27

CHAPTER

Automatic Ice Makers

The automatic ice maker is an independent appliance, installed in the freezer or in the freezer compartment of a refrigerator. The ice maker has three distinct operations: fill, freeze, and harvest the ice cubes. It is the refrigerator/freezer cooling system that allows the water to freeze into whatever shape is designed by the ice mold or tray. The amount of time it takes for the ice maker to produce and harvest ice cubes will depend on:

• Freezer temperature

• Food load conditions

• Number of door openings

• Ambient temperature

Safety First

Any person who cannot use basic tools or follow written instructions should not attempt to install, maintain, or repair any automatic ice makers. Any improper installation, preventive maintenance, or repairs could create a risk of personal injury or property damage.

If you do not fully understand the installation, preventive maintenance, or repair procedures in this chapter, or if you doubt your ability to complete the task on your automatic ice maker, please call your service manager.

The following precautions should also be followed:

• Never place fingers or hands on the automatic ice maker mechanism while the refrigerator/freezer is plugged in.

• Disconnect the electrical supply to the freezer or refrigerator before servicing the automatic ice maker.

• Be careful of any sharp edges on the automatic ice maker, which might result in personal injury.

• Do not attempt to operate the automatic ice maker unless it has been properly reinstalled, including the grounding and electrical connections.

Before continuing, take a moment to refresh your memory on safety procedures in Chapter 2.

Automatic Ice Makers in General

Much of the troubleshooting information in this chapter covers automatic ice makers in general, rather than specific models, in order to present a broad overview of service techniques. The illustrations that are used in this chapter are for demonstration purposes only, to clarify the description of how to service ice makers. They in no way reflect on a particular brand’s reliability.

Principles of Operation for Type-1 and Type-2 Automatic Ice Makers

The automatic ice maker is an electromechanical device that, when properly installed in the freezer compartment of a refrigerator or freezer, will automatically perform the following functions:

• Detect when water is completely frozen in the ice cube molds

• Eject the ice cubes into a storage container

• Refill the ice cube maker mold with water

• Stop the operation of the ice cube maker when the storage bin is full or when the shutoff arm is in the up position

The freezer temperature determines the efficiency of the automatic ice maker. The colder the temperature in the freezer, the faster ice will freeze in the mold or tray. In order for the ice maker to harvest the ice cubes, the temperature in the freezer should be colder than 12 degrees Fahrenheit.

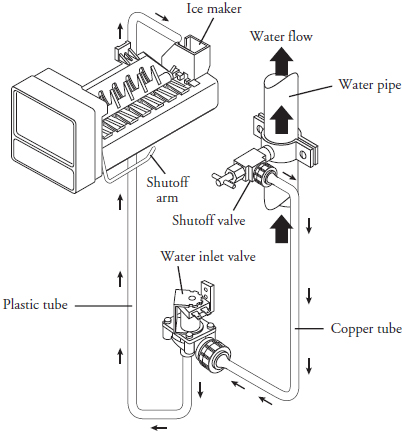

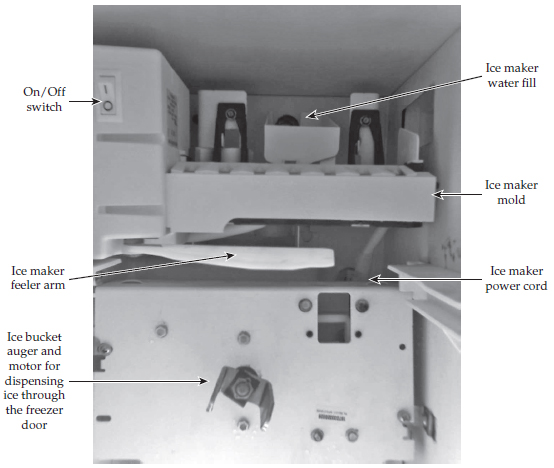

The water supply (Figure 27-1) is metered into the ice maker mold or tray by a water valve, usually located in the compressor compartment. The water freezes in the automatic ice maker mold or tray, as it would in a manual ice cube tray.

FIGURE 27-1 A typical ice maker water supply installation. Note the direction of the water flow.

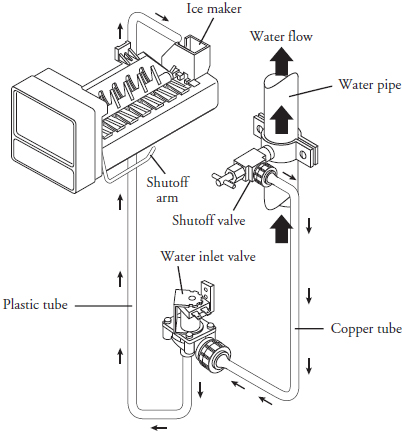

Type-1 Ice Maker

Type-1 ice makers, as illustrated in Figure 27-2, have a thermostat that is mounted on the ice maker mold, which will sense the temperature of the ice. When the water and ice have cooled down to 17 degrees Fahrenheit (±3 degrees), the thermostat will activate the ice maker motor and heater circuit. The motor will rotate the ejector blade, allowing it to rest on the ice cubes and, at the same time, exert pressure. The ice maker mold heater will warm up the ice cubes just enough to release them from the mold. This procedure will take approximately three to five minutes to release the ice cubes from the mold.

FIGURE 27-2 Type-1 ice maker.

When the ice cubes become free from the ice maker mold, the ejector blade will continue to rotate, scooping the ice cubes out of the ice maker mold and depositing them into the ice bucket. The shutoff arm moves up and down as the ice maker cycles.

At the end of the cycle, the arm will lie on top of the ice cubes. As the cubes fill the ice bucket, the shutoff arm rises to a designated point and turns off the ice maker, halting ice production. As the ice level in the bucket falls from use, the ice maker cycle will resume. Then the water valve opens again, allowing the water to enter the ice maker mold to be frozen into ice cubes, thus beginning the cycle all over again. The fill time for the type-1 ice maker is approximately seven seconds. This type of ice maker can produce up to eight pounds of ice within a 24-hour period, providing the conditions are ideal. Some customers will have ice production between three to five pounds per day, depending on usage and door openings.

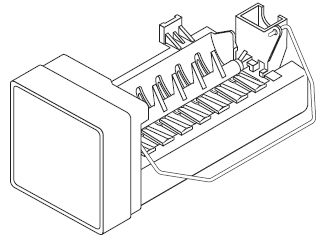

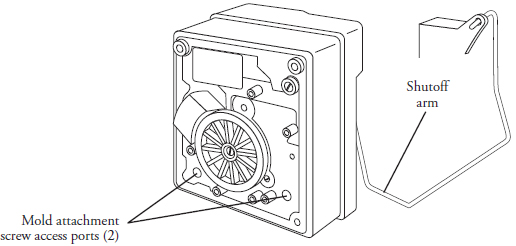

Type-2 Ice Maker

The type-2 ice maker (Figure 27-3) has the components in the ice maker head necessary for the ice-making operation. The temperature in the freezer compartment must be below 15 degrees Fahrenheit before the ice maker will begin to operate. Inside the ice maker head assembly is a thermostat that senses the temperature in the freezer compartment. When the thermostat is satisfied, it will energize the timer motor. When the motor is energized, it will begin to turn a timing gear and the shutoff arm will also begin to move. The shutoff arm will descend into the ice bucket to determine how much ice is there. If the bucket is full, the shutoff arm will rest against the ice cubes and the ice maker will not cycle. If the shutoff arm continues to its normal position, the ice bucket is not full and the cycle will continue.

