2.3 Warehouse Processing

This section will focus on IM goods movement postings that leverage the SAP S/4HANA functionality. These processes have been enabled via SAP Fiori apps and include the goods receipt for PO, transfer postings from storage location to storage location, transfer posting from plant to plant, and ad hoc IM goods movement postings. The section concludes with information on the obsolescence of various IM transactions.

2.3.1 Post Goods Receipt to Purchase Order

The SAP ERP MM–PUR module is used by companies to purchase items. The PO is an official commercial and legal document to communicate quantity, agreed price, product details, expected delivery date, and other information to a vendor. Purchase order documents are also used by other departments such as planning, inventory management, and invoice verification for planning, tracking, and payment processing.

The PO is used in the warehouse to facilitate the goods receipt process. Based on the physical receipt, the quantity received, and the paperwork provided from the vendor, a warehouse receipt will be performed in SAP S/4HANA. To perform goods receipt, you can use an SAP Fiori app (Post Goods Receipt for Purchase Order) or Transaction MIGO.

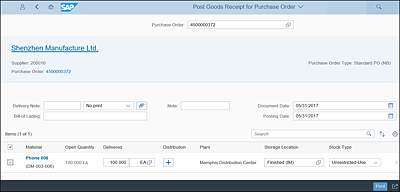

Figure 2.2 shows a transaction flow for the PO goods receipt process in SAP S/4HANA.

Figure 2.2 Initial PO Receipt Processing SAP Fiori App Screen

As shown in the figure, you can enter Purchase Order number, select items to receive with actual quantity, and click on Post. You’ll receive the message shown in Figure 2.3.

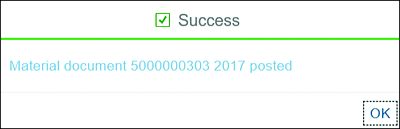

Figure 2.3 The Message Received When a PO Receipt Is Completed Correctly

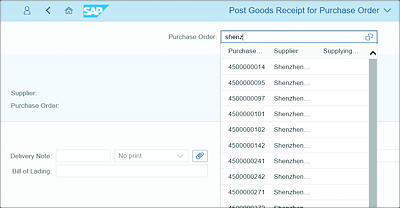

An additional feature of the SAP Fiori app is the ability to search for Purchase Order number by entering the vendor name or other attributes of the PO (see Figure 2.4).

Figure 2.4 Dynamic Search Capability within the PO Receipt SAP Fiori App

Note that this SAP Fiori app can’t be used with batch-managed or serial number-managed materials. In those cases, you’ll need to leverage Transaction MIGO in the SAP GUI.

To access Transaction MIGO, use the following menu path: Logistics • Materials Management • Inventory Management • Goods Movement • Goods Movement or GR for Purchase Order.

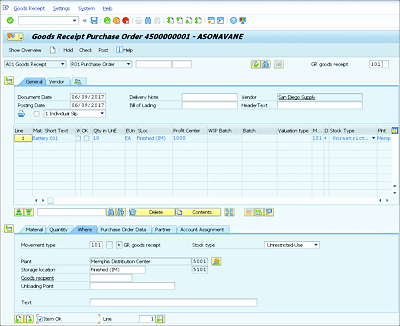

You can process this transaction by entering a purchaser order number, and the system will propose data from the PO (e.g., material number, quantity, receiving storage location, stock type, etc.), as shown in Figure 2.5. You then verify and update information, such as receiving storage location, quantity, stock type (e.g., Unrestricted, Quality Stock, Blocked Stock), and post goods receipt.

Figure 2.5 SAP Business Suite: Transaction MIGO Goods Receipt Screen

The following items are features of the goods receipt transaction/app:

- In the SAP Fiori app, you can enter the vendor name (text), and the system will show all relevant POs.

- The goods receipt location will be proposed based on the master data setup; however, you can modify the location.

- Goods receipt is valuated on the basis of the PO price or the invoice price. Goods receipt posted with the Blocked Stock type won’t be part of valuated stock.

2.3.2 Transfer Stock in Plant

In SAP ERP IM, there exists traditional functionality to move material between plants and storage locations. The functionality allows for one-step and two-step transfers.

The two-step transfer functions will post inventory into transit from the shipping locations and will be received from in transit by the receiving facility. This is a traditional functionality in the SAP Business Suite, and has been transitioned to the SAP Fiori apps with enhanced usability.

