10.5

“I’M LAZY; I WANT A MACHINE TO DO WORK FOR ME”

Engineering is the process of applying science, math, and other practical knowledge toward inventing new machines. You’ve been engineering this entire time, and you didn’t even realize it! But the inventions in this section tend more toward the classical conception of engineering: the building of engines to perform different tasks for you, freeing you up to do anything else (including, but not limited to, keeping an eye on the engine you’ve built).

Engineering is the process of applying science, math, and other practical knowledge toward inventing new machines. You’ve been engineering this entire time, and you didn’t even realize it! But the inventions in this section tend more toward the classical conception of engineering: the building of engines to perform different tasks for you, freeing you up to do anything else (including, but not limited to, keeping an eye on the engine you’ve built).

Waterwheels and windmills are the first technologies you’ll invent that harness the Earth’s natural processes, making them do your work so you don’t have to. You’ll make them even better with Pelton turbines. Flywheels smooth out power production and are useful in all sorts of engines, including steam engines, which are incredibly useful machines that require only water as a reactive agent and can run on anything that burns.

We know our more mechanically minded readers will have been anxiously awaiting this section, and we are happy to now give you everything you need to invent these technologies you’ve been looking forward to. In other words: time travelers . . .

. . . start your engines.

10.5.1: WATERWHEELS AND WINDMILLS

If we learn to feast toil-free on the fruits of the earth, we taste again the golden age.

—You (also, Antipater of Thessalonica)

WHAT THEY ARE

A way to harness actual forces of nature to make them work for you, for once

BEFORE THEY WERE INVENTED

If you wanted some grain ground or wood sawed or rocks smashed or tools sharpened or ore crushed or bellows operated or iron wrought or paper pulped or water pumped you had to do it yourself, by hand, like a gosh-darned chump

ORIGINALLY INVENTED

300 BCE (first waterwheels and cams)

270 BCE (right-angle gears)

40 BCE (trip hammers)

100 CE (first wind-powered wheel)

400 CE (waterwheels powered by falling water)

600 CE (dams for waterwheels)

900 CE (first windmills)

1185 CE (first modern windmills)

PREREQUISITES

wheels, wood or metal, cloth (for windmills)

HOW TO INVENT

Both waterwheels and windmills are instantiations of the same idea: the planet has all these liquids and gases always moving around its surface, so wouldn’t it be nice if we could make them do something for us?

A waterwheel is simple to invent: it’s just a giant wheel with paddles on it so water can push it. Dip it in a stream and it’ll rotate as water flows by, but this captures only 20 to 30 percent of the water’s total energy. You can double that number to 60 percent by powering it with falling water instead: this way it’s not just the water’s movement that’s powering your wheel but its mass as well. Do this by replacing the paddles on your wheel with cups, and then positioning your waterwheel beneath a waterfall. If those aren’t around, you can create an artificial one: just direct a stream through a trough that exits above your wheel. While you’re at it, if you dam up that stream so that the only way water can get out is by going through your waterwheel, the lake you create actually functions as a store of power ready to be used whenever you need it. That’s the world’s first battery, and you just invented it.

Your wheel will be connected by a shaft to the inside of your mill, and that shaft will rotate at the same speed and in the same direction as your wheel. This is useful for certain kinds of work—rotating a conveyor belt, for instance—but you can transform this rotational motion into all sorts of different movements with the help of some simple technology.

Add right-angle gears (see Appendix H) and you can make a vertical waterwheel rotate another horizontal wheel instead, which is great for grinding grain. Just set up two stone wheels: your rotating one, and one beneath it that’s fixed in place. Feed your grain into a hole in the middle of your rotating wheel, and it’ll grind it into flour and push it out at the edges. Change the relative sizes of the gears you use and you’ll adjust how fast that grinding happens and with how much torque. Attach a crank to your waterwheel and you’ve changed its rotational motion into a back-and-forth one, which you can use to invent mechanical saws, pumps, or bellows. Replace your crank with a trip hammer and your waterwheel can now repeatedly smash rocks (or hammer steel) instead. All come from the same source: water pushing against a wheel!