FIGURE 27-3 Type-2 ice maker.

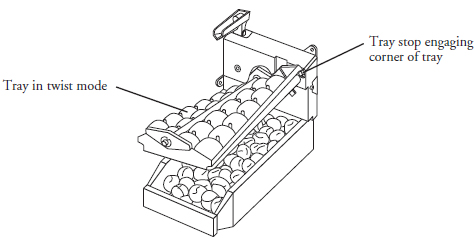

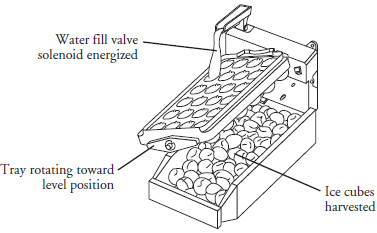

If the cycle continues, the tray will begin to rotate. When the tray has rotated about 140 degrees, one corner of the tray engages the tray stop, which prevents that part of the tray from rotating further (Figure 27-4). The rest of the tray will continue to rotate and twist the tray to about 40 degrees. At this point, the twisting of the tray will loosen the ice cubes. As the shaft continues to turn, the tray stop will begin to retract. As this happens, the tray will rapidly release the ice cubes into the ice bucket. After the ice has been released, the tray will continue to rotate until it has completed its 360-degree rotation. Near the end of the tray rotation, the water valve fill switch is energized, allowing the water to enter and fill the tray for the next cycle (Figure 27-5). The fill time for type-2 ice makers is approximately 12 seconds.

FIGURE 27-4 The ice tray will twist, releasing the ice cubes.

FIGURE 27-5 The ice cube tray must return to a level position after the filling cycle is complete.

Ice Production Rate

Before a technician can repair an ice maker, he or she must test the freezer compartment temperature first. The freezer capacity must maintain a temperature of 0 degrees Fahrenheit (plus or minus 5 degrees) under loaded conditions. To ensure that the ice maker functions properly, the refrigeration system must be capable of reducing the temperature at the ice maker thermostat to approximately 17 degrees Fahrenheit (plus or minus 3 degrees). The greater the system capacity, the shorter the ice freezing cycle and the higher the ice production rate.

Airflow direction around the ice maker mold, consumer usage, and ambient temperatures will also affect the ice production rate. The only component in the ice maker that can alter the length of the ice freezing cycle is the thermostat.

The amount of water and the temperature of the water that enters the ice maker mold can affect ice production. The fill level is affected by water pressure, water line saddle valve or tee, water valve flow washer, and ice maker timing. Never install a water line to the ice maker using a self-piercing saddle valve. This type of valve will reduce the water pressure in the line to the ice maker in a short matter of time.

Under optimum conditions, ice harvests of 3.5 to 4.5 pounds in 24 hours can be expected. Realistically the consumer may have only 2.5 to 3.5 pounds in 24 hours. To obtain this amount of ice, three conditions must exist: correct airflow temperature, correct freezer temperature, and correct temperature at the ice maker mold.

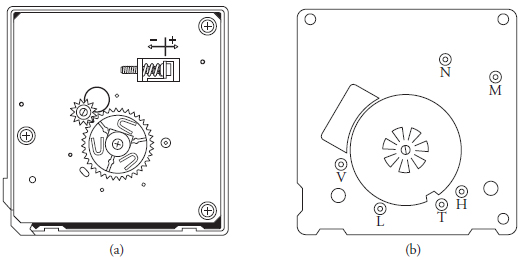

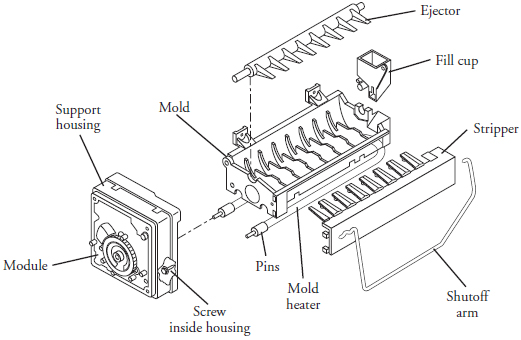

Testing the Type-1 Ice Maker

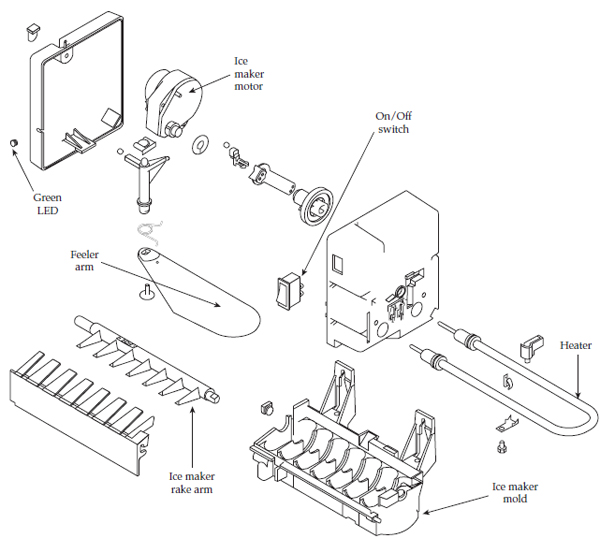

The type-1 ice maker is designed to allow all of the components to be tested without removing the ice maker and without moving the refrigerator away from the wall to test the water valve. The ice maker in Figure 27-6a is the old-style ice maker, and it is not in production any more. Parts for this ice maker are still available, however. Figure 27-6b is the new-style modular ice maker. The components that make up this ice maker are illustrated in Figure 27-7.

FIGURE 27-6 (a) Old-style type-1 ice maker. (b) New-style type-1 ice maker.

FIGURE 27-7 Exploded view of new-style type-1 ice maker.

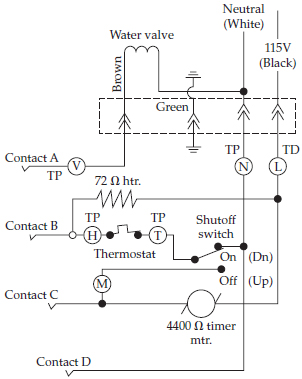

The test holes that are on the ice maker head module (see Figure 27-6b) are identified as “N,” “M,” “H,” “T,” “L,” and “V.” These are the test points for testing this type of ice maker. The letters indicate the following:

• N = neutral side of line voltage

• M = ice maker motor connection

• H = mold heater connection

• T = Ice maker thermostat

• L = L1 side of line voltage

• V = ice maker water valve connection

This test requires the electricity to be turned on.

