CHAPTER 2

EAL Unit QELTK3/003

Understanding the practices and procedures for overseeing and organizing the work environment (electrical installation)

Learning outcomes

When you have completed this chapter you should:

1. Understand the types of technical and functional information that are available for the installation of electrotechnical systems and equipment.

2. Understand the procedures for supplying technical and functional information to relevant people.

3. Understand the requirements for overseeing health and safety in the work environment.

4. Understand the requirements for liaising with others when organizing and overseeing work activities.

5. Understand the requirements for organizing and overseeing work programmes.

6. Understand the requirements for organizing the provision and storage of resources that are required for work activities.

Assessment criteria 1.1

Specify sources of technical and functional apply to electrotechnical installations

Assessment criteria 1.2

Interpret technical and functional information and data

To carry out and complete an electrical installation makes use of many forms of information and can be subdivided into two categories namely:

• functional;

• technical.

Functional information is written to explain how an item works or operates, and how things are to be done, assembled or installed. We see this in manufacturer’s data sheets. Regulation 643.10 informs us that equipment shall be subjected to functional testing, as appropriate, to verify that it is properly mounted, adjusted, installed and operates correctly.

Technical information is the engineering data contained in, for example, a specification, the IET Regulations, or the On Site Guide or the IET Guidance Notes.

Both types of information are communicated in lots of different ways. For instance technical information in the electrical installation industry is drawn from the following:

• Guidance Notes (1–8);

• GS 38 (Safe Isolation Procedure);

• codes of practice (BS 7671 and On-Site Guide);

• manufacturers’ data sheets;

• British Standards (BS) and British Standard European Norms (BS EN);

• technical books and drawings;

• the Internet.

Being aware of how to extract information and realizing how credible that information is can therefore act as a safeguard when, for example, confirming that replacement components or equipment are fully compatible with the required specification. It can also help ensure that when changes are made to specific codes of practice such as the wiring regulations (BS 7671) then you can embrace and be vigilant of those changes. For instance, only approved test equipment is designed to comply with the rigorous requirements to carry out the safe isolation procedures listed within GS38 – a document specifically written by the Health and Safety Executive. However, being aware of such a document is not enough, since the actual requirement could be subjected to review and possible amendment, which means it is vital that all practising electricians are pro-active in the pursuit of good practice by attending relevant courses.

Interpreting and recording the testing element of an installation is also indelibly linked with data and information since IET Regulations 641 advise us that every installation shall, during erection and on completion before being put into service, be inspected and tested to verify that the regulations have been met. Regulation 643 also advises that where required, periodic inspection and testing shall be carried out in order to determine if the installation is in a satisfactory condition for continued service. Any such tests therefore must be recorded so that they can prove and maintain safety and also can be used as a comparison during any future re-testing. A schedule of test results is therefore a written record of the results obtained when carrying out the electrical tests required by Part 6 of the IET Regulations.

Figure 2.1 Amendment 3 has introduced the term ‘electrically skilled’ in order to make it clearer who can and cannot work on electrical parts of sites.

The schedule brings together all the detailed information about the testing of that particular installation. In the same way, a work schedule brings together the detail of the whole project.

Key fact

Key fact

The type of wiring system to be used will be indicated on the specification.

Interpretation of information is therefore very important and can be seen through the following:

• Specifications – these are details of the client’s requirements, usually drawn up by an architect. For example, the specification may give information about the type of wiring system to be employed or detail the type of luminaires or other equipment to be used.

• Manufacturer’s data – if certain equipment is specified, let’s say a particular type of luminaire or other piece of equipment, then the manufacturer’s data sheet will give specific instructions for its assembly and fixing requirements. It is always good practice to read the data sheet before fitting the equipment. A copy of the data sheet should also be placed in the job file for the client to receive when the job is completed.

• User instructions – give information about the operation of a piece of equipment. Manufacturers of equipment provide ‘user instructions’ and a copy should be placed in the job file for the client to receive when the project is handed over.

• Job sheets and time sheets – give ‘on site’ information. Job sheets give information about what is to be done and are usually issued by a manager to an electrician. Time sheets are a record of where an individual worker has been spending his time, which job and for how long. This information is used to make up individual wages and to allocate company costs to a particular job. We will look at these again later under the sub-heading ‘on-site documentation’.

Key fact

Key fact

When Installing equipment always read the manufacturer’s data. User Instructions will dictate Its different modes of operation.

Let us now look in more detail at these sourses of information.

Drawings and diagrams

Many different types of electrical drawing and diagram can be identified, which give relevant information for the installation, termination and connection of conductors: layout, schematic, block, wiring and circuit diagrams. The type of diagram to be used in any particular application is the one that most clearly communicates the desired information.

Definition

Definition

Layout drawings tend to be drawn to scale so that the positional relationship of the components can be appreciated.