Windmills work on the same principle, but rather than water rotating a wheel, wind pushes against a set of sails mounted like a fan around the drive shaft. This introduces a bunch of complicating factors, which we will now explore through a fictional dialogue between a waterwheel-loving critic of windmills—let’s call her Dr. Waterwheels—and a well-informed and reasonable windmill apologist, whom we’ll call Chompsky. We’re going to imagine that Dr. Waterwheels is a human but that Chompsky is an adorable talking dog who’s panting happily as he gets belly scratches from the doctor, because nobody can stop us from imagining whatever we want, least of all you:

|

Statement from Dr. Waterwheels (human, lover of waterwheels, windmill skeptic) |

Response from Chompsky (adorable talking dog, well informed on windmills, super-scratchable belly) |

|

Waterwheels are the best, Chompsky! They use water, whose flow is predictable and usually only changes slowly. Meanwhile, wind is famously unpredictable, wild, and capricious! |

That’s true, Dr. Waterwheels, but you can build windmills anywhere, while waterwheels can only be built near water, so I suppose it balances out. Can you scratch my belly a little higher up? |

|

Is this better? |

Yes, thank you. My leg is doing that adorable thing where it kicks, so you know you’re scratching at just the right spot. Do you have any other issues with windmills? |

|

I do! If my waterwheel is turning too fast, I can simply remove it from the water and it’ll stop. But a windmill can’t escape the wind! |

While you’re right in saying windmills can’t escape the wind, we can easily design them to handle wind overload. The blades of a windmill can be built out of wooden frames, which then get covered by sheets. When the sheets are removed, the wind goes right through the blades instead of turning them to generate force, which allows the amount of power the windmill extracts from the wind to be controlled. |

|

Okay, maybe . . . but water still always comes from the same direction. Wind can comes from every direction ever. What are you going to do, rotate your windmills every time the wind changes? |

That’s precisely what happens, yes. This can be done by hand, but if we’re clever we can make the windmill self-adjusting by adding another paddle to the back of the windmill at a right angle to the drive fan, like on a weather vane. Then, any wind against the paddle turns the windmill to face it automatically. In fact, if we want to get even fancier, we can replace the paddle with a tiny windmill fan that rotates the entire structure along a circular geared track to the same effect! But it’s probably worth pointing out that while it’s true that wind can come from any direction, there are prevailing winds in many areas throughout the planet, which makes it possible to know the average direction wind will come from most of the time. |

|

I guess. But water still carries way more energy than wind. For example, it’s much easier to be swept away over the horizon by a river than it is to be blown away over the horizon by wind! So you have to admit a single waterwheel will often be able to do more work than a single windmill. |

Yes, well, we all do the best we can with what we’ve got. Am I a good dog? |

|

You are a good dog. Who’s a good dog? |

I am. |

|

Yes you are. What a good dog. What a good dog. Good old Chompers. Look at your little face. |

[belly scratches intensify; dialogue ends] |

Table 12: Incidentally, the idea of education and insight happening through a dialogue between two individuals is called the “Socratic Method,” and it’s been a powerful teaching technique since its popularization by Socrates around 400 BCE. We used it here to discuss engineering with a talking dog!

And that’s how you invent windmills and waterwheels.

10.5.2: PELTON TURBINES

Between Earth and Earth’s atmosphere, the amount of water remains constant; there is never a drop more, never a drop less. This is a story of circular infinity, of a planet birthing itself.

—You (also, Linda Hogan)

WHAT THEY ARE

A better version of a waterwheel that’s not only smaller but can also be over 90 percent efficient, which compares really well to that 60 percent we were messing around with with waterwheels

BEFORE THEY WERE INVENTED

People got by with waterwheels, but they didn’t know what they were missing, and now they probably all feel like idiots

ORIGINALLY INVENTED

1870s CE

PREREQUISITES

waterwheels made of wood or, even better, metal

HOW TO INVENT

The waterwheels you invented in the last section (if you’re reading this guide linearly) or that you might get around to eventually (if you’ve flipped directly to this section while muttering, “Gosh darn it, I need turbines stat”) are powered by water in two ways: the mass of the water causing rotation, and the kinetic energy transferred by moving water when it hits the wheel. Pelton turbines work with the same mass of water but capture much more of its energy, which makes them much more efficient.*