The following test holes, when jumped out with a jumper wire, will perform the following:

• T − H = Jumps out the thermostat and starts the ice maker cycle.

• H − N = Turns on the ice mold heater.

• M − N = Runs the ice maker motor.

• L − N = Do not use a jumper wire. It will short out the refrigerator and/or ice maker. If you place your voltmeter leads in these test holes, your meter will read 120 volts.

• L − V = The ice maker water valve will turn on.

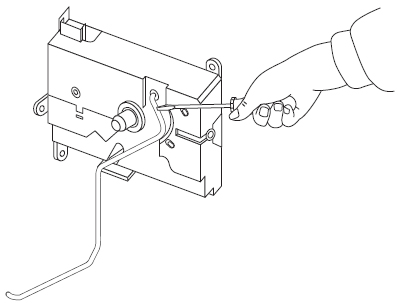

All electrical components in a type-1 ice maker can be resistance tested from the front module with the outer cover removed and the 120 volts disconnected from the refrigerator (Figures 27-6 and 27-8).

FIGURE 27-8 A resistance check can be performed on all components from the front of the ice maker module. Be safe. Unplug the refrigerator or turn off the circuit breaker to the refrigerator.

Inserting the ohmmeter leads between test points L and H will check the resistance of the heater (72 ohms, ± 10 percent).

Inserting the leads between L and M will check the motor resistance (approximately 4400 ohms).

Inserting the ohmmeter leads between test points V and N will check the resistance of the water valve coil (approximately 300 ohms). This check is especially helpful since it allows you to check the continuity of the water valve without having to remove the water valve or pull the refrigerator away from the wall.

NOTE Caution should be used when working with live wires. Avoid getting shocked. Stay clear of live wires. Only handle the meter probes by the insulated handles.

