4.2 SAP Extended Warehouse Management Basics

SAP Extended Warehouse Management (EWM) is a complete, best-of-breed, warehouse management solution that allows small, medium, and large businesses to run more efficient warehouse processes. It supports production and distribution center operations. Since its first release in 2005, SAP has continued to enhance the functionality to keep up with new business requirements and changes in industry trends via a traditional release management protocol, which is currently at release 9.4.

In this section, we’ll focus primarily on EWM functionality and deployment options in conjunction with SAP S/4HANA, and we’ll address the following commonly issues:

- Available deployment options

- EWM in SAP S/4HANA vs. classic EWM

- Functionality included in embedded EWM in SAP S/4HANA

- New functionality included in release 1709

4.2.1 SAP Extended Warehouse Management Deployment Options

With SAP S/4HANA, starting in the 1610 release, EWM is offered embedded in the SAP S/4HANA core. This allows for the EWM functionality to be leveraged without interfacing data. The traditional EWM offering was in the SAP SCM product offering and not the traditional SAP Business Suite. A number of data elements and technical infrastructure requirements were needed to send data, both master and transactional, back and forth from the traditional SAP Business Suite and SAP SCM. These interfaces and technical considerations have been removed with the embedded EWM offering in SAP S/4HANA.

With release 1610, both basic warehousing and extended warehousing are running on a common code base embedded in SAP S/4HANA. The embedded EWM approach as a deployment option supports warehouse management operations with simplified integration to SAP S/4HANA business processes.

A decentralized deployment option will continue to be available. This option provides proven customer value such as high-velocity, high-volume data-processing distribution centers. This solution also safeguards EWM data when existing decentralized EWM customers decide to migrate their SAP ERP system to SAP S/4HANA. The decentralized option is often used to allow warehouses to operate decoupled from the core IT platform. These decentralized warehouse management solutions allow the warehouse to operate during central instance downtimes, planned or unplanned, and allow for a localized implementation.

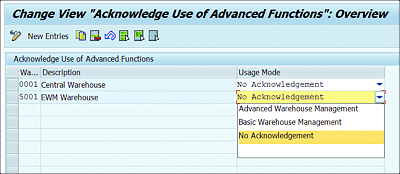

In embedded EWM in the SAP S/4HANA core, the warehouse functionality is grouped in two sets. You need to activate the usage of advanced functionality within the configuration. The two options are basic Warehouse Management and advanced Warehouse Management and are listed in groups of the same names.

4.2.2 Basic Warehouse Management

Basic Warehouse Management covers the functionality offered in the traditional SAP Business Suite. It supports a number of warehousing processes and has been implemented by numerous SAP clients. Business processes such as bin-level inventory management, picking and shipping to customers, receiving and putaways of material from vendor, and interplant inbounds are supported, in addition to internal bin level warehouse management tasks. Over the years, SAP has evolved the EWM offering in the warehousing space to include more advanced functions. Let’s explore the basic Warehouse Management a little further:

-

Inventory management

Inventory management allows for bin-level inventory tracking. It supports functions such as managing inventory in batches and managing inventory on pallets or other warehouse conveyances. -

Inbound processing

All prereceiving, receiving (material into the warehouse), and putaway (inventory into storage) activities are supported, as well as inbound notifications either manually or via electronic interfacing. -

Outbound processing

The outbound shipping process includes shipping to customers, vendors, or between plants. The functionality includes delivery and shipment processing for transportation management, as well as picking and removal strategies such as First In First Out (FIFO). -

Internal warehouse movements

These movements support the different physical and logical statuses of inventory in the warehouse, including processes to physically move material from bin to bin or warehouse to warehouse. Additional warehouse movements block materials for quality reasons and perform numerous other internal status changes. -

Physical inventory

These processes and controls are in place to ensure inventory is accurate in the warehouse via cycle counting, periodic inventories, and other counting methods. -

Reporting

Numerous basic Warehouse Management reports are supported in the traditional SAP Business Suite, including inventory levels, goods movements, and business process monitoring functions such as open deliveries for shipping or receiving. In addition, traditional information system reports are available that allow you to view inventory values and inventory turns, just to name a few.

4.2.3 Advanced Warehouse Management

Advanced Warehouse Management covers all of the same functions just listed but includes an entirely new suite of business processes and functionality offerings. The advanced Warehouse Management setting activates all of the EWM functions offered in the SAP SCM suite.

Companies need to determine just how complex their warehouse operations are to determine which whether they need basic or advanced Warehouse Management. If the operations are somewhat simplistic and generally covered by the preceding list, then the basic Warehouse Management setting will suffice. If the business requirements are much more complex and optimized, the advanced Warehouse Management (i.e., EWM) functionality should be used. As is often the case with software, if you choose the more complex advanced Warehouse Management setting, it provides much more functionality but requires more data, more transactions, and more process rigor to sustain.