Let’s explore both the one-step and two-step transfer.

Stock Transfer between Storage Locations (One-Step Transfer)

One-step stock transfers are used to immediately move material from one storage location to another without posting material in transit. Stock transfer from one storage location to another is carried out within the same plant. Because this transfer is carried out within the same plant and with the same valuation data, this transfer isn’t valuated; that is, no accounting document will be generated with exception to the material with split valuation.

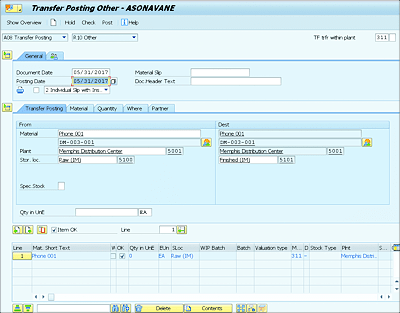

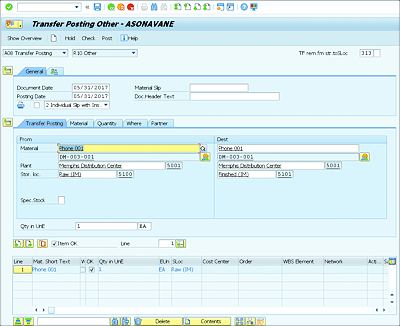

With SAP S/4HANA, you need to use Transaction MIGO or Transaction MIGO_TR to perform this movement. Alternatively, you can use the SAP Fiori app called Transfer Stock-In Plant or Manage Stock. Figure 2.6 shows a transfer using Movement Type 311 to move material from one storage location to another within the same plant.

Figure 2.6 Transaction MIGO: Transfer Posting Other Screen

Within Transaction MIGO, you’ll work with a number of tabs and have to enter very specific information. On the Transfer Posting tab, you’ll enter the material number, plant, and storage location. On the Quantity tab, you’ll enter the quantity of the material being transferred.

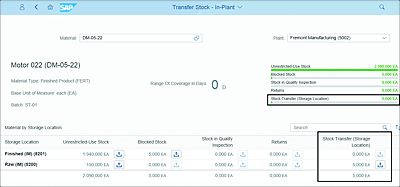

Figure 2.7 shows the same process flow using the Transfer Stock – In Plant SAP Fiori app.

Figure 2.7 Transfer Stock - In Plant SAP Fiori App

Within this transaction, you need to enter the Material and the Plant. The SAP Fiori app will pull in information such as material details and shows the material stock overview.

The SAP Fiori app shows the material in each storage location. To select the storage location to which you want to move the material, click on the Transfer icon (up arrow) next to the inventory you wish to transfer. After you’ve clicked this icon, it will allow you to choose a destination storage location and destination stock type by clicking the down arrow transfer button. In this example, we’ll be transferring material from Storage location Finished IM 5201 to Storage location Raw IM 5200.

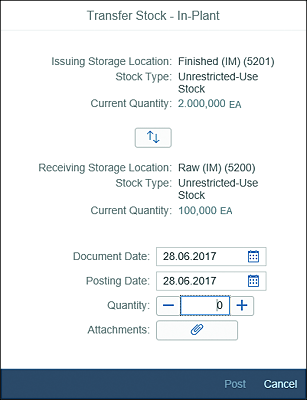

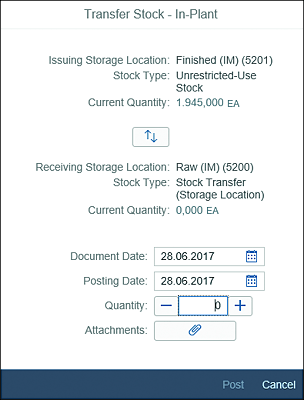

At this point, you’ll be prompted with the screen shown in Figure 2.8.

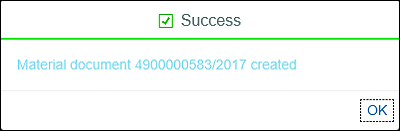

In this screen, you enter the date and quantity for the posting to be processed. After you’ve confirmed all the information, select the Post button. The message shown in Figure 2.9 appears.

Figure 2.8 Entering the Quantity to Transfer

Figure 2.9 Transfer in Plant Success Message

There are a few additional considerations within this SAP Fiori app. A financial document won’t be posted for moves within a plant unless split valued materials are processed. This transaction can be used for additional transfers within a plant most commonly used for stock status changes (transfers from Unrestricted to Blocked Stock or Quality stock).