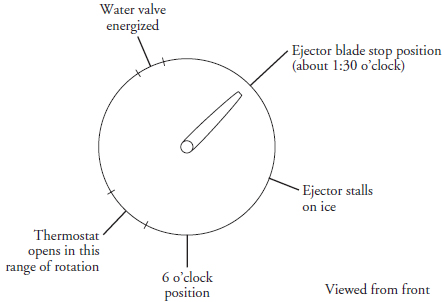

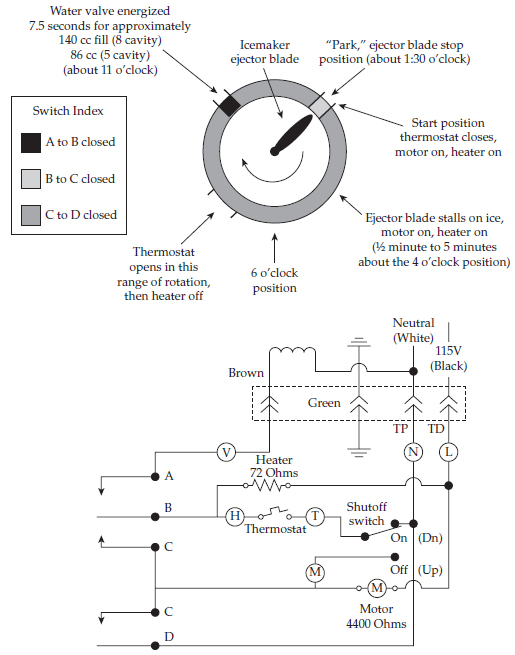

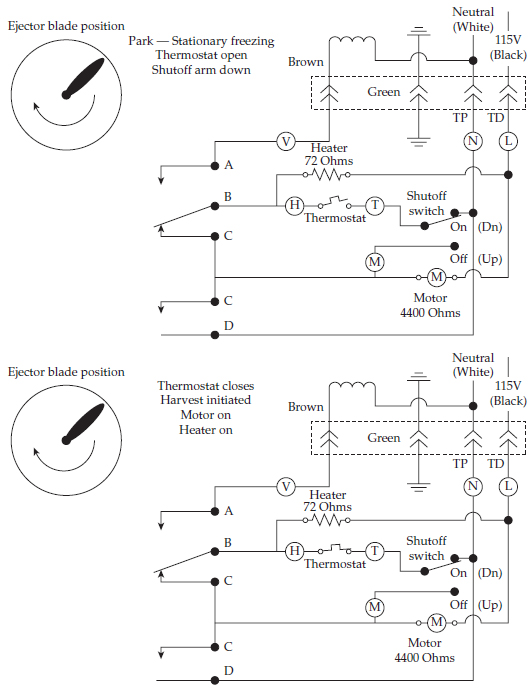

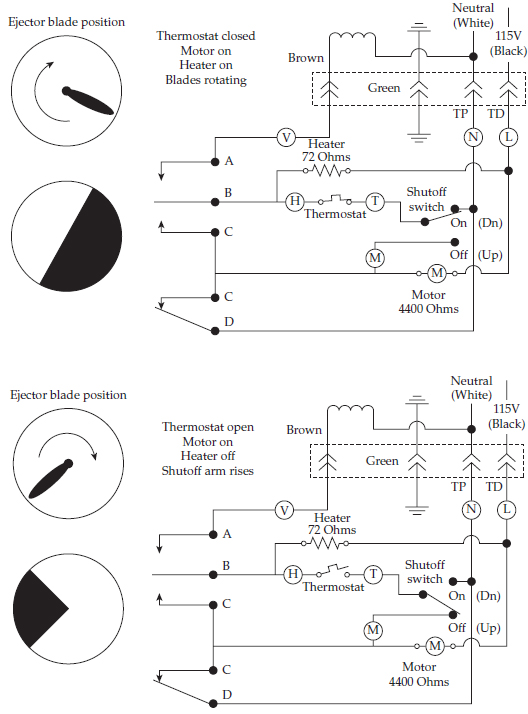

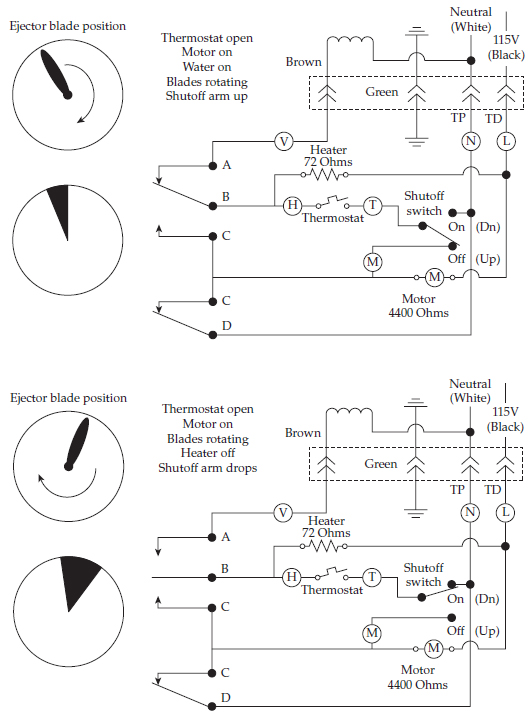

To test this ice maker, the unit must be installed and plugged into the freezer ice maker receptacle, the shutoff arm must be placed in the down position, and the temperature in the freezer should be colder than 12 degrees Fahrenheit. Set your multimeter for voltage, and place one probe in test point “L” and the other probe in test point “N.” Be sure that the test probes go into the test points about 1/2 inch. You should have a reading of 120 volts, which indicates line voltage to the ice maker. Next, place the meter probes in test points “T” and “H.” This will verify if the bimetal thermostat is open or closed. If the thermostat is open, you will read 120 volts. If it is closed, you will read no line voltage. At this point, you are going to use an insulated jumper wire (Figure 27-9) to short the test points “T” and “H.”1 This procedure will run the motor. If the motor doesn’t run, replace the ice maker module assembly. If the ice maker motor runs, replace the bimetal thermostat. If you leave the jumper wire in for half of a revolution, you will feel the mold heater heating up. This means that the mold heater is working. Now remove the jumper wire, and the water valve will be energized in the last half of the revolution. The ejector blade shown in Figure 27-10 is rotating clockwise. This illustration shows what is about to happen as the cycle begins (from the stop position) and rotates 360 degrees back again.

FIGURE 27-9 The jumper wire is used to short out the test points on the ice maker module.

FIGURE 27-10 Indicating the ejector blade position when ice maker is cycling.

Another way to test the water valve without cycling the ice maker is to place one end of the jumper wire in test point “N” and the other end in test point “V.” Water will immediately enter the ice maker mold, so be ready to disconnect the jumper wire. If no water enters the mold, check the water supply, the water valve, and the connecting tubing.

Testing the Type-1 Electronic Ice Maker

When this type of ice maker is turned on (Figure 27-11), a green LED will light on the right side of the cover. This indicator will let the consumer and the technician know that there is power (voltage) to the ice maker. The LED is also used for a fault code if something is wrong with the ice maker function. When a fault occurs, the LED will flash on and off for half a second at a time until the ice maker is repaired. To place the electronic ice maker in the service test mode, you will need to locate the technical data sheet in the refrigerator or locate the service manual for the model you are servicing. Figure 27-12 depicts an exploded view of a type-1 electronic ice maker.

FIGURE 27-11 Type 1 (electronic ice maker) mounted on the rear wall in a side-by-side refrigerator.

FIGURE 27-12 Exploded view of type-1 (electronic model) ice maker.

Testing the Type-2 Ice Maker

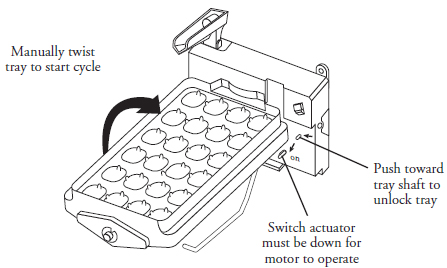

In testing the operation of the type-2 ice maker head, you will have to initiate the harvest cycle. Do not remove the ice maker for this test. The shutoff arm will not operate during the manual harvest. When performing the following procedures, refer to Figure 27-13. To cycle the ice maker, do the following:

FIGURE 27-13 Manually twist the ice the tray reaches 30 degrees, release the switch actuator.

1. Place the shutoff arm in the “on” position.

2. Push the switch actuator tab down, and hold it. This will activate the ice maker motor.

3. Push the tray lock tab toward the tray shaft. This will unlock the tray.

4. Twist the tray clockwise. This will start the cycle.

5. As the tray turns past 30 degrees, you can release the switch actuator tab.

6. After the harvest cycle is complete, empty the water from the ice tray. This will prevent the next automatic harvest cycle that occurs from dumping water into the ice bucket. When you perform a manual harvest, you interrupt the timing sequence only. A manual harvest will not reset the timing mechanism.

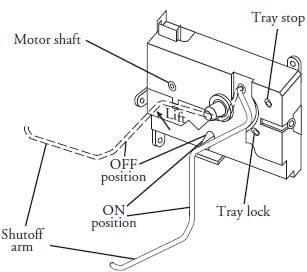

If you are unable to start the harvest cycle, check the motor shaft to see if it turns while you depress the switch actuator (Figure 27-14). Also check the temperature in the freezer. If the temperature is above 15 degrees Fahrenheit, the ice maker will not operate. If the motor shaft still does not rotate, remove the ice maker and test the unit on the work bench. Use a test cord to test the ice maker motor (Figure 27-15).2

FIGURE 27-14 To shut off the ice maker, lift the shutoff arm and rest it on the tab, as indicated by the broken lines.

FIGURE 27-15 A test cord to test a type-2 ice maker.

Water/Temperature Problems

The water quality can cause the ice maker to malfunction or produce poor-quality ice cubes. If the minerals in the water or sand particles become lodged in the water valve fill screen, it can restrict or stop the water from entering the ice maker mold. If sand particles bypass the fill screen in the water valve, it can possibly keep the water valve from closing completely, thus causing the water to enter the ice maker mold continuously. If this condition happens, the ice maker will produce small cubes or may even flood the ice maker compartment and freezer. Another indication of a defective water valve is that the ice maker fill tube will be completely frozen shut, possibly causing water to flow onto the floor every time the ice maker cycles. The minerals in the water can also cause lime deposits to build up on the ice maker mold. If this happens, the ice cubes will not be released easily from the mold.

Ice production can be slowed down if the temperature in the freezer compartment is above normal. To correct this problem, adjust the temperature controls to a colder position. The more the doors are opened, the colder the temperature setting must be.

Step-by-Step Troubleshooting Type-1 Ice Makers by Symptom Diagnosis

When servicing an appliance, don’t overlook the simple things that might be causing the problem. Step-by-step troubleshooting by symptom diagnosis is based on diagnosing malfunctions, with possible causes arranged in categories relating to the operation of the automatic ice maker. This section is intended only to serve as a checklist to aid you in diagnosing a problem. Look at the symptom that best describes the problem you are experiencing with the automatic ice maker, and then correct the problem.

Ice Maker Producing Too Much Ice

• Check to see if the shutoff arm is not connected to the actuator in the ice maker head.

• Check the shutoff arm. Is it bent out of its original shape?

• Check the shutoff linkage in the ice maker head. Is it broken?

Ice Maker Will Not Make Ice/Low Ice Production

• Check freezer temperature.

• Is the shutoff arm in the “off” position?

• Check motor operation. Did it stall? Are the gears stripped?

• Test the voltage at the ice maker. Is the ice maker plugged into the receptacle?

• Test the thermostat for continuity. Bypass the thermostat. Will the ice maker run?

• Check the shutoff linkage in the ice maker head. Is it broken?

• Is the water supply turned on? Does water enter the ice maker mold when it cycles?

• Check the ice maker fill tube. Is it frozen?

• Check for an ice jam.

• Check for defective wiring.

Ice Cubes Are Too Small

• Check the ice maker. Is it level?

• Check the fill tube. Is it frozen?

• Check the water supply.

• Check the ice maker water valve.

• Check the water pressure. Is it between 20 and 120 psi?