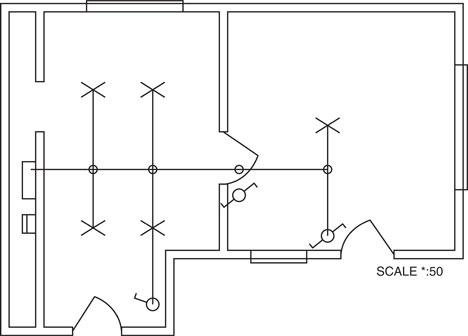

Layout drawings or site plan

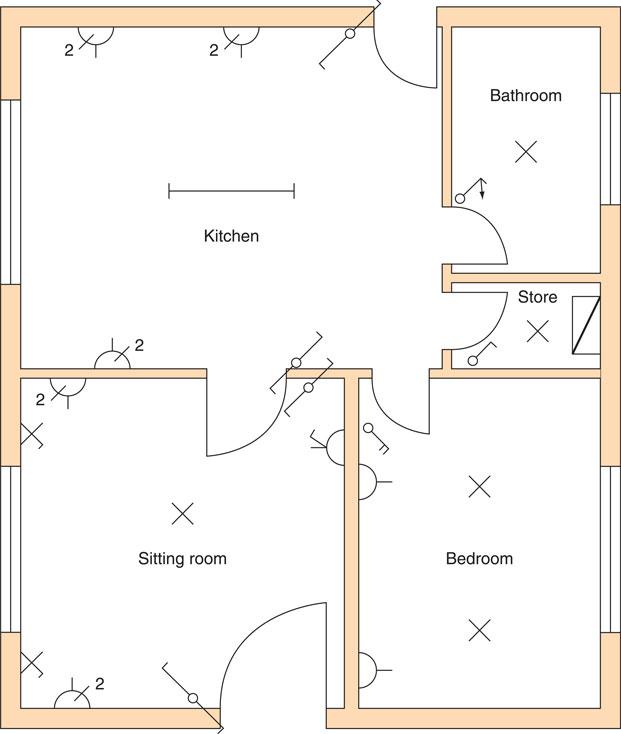

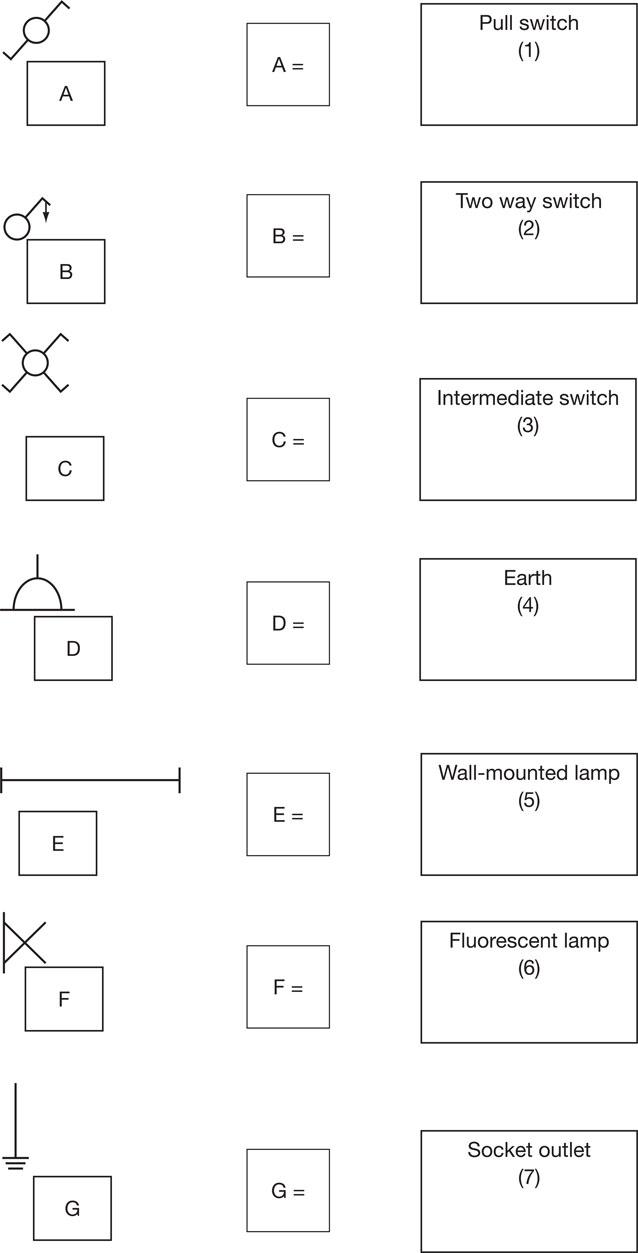

These are scale drawings based upon the architect’s site plan of the building and show the positions of the electrical equipment that is to be installed. The electrical equipment is identified by a graphical symbol.

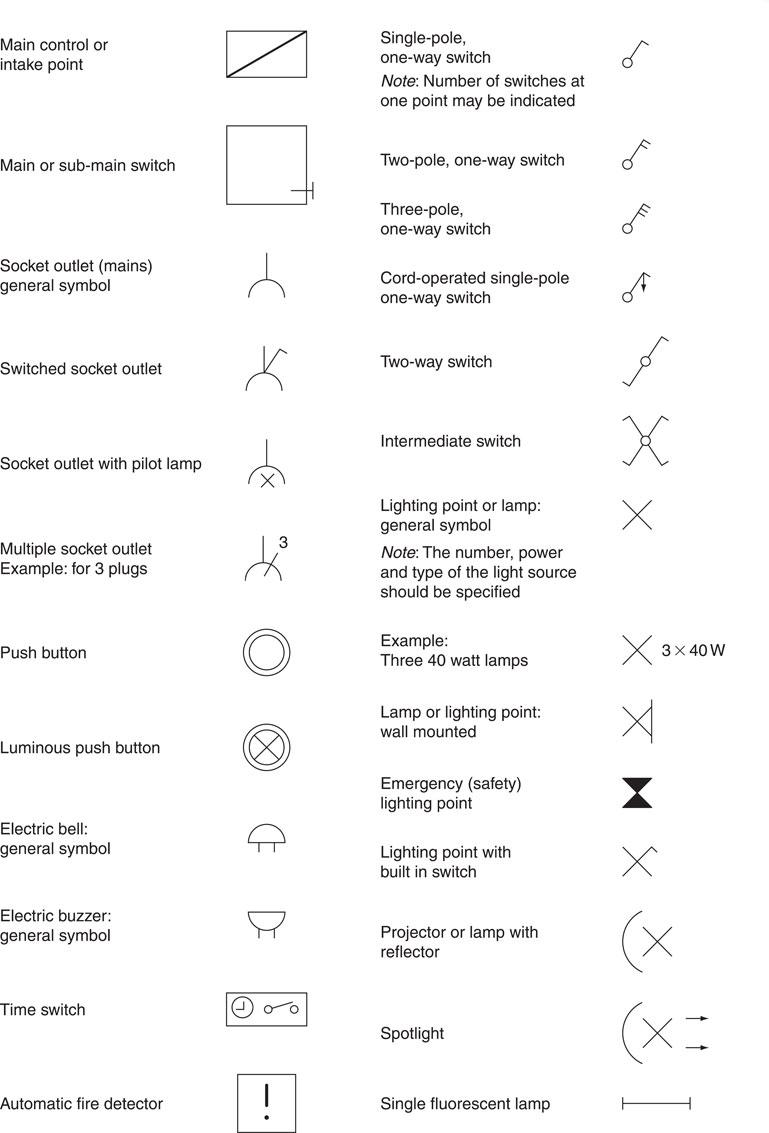

The standard symbols used by the electrical contracting industry are those recommended by the British Standard BS EN 60617, Graphical Symbols for Electrical Power, Telecommunications and Electronic Diagrams. Some of the more common electrical installation symbols are given in Fig. 2.4.

The site plan or layout drawing will be drawn to a scale smaller than the actual size of the building, so to find the actual measurements you must measure the distance on the drawing and then multiply by the scale. For example, if the site plan is drawn to a scale of 1:100, then 10 mm on the site plan represents 1 m measured in the building. A layout drawing is shown in Fig. 2.2 of a small domestic extension. It can be seen that the mains intake position, probably a consumer’s unit, is situated in the storeroom, which also contains one light controlled by a switch at the door. The bathroom contains one lighting point controlled by a one-way switch at the door. The kitchen has two doors and a switch is installed at each door to control the fluorescent luminaire. There are also three double sockets situated around the kitchen. The sitting room has a two-way switch at each door controlling the centre lighting point. Two wall lights with built in switches are to be wired, one at each side of the window. Two double sockets and one switched socket are also to be installed in the sitting room. The bedroom has two lighting points controlled independently by two one-way switches at the door.

Top tip

Top tip

When dealing with scale diagrams look at the situation and ask yourself: am I going from the actual to the scale? (Divide by the scale ratio.) Or scale to the actual dimension (multiply by the scale ratio).

The wiring diagrams and installation procedures for all these circuits can be found in EAL Electrical Installation Work: Level 2.

Definition

Definition

When the installation is completed a set of drawings should be produced that indicate the final positions of all the electrical equipment.

As-fitted drawings

When the installation is completed a set of drawings should be produced that indicate the final positions of all the electrical equipment. As the building and electrical installation progresses, it is sometimes necessary to modify the positions of equipment indicated on the layout drawing because, for example, the position of a doorway has been changed. The layout drawings indicate the original intentions for the positions of equipment, while the ‘as-fitted’ drawing indicates the actual positions of equipment upon completion of the job.

Figure 2.2 Layout drawing or site plan for electrical installation.

Detail drawings and assembly drawings

These are additional drawings produced by the architect to clarify some point of detail. For example, a drawing might be produced to give a fuller description of the suspended ceiling arrangements.

Definition

Definition

Detail drawings are additional drawings produced by the architect to clarify some point of detail.

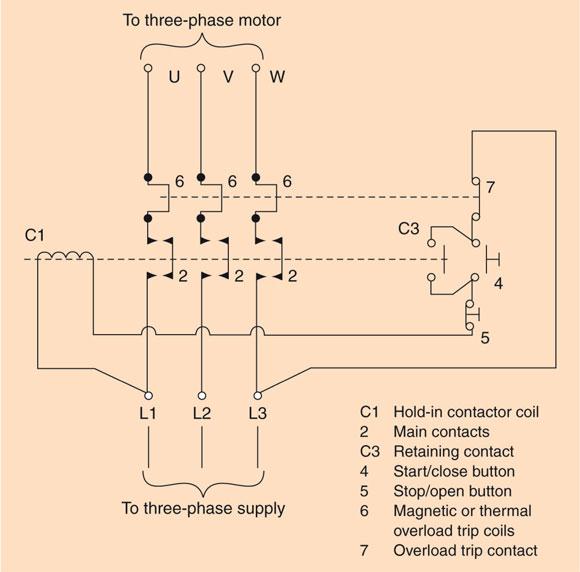

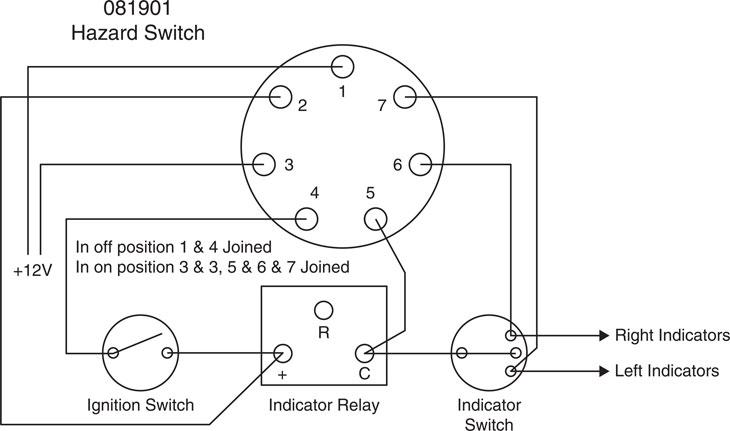

Schematic diagrams

A schematic diagram is a diagram in outline of, for example, a motor starter circuit as shown in Fig 2.3 and 2.4. It uses graphical symbols to indicate the interrelationship of the electrical elements in a circuit. These help us to understand the working operation of the circuit.