The basic idea is to take water under pressure (the easiest way to achieve this is to run water through a pipe going downhill, with a smaller opening at the bottom of that pipe than at the top: the water’s weight at the bottom forces it to pressurize) and make it hit your wheel like a super-powered hose. It didn’t take any special thinking to replace the paddles on a waterwheel with cups to catch the water, but the innovation Johnny Pelton* came up with was to fire the water not directly into the middle of the cups but to put two cups on the wheel and to aim the water right at the wedge-shaped split between the two.*

You can see why that made a difference simply by imagining standing beside a brick wall and spraying a hose at it. Fire that hose straight at the wall with any sort of water pressure and you’re going to get wet: the water will hit the wall and splash right back toward you. That’s energy in the water that’s wasted instead of captured, and that’s what was happening when water was fired into the middle of these waterwheel cups, where they were their flattest. But if your wall had a curve to it, and you aimed your water at an oblique angle just at the edge of that curve, you wouldn’t get wet at all. Instead of being suddenly bounced off the wall, the water would be gently redirected, whipping around the curve to exit from the far edge. That’s precisely how Pelton turbines work: the water imparts much more of its energy as it whips around the cups than it can when it smashes directly into them, which makes the wheel turn faster. The reason Pelton uses two cups instead of just directing the water to the edge of a single cup is for balance: this way the wheel has equal forces on both sides.

A Pelton turbine rotating at half the speed of the water hitting it will capture nearly all that water’s energy. You’ll be able to tell when you’ve got that set up properly because water coming out the far sides of your cups will be almost motionless, and that’s the mark of a well-built Pelton turbine. Now you’re extracting energy from moving water with over 90 percent efficiency! This not only gives you more power from the same water but also unlocks new power sources the world over, because streams and waterfalls that were too small for waterwheels will power a Pelton turbine just fine.

At this point you’re probably thinking that it’s pretty embarrassing humanity took more than two thousand years after inventing waterwheels to figure out that if we aimed the water to the side of our little cups instead of the middle we could almost double their efficiency! But it actually gets worse: origin stories for Pelton’s turbine include “One day Pelton was hosing down some rocks and a cow got too close so he fired his hose at his cow and the water hit her between her cuplike nostrils and it knocked her head back and that’s how he invented his turbine.” We’re not going to tell you if that story is true, because here is a fact: there’s no good way out of this. If it’s true, we’re just a bunch of knuckleheads who need soggy cows to make even basic scientific advances. If it’s false, we’re still a bunch of knuckleheads who are apparently all more than willing to believe that no scientific advancement can happen without some soggy cow to show us the way.29

10.5.3: FLYWHEELS

Change does not roll in on the wheels of inevitability, but comes through continuous struggle.

—You (also, Martin Luther King Jr.)

WHAT THEY ARE

A way to store and extract energy using nothing more than a big old wheel

BEFORE THEY WERE INVENTED

Rotational energy couldn’t be stored, output from engines couldn’t be smoothed, and wheels were significantly less fly

ORIGINALLY INVENTED

300 BCE (in pottery)

1100 CE (in machinery)

PREREQUISITES

wheel, steel (for dense and sturdy flywheels, and also for ball bearings)

HOW TO INVENT

Flywheels exploit the fact that objects in motion tend to stay in motion.* If you have a heavy wheel that takes a lot of energy to start spinning, it’ll also take a lot of energy to stop it. And that makes them batteries that store momentum instead of electricity! Wheels will slow down over time due to friction, so they’re not perfect batteries, but a dense or large flywheel can run for a really long time before it stops. They were first used in pottery (potters’ wheels are just big, heavy wheels that spin for a while once you get them moving, and that, my clay-covered friend, is a flywheel), but (no surprises here) it took humans a while to realize they could be used for anything else. Turns out, all you need to do is attach them to a rod rotated by an engine, and you’re in business!

Besides storing energy, they can also be used to smooth out machinery. In piston engines (see Section 10.5.4), the pistons move intermittently, and in many uses you’ll want constant power. If you’re powering a tractor, for example, you’ll probably want to move forward at an even pace, rather than in fits and starts every time a piston fires. If your pistons power a flywheel instead of your machinery directly, the wheel will continue to rotate even when the pistons aren’t providing power, generating a much smoother force.