• Check for a self-piercing saddle valve. Mineral deposits will restrict the opening.

• Cycle the ice maker, and catch the fill water in a glass. Measure the amount of water. Are there at least 140 cc of water in the glass?

• Test for openings in the mold heater.

• Check the ice maker thermostat. There might be insufficient thermal bond between the thermostat and the ice maker mold.

Ice Maker Is Producing Hollow Ice Cubes

• Cycle the ice maker, and catch the fill water in a glass. Measure the amount of water. Are there at least 140 cc of water in the glass?

• Check for improper airflow in the freezer compartment. Direct the airflow away from the ice maker thermostat.

• Check the ice maker thermostat.

• Check the temperature in the freezer compartment.

Ice Maker Is Flooding the Freezer Compartment or Ice Bucket

• Check the thermostat.

• Check for an ice jam when the ice maker is in the fill position.

• Check for a leaky water valve.

• Check for proper ice maker water fill. Too much water will spill over the mold, causing the ice in the bucket to freeze together.

• Check the ejector blade position. If the blade is in the 12 o’clock position, the ice maker motor has stalled.

• Check the ice maker module for contamination and/or burned switch contacts.

• Check the linkage for proper operation.

• Is the refrigerator level? Is the ice maker level?

• Check water pressure. Ice makers fill according to time, not volume. Water pressure should be between 20 and 120 psi.

• Is the fill tube located in the fill cup?

Step-by-Step Troubleshooting Type-2 Ice Makers by Symptom Diagnosis

When servicing an appliance, don’t overlook the simple things that might be causing the problem. Step-by-step troubleshooting by symptom diagnosis is based upon diagnosing malfunctions, with possible causes arranged into categories relating to the operation of the automatic ice maker. This section is intended only to serve as a checklist to aid you in diagnosing a problem. Look at the symptom that best describes the problem you are experiencing with the automatic ice maker, and then proceed to correct the problem.

Ice Maker Will Not Run

• Test the freezer temperature.

• Check the shutoff arm. Is it in the “off” position?

• Run an ice maker test. Does the ice maker motor run?

• Check for defective wiring.

• Is the ice maker plugged into the receptacle?

• Test for voltage at the ice maker receptacle.

Ice Cubes Are Stuck Together

• Test temperature of freezer.

• Check for proper fill.

• Check ice tray for mineral deposits. Mineral deposits will cause the ice to stick to the tray, which can cause the ice cubes to stick together on the next cycle.

Ice Maker Spills Water from the Tray

• Check the ice tray. When the harvest cycle is complete, the ice cube tray should return to its starting position and the tray should be level.

• Check the inlet water fill tube. Be sure that the fill tube and fill trough fit together properly.

• Check for a leaking water inlet valve.

Water Will Not Enter Ice Tray

• Check for proper water supply to ice maker.

• Check water valve strainer for restrictions.

• Check the water valve.

• Check for proper water pressure.

• Check wiring circuit.

Ice Cubes Too Small, or Some of the Ice Cube Compartments Are Empty

• Check the ice maker. Is it level?

• Check the fill tube. Is it frozen?

• Check the water supply.

• Check the ice maker water valve.

• Check the water pressure. Is it between 20 and 120 psi?

• Check for a self-piercing saddle valve. Mineral deposits will restrict the opening.

• Cycle the ice maker and catch the fill water in a glass. Measure the amount of water. Are there at least 200 cc of water in the glass? The fill time will be between 12 and 13 seconds.

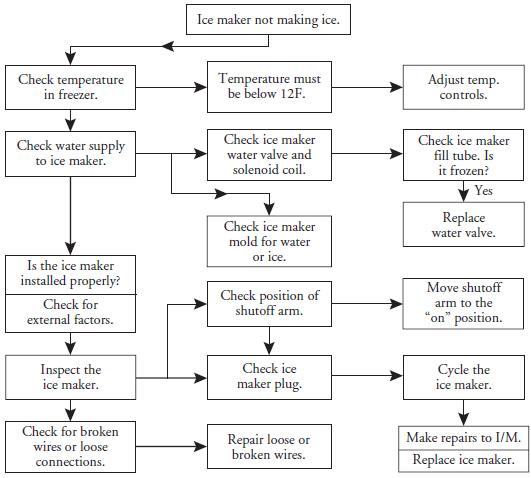

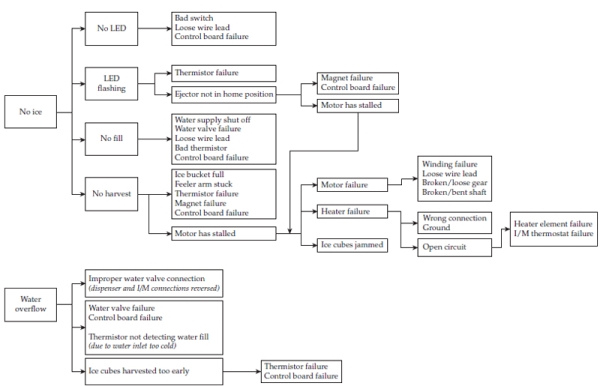

Diagnostic Chart

The diagnostic chart (Figure 27-16 and 27-17) will help you to pinpoint the likely cause of the problem with an ice maker.

FIGURE 27-16 The diagnostic flowchart: Ice maker not making ice.

FIGURE 27-17 The diagnostic flowchart: Type-1 electronic ice maker.

Repair Procedures

Each repair procedure is a complete inspection and repair process for a single ice cube maker component, containing the information you need to test and replace components.

Any person who cannot use basic tools should not attempt to install, maintain, or repair any ice makers. Any improper installation, preventative maintenance, or repairs will create a risk of personal injury, as well as property damage. Call the service manager if installation, preventative maintenance, or the repair procedure is not fully understood.

Type-1 Ice Maker: Module

The ice maker module runs all of the operations of the ice maker. It is located on the end of the ice maker (Figure 27-8). All diagnostic tests can be performed on the ice maker module.

The typical complaints associated with failure of the ice maker module are:

• Ice maker is not making any ice.

• Ice maker stalls in the middle of cycling.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by checking the ice maker and the temperature in the freezer. It will be helpful if you can locate the actual service manual for the ice maker model you are working on to properly diagnose the ice maker. The service manual will assist you in properly placing the ice maker in the service test mode for testing the ice maker functions.

2. Check for external factors. You must check for external factors not associated with the ice maker. For example, is the ice maker installed properly? The voltage at the wall receptacle and the ice maker receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the ice maker, disconnect the electricity to the refrigerator/freezer. This can be done by pulling the plug from the receptacle. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the ice maker cover, you can position the ice maker in such a way that the wiring will not make contact with metal. This will allow you to test the ice maker components without electrical mishaps.