Let’s explore advanced Warehouse Management a little more in detail:

-

Inventory management optimization (e.g., slotting)

This functionality grouping includes the same basic bin management functions but includes the concept of slotting. Slotting is a process that determines ideal product placement determination based on dynamic inventory conditions such as planned future usage. It also includes rearrangement processes to move material into ideal locations. -

Inbound process optimization (e.g., deconsolidation)

The functionality for inbound receiving includes the basic offering but also many other business processes. In the basic process, material is received and transferred into storage. The advanced functionality allows for deconsolidating inbound material and then grouping materials on the inbound dock for optimized grouped putaway. -

Accelerated returns processing

Embedded EWM allows for the creation of unplanned returns directly in EWM. This speeds the inbounds returns process and allows the warehouse to receive material into stock that is actually on hand. -

Outbound process optimization (e.g., wave management)

The outbound process includes a number of enhanced functions but specifically focuses on wave management. Wave management allows for deliveries to be grouped by a number of criteria to allow for optimized picking. -

Outbound process delivery and picking

Advanced outbound processes are introduced in the embedded EWM offering that include advanced e-commerce functionality such as picking to cart which allows users to pick multiple customer deliveries in one operation. In addition functionality has been enabled for more advanced change and cancelling of deliveries in EWM -

Material flow control

This functionality allows for much more complex integration to automated machinery in the warehouse. This includes conveyor systems, picking automation tools, and autonomous machinery in the warehouse. Basic Warehouse Management only has very rudimentary integration capabilities. -

SAP Yard Management (e.g., transportation unit [TU] handling, dock appointment scheduling)

This functionality expands the visibility of inventory outside the walls of the warehouse. It allows for scheduling and guard shack functions and provides visibility to trailers and trucks in the yard. -

Labor management

This functionality manages labor in the warehouse and is key in measuring warehouse labor effectiveness. It monitors actual execution of warehouse functions to planned estimates. The labor management functionality also provides management tools to help estimate labor needs. Advanced labor management is offered with additional functionality to track and monitor shift based RF users along with time and attendance. This includes more in-depth features like time and distance traveled with enhanced flexibility of labor standards. -

Value-added services (VAS)

These services are functions performed in the warehouse on a customer’s behalf either as a billable or nonbillable service. They typically include processes such as customer-specific packaging or other wrappings. -

Kitting

This business process is used to support production operations when the warehouse is asked to store and stage raw materials for production. Some staging operations require a number of materials and very specific picking requirements. -

Cross-docking

This functionality isn’t supported in the basic Warehouse Management traditional offering. Cross-docking allows for material that is received to be placed on the receiving dock and then be grouped and picked immediately, versus having material go into storage and then having to be picked for an urgent outbound process. -

Warehouse billing

This functionality is used to support both warehousing provided on behalf of a client and warehouse services provided on your behalf from a vendor. It tracks movements in the system and allows for billing. -

Work scheduling

Warehouse tasks are still leveraged for specific moves and sometimes somewhat mimic the basic warehouse transfer order document. Warehouse tasks offer much more detail in enabling business processes. They can be created for yard moves in addition to any other movements needed in the warehouse. Warehouse tasks lay the foundation of what needs to be done in the warehouse. In addition, the warehouse orders are still used to group warehouse tasks for optimized execution. -

Warehouse execution

The Radio Frequency Framework (RF Framework) is used to manage RF processing of operations in the warehouse. This functional offering is much more robust than the basic RF offering in that it supports multiple device types and sizes, offers a much higher level of configurability to optimize transaction processing by operators, and allows for a better user experience by providing user-specific preferences. The RF Framework can be used to enable a number of processes, such as confirming putaway, picking, loading, replenishments, and physical inventory processing. -

Reporting

The reporting capabilities remain the same from the SAP SCM suite reporting offerings. The key reporting tools are the Warehouse Monitor and the Warehouse Cockpit. The Warehouse Monitor is used to view the current status of activities in the warehouse by tracking past due outbounds and inbounds. It’s a centralized component to view all activity in the warehouse. The Warehouse Monitor has been enhanced with new nodes like shifts and time attendance in Labor Management. The Warehouse Cockpit is used to collect performance data and present the data using a graphical layout. The Warehouse Cockpit provides dashboard-level reporting for leadership in the organization.

You can select either option (see Figure 4.4) based on your business requirements using the SAP Customizing Implementation Guide (IMG) at SCM Extended Warehouse Management • Extended Warehouse Management • Master Data • Acknowledge Use of Advanced Functions.

Figure 4.4 Choosing Basic or Advanced Warehousing

With the introduction of embedded EWM in SAP S/4HANA, you now have four combinations of warehouse management functionality at your disposal. You can run traditional Warehouse Management functionality, traditional decentralized Warehouse Management, embedded EWM, and decentralized EWM. You can also run all of these combinations in a single SAP S/4HANA client.