Figure 21: A “flywheel,” also known by its less technical name, “wheel on a stick.”

Flywheels can also release energy faster than it was originally produced. It might take you hours to get a flywheel up to speed, but attach a heavy load to your flywheel and you can direct all that energy toward doing work in an instant, giving you access to brief but powerful bursts of energy far beyond what you can normally produce. There is, of course, an upper limit on how much energy any flywheel can store: once a wheel rotates fast enough, it exceeds its own tensile strength, tears itself apart, and all those shards fly off at an incredibly fast speed. This is why a steel flywheel is safer than a cast-iron one: steel’s greater strength minimizes the chance any flywheel inside your machinery transforms itself into a surprise metal bomb.

You can increase the energy any flywheel stores by increasing either its size or its speed. The energy stored in a rotating wheel is related to the square of its speed, so a smaller fast wheel will get better results than a larger slow one. And finally, while flywheels may seem old-fashioned, they aren’t just used on piston-powered machinery: experimental flywheels were constructed by NASA in 2004 CE as a way to cheaply and reliably store energy in space. So technically, by inventing the flywheel you’ve also taken the first steps toward your new civilization’s space program. Nice!

10.5.4: STEAM ENGINES

The introduction of so powerful an agent as steam to a carriage on wheels will make a great change in the situation of humanity.

—You (also, Thomas Jefferson)

WHAT THEY ARE

Engines that use the fact that water takes up more space when it’s boiled to get things done, which is a technology so useful that when they finally got invented, society restructured itself around these machines in an event we call “the Industrial Revolution”

BEFORE THEY WERE INVENTED

If you wanted something done, you had to do it yourself, or get an animal to do it, or pay someone else to do it, but you certainly couldn’t just boil some water and call it a day

ORIGINALLY INVENTED

100 CE (steam-powered toys that were technically steam turbines)

1606 CE (earliest steam-powered water pump)

1698 CE (first practical steam-powered pump)

1765 CE (separate condensation chamber, commercialized in 1776)

1783 CE (steam-powered boats)

1804 CE (steam-powered trains)

1884 CE (reinvention of steam turbines)

PREREQUISITES

Iron (for boilers), cast iron (for piston rings and cylinders), steel, welding

HOW TO INVENT

Steam engines probably sound old-fashioned, but even today the vast majority of electricity worldwide is generated with steam. The only real difference between old-fashioned steam engines and our newfangled ones is instead of burning wood in our boilers, we use coal, gas, or the godlike powers of the very atoms themselves. That’s right: even with the civilization-ending power of nuclear reactors at our disposal, we still mostly just use them to boil us up some water.

The earliest steam engines were invented without much scientific theory behind how they worked, so merely by flipping through this section before you decide to throw a steam engine together, you’re already starting off on a better foot than its original inventors ever did. It’s been said that science owes more to the steam engine than the steam engine owes to science, and while that’s not true (science don’t owe nobody nothin’), it does give you a sense of how much humans were able to learn by studying these engines they’d invented, including but not limited to the second law of thermodynamics.*

A steam engine is made of two parts:

-

a boiler, which uses some form of combustion to boil water, producing steam under pressure

-

an engine that uses that steam to move a piston, turbine, or itself

The boiler part is easy, once you’ve got metal: just have airtight pipes of water that run through your fire-heated combustion chamber (this is called a “water tube boiler”) or have pipes of fire-heated gas that run through your airtight and partially filled water chamber (“fire tube”). Either produces pressurized steam (and introduces the risk of your boilers exploding, so, uh, heads-up on that), but water tubes tend to be cheaper. Once you’ve got steam, you can run it through a second combustion chamber to heat it up even more, producing a superheated steam that carries more energy and can therefore do more work. Superheated steam can also be cooled a bit without it condensing back into water, which is great because then you don’t have to worry about water clogging up your nice new steam engine all the time.