An electrical schematic diagram looks very much like a circuit diagram.

Definition

Definition

A schematic diagram is a diagram in outline of, for example, a motor starter circuit.

Figure 2.3a Schematic diagram – DOL motor starter.

Figure 2.3b Schematic diagrams can be invaluable when dealing with unfamiliar equipment.

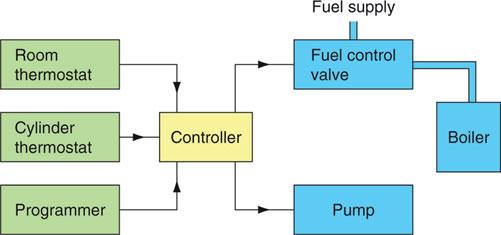

Block diagrams

A block diagram is a very simple diagram in which the various items or pieces of equipment are represented by a square or rectangular box as shown in Fig 2.5. The purpose of the block diagram is to show how the components of the circuit relate to each other and therefore the individual circuit connections are not shown.

Definition

Definition

A block diagram is a very simple diagram in which the various items or pieces of equipment are represented by a square or rectangular box.

Wiring diagrams

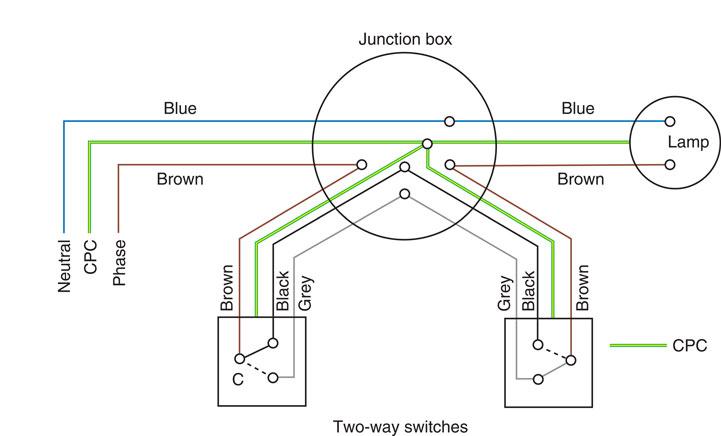

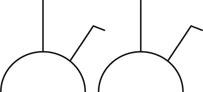

A wiring diagram or connection diagram shows the detailed connections between components or items of equipment. They do not indicate how a piece of equipment or circuit works. The purpose of a wiring diagram is to help someone with the actual wiring of the circuit. Figure 2.6 shows the wiring diagram for a two-way lighting circuit.

Definition

Definition

A wiring diagram or connection diagram shows the detailed connections between components or items of equipment.

Try this

Try this

The next time you are on site:

• Ask your supervisor to show you the site plans.

• Ask them to show you how the scale works.

Circuit diagrams

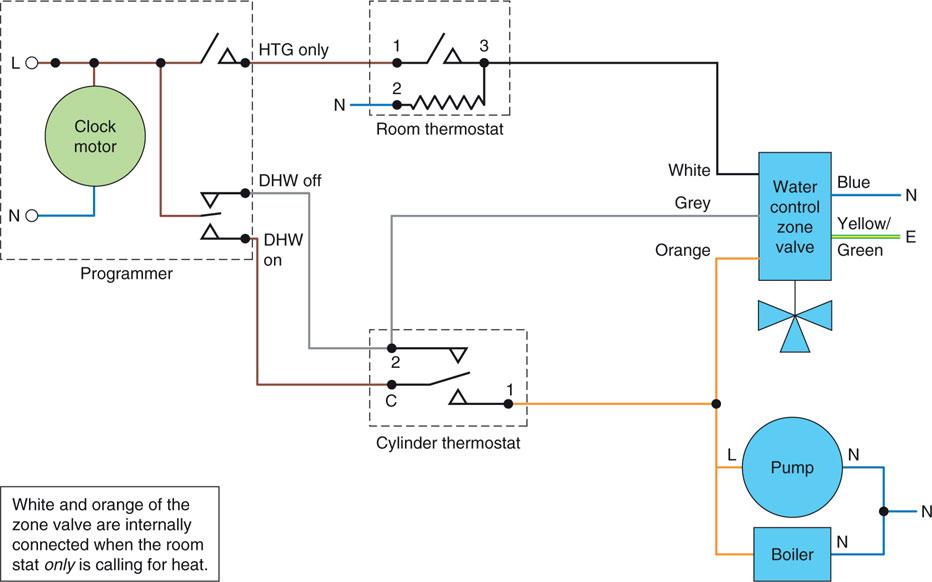

A circuit diagram shows most clearly how a circuit works. All the essential parts and connections are represented by their graphical symbols. The purpose of a circuit diagram is to help our understanding of the circuit. It will be laid out as clearly as possible, without regard to the physical layout of the actual components, and therefore it may not indicate the most convenient way to wire the circuit. The circuit diagram for a domestic space heating system is shown in fig 2.7.

Definition

Definition

A circuit diagram shows most clearly how a circuit works.

Figure 2.4 Some BS EN 60617 installation symbols.

Figure 2.5 Block diagram – space-heating control system (Honeywell Y. Plan).

Figure 2.6 Wiring diagram of two-way switch control.

Figure 2.7 Circuit diagram – space-heating control system (Honeywell Y. plan).

Assessment criteria 1.3

Identify and interpret technical and functional information relating to electrotechnical products or equipment

Detailed product data can be extracted from manufacturers’ user manuals, which will describe how to operate equipment through various settings in order to engage various modes of operation and perhaps adjust the equipment for different environments. Examples of such devices include electronic thermostats and air conditioning equipment.

Equally important is to ensure that equipment is rated to the correct values such as working voltage, current or power rating or even breaking capacity, which is a value of current associated with a short circuit fault condition. For instance, a given component might fail because its rating is incorrect, especially if it’s under rated in relation to the specification. Replacing such an item without consulting the specification or manufacturer’s data will only cause it to fail again.

Assessment criteria 1.4

Describe the work site requirements and procedures in terms of services provision etc.

Assessment criteria 1.5

Identify equipment and systems that are compatible to site operations and requirements

Construction site

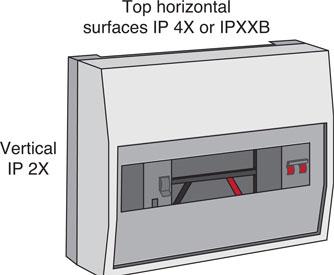

The IET Regulations have given us the whole of Section 704 for the regulations which relate to Construction and Demolition site installations.

Construction and demolition sites are potentially dangerous in many ways, tripping, falling, and the constantly changing and temporary nature of the working environment create the hazard. The risk of electric shock is high because of the following factors:

• a construction site or demolition site is, by definition, a temporary state. Upon completion there will be either a building with all the necessary safety features, or a brown field site where the building previously stood.

• there is the possibility of damage to cables and equipment as a consequence of the temporary nature of the site and because the site is not always sealed in the early stages from the weather.

• mobile equipment such as electrical tools and hand lamps with trailing leads will be in use.

• there will be many extraneous conductive parts on site which cannot practically be bonded because of the changing nature of the construction process.

A construction site will have many people working on a building project throughout the construction period. The groundwork people lay the foundations, the steel work is erected, the bricklayers build the walls, the carpenters put on the roof and only when the building is waterproof do the electricians and mechanical service trades begin to install the electrical and mechanical systems. If there was an emergency and the site had to be evacuated, how would you know who, or how many people were on site? You can see that there has to be a procedure for logging people in and out, so that the main contractor can identify who is on-site at any one time.