Stock Transfer between Storage Locations (Two-Step Transfer)

This scenario will highlight the process of moving material between storage locations with a posting into in-transit from the source plant, followed by a receipt from in-transit by the receiving plant. This scenario will process using movement types 313 (Transfer Storage Location to Storage Location Removal from Stock) and 315 (Transfer Storage Location to Storage Location Placement into Stock).

This functionality is enabled via both the SAP Business Suite GUI and the SAP Fiori app called Transfer Stock in Plant.

Figure 2.10 shows the Transaction MIGO flow to transfers from storage location to storage location in two steps. Use Transaction MIGO with Movement type 313 to transfer stock from the issuing location to the destination location.

Figure 2.10 Transaction MIGO Transfer Posting 313 Movement Type from Source Location to Destination Location

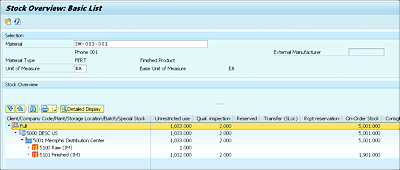

You’ll enter the relevant information such as material, plant, storage location, and quantity, and then you’ll post the movement. The movement will show in Transaction MMBE Stock Overview: Basic List screen as a Transfer SLoc quantity (see Figure 2.11).

The receiving storage location will process Transaction MIGO with Movement type 315 to receive the material from the SLoc transfer in-transit location (see Figure 2.12).

Figure 2.11 Transaction MMBE Showing Inventory in the Transfer SLoc Location

Figure 2.12 Transaction MIGO Place in Storage Screen

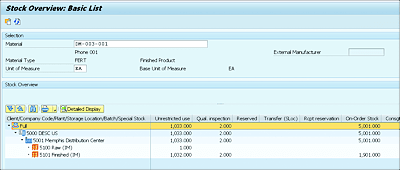

The receiving location will process the relevant information and post the movement via Transaction MIGO. The inventory will now show in the receiving location (see Figure 2.13).

Figure 2.13 Inventory in the Receiving Location and Inventory Removed from the Transfer SLoc

In addition to Transaction MIGO in SAP Business Suite, with SAP S/4HANA, you can leverage an SAP Fiori app to process these transfers. To execute the transfer, you need to execute the Transfer Stock - In-Plant app (see Figure 2.14).

Figure 2.14 SAP Fiori App: Transfer Stock - In-Plant

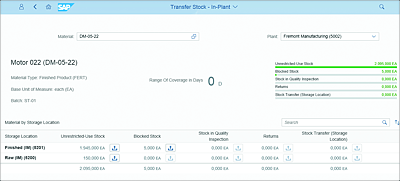

The initial screen in the SAP Fiori app requires you to enter the Plant and the Material number. It will show material-specific information in addition to the material stock overview situation.

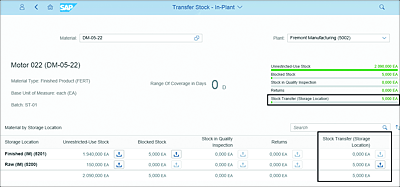

After the material to move has been determined, you need to click on the storage location and stock category to remove the material. Click on the Transfer button (up arrow), and then select the destination location by clicking the Place Into (down arrow) icon. For a storage location to storage location two-step posting into In Transit, select the destination selection Stock Transfer (Storage Location), as shown in Figure 2.15.

Figure 2.15 Stock Transfer in Plant: Two-Step SLoc Transfer Confirmation

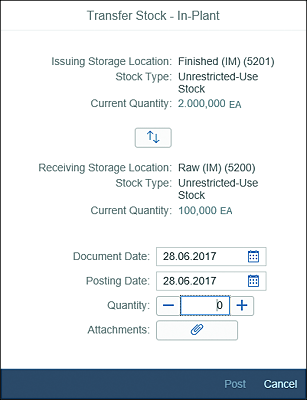

On this screen, you enter the quantity to be transferred and the system posting date for the transfer. When all inputs are confirmed, click the Post button. A success message will appear.