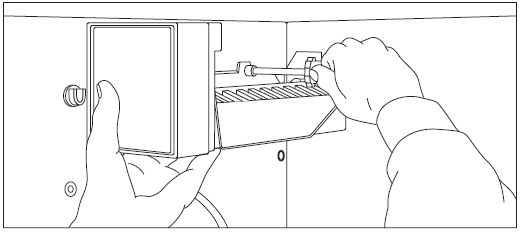

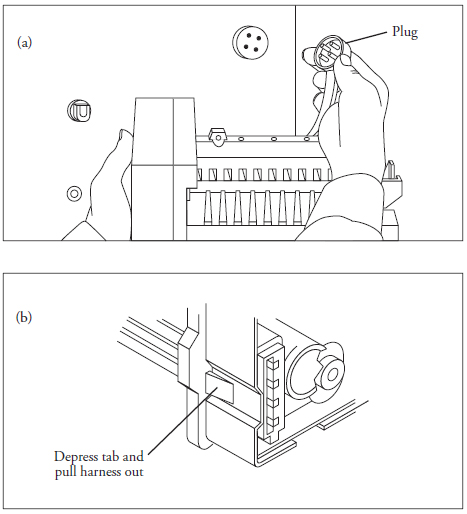

4. Gain access to the ice maker. Open the freezer door to access the ice maker. Remove the screws that secure the ice maker to the wall of the freezer (Figure 27-18). Next, unplug the ice maker from the receptacle and remove the ice maker (Figure 27-19a). Now depress the retaining tab, and pull the wiring harness from the ice maker head (Figure 27-19b).

FIGURE 27-18 Support the ice maker when removing the screws.

FIGURE 27-19 (a) Pull the ice maker plug out of the receptacle. (b) Remove the wire harness by depressing the tab, and then pull it.

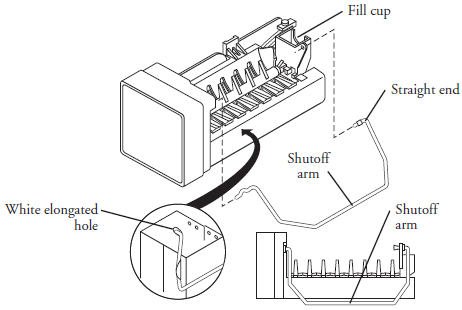

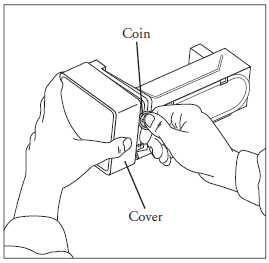

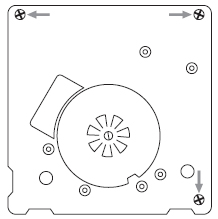

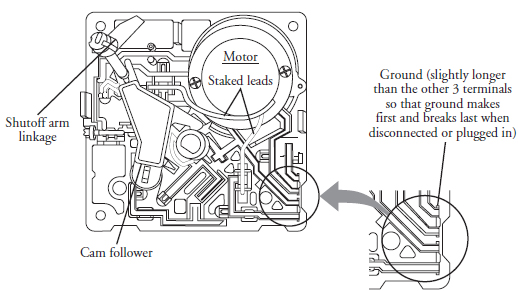

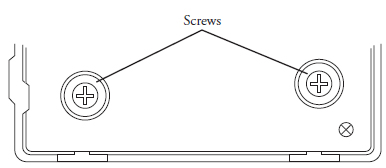

5. Disassemble and remove the ice maker module. After testing the ice maker and determining that you must replace the ice maker module, it is time to disassemble it. Insert a flat-blade screwdriver between the shutoff arm and the white elongated hole on the ice maker head (Figure 27-20). Remove the shutoff arm by prying the arm out of the ice maker head. Pry off the ice maker cover (Figure 27-21) with a coin or a screwdriver. This will expose the ice maker module. To remove the ice maker module, remove the three screws (Figure 27-22), and pull the module out of the ice maker head. Inspect the module linkage and switch contacts (Figure 27-23).

FIGURE 27-20 Removing the shutoff arm by prying it out of the slot. When installing the shutoff arm, be sure that the end is pressed in all the way.

FIGURE 27-21 Gain access to the ice maker module.

FIGURE 27-22 Removing the three screws to remove the module.

FIGURE 27-23 Inspecting the shutoff arm linkage, cam follower, and switch contacts.

WARNING The ground terminal is slightly longer than the other three terminals. The ground connection is either made first or breaks last when the wiring harness is removed or plugged in.

6. Install a new ice maker module. To install the new ice maker module, just reverse the order of disassembly, and reassemble. To reinstall the shutoff arm on the ice maker (see Figure 27-20), you must first insert the straight end into the round hole in the fill cup. Be sure the flat side on the arm goes through the fill cup. This will prevent the shutoff arm from coming out of the fill cup hole. Next, insert the other end of the shutoff arm into the white elongated hole in the ice maker housing. Do not install the arm into any of the round holes in the ice maker housing. Push on the arm so that it will be completely in place and even with the ice maker surface. Reinstall the ice maker in the freezer, and test it.

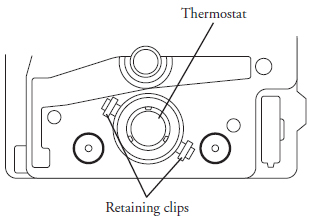

Type-1 Ice Maker: Thermostat

The ice maker thermostat is located in the ice maker housing, and it is secured to the ice maker mold with two clips. Make sure the freezer temperature is colder than 12 degrees Fahrenheit. Remember that the ice maker thermostat will close between 15 and 17 degrees Fahrenheit.

The typical complaints associated with failure of the ice maker thermostat are:

• Ice maker is not making any ice cubes.

• Ice maker is producing hollow ice cubes.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by checking the ice maker and the temperature in the freezer. It will be helpful if you can locate the actual service manual for the ice maker model you are working on to properly diagnose the ice maker. The service manual will assist you in properly placing the ice maker in the service test mode for testing the ice maker functions.

2. Check for external factors. You must check for external factors not associated with the ice maker. Is the ice maker installed properly? The voltage at the wall receptacle and the ice maker receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the ice maker, disconnect the electricity to the refrigerator/freezer. This can be done by pulling the plug from the receptacle. Or disconnect the electricity at the fuse panel or at the circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the ice maker cover, you can position the ice maker in such a way that the wiring will not make contact with metal. This will allow you to test the ice maker components without electrical mishaps.

4. Gain access to the ice maker thermostat. Open the freezer door to access the ice maker. Remove the screws that secure the ice maker to the wall of the freezer (see Figure 27-18). Next, unplug the ice maker from the receptacle, and remove the ice maker (see Figure 27-19a). Now press the retaining tab, and pull the wiring harness from the ice maker head (see Figure 27-19b). Insert a flat-blade screwdriver between the shutoff arm and the white elongated hole on the ice maker head (see Figure 27-20). Remove the shutoff arm by prying the arm out of the ice maker head. Pry off the ice maker cover (see Figure 27-21) with a coin or a screwdriver. This will expose the ice maker module. To remove the ice maker module, remove the three screws (see Figure 27-22), and pull the module out of the ice maker head. Inspect the linkage, the cam follower, and the switch contacts. Next, remove the two screws that secure the ice maker head to the mold (Figure 27-24). Separate the ice maker head from the mold assembly, and you will see the thermostat on the mold side of the ice maker head.