Figure 2.8 Many different skilled jobs are required on site, so it's important that everyone follows a safe system of working.

With so many people employed through many different companies and agencies it is little wonder that sites employ both an induction programme and a site visitor procedure. The aim is to bring about a safe system of work which includes the sharing of information about how this is brought about. This means defining who are the key personnel or duty holders, what processes are involved and where the documents in relation to these processes are kept. Furthermore, sign posting where key operations are undertaken will bring about clarity of the specific and potential hazards that exist on site.

Such a programme therefore indicates how the site is complying with the Workplace (Health, Safety and Welfare) Regulations 1992. These regulations ensure that provision is made regarding the following:

• ventilation (is adequate when working inside);

• indoor temperature (16°C if mostly seated/13°C for work involving physical work);

• space (sufficient space to operate freely and therefore safely. An important consideration for an electrician);

• seating (ensuring that workstations are sufficiently comfortable);

• maintenance (ensuring that vital equipment is maintained in a safe and efficient order);

• traffic routes (pedestrians should be given their own walkways).

The induction programme will also share specific information in relation to where materials are to be stored, and procedures and locations involving waste disposal, including the separation of waste and the locations of appropriate containers. Again, this indicates how the site complies with the Environmental Protection Act 1990, the Control of Pollution Act 1989 and the Hazardous Waste Regulations 2005.

Furthermore, on large installations there may be more than one position for the distribution of temporary electrical supplies and cables may radiate from the site of the electrical mains intake position to various sub-mains locations. Although these sort of arrangements would normally have been drafted by an appropriate design engineer, the location, routing and positioning of such services would be indicated on an architect site plan so that all trades are aware of their location.

What employees should never lose sight of is that everyone on site is held responsible to the Health and Safety Act 1974 and this means they have a duty of care towards other workers and visitors, including reporting any suspected safety issue. Witnessing any episodes whereby equipment or service in use is either incompatible to its environment or impinged in its operation must be reported without delay.

Assessment criteria 2.1

State the limits of their responsibility for supplying technical and functional information

Part 2 of The IET Regulations describe people as an ordinary person, an instructed person (electrically) or a skilled person (electrically).

When you begin your apprenticeship you are an ‘ordinary person’, that is, someone who has no knowledge of the hazards which electricity can create. However, in just a few weeks or months you will become an instructed person electrically, because you will be carrying out electrical work under supervision. When you have completed your apprenticeship you will be a skilled person electrically, able to carry out electrical work safely, and able to perceive risks and avoid the hazards which electricity can create.

There are many different people involved in an electrical installation project and the transfer of information to those persons will largely depend on their roles, experience, position and responsibility within the electrical company.

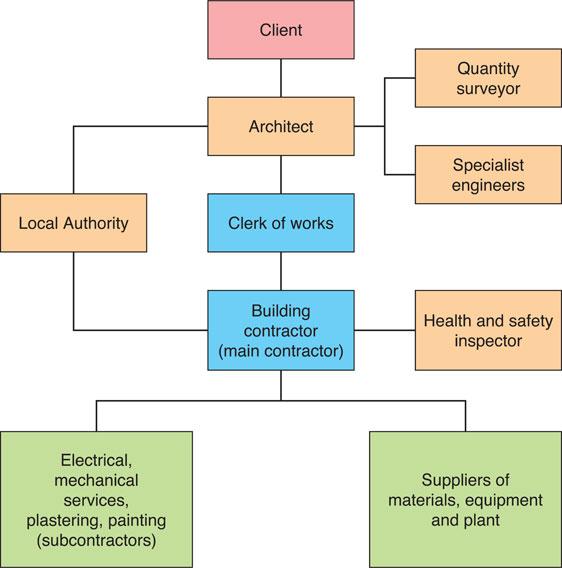

Members of the construction team and their role within the industry

The construction industry is one of the UK’s biggest employers, and carries out contracts to the value of about 10% of the UK’s gross national product. In all these various construction projects the electrical industries play an important role, supplying essential electrical services to meet the needs of those who will use the completed building. All the processes involved in the industry, however, are underpinned by the use of information, in essence: a team of professionals working together to produce the desired results. We can call this team of professionals the building team and their interrelationship and how they use and share information is expressed as follows.

The client is the person or group of people with the actual need for the building, such as a new house, office or factory. The client is responsible for financing all the work and, therefore, in effect, employs the entire building team. The client could be an individual or a group of people representing a housing association.

Figure 2.9 Clients often request to be shown around a site.

They would need to specify their requirements to the building contractor regarding the design and specification and would probably engage an architect to do this.

The architect is the client’s agent and is considered to be the leader of the building team. The architect must interpret the client’s requirements and produce working drawings. During the building process the architect will supervise all aspects of the work until the building is handed over to the client.

Figure 2.10 The building team.

The quantity surveyor measures the quantities of labour and materials necessary to complete the building work from drawings supplied by the architect. A quantity surveyor must therefore maintain detailed records regarding how the project is progressing in relation to the use of materials and costing.

A site / project manager will have overall responsibility for the successful planning, execution, monitoring and control of a project, usually working for the main construction contractor. They must have a combination of skills, including an ability to ask questions of all the team members and resolve conflicts, as well as more general management skills. The project manager, who is managing the installation, would have access to the latest working drawings and should ensure that all the trades are updated with any changes to the specification that have been drawn from architect’s instructions or client requirements.

Building surveyors provide advice on property and construction, including residential, commercial, industrial, leisure and agriculture projects.

They work on the design and development of new buildings as well as the restoration and maintenance of existing ones.

Building surveyors often work to keep buildings in good condition and look for ways to make buildings sustainable. They may be called upon to give evidence in court in cases where building regulations have been breached and as expert witnesses on building defects. Building surveyors have access to detailed plans, including information they would need to share regarding the restrictions that apply due to planning consent, especially if a building is listed.

Contracts managers oversee projects working for the sub-contractor, from the start through to completion, ensuring that work is completed on time and within its budget. Information is often extracted from Gantt charts. For instance, any details of planned or unplanned events that impact on expenditure or project completion would need to be discussed with the client. A contracts manager is sometimes in charge of a single scheme, or may look after several smaller ones.

An estimator in the construction industry is responsible for compiling estimates of how much it will cost to provide a client with products or services. He or she will do this by working out how much a project is likely to cost and quotes accordingly. The job involves assessing material, labour and equipment required and comparing quotes from sub-contractors and suppliers.

Construction buyers are responsible for ensuring that the materials required for construction projects are provided to schedule and according to projected budgets. They have a vital part to play in helping to ensure the profitability of contracts since they are responsible for ensuring that the most cost effective and appropriate materials are purchased.

Structural engineers design buildings to withstand stresses and pressures caused by environmental conditions and human use. They ensure buildings and other structures do not deflect, rotate, vibrate excessively or collapse and that they remain stable and secure throughout their use. They work closely with architects and other professional engineers to choose appropriate materials, such as concrete, steel, timber and masonry, to meet design specifications.

Specialist engineers advise the architect during the design stage. They will prepare drawings and calculations on specialist areas of work.

The clerk of works is the architect’s ‘on-site’ representative. He or she will make sure that the contractors carry out the work in accordance with the drawings and other contract documents. They can also agree general matters directly with the building contractor as the architect’s representative.

The building control inspector from the local council will ensure that the proposed building conforms to the relevant planning and building legislation.

The health and safety inspectors ensure that the government’s legislation concerning health and safety is fully implemented by the building contractor.

The building contractor will enter into a contract with the client to carry out the construction work in accordance with contract documents. The building contractor is usually the main contractor and may engage subcontractors to carry out specialist services such as electrical installation, mechanical services, plastering and painting.

Subcontractors are individuals or companies employed by the main contractor to perform specific, often specialist, tasks as part of the construction process. Specialisms of the subcontractors may include:

• electrician;

• gasfitter;

• plumber;

• heating and ventilation engineer;

• bricklayer;

• carpenter and joiner;

• plasterer;

• tiler;

• decorator;

• groundworker.

The construction of a new building is a complex process that requires a team of professionals working together to produce the desired results. We can call this team of professionals the building team, and their interrelationship is described in Fig. 2.10. Within this is the electrical team.