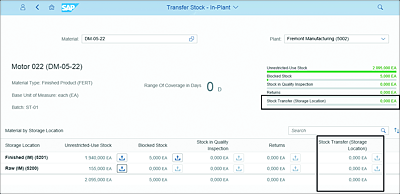

Within the SAP Fiori app, the stock in transit is shown in both the Stock Transfer (Storage Location) column and in the header Stock Transfer section (see Figure 2.16).

At this point, the inventory is in transit between the source storage location and the destination storage location. For the receiving storage location to process the receipt, you’ll use the Transfer Stock in Plant SAP Fiori app, and click the Transfer icon to move the material from the destination location Stock Transfer category (up arrow) and place the inventory in the destination SLoc Unrestricted-Use Stock category (see Figure 2.17).

Figure 2.16 Inventory in Transit between the Two Storage Locations

Figure 2.17 Transfer Stock - In-Plant Receipt into Destination SLoc Screen

The Transfer Stock - In-Plant screen shown in Figure 2.18 is now updated to show the inventory in the destination plant and show the in-transit stock removed.

Note that within the process flow, no accounting document will be posted for transfers within a plant. Additionally, you can only post unrestricted-use stock into in-transit; you can’t post blocked or quality stock into in-transit.

Figure 2.18 Transfer Stock - In-Plant

2.3.3 Transfer Stock Cross Plant

Within SAP S/4HANA, the ability to transfer material between plants has been included in the SAP Fiori app called Transfer Stock Cross Plant. This functionality is also available in the SAP Business Suite with little changes to the traditional functionality.

The functionality to move material from plant to plant is also very similar to the process of moving material from storage location to storage location.

When moving material from plant to plant, there are two scenarios available: movement within a company code (can be one- or two-step posting) or movement from plant to plant across company codes (can only be processed as a two-step posting).

We’ll start by showing the transaction flow for a plant to plant within the same company code using a one-step transfer, and then we’ll move on to the two-step transfer.

Cross Plant Stock Transfer (One-Step Transfer)

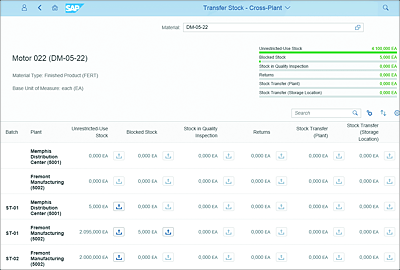

You’ll start by executing the Transfer Stock - Cross-Plant SAP Fiori app, as shown in Figure 2.19.

Figure 2.19 Transfer Stock - Cross-Plant SAP Fiori App: Initial Screen

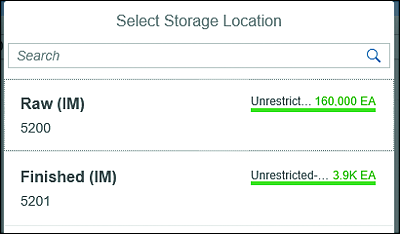

Within this SAP Fiori app, you select the material you want to transfer, and the output will show all the plants and storage locations in which this material exists. You’ll then select the plant you want to remove the inventory from by selecting the Transfer From (up arrow) icon. This opens the Transfer To (down arrow) icons that will allow the material to be transferred. After you select the destination location, a pop-up appears asking for additional details (Figure 2.20).

In this pop-up, you confirm the quantity being transferred, the date of the transfer, and the issuing and receiving storage locations (Figure 2.21). If you need help determining the storage locations, the dropdown menu will show what storage locations the material is currently stored in.

Figure 2.20 Additional Details Pop-Up

Figure 2.21 Storage Location Dropdown

After the information is input and validated, select Post to post the material into the destination storage location. A successful posting message will be displayed. The material document posted for this movement will default to a 301 Movement Type.

Cross Plant Stock Transfer (Two-Step Transfer)

This section will highlight the business process to transfer material from plant to plant with the material moving to in-transit instead of a direct posting into inventory. SAP S/4HANA supports this goods movement via the Transaction MIGO in SAP Business Suite, and it’s supported via the SAP Fiori app called Transfer Stock - Cross-Plant. Now let’s discuss the transaction flow.

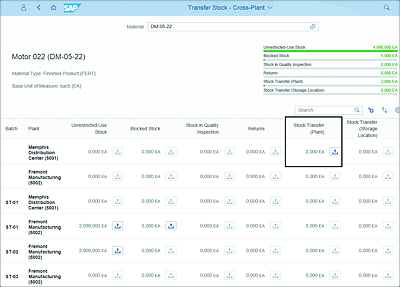

The first step you’ll need to execute when performing this movement is to open the Transfer Stock - Cross-Plant SAP Fiori app (see Figure 2.22).

