Pulling

on the handgrip exerts inward force on the fingertips and the fingers collapse at the cut

joints.

You can use the ready-made plastic hand for your projects. Mount it as detailed in the

previous section on the two-pincher claw arm. You can make your own fingers from a variety

of materials. One approach is to use the plastic pieces from some of the toy construction

kits. Cut notches into the plastic to make the joints. Attach a length of 20- or 22-gauge

stove wire to the fingertip and keep it pressed against the finger using nylon wire ties. Do

not make the ties too tight, or the wire won’t be able to move. An experimental plastic finger

is shown in Fig. 28-17.

Figure 28-17 A design for an experimental compliant finger. Make the finger spring-loaded

by attaching a spring to the back of the finger (a strip of lightweight spring metal also works).

You can mount three of four such fingers on a plastic or metal “palm” and connect all

the cables from the fingers to a central pull rod. The pull rod is activated by a solenoid or

motor. Note that it takes a considerable pull to close the fingers, so the actuating solenoid

or motor should be fairly powerful.

The finger opens again when the wire is pushed back out as well as by the natural spring

action of the plastic. This springiness may not last forever, and it may vary if you use other

materials. One way to guarantee that the fingers open is to attach an expansion spring, or

a strip of flexible spring metal, to the tip and base of the finger, on the back side. The spring

should give under the inward force of the solenoid or motor, but adequately return the finger

to the open position when power is cut.

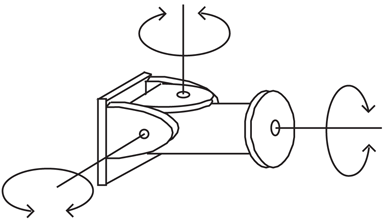

The human wrist has three degrees of freedom: it can twist on the forearm, it can rock up

and down, and it can rock from side to side. You can add some or all of these degrees of

freedom to a robotic hand. A basic schematic of a three-degree-of-freedom wrist is shown

in Fig. 28-18.

Figure 28-18 The three basic degrees of freedom in a

human or robotic wrist (wrist rotation in the human arm is

actually accomplished by rotating the bones in the forearm).

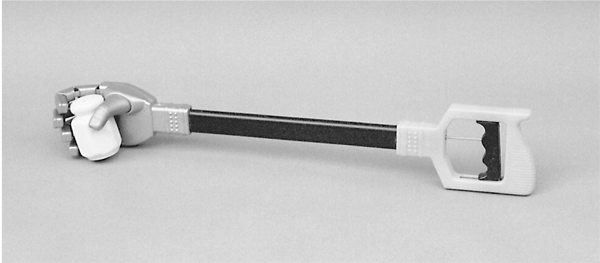

With most arm designs, you'll just want to rotate the gripper at the wrist. Wrist rotation

is usually performed by a motor attached at the end of the arm or at the base. When the

motor is connected at the base (for weight considerations), a cable or chain joins the motor

shaft to the wrist. The gripper and motor shaft are outfitted with mating spur gears. You can

also use chains (miniature or #25) or timing belts to link the gripper to the drive motor. Fig. 28-19 shows the wrist rotation scheme used to add a gripper to the revolute coordinate arm

described in Chapter 27.

Figure 28-19 A two-pincher gripper (from the plastic toy robotic arm detailed earlier in the

chapter), attached to the revolute arm described in Chapter 27. A small stepper motor and gear

system provide wrist rotation.

You can also use a worm gear on the motor shaft. Remember that worm gears introduce

a great deal of gear reduction, so take this into account when planning your robot. The wrist

should not turn too quickly or too slowly.

Another approach is to use a rotary solenoid. These special-purpose solenoids have a

plate that turns 30° to 50° in one direction when power is applied. The plate is spring-loaded,

so it returns to its normal position when the power is removed. Mount the solenoid

on the arm and attach the plate to the wrist of the gripper.

To learn more about . . . |

Read |

|

Using DC motors and shaft encoders |

Chapter 20, "Working with DC Motors" |

|

Using stepper motors to drive robot parts |

Chapter 21, "Working with Stepper Motors" |

|

Different robotic arm systems and assemblies |

Chapter 26, "Reaching Out with Robot Arms" |

|

Building a robotic revolute coordinate arm |

Chapter 27, "Build a Revolute Coordinate Arm" |

|

Interfacing feedback sensors to computers and microcontrollers |

Chapter 14, "Computer Peripherals" |