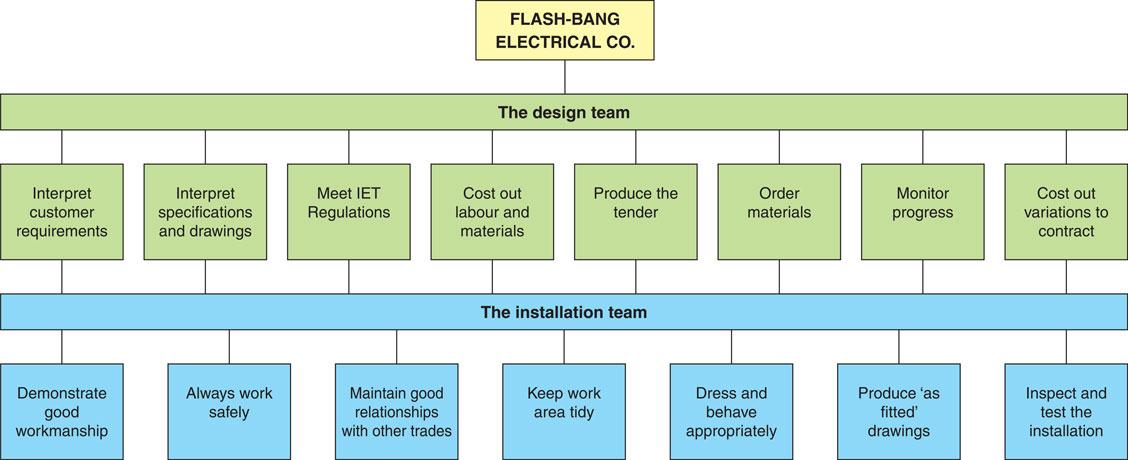

The electrical team

The electrical contractor is the subcontractor responsible for the installation of electrical equipment within the building.

Electrical installation activities include:

• installing electrical equipment and systems in new sites or locations;

• installing electrical equipment and systems in buildings that are being refurbished because of change of use;

• installing electrical equipment and systems in buildings that are being extended or updated;

• replacement, repairs and maintenance of existing electrical equipment and systems.

Try this

Try this

MY TEAM

Sketch a block diagram, similar to those shown in Figs. 2.10 and 2.12, that represents the team in which you work.

Figure 2.11 The electrical contractor is responsible for the installation of electrical equipment.

An electrical contracting firm is made up of a group of individuals with varying duties and responsibilities. There is often no clear distinction between the duties of the individuals, and the responsibilities carried by an employee will vary from one employer to another. If the firm is to be successful, the individuals must work together to meet the requirements of their customers. Good customer relationships are important for the success of the firm and the continuing employment of the employee.

The customer or his or her representatives will probably see more of the electrician and the electrical trainee than the managing director of the firm and, therefore, the image presented by them is very important. They should always be polite and be seen to be capable and in command of the situation. This gives a customer confidence in the firm’s ability to meet his or her needs. The electrician and his trainee should be appropriately dressed for the job in hand, which probably means an overall of some kind. Footwear is also important, but is sometimes a difficult consideration for a journeyman electrician. For example, if working in a factory, the safety regulations may insist that protective footwear be worn, but rubber boots with toe protection may be most appropriate for a building site. However, neither of these would be the most suitable footwear for an electrician fixing a new light fitting in the home of the managing director! The electrical installation in a building is often carried out alongside other trades.

Key fact

Key fact

Whilst the detailed drawing and plans will normally be produced by the architect, the clerk of work is the person who monitors that they are being put into place on site.

It makes sound sense to help other trades where possible and to develop good working relationships with other employees.

The employer has the responsibility of finding sufficient work for his employees, paying government taxes and meeting the requirements of the Health and Safety at Work Act. The rates of pay and conditions for electricians and trainees are determined by negotiation between the Joint Industry Board and the Trades Unions, which will also represent their members in any disputes. Electricians are usually paid at a rate agreed for their grade; movements through the grades are determined by a combination of academic achievement and practical experience. The electrical team will consist of a group of professionals and their interrelationship can be expressed as shown in Fig. 2.12.

Top tip

Top tip

As an employee only answer questions within your full understanding and experience. If unsure, ask your supervisor.

Figure 2.12 The electrical team.

Assessment criteria 2.2

Specify organizational policies/procedures for the handover and demonstration of electrotechnical systems, products and equipment, including requirements for confirming and recording handover

The commissioning of the electrical and mechanical systems within a building is a part of the ‘handing-over’ process of the new building by the architect and main contractor to the client or customer in readiness for its occupation and intended use. To ‘commission’ means to give authority to someone to check that everything is in working order. If it is out of commission, it is not in working order. Following the completion, inspection and testing of the new electrical installation, the functional operation of all the electrical systems must be tested before they are handed over to the customer. It is during the commissioning period that any design or equipment failures become apparent, and this testing is one of the few quality controls possible on a building services installation.

This is the role of the commissioning engineer, who must assure himself or herself that all the systems are in working order and that they work as they were designed to work. This engineer must also instruct the client’s representative, or the staff who will use the equipment, in the correct operation of the systems as part of the handover arrangements.

The commissioning engineer must also test the operation of all the electrical systems, including the motor controls, the fan and air conditioning systems, the fire alarm and emergency lighting systems. However, before testing the emergency systems, it is important to first notify everyone in the building of the intention to test the alarms so that they may be ignored during the period of testing.

Figure 2.13 The commissioning engineer will test the operation of all the electrical systems.

Commissioning has become one of the most important functions within a building project’s completion sequence. The commissioning engineer will therefore have access to all relevant contract documents, including the building specifications and the electrical installation certificates as required by the IET Regulations (BS 7671), and have a knowledge of the requirements of the Electricity at Work Regulations and the Health and Safety at Work Act.

In summary, when handing over an installation to the client you are effectively saying to the client, ‘here is your installation complete with information or a breakdown of the systems and equipment in place’. The client will inherit an operation manual, as well as technical documents such as: ‘fitted drawings’, details of the specifications and the electrical installation certificates required by Part 6 of the IET Regulations, warranties and manufacturers guides.

Assessment criteria 2.3

State the appropriateness of different customer relations methods and procedures

Effective communication is not just important in electrical installation, it is true of all industries. When we talk about good communication we are talking about transferring information from one person to another both quickly and accurately. We can do this through various forms, ranging from talking to other people directly and personally, to looking at drawings and plans and entering into a discussion with colleagues or other professionals who have a vested interest in the project. However, interaction also takes place with customers, clients as well as members of the public and therefore it is incredibly important to stress that employees remain respectful at all times – even if irritated. You are representing your company!

Assessment criteria 2.4

Identify methods of providing technical and functional information appropriate to the needs of clients etc.