Figure 2.22 Transfer Stock - Cross-Plant: Stock Transfer (Plant) Column

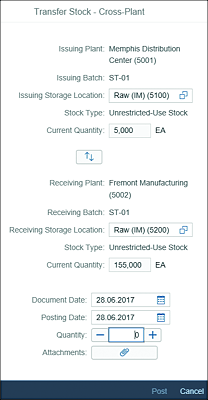

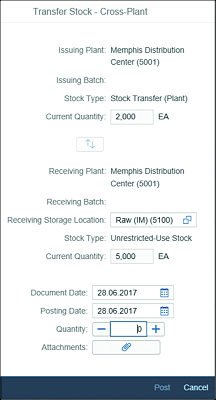

Within this screen, you can select the material you want to transfer and the plant/storage location you want to transfer from. You’ll need to select the Transfer From (up arrow) and the Transfer To (down arrow) icons accordingly. To process the transfer as a two-step transfer, the Transfer To (down arrow) selection must be made into the destination plant Stock Transfer (Plant) column. After you’ve made those selections, you’ll be presented with a transfer details pop-up (see Figure 2.23).

Within this pop-up, you can select the quantity to transfer, the date of the transfer, and the source storage location to pull the material from.

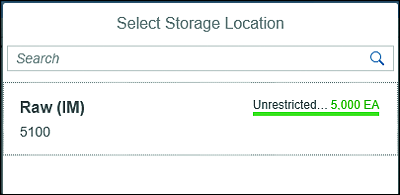

To determine the best storage location to pull the material from, you can choose the issuing storage location dropdown function, and the SAP Fiori app will show you the current storage location stock level in that plant (see Figure 2.24).

Figure 2.23 Transfer Stock - Cross-Plant: Issuing Plant Details Pop-Up

Figure 2.24 Transfer Stock - Cross-Plant: Issuing Storage Location Dropdown Stock Overview

After you select the issuing storage location, click on Post. You’ll receive a successfully posted message. The material will now be showing in the destination plant stock transfer location (see Figure 2.25). The Movement Type 303 is used to post the inventory into transit.

Figure 2.25 Transfer Stock - Cross-Plant: Inventory Showing in Transit at the Plant Level

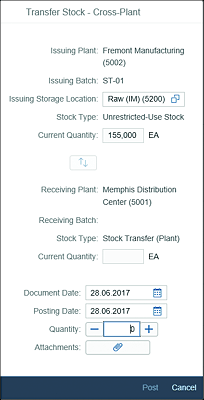

The next step is to process the placement of material into the receiving plant. From the initial screen, select the Transfer From (up arrow) icon from the receiving plant Stock Transfer (Plant) column, and click the Transfer To (down arrow) icon in the corresponding stock category.

After those selections are made, a pop-up message appears, as shown in Figure 2.26.

Here the receiving plant confirms the quantity, confirms the receipt date, and chooses the receiving storage location. After they have entered this information, click on the Post button to receive the material. A success message appears, and the material is placed into stock. Goods movement 305 is posted for this transaction. If transferring batch-managed inventory between plants, make sure to select the correct batch on the initial screen, both for the issuing and receiving transactions.

Figure 2.26 Transfer Stock – Cross-Plant: Receiving Plant Details Pop-Up

2.3.4 Post Goods Movements

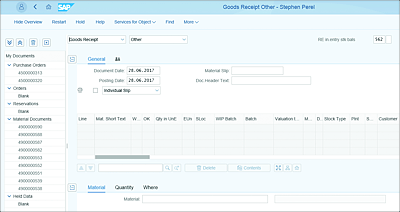

Within SAP S/4HANA, SAP has provided the Post Goods Movement SAP Fiori app. This transaction serves as a single SAP Fiori app for processing most standard movement types. The Post Goods Movement app functions in a similar manner as the Transaction MIGO in the SAP Business Suite in both movements supported and appearance.

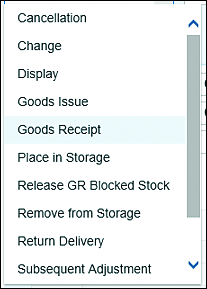

Figure 2.27 shows the Post Goods Movement App. Here, you can see the Goods Receipt and other executable actions as selected in the initial processing of the transactions. This behavior mimics the traditional Business Suite MIGO functionality.