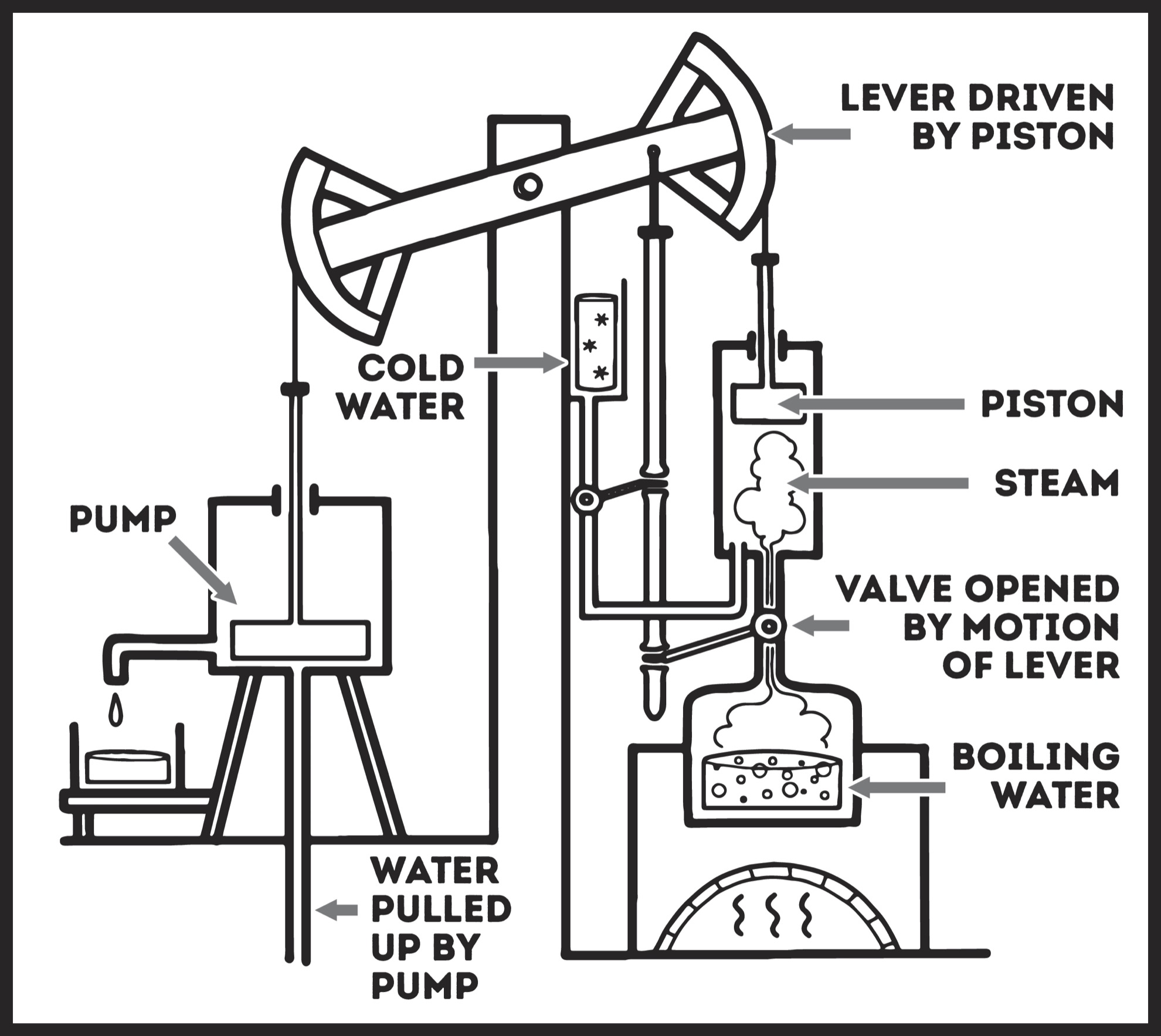

Putting steam to work in an engine can be done in a couple of ways, and the simplest is to inject steam into a piston. A piston is simply a mass that moves freely inside a cylinder, and it takes a little bit of precision engineering: you need a metal cylinder that’s the same width all around, and a piston that’s just slightly smaller so it can move freely within that tube.* To give this piston an airtight seal, you can attach a cast-iron ring to your piston: a spring-loaded piece of metal that makes constant contact with the cylinder. Before cast-iron seals, pistons would have hemp tightly wrapped around their bases as a seal. Hemp is dense, it doesn’t wear out quickly under friction, and it works almost—but not quite—as well as a piston ring. Don’t worry: some leakage of steam is okay, and your engine will still work, just not as efficiently.