FIGURE 27-24 Removing the two screws.

5. Remove the thermostat. To remove the thermostat, use needle nose pliers to pull out the retaining clips (Figure 27-25). Remove the thermostat.

FIGURE 27-25 Removing the retaining clips with a pair of needle nose pliers.

6. Install a new thermostat. To install the new thermostat, just reverse the order of disassembly, and reassemble the ice maker. Be sure that you properly index the pins on the thermostat. Before you assemble the ice maker head to the mold assembly, you must apply new thermal bonding material to the thermostat. This will allow the thermostat to make better contact with the ice maker mold. Reinstall the ice maker in the freezer, and test.

Type-1 Ice Maker: Mold and Heater Assembly

The ice maker mold and heater assembly is attached to the ice maker head. This component is replaced as one unit.

The typical complaints associated with failure of the ice maker mold and heater assembly are:

• Ice maker is not making any ice.

• Ice will not come out of the mold.

• There are black pieces of mold coating material in the ice cubes.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by checking the ice maker and the temperature in the freezer. It will be helpful if you can locate the actual service manual for the ice maker model you are working on to properly diagnose the ice maker. The service manual will assist you in properly placing the ice maker in the service test mode for testing the ice maker functions.

2. Check for external factors. You must check for external factors not associated with the ice maker. Is the ice maker installed properly? The voltage at the wall receptacle and the ice maker receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the ice maker, disconnect the electricity to the refrigerator/freezer. This can be done by pulling the plug from the receptacle. Or disconnect the electricity at the fuse panel or circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the ice maker cover, you can position the ice maker in such a way that the wiring will not make contact with metal. This will allow you to test the ice maker components without electrical mishaps.

4.

Gain access to the ice maker mold assembly. Open the freezer door to access the ice maker. Remove the screws that secure the ice maker to the wall of the freezer (see

Figure 27-18). Next, unplug the ice maker from the receptacle, and remove the ice maker (see

Figure 27-19a). Now press the retaining tab, and pull the wiring harness from the ice maker head (see

Figure 27-19b).

Insert a flat-blade screwdriver between the shutoff arm and the white elongated hole on the ice maker head (see Figure 27-20). Remove the shutoff arm by prying it out of the ice maker head. Pry off the ice maker cover (see Figure 27-21) with a coin or screwdriver. Insert a Phillips screwdriver into the access ports in the module (Figure 27-26) to loosen the screws. Separate the ice maker head assembly from the mold assembly. Also remove the ejector, the fill cup, the stripper, and the shutoff arm (see Figure 27-8). Do not remove the heater; the heater and mold come as a complete assembly.

FIGURE 27-26 The entire ice maker head can be removed by loosening the two screws through the access ports.

5. Install a new ice maker mold assembly. To install a new ice maker mold assembly, just reverse the order of disassembly, and reassemble. When assembling the ice maker, apply a thin film of silicone grease to the end of the ejector that goes into the fill cup. This will prevent the ejector from freezing to the fill cup. Also apply a thin film of silicone grease to the other end of the ejector. Before installing the stripper, apply a heavy film of silicone grease to the top surface of the mold that is covered by the stripper. This will prevent the water from wicking over the ice maker mold every time it cycles. Before you assemble the ice maker head to the mold assembly, you must apply new thermal bonding material to the thermostat. This will allow the thermostat to make better contact with the ice maker mold. Reinstall the ice maker in the freezer, and test it.

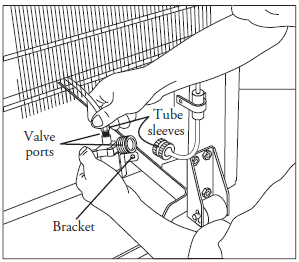

Water Valve

The water valve controls the flow of water into the ice maker, and is solenoid-operated and located in the rear of the refrigerator/freezer. When it is energized, water in the supply line will pass through the valve body and into the ice maker.

The typical complaints associated with failure of the water valve are:

• Ice maker is not making any ice.

• Ice maker fill tube is frozen.

• Ice maker mold fills with very little water.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by checking the ice maker and the temperature in the freezer. It will be helpful if you can locate the actual service manual for the ice maker model you are working on to properly diagnose the ice maker. The service manual will assist you in properly placing the ice maker in the service test mode for testing the ice maker functions.

2. Check for external factors. You must check for external factors not associated with the ice maker. Is the ice maker installed properly? Check the water supply to the water valve. The voltage at the wall receptacle and the ice maker receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the water valve, disconnect the electricity to the refrigerator/freezer. This can be done by pulling the plug from the receptacle. Or disconnect the electricity at the fuse panel or circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the rear cover, you can position the ice maker in such a way that the wiring will not make contact with metal. This will allow you to test the water valve without electrical mishaps.

4. Gain access to the water valve. To access the water valve, pull the refrigerator/freezer away from the wall. Remove the back access panel. Shut off the water supply to the ice maker.

5. Remove the water valve. Remove the water inlet tube from the water valve. Then remove the screws from the water valve bracket that secure the valve to the cabinet (Figure 27-27). Next, remove the ice maker fill line. Finally, disconnect the wiring harness from the solenoid coil of the valve.

FIGURE 27-27 Disconnect the water inlet line and the outlet line. Disconnect the wiring harness from the solenoid coil.

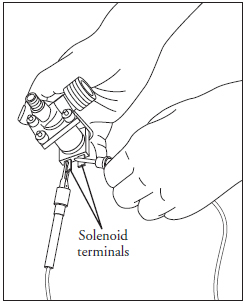

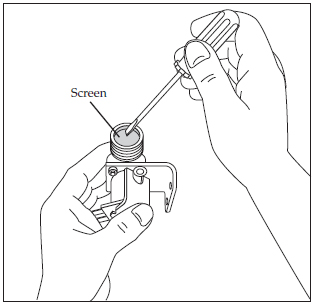

6. Test the water valve. Using your ohmmeter, set the scale on R x 10, and place the probes on the solenoid coil terminals (Figure 27-28). The meter should show resistance between 200 and 500 ohms. If not, replace the water valve. If you determine that the water valve is good but there is little water flow through the valve, inspect the inlet screen. If this screen is filled with debris, it must be cleaned out. To accomplish this, use a small flat-blade screwdriver and pry out the screen (Figure 27-29). Then wash out the screen, making sure that all of the debris is removed. After cleaning out the debris, reinstall the screen, and test the water valve.

FIGURE 27-28 Testing the solenoid coil for resistance.

FIGURE 27-29 Removing the inlet screen. Clean it out with warm water and soap.

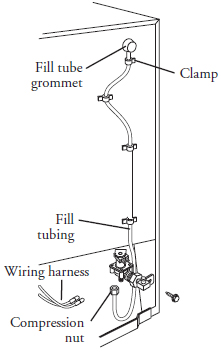

7. Install a new water valve. To install the new water valve, just reverse the disassembly procedure, and reassemble. Also reconnect the ground wire from the water valve bracket to the refrigerator/freezer cabinet. Secure the water supply line to the cabinet. This will prevent the supply line from leaking when the refrigerator/freezer is pushed back against the wall. Check for water leaks before you push the refrigerator/freezer back against the wall. Also inspect the fill tubing for any cracks, etc. (Figure 27-30).

