7.6 Quality Inspections

The quality inspection component helps users determine whether a product consistently meets defined quality requirements. In a quality inspection, a material or product is inspected using master data predefined in the inspection planning component.

7.6.1 Inspection Lot Creation

A quality inspection is processed on the basis of inspection lots. To inspect a specified quantity of a material, an inspection lot is created in the SAP S/4HANA system. The inspection lots are created automatically by the system or manually by the user based on the master data setup. During the inspection lot creation process, transactional data such as purchase order data and master data relevant for quality is automatically copied to the inspection lot. The SAP S/4HANA system uses the inspection lot to record, process, and manage information for a quality inspection. This information includes the following:

-

Inspection processing data such as the following:

- Inspection lot origin (e.g., purchase order GR inspection, in-process inspection, production order GR inspection, etc.)

- Inspection date

- Processing status of inspection lot

- Inspection specifications (e.g., the task list/inspection plan or material specification according to which the products in the inspection lot will be inspected)

- Original document reference that triggered the inspection lot such as purchase order, production order, and material document

-

Inspection results

- Recorded characteristic values

- Recorded defects

- Usage decision (a decision that specifies whether the goods in the inspection have been accepted, rejected, partially accepted, accepted with condition, etc.)

7.6.2 Create Inspection Lot Manually

Manual lots are created to carry out unplanned inspections for the various materials and equipment. When you create an inspection lot manually, you can’t reference an original document (e.g., a GR document, an order, or a delivery note).

When you create an inspection lot manually for a material and lot origin combination, an inspection type for the specified origin should be active in the material master for that material. Inspection lots can’t be created manually for the following lot origins:

- 10: Delivery to customer with sales order

- 13: Repetitive manufacturing

- 14: Calibration inspection

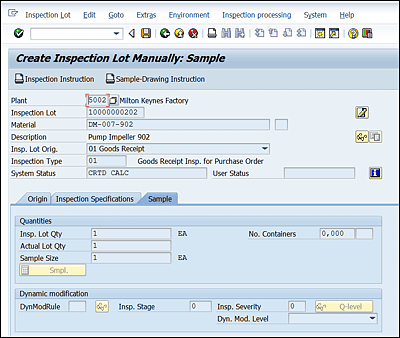

To manually create an inspection lot, navigate to Logistics • Quality Management • Quality Inspection • Inspection Lot Processing • Inspection Lot • Create (QA01) (see Figure 7.21).

Figure 7.21 Inspection Lot

Save your data. You can print inspection instructions by clicking Inspection Instruction.

7.6.3 Resetting the Inspection Lot

This function is used to reset the inspection lot for an inspection lot (e.g., because you want to use a different inspection plan to inspect the goods). Navigate to Logistics • Quality Management • Quality Inspection • Inspection Lot • Processing • Cancel Sample Calculation (QAC3), or Transaction QAC3.

You can only reset the inspection lot if the following are true:

- The inspection lot is marked for cancellation.

- The inspection results are recorded for the inspection lot.

- Defects have been recorded for the inspection lot.

- A usage decision has been made for the inspection lot.

7.6.4 Results Recording/Defect Recording

Using this transaction, you can do the following:

- Record, valuate, and close results for inspection characteristics.

- Record defects for the inspection operations (if any).

- Activate the notification for defects recorded (if any defects exists).

To record inspection results, the following conditions must be met:

- The inspection lot status should be REL – Released.

- Task lists (inspection plan or routing) are assigned to the inspection lot.

- A sample calculation has been carried out.

Results recording for inspection lots can be accessed in the following two ways:

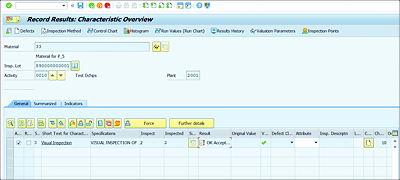

Figure 7.22 displays an example of the results recordings. Defects can be reported by clicking the Defects button.

Figure 7.22 Results Recording

Inspection Lot Completion

After the inspection results recording is completed for an inspection lot, then you must give a decision about the usage of the inspected material and close the inspection lot. Using the usage decision component, you can do the following:

- Close an inspection (inspection lot completion).

- Make the usage decision for an inspection lot.

- Make stock postings for inspection lots.

- Change the shelf life of batch-managed material.

Note

You can only make the usage decision for an inspection lot when all required inspection characteristics (mandatory) have been closed. After the usage decision has been given for an inspection lot, you can no longer change the inspection results. However, you can still process long-term inspection characteristics.

In the usage decision component, you can display the following inspection data:

- Overview of inspection characteristics

- Overview of defects

- Overview of stocks for the inspection lot (displayed if the inspection lot is stock relevant)

Stock Postings

If an inspection lot is stock-relevant, you can post the stock for the inspection lot manually while you’re in the process of making the usage decision.

Note

On the basis of your stock postings, the system makes the corresponding postings in the SAP ERP Materials Management (SAP ERP MM) component.

You can post quantities of material from an inspection lot to the following stock types:

- Unrestricted-use stock

- Scrap

- Sample usage

- Blocked stock

- New material

Note

Stock posting need not to be carried out at the time of usage decision. Stock posting can be done at the various stages of the inspection lot completion process:

- Making a usage decision and stock posting

- Making a stock posting before making a usage decision

- Making a stock posting after making a usage decision

- Completing the inspection without a usage decision

The usage decision for an inspection lot can be changed after saving the usage decision, but a stock posting can’t be changed after the usage decision is saved.

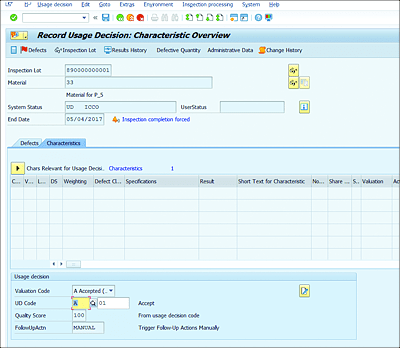

To do this, navigate to Logistics • Quality Management • Quality Inspection • Inspection lot • Usage Decision • Record (QA11), or Transaction QA11 (see Figure 7.23).

Figure 7.23 Usage Decision