When you take steam from your boiler and vent it into a piston, the steam expands, pushing the piston up. As the steam cools it condenses, which causes pressure in the piston to drop, and the outside air pressure to push that piston back down again. Since you generally want this steam to cool quickly, squirt cold water into the piston to speed up cooling. There’s your engine. The up-down motion of the piston can drive a saw, power a pump, or be converted into circular motion via a crank (see Appendix H).

Figure 22: A machine that will power your civilization: the steam engine.

This brings your steam engine to the state of the art in 1698 CE, but if you’re suspecting that heating and then cooling the same piston over and over wastes a whole bunch of energy, then put on a deerstalker* and call yourself Sherlock Holmes,* because your suspicions are correct! You can advance your engine almost eighty years by changing its design so that the hot parts stay hot and the cool parts stay cool. Do this by introducing a connection from your piston to a separate condensation chamber, which gets opened by the piston rising. The high pressure of the piston environment pushes the steam into the condensation chamber, which you can quickly cool with a spray of cold water.

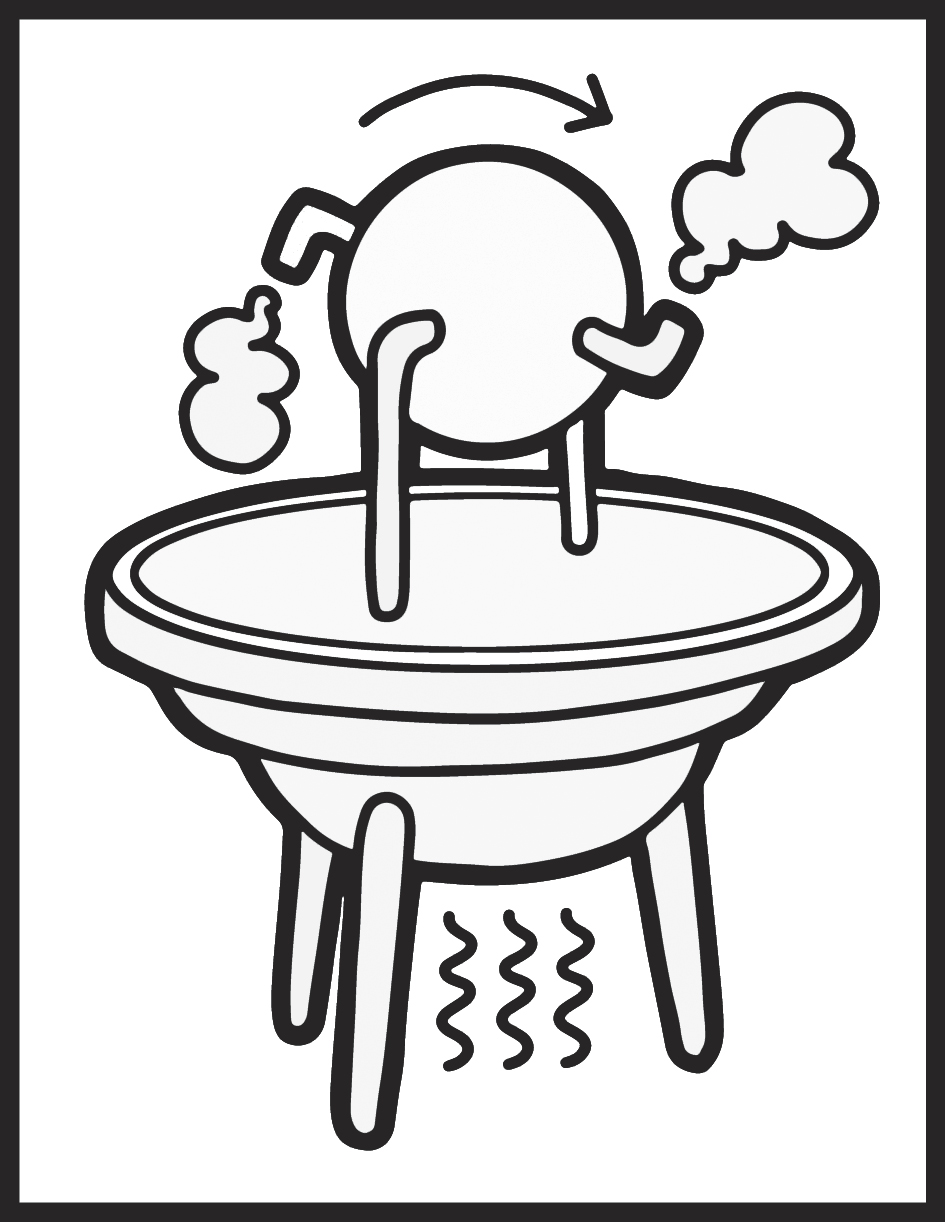

If you don’t want to build a piston, there’s another way to generate power with steam, and it’s actually the first one humans discovered way back around 100 CE. It’s called an “aeolipile,” and you make one by boiling water and directing the steam into a rotating sphere, with exit nozzles positioned like this:

Figure 23: A machine that could’ve powered the ancient Greek civilization: the aeolipile.

The steam coming out of the nozzles acts as jets, spinning the sphere. This is a steam-powered rocket engine, but the Greeks who invented it never considered it to be anything more than a toy. You’re about to show them up, because you’re about to turn your aeolipile into a gosh-darned dynamo.

As you’ll see in Section 10.6.2, dynamos transform mechanical rotation into direct current—electricity!—by exploiting the fact that wires moving through a magnetic field get a current induced in them. By putting a motionless magnet inside the sphere, and wrapping wires around the outside of your rotating sphere, you’ll generate power. And if you don’t want to build aeolipiles, you can always direct your jets of steam to fan blades on a turbine—similar to how you powered your Pelton turbine with water—and you’ll generate rotational motion (and electricity, if you want) that way instead.*