Users can choose the executable action and the reference documents similar to in Transaction MIGO.

Figure 2.28 shows the Executable Actions that are supported. The Executable Actions are displayed when selecting the down arrow in the top left selection box, as filled by the term Goods Receipt in Figure 2.27.

Figure 2.27 Post Goods Movement: Initial Screen

Figure 2.28 Post Goods Movement App: Executable Actions

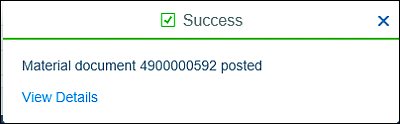

The reference documents enabled are influenced by the Executable Action that is selected. After all of the needed information is entered in the Post Goods Movement app, the standard Transaction MIGO Check and Post functions are available. The Check and Post functions allow the processor to verify that the information entered in the transaction is correct and then to post the goods movement. The item OK selection is also enabled similar to standard Transaction MIGO. The item OK selection is a check box at the bottom of the item portion of the screen, if this check box is not selected the item will not be included in the posting. This allows the user to enter multiple items but only post specified items. After all information is entered, processed, and posted, you’ll get a success message (see Figure 2.29).

Figure 2.29 Post Goods Movement Success Message

This SAP Fiori app is very helpful for supervisor levels and users who have to perform a number of ad hoc goods movements.

2.3.5 Output Material Documents

Many IM processes require the generation of physical outputs such as goods receipt labels and goods receipt slips. SAP S/4HANA support for the creation of outputs from the IM module is the Output Material Document app, which functions similar to Transaction MB90 in SAP Business Suite. In addition, the traditional SAP ERP IM automatic printing functions are supported in SAP S/4HANA.

The IM output types shown in Table 2.2 are supported by the Output Material Document app and SAP S/4HANA.

| Type | Description |

|---|---|

| WA01 | GI slip, version 1 |

| WA02 | GI slip, version 2 |

| WA03 | GI slip, version 3 |

| WAE1 | GI label, version 1 |

| WAE2 | GI label, version 2 |

| WAE3 | GI label, version 3 |

| WE01 | GR slip (POs), version 1 |

| WE02 | GR slip (POs), version 2 |

| WE03 | GR slip (POs), version 3 |

| WF01 | GR slip (orders), version 1 |

| WF02 | GR slip (orders), version 2 |

| WEE1 | GR label, version 1 |

| WEE2 | GR label, version 2 |

| WEE3 | GR label, version 3 |

Table 2.2 IM Output Types Supported by the Output Material Document App and SAP S/4HANA

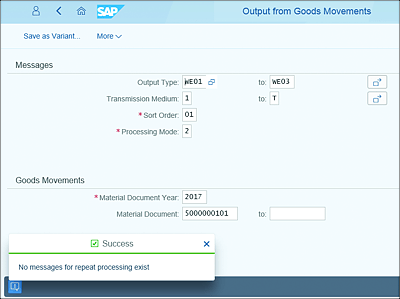

You can add information into the Output Material Document app (e.g., appropriate output type, transmission medium, and processing medium) and enter goods movement document details (e.g., year and material document number). After this information is entered, click the Execute button to print the document. You’ll also receive a success message, as shown at the bottom of Figure 2.30.

Figure 2.30 Output Material Document Success Message

2.3.6 Transaction MIGO and Transaction Obsolescence

Within SAP S/4HANA, a significant change has been made in the IM module to phase out a number of traditionally commonly used transactions. The following transactions are no longer supported in SAP S/4HANA, but you can use Transaction MIGO in their place: Transactions MB01, MB02, MB03, MB04, MB05, MB0A, MB11, MB1A, MB1B, MB1C, MB31, MBNL, MBRL, MBSF, MBSL, MBST, and MBSU.

In addition, a number of transactions are still available but will be phased out in future releases. You should use SAP Fiori apps instead of these transactions (see Table 2.3).

| Old Transaction | SAP Fiori app |

|---|---|

| MMBE_OLD | Stock - Single Material |

| MMBE | Stock - Single Material |

| MB51 | Material Documents Overview |

| MB52 | Stock - Multiple Materials |

| MB5B | Stock - Multiple Materials |

Table 2.3 SAP Fiori Apps