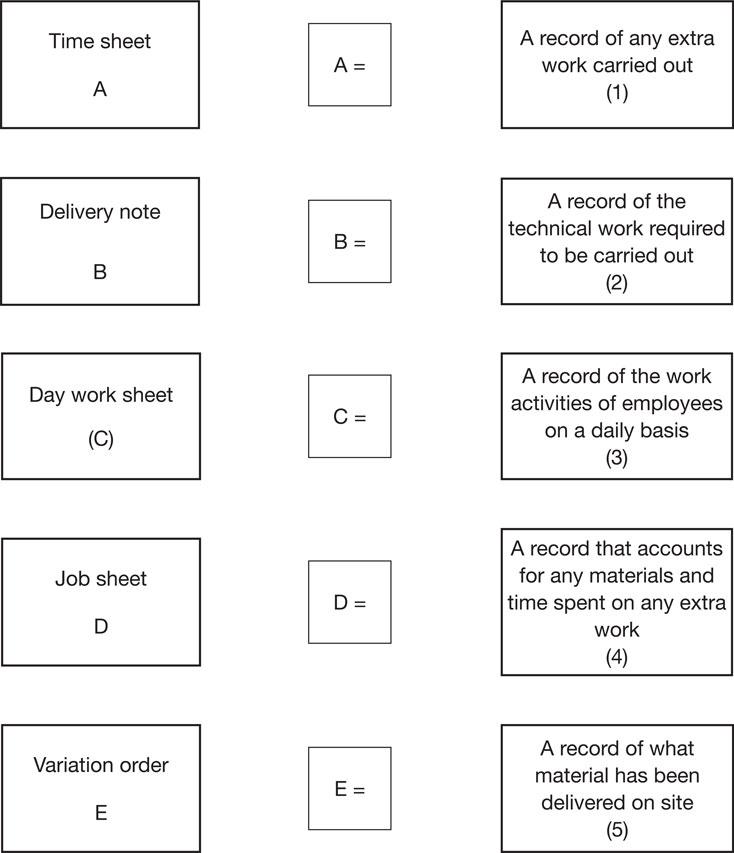

On-site documentation

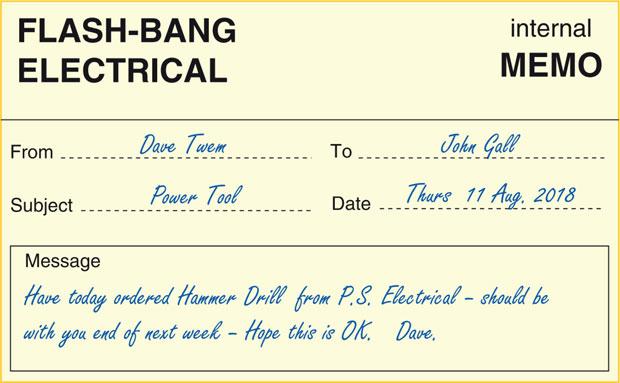

A lot of communication between and within larger organizations takes place by completing standard forms or sending internal memos, fax, texting or E.mails. Written messages have the advantage of being ‘auditable’. An auditor can follow the paperwork trail to see, for example, who was responsible for ordering certain materials.

When completing standard forms, follow the instructions given and ensure that your writing is legible. Do not leave blank spaces on the form, always specifying ‘not applicable’ or ‘N/A’ whenever necessary. Sign or give your name and the date as asked for on the form. Finally, read through the form again to make sure you have answered all the relevant sections correctly. Internal memos are forms of written communication used within an organization; they are not normally used for communicating with customers or suppliers.

Figure 2.14 shows the layout of a typical standard memo form used by Dave Twem to notify John Gall that he has ordered the hammer drill.

Letters and E.mails provide a permanent record of communications between organizations and individuals. They may be handwritten for internal use but formal business letters give a better impression of the organization if they are typewritten. A letter or E.mail should be written using simple concise language, and the tone of the letter should always be polite, even if it is one of complaint. Always include the date of the correspondence. The greeting on a formal letter should be ‘Dear Sir/Madam’ and conclude with ‘Yours faithfully’. A less formal greeting would be ‘Dear Mr Smith’ and conclude ‘Yours sincerely’. Your name and status should be typed below your signature.

Figure 2.14 Typical standard memo form.

Delivery notes

When materials are delivered to site, the person receiving the goods is required to sign the driver’s ‘delivery note’. This record is used to confirm that goods have been delivered by the supplier, who will then send out an invoice requesting payment, usually at the end of the month.

Definition

Definition

A delivery note is used to confirm that goods have been delivered by the supplier, who will then send out an invoice requesting payment.

The person receiving the goods must carefully check that all the items stated on the delivery note have been delivered in good condition. Any missing or damaged items must be clearly indicated on the delivery note before signing, because by signing the delivery note the person is saying ‘yes, these items were delivered to me as my company’s representative on that date and in good condition and I am now responsible for these goods’. Suppliers will replace materials damaged in transit provided that they are notified within a set time period, usually three days. The person receiving the goods should try to quickly determine their condition. Has the packaging been damaged, does the container ‘sound’ like it might contain broken items? It is best to check at the time of delivery if possible, or as soon as possible after delivery and within the notifiable period. Electrical goods delivered to site should be handled carefully and stored securely until they are installed. Copies of delivery notes are sent to head office so that payment can be made for the goods received.

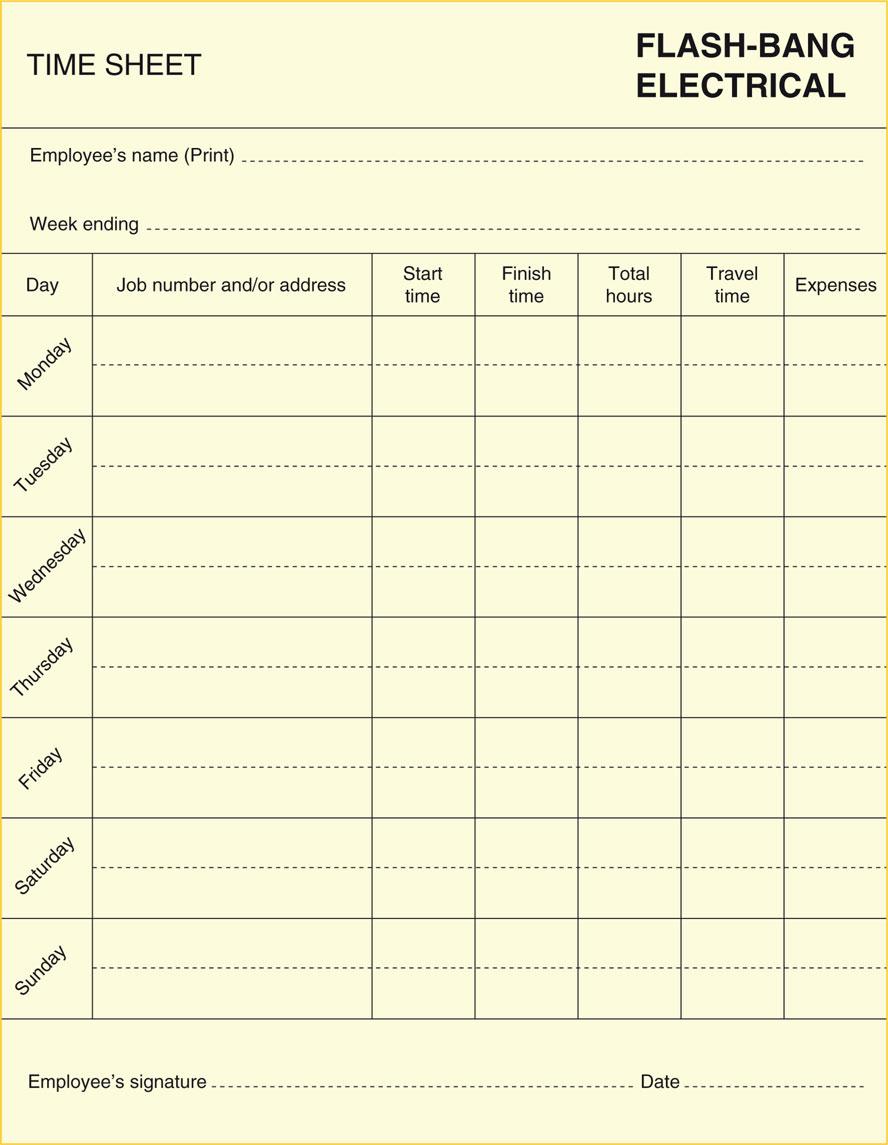

Time sheets

A time sheet is a standard form completed by each employee to inform the employer of the actual time spent working on a particular contract or site. This helps the employer to bill the hours of work to an individual job. It is usually a weekly document and includes the number of hours worked, the name of the job and any travelling expenses claimed. Office personnel require time sheets such as that shown in Fig. 2.15 so that wages can be made up.

Definition

Definition

A time sheet is a standard form completed by each employee to inform the employer of the actual time spent working on a particular contract or site.