Here’s the bad news: all steam engines, whether piston-based, rocket-based, or otherwise, are fundamentally inefficient. No matter what you do, lots and lots of energy gets wasted as heat. Even with higher-pressure steam, condensers, and multiple-expansion steam engines (engines that use steam to move a piston more than once), your engines probably won’t get much better than 20 percent efficiency. But even the most advanced steam engines in the modern era range from just 40 to 50 percent efficiency, so don’t feel too bad: they still power our world, and they’ll power yours just fine too.

The other major weakness of steam engines is their power-to-weight ratio. All that metal and water in a steam engine is heavy, and while they work great in buildings or in giant vehicles where their added weight isn’t a huge factor (think trains and giant boats), they’re less useful in smaller vehicles like planes and cars. For those scenarios, you’ll want to invent the lighter internal combustion engine.

Steam engines are external combustion: you burn something outside the engine to produce steam, then pipe that into your engine. Internal combustion cuts out the middleman entirely, and instead has you blowing something up inside the piston itself to move it. A volatile fuel gets mixed with air so it’ll burn easily, which is pushed into a piston’s cylinder and compressed. An electrical spark causes ignition, pushing the piston out, and as it resets exhaust gases are expelled.* Each piston travels through this cycle of intake, compression, combustion, and exhaust, so that one piston is firing as the others are resetting. These engines are obviously a bit more complicated than steam engines (you’re relying on a controlled series of explosions to drive your engine instead of good old water), but the problems involved aren’t insurmountable. Four pistons in series can be arranged so one is exploding as another is refueling—this gives you more constant thrust—and cams on a rod can be used to coordinate intake and outtake valves so that the pistons work properly in series. Another rod can be bent and attached to each piston to coordinate their thrust, which itself is connected to a flywheel to smooth out its motion (see Section 10.5.3).

Figure 24: An internal combustion engine: piston 1 is combusting fuel, piston 2 is venting exhaust, piston 3 is intaking fuel, and piston 4 is compressing the fuel in preparation to burn it. You’ll get there!

But before you rush toward inventing an internal combustion engine, keep in mind: they’re more complicated to build, more expensive to run, and require higher-grade fuel. In an era when you have to invent everything from scratch, something like your steam engine—a machine that runs on water and is powered by literally anything that burns—is invaluable.