3.5 Reporting in Manufacturing

The majority of the reporting changes in SAP S/4HANA in the manufacturing space are contained in the SAP Fiori apps as described in the preceding sections. This includes enhanced analytics on MRP and scrap measurements.

The SAP Overall Equipment Effectiveness Management report is an enhanced reporting function in SAP S/4HANA. The following subsection will detail the functionality offered for SAP OEE Management reporting.

3.5.1 SAP Overall Equipment Effectiveness Management

SAP OEE Management reporting is an industry standard reporting concept that combines information from production and maintenance to determine how well production operations are performing. Traditional manufacturing metrics focus on yield and scrap performance without taking maintenance or quality results into consideration to get an overall understanding of production. SAP OEE Management reporting attempts to integrate these components to help plant management understand the production throughput, the quality of the goods produced, and the effective management of the equipment used in the production process.

SAP OEE Management reporting attempts to break down complex manufacturing, quality, and maintenance metrics into a few key KPIs, which quickly allow for analysis of the data and corrective action.

The SAP OEE Management offering does require integration into the SAP Manufacturing Integration and Intelligence (MII) software component as a prerequisite for using the SAP Fiori apps offered.

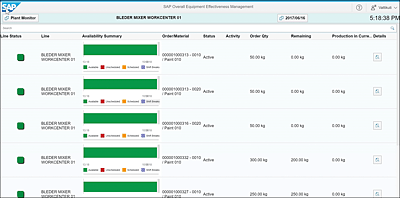

When using the SAP OEE Management reporting tool, the Plant Level Analysis app is run to show the overall performance of the shop floor. This report utilizes predetermined color coding to indicate if a production line is operating effectively. If the color coding is showing as green, then the shop floor operations are executing as expected. If the indicators are yellow or red, this indicates a deviation that should be addressed. Figure 3.31 shows the plant-level indicators.

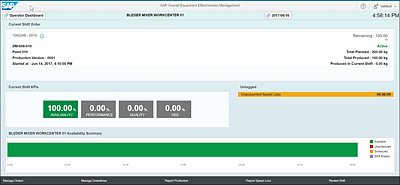

If you investigate the line level information based on the analysis at the plant level, more detailed information and line specific KPIs are provided (see Figure 3.32). The line-specific KPIs show the line capacity, the quality and performance of the line, and the SAP OEE Management KPI for the line. Based on the information obtained at the line level, corrective action can be planned, either by changing production utilization on the line or by planning a maintenance on the equipment.

Figure 3.31 Plant-Level SAP OEE Management Reporting

Figure 3.32 Work Center for SAP OEE Management Reporting

SAP OEE Management reporting is a tool that can help manage the shop floor with a focus on integrated and holistic performance. This functionality is enabled via SAP S/4HANA as a standard offering with the integration of SAP MII. It allows plant leadership to quickly review how the plant is operating and react to data points quickly. It supports lean operations and best practices in the manufacturing space.

3.5.2 Demand-Driven Material Requirements Planning

MRP functionality and technology has been a major tool used by companies for more than 50 years. As businesses change, the technology used to help planning needs to evolve as well. SAP S/4HANA introduces the concept of Demand-Driven MRP (DDMRP) to offer new tools to help modern organizations change.

DDMRP uses strategically placed inventory buffers to decouple demand and supply, breaking the direct connection between dependencies. This dramatically reduces lead times and enables you to plan against actual demand (sales orders). Ironically, to protect and promote flow, you must strategically and purposefully slow or interrupt flow at certain critical points.