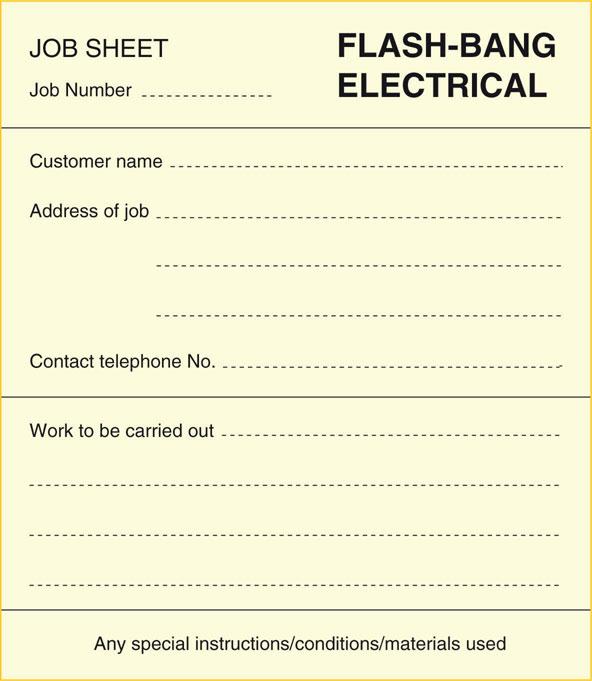

Job sheets

A job sheet or job card such as that shown in Fig. 2.16 carries information about a job that needs to be done, usually a small job. It gives the name and address of the customer, contact telephone numbers, often a job reference number and a brief description of the work to be carried out. A typical job sheet work description might be:

• Job 1 Upstairs lights not working.

• Job 2 Funny fishy smell from kettle socket in kitchen.

Definition

Definition

A job sheet or job card such as that shown in Fig. 2.14 carries information about a job which needs to be done, usually a small job.

An electrician might typically have a ‘jobbing day’ where he picks up a number of job sheets from the office and carries out the work specified. Job 1, for example, might be the result of a blown fuse, which is easily rectified, but the electrician must search a little further for the fault that caused the fuse to blow in the first place. The actual fault might, for example, be a decayed flex on a pendant drop that has become shorted out, blowing the fuse. The pendant drop should be re-flexed or replaced, along with any others in poor condition. The installation would then be tested for correct operation and the customer given an account of what has been done to correct the fault. General information and assurances about the condition of the installation as a whole might be requested and given before setting off to job 2.

The kettle socket outlet at job 2 is probably getting warm and, therefore, giving off that ‘fishy’ Bakelite smell because loose connections are causing the Bakelite socket to burn locally. A visual inspection would confirm the diagnosis. A typical solution would be to replace the socket and repair any damage to the conductors inside the socket box. Check the kettle plug top for damage and loose connections. Make sure all connections are tight before reassuring the customer that all is well; then, off to the next job or back to the office.

Figure 2.15 Typical time sheet.

The time spent on each job and the materials used are sometimes recorded on the job sheet, but alternatively a daywork sheet can be used. This will depend upon what is normal practice for the particular electrical company. This information can then be used to ‘bill’ the customer for work carried out.

Figure 2.16 Typical job sheet.

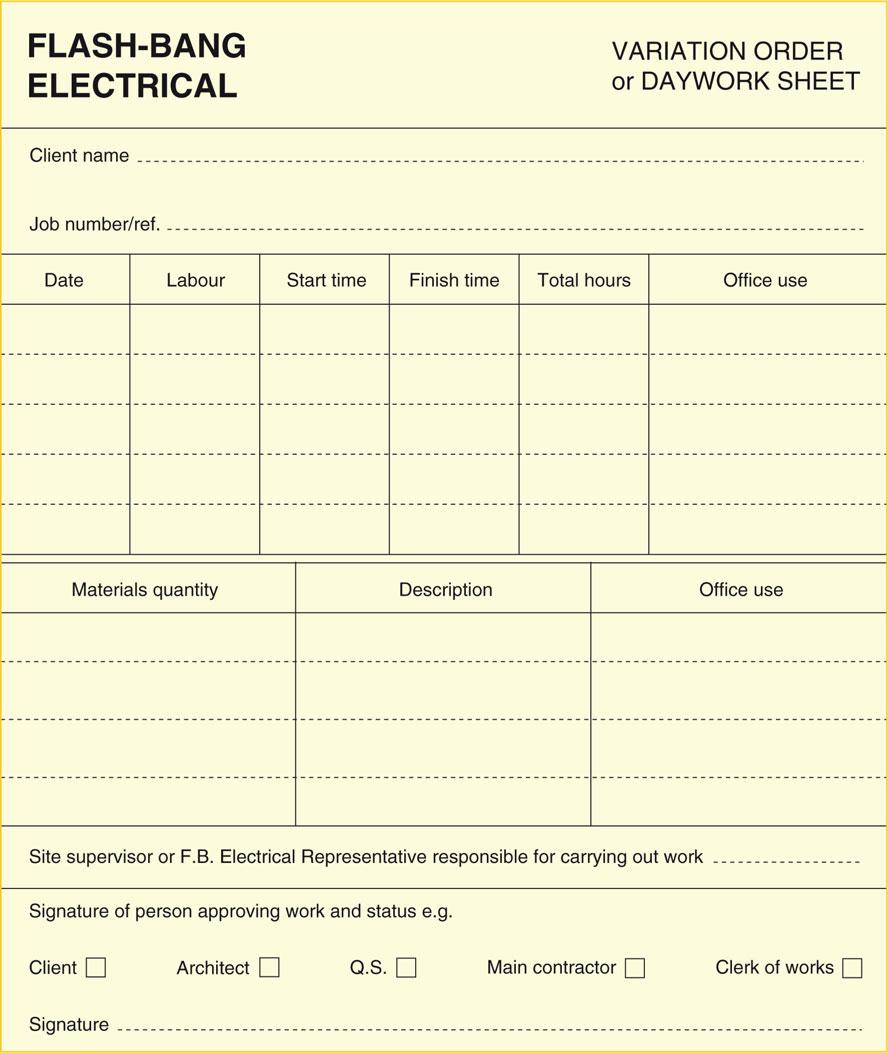

Daywork sheets or variation order

Daywork is one way of recording variations to a contract, that is, work done that is outside the scope of the original contract. If daywork is to be carried out, the site supervisor must first obtain a signature from the client’s representative, for example the architect, to authorize the extra work. A careful record must then be kept on the daywork sheets of all extra time and materials used so that the client can be billed for the extra work. A typical daywork sheet or variation order is shown in Fig. 2.17.

Definition

Definition

Daywork is one way of recording variations to a contract.

Reports

On large jobs, the foreman or supervisor is often required to keep a report of the relevant events that happen on the site – for example, how many people from your company are working on site each day, what goods were delivered, whether there were any breakages or accidents, and records of site meetings attended. Some firms have two separate documents, a site diary to record daily events and a weekly report, which is a summary of the week’s events extracted from the site diary. The site diary remains on site and the weekly report is sent to head office to keep managers informed of the work’s progress.

Figure 2.17 Typical daywork sheet or variation order.

Assessment criteria 2.5

Explain the importance of ensuring that information provided is accurate and complete etc.

Aside from reports other methods of transferring information on a modern day site would include texting as well as e-mail; however, a very important point to remember is to think about the person you are communicating with in order to:

• use the correct tone of language;

• ensure information is sufficient for the task in hand;

Figure 2.18 Always write up verbal agreements to ensure that there is a record of what was agreed.

• ensure information is clear and to the point and is not ambiguous;

• consider the persons in their role/position;

• ensure that it is the correct format.

Top tip

Top tip

Always write up any verbal agreement so that there is a written record of anything agreed.

By following the above advice you will ensure that people in authority are given the relevant information needed for a particular task. If you are not in a position to give that information then you should refer the matter to a more senior person, otherwise misinformation could lead to a loss of reputation, or even a loss of life if vital safety information is not given or understood.

Information including agreements between different trades are also made verbally person to person, therefore it is vital that any such agreements are also recorded on paper so that a written record then exists. This extends to a commissioning engineer, as mentioned previously, who has to hand over an installation and prove that it complies with the actual design specification and certain industry standards such as BS 7671. This is why following the completion of all new electrical work or additional work to an existing installation, the installation must be inspected and tested and an installation certificate issued and signed by a skilled person who must have a sound knowledge of the type of work undertaken, be fully versed in the inspection and testing procedures contained in the IET Regulations (BS 7671) and employ adequate testing equipment. This extends to:

1 Electrical Installation Certificate following the completion of a new installation or for alterations or additions to an existing installation.

2 Minor Electrical Installation Works Certificate: this form is intended to be used for the addition of a socket outlet or lighting point to an existing circuit or for a repair or modification to the installation. The work does not extend to the addition of a new circuit.

