4.3 Master Data Simplifications

Master data is one of the most important aspect of a successful system implementation. The master data and the system configuration control the warehouse processes. Master data in EWM has traditionally been handled via interfaces, but with the embedded EWM offering, this model has changed. In EWM in the SAP S/4HANA environment, SAP’s primary focus is on one system with reduced data redundancy and overall simplification of the data structures.

This section will take a closer look at various data components, such as business partners, material masters, and batch masters in embedded EWM in SAP S/4HANA.

4.3.1 Business Partners in Extended Warehouse Management

Business partners are external entities you interact with, for example, customers, vendors, and carriers. Each of these requires the creation of a dedicated systemic business partner.

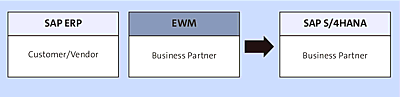

In a decentralized EWM environment, business partners are transferred from SAP S/4HANA to EWM via the Core Interface (CIF). However, in embedded EWM in SAP S/4HANA, EWM reads business partners directly from the central database, and there is no need to replicate the data in EWM, as seen in Figure 4.5.

Figure 4.5 Business Partner Data Transfer in EWM

No additional setup is required for EWM to read business partner data from the SAP S/4HANA central database. Key benefits of this approach include the following:

-

Reduced database footprints

Data is stored in only the SAP S/4HANA structures, reducing the database size needed for storing data in multiple tables. -

Reduced total cost of ownership (TCO)

Without having to monitor multiple databases and system applications, the overall system landscape is greatly simplified with embedded EWM, which avoids data replication and monitoring. -

Simplified setup and operations

The ability to leverage a single software offering of all your warehousing needs allows a much more streamlined system install and monitoring. This is increased if you consider the simplified landscape management for development and testing systems.

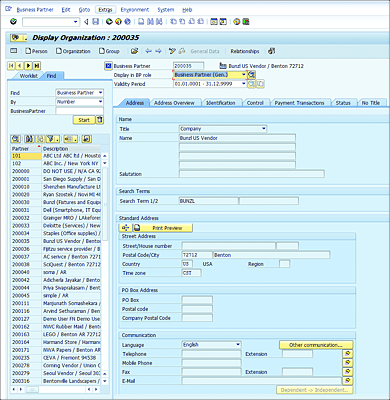

The look and function of the business partner hasn’t changed in SAP S/4HANA, as shown in Figure 4.6.

Figure 4.6 Maintaining Business Partners Using Transaction BP in SAP S/4HANA

4.3.2 Material Master in Extended Warehouse Management

The material master, or product master, as it’s called in EWM, is perhaps the most important master data element in the system. Every warehouse operation involves a product, and every aspect of that operation (what steps are involved, how it flows, what bins are involved, etc.) is decided based on the information stored in the product master.

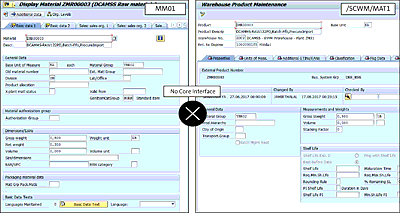

In a decentralized EWM environment, the product master is derived from the material master data of SAP ERP. Materials are created in SAP ERP and then distributed via the SAP ERP–EWM interface to EWM using the CIF technology (see Figure 4.7). After the SAP ERP data is interfaced to EWM, the additional EWM data, that is, picking and putaway strategies, slotting rules, and so on, can be added to the product master to control the warehouse processes for that product.

Figure 4.7 Material/Product Master Data Model in a Decentralized EWM Environment

In the embedded EWM in SAP S/4HANA deployment model, the material/product data model is much simplified. As soon as a material is created in SAP S/4HANA, it’s immediately available in the EWM module. This approach also eliminates the need for additional setup to connect two systems and then send CIF materials from SAP ERP to EWM (see Figure 4.8).

Figure 4.8 Product Master in SAP S/4HANA

4.3.3 Batch Master in Extended Warehouse Management

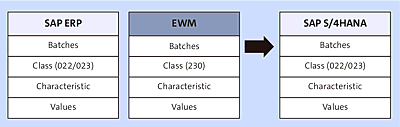

With the embedded EWM model, batch master records are also maintained locally in SAP S/4HANA and aren’t required for the CIF. Because batch data is maintained centrally, batch class type 022 and 023 are used (see Figure 4.9). There is no need to map class type 230 as is needed in the decentralized environment.

Figure 4.9 Representation of Batch Structure in Both the Decentralized and Embedded EWM Models

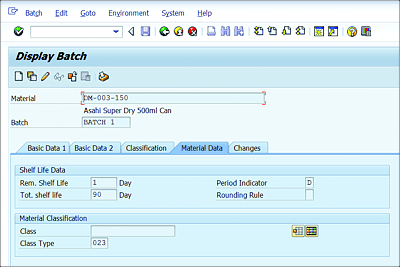

With embedded EWM in SAP S/4HANA, users can manage batches with shelf-life data without using batch classification. Batches are created in SAP S/4HANA, and users can maintain the shelf-life data directly in the Material Data tab, as shown in Figure 4.10.

Figure 4.10 Maintaining Shelf-Life Data in SAP S/4HANA without Classification

4.3.4 Product Data Valuation in Extended Warehouse Management

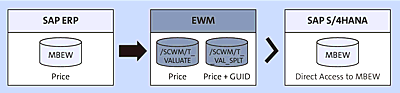

In the decentralized EWM environment, users maintain material price and split valuation in SAP ERP and are required to replicate data in EWM on a regular basis to keep both systems up to date. This isn’t the case in embedded EWM in SAP S/4HANA, as seen in Figure 1.11. EWM processes will read data directly from table MBEW. This will reduce the database footprint and, at the same time, provide up-to-date pricing in EWM.

Figure 4.11 Valuation Transfer in SAP S/4HANA Embedded EWM

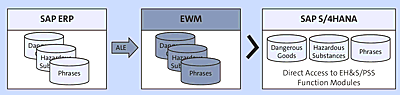

4.3.5 Dangerous Goods and Hazardous Data

In the same manner as the preceding master data, dangerous goods, hazardous substances, and phrases data are read directly from the SAP ERP table (see Figure 4.12).

Figure 4.12 Dangerous Goods, Hazardous Substances, and Phrases Master Data Integration in Embedded EWM

4.3.6 Elimination of Redundant Tables

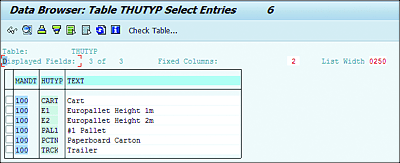

In the decentralized environment, users have to maintain the handling unit type in both SAP ERP and EWM systems. However, with EWM in SAP S/4HANA, it’s stored only in one table, THUTYP (see Figure 4.13). Although table /SCWM/THUTYP does exist in the system, it isn’t required.

Figure 4.13 Table THUTYPE in SAP S/4HANA

A similar approach is adopted for catch weight tolerance groups and serial number profiles. These small steps not only reduce the double maintenance but also avoid data mismatches between the systems.