FIGURE 27-30 Checking for defective tubing. Check the clamp and compression nuts for leaks.

Water Fill Valve Adjustment

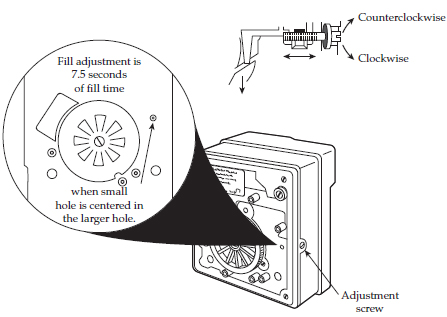

The average water fill for a type-1 ice maker is 140 cc. This type of ice maker will produce eight cubes per harvest. If the technician needs to adjust the fill adjustment screw, which is located on the side of the ice maker head (Figure 27-31), turning the fill adjustment screw clockwise decreases the fill amount and decreases the cycle time slightly; turning the fill adjustment screw counterclockwise increases the fill amount and increases the cycle time slightly.

FIGURE 27-31 The illustration depicts where the water fill adjustment screw is located in the ice maker. The factory presets the adjustment. Before making adjustments check the water supply and type of shutoff valve first.

By adjusting the water fill to the ice maker you can increase or decrease the amount of water in the mold by:

• Quarter-turn of the adjustment screw = 2.5 cc or .08 ounces

• Half-turn of the adjustment screw = 5 cc or .16 ounces

• Three-quarter-turn of the adjustment screw = 7.5 cc or .24 ounces

• One turn of the adjustment screw = 10 cc or .36 ounces

Ice maker cycle times will vary depending on the type of refrigerator or freezer in the consumer’s home (side-by-side versus top-mount or bottom mount). Cycle times vary between 2 and 2½ hours and can produce up to 96 ice cubes within a 24-hour period.

Type-2 Ice Maker: Head and Tray

The typical complaints associated with failure of the type-2 ice maker head are:

• Ice maker is not making any ice.

• Ice will not come out of the mold.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by checking the ice maker and the temperature in the freezer. It will be helpful if you can locate the actual service manual for the ice maker model you are working on to properly diagnose the ice maker. The service manual will assist you in properly placing the ice maker in the service test mode for testing the ice maker functions.

2. Check for external factors. You must check for external factors not associated with the ice maker. Is the ice maker installed properly? The voltage at the wall receptacle and the ice maker receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Disconnect the electricity. Before working on the ice maker, disconnect the electricity to the refrigerator/freezer. This can be done by pulling the plug from the receptacle. Another way to disconnect the electricity is at the fuse panel or circuit breaker panel. Turn off the electricity.

WARNING Some diagnostic tests will require you to test the components with the power turned on. When you disassemble the ice maker, you can position the ice maker in such a way that the wiring will not make contact with metal. This will allow you to test the ice maker without electrical mishaps.

4. Gain access to the ice maker. Open the freezer door to access the ice maker. Remove the screws that secure the ice maker to the wall of the freezer. Next, unplug the ice maker from the receptacle and remove the ice maker.

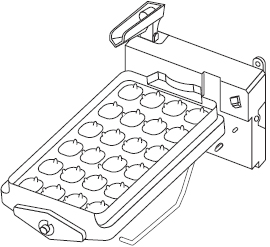

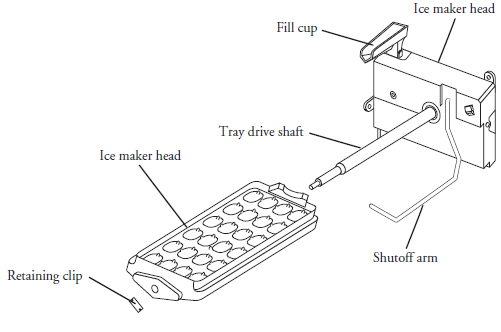

5. Disassemble and remove the ice maker head assembly. After testing the ice maker and determining that you must replace the ice maker head assembly, it’s time to disassemble it. First, remove the retaining clip from the end of the tray, and then slide the tray off the ice maker drive shaft (Figure 27-32). Next, remove the fill cup and screw. On the back of the ice maker head is a clamp that holds the tray drive shaft in place; remove it. Pull the shaft out of the ice maker head. Then place a flat-blade screwdriver behind the shutoff arm, and pry it loose (Figure 27-33).

FIGURE 27-32 Always reinstall the ice cube tray in the same position as when it was removed. If the ice tray is installed upside down, water will flood the ice bucket every time the ice maker cycles.

FIGURE 27-33 Gently pry off the shutoff arm.

6. Install a new ice maker head. To install the new ice maker head, just reverse the order of disassembly, and reassemble. When replacing a defective ice maker head, only replace it with an exact replacement with the same amount of cycle operation time. Reinstall the ice maker in the freezer, and test.

Type-2 Ice Maker Tray

The typical complaints associated with failure of the type-2 ice maker tray are:

• Ice maker is not making any ice.

• Ice will not come out of the mold.

• Water in the tray freezes into a solid block of ice.

To handle these problems, perform the following steps:

1. Verify the complaint. Verify the complaint by checking the ice maker and the temperature in the freezer. It will be helpful if you can locate the actual service manual for the ice maker model you are working on to properly diagnose the ice maker. The service manual will assist you in properly placing the ice maker in the service test mode for testing the ice maker functions.

2. Check for external factors. You must check for external factors not associated with the ice maker. Is the ice maker installed properly? The voltage at the wall receptacle and the ice maker receptacle is between 108 volts and 132 volts during a load on the circuit. Do you have the correct polarity? (See Chapter 6.)

3. Remove the ice maker tray. To remove the ice maker tray, remove the retaining clip from the end of the tray, and then slide the tray off the ice maker drive shaft (see Figure 27-32).

4. Install a new ice tray. To install the new ice tray, just reverse the disassembly procedure, and reassemble. Always reinstall the tray in the same position as that from which it was removed for proper operation. Test the ice maker. Let it run through a complete cycle and harvest. Then inspect the ice maker tray.

Type-1 Ice Maker Cycle Chart and Wiring Schematic

Figure 27-34 illustrates the complete cycle of the type-1 ice maker. A wiring schematic for a type-1 ice maker (electronic model) is depicted in Figure 27-35.

FIGURE 27-34 One operation cycle is equal to one revolution of the ejector arm.

FIGURE 27-35 Wiring schematic of a type-1 ice maker (electronic model).

Endnotes

1. The jumper wire should be made of 14-gauge wire and should be approximately 8 to 10 inches long, with 5/8 inch of the insulation removed from both ends. Do not short any contacts other than those specified in this test procedure. Why? Because you can damage the ice maker, injure yourself, or both.

2. You can purchase this ice maker test cord from your parts distributor.