3 Electrical Installation Condition Report: all electrical installations must be periodically inspected and tested for the purpose of completing an electrical installation condition report.

Assessment criteria 2.6

Describe methods for checking that relevant persons have an adequate understanding of the technical and non-technical information provided, including appropriate health and safety information

When accidents occur it is almost inevitable that it was caused by a breakdown of communication. The breakdown can occur verbally, written or by the fact that the receiver did not gain full understanding or comprehension of what was required. This is especially true when it comes to handing over information to another person. Consider for a moment you are on the phone and trying to describe and explain the following:

• outstanding work required to complete an installation;

• outstanding work required to complete the testing phase;

• outstanding spares and materials required;

• outstanding tools required;

• list of requested on-site dimensions and measurements.

Top tip

Top tip

Communication is a three-way process

• sending;

• receiving;

• sender checks for understanding.

In trying to recall all this information the possibility for error would be enormous. This is why it is vital that information is: written down, kept up-to-date (if anything changes) and the information is retained and filed for future reference. Other useful strategies when handing something over is to talk and walk through what remains to be done, but allowing time for questioning to ensure that full comprehension has taken place. Often people simply nod their head and say yes but in truth have no real comprehension of what is required.

Another strategy to reduce the possibility of error is to – whenever possible – task the same person who removed certain equipment to re-install it. Equally effective is labelling equipment that has been removed, which will make the re-installation process that much easier. Both are examples of strategies that can underpin best practice.

Figure 2.19 Don’t simply nod your head and say yes when you aren’t sure of something.

Assessment criteria 3.1

State the applicable health and safety requirements with regard to overseeing the work of others

Assessment criteria 3.2

State the procedures for interpreting risk assessments etc.

Construction site – safe working practice

Many governments have passed laws aimed at improving safety at work, but the most important recent legislation has been the Health and Safety at Work Act 1974. This Act should be thought of as an umbrella Act that other statutory legislation sit under. Following this Act many other statutory Acts have led to employers implementing safe systems of work, including providing safety signs and personal protective equipment (PPE), and provide training in how to recognize and use different types of fire extinguishers.

If your career in the electrical industry is to be a long, happy and safe one, you must always wear appropriate PPE such as footwear and head protection and behave responsibly and sensibly in order to maintain a safe working environment. Before starting work, make a safety assessment: what is going to be hazardous, will you require PPE, do you need any special access equipment? Construction sites can be hazardous because of the temporary nature of the construction process. The surroundings and systems are always changing as the construction process moves to its completion date when everything is finally in place.

Safe methods of working must be demonstrated by everyone at every stage. ‘Employees have a duty of care to protect their own health and safety and that of others who might be affected by their work activities.’ To make the work area safe before starting work and during work activities, it may be necessary to:

• use barriers or tapes to screen off potential hazards;

• place warning signs as appropriate;

• inform those who may be affected by any potential hazard;

• use a safe isolation procedure before working on live equipment or circuits;

• obtain any necessary ‘permits to work’ before work begins.

Safety first

Safety first

Everyone has a responsibility towards health and safety. Failure to act or ignoring procedures that lead to the injury of another is a breach of responsibility and punishable through law.

Get into the habit of always working safely and being aware of the potential hazards around you when you are working. Having chosen an appropriate wiring system that meets the intended use and structure of the building and satisfies the environmental conditions of the installation, you must install the system conductors, accessories and equipment in a safe and competent manner.

The structure of the building must be made good if it is damaged during the installation of the wiring system; for example, where conduits and trunking pass through walls and floors. All connections in the wiring system must be both electrically and mechanically sound and the actual conductors must be chosen so that they will carry the full design current under the installed conditions.

Figure 2.20 It is important that warning signs are displayed and maintained where appropriate.

If the wiring system is damaged during installation it must be made good to prevent future corrosion. For example, where galvanized conduit trunking or tray is cut or damaged by pipe vices, it must be made good to prevent localized corrosion.

All tools must be used safely and sensibly. Cutting tools should be sharpened and screwdrivers ground to a sharp square end on a grindstone. It is particularly important to check that the plug and cables of hand-held electrically powered tools and extension leads are in good condition. Damaged plugs and cables must be repaired before you use them. All electrical power tools of 110 V and 230 V must be tested with a portable appliance tester (PAT) in accordance with the company’s health and safety procedures, but probably at least once each year.

Tools and equipment that are left lying about in the workplace can become damaged or stolen and may also be the cause of people slipping, tripping or falling. Tidy up regularly and put power tools back in their boxes. This is called ‘good housekeeping’ and is an important part of Appendix F of the Electrician’s Guide to the Building Regulations. You personally may have no control over the condition of the workplace in general, but keeping your own work area clean and tidy is the mark of a skilled and conscientious craftsman. Finally, when the job is finished, clean up and dispose of all waste material responsibly. This is an important part of your company’s ‘good customer relationships’ with the client. We also know that we have a ‘duty of care’ for the waste that we produce as an electrical company.

Top tip

Top tip

Tools should be checked before and after use to ensure that they remain tit for purpose.

We have also said many times in this book that having a good attitude to health and safety, working conscientiously and neatly, keeping passageways clear and regularly tidying up the workplace are signs of a good and competent craftsman. But what do you do with the rubbish that the working environment produces? Well:

• All the packaging material for electrical fittings and accessories usually goes into either your employer’s skip or the skip on site designated for that purpose.

• All the offcuts of conduit, trunking and tray also go into the skip.

• In fact, most of the general site debris will probably go into the skip and the waste disposal company will take the skip contents to a designated local council landfill area for safe disposal.

• The part coils of cable and any other reusable leftover lengths of conduit, trunking or tray will be taken back to your employer’s stores area. Here it will be stored for future use and the returned quantities deducted from the costs allocated to that job.

• What goes into the skip for normal disposal into a landfill site is usually a matter of common sense. However, some substances require special consideration and disposal. We will now look at asbestos which is classified as ‘special waste’ or ‘hazardous waste’.

Asbestos is a mineral found in many rock formations. When separated it becomes a fluffy, fibrous material with many uses. It was used extensively in the construction industry during the 1960s and 1970s for roofing material, ceiling and floor tiles, fire resistant board for doors and partitions, for thermal insulation and commercial and industrial pipe lagging.

Figure 2.21 Asbestos fibres can cause lung disease.

In the buildings where it was installed some 40 years ago, when left alone, it does not represent a health hazard, but those buildings are increasingly becoming in need of renovation and modernization. It is in the dismantling and breaking up of these asbestos materials that the health hazard occurs.

Safe system of work

Understanding how employers implement a safe system of work is fundamental for any operative irrespective of how experienced they are. Formal risk assessments have to be undertaken by an employer in order to highlight any hazards present in the work area. This also includes identifying who is at risk and scrutinizing any existing control measure including its effectiveness. In certain high-risk areas or hazardous environments a permit to work is used, which ensures that an operation is only carried out once full authority has been granted and that the person undertaking the job is fully aware of his or her responsibilities. Finally, used extensively in the electrical installation industry, method statements signpost: exactly how a task is to be implemented; which tools are to be used; and even how waste material is to be disposed of so that no one involved is left in doubt about the job requirements.

Assessment criteria 4.1

Describe techniques for the communication with others

Assessment criteria 4.3

Specify their role in terms of responsibility for other staff etc.

Figure 2.22 Site safety starts before you even enter the site.

An electrician working for an electrical contracting company works as a part of the broader construction industry. This is a multi-million-pound industry carrying out all types of building work, from basic housing to hotels, factories, schools, shops, offices and airports. The construction industry is one of the UK’s biggest employers, and carries out contracts to the value of about 10% of the UK’s gross national product.

Although a major employer, the construction industry is also very fragmented. Firms vary widely in size, from the local builder employing two or three people to the big national companies employing thousands. Of the total workforce of the construction industry, 92% are employed in small firms of fewer than 25 people. The yearly turnover of the construction industry is about £35 billion. Of this total sum, about 60% is spent on new building projects and the remaining 40% on maintenance, renovation or restoration of mostly housing. In all these various construction projects the electrical industries play an important role, supplying essential electrical services to meet the needs of those who will use the completed building.

Assessment criteria 5.4

Identify within the scope of the work programme and operations their responsibilities

Assessment criteria 4.4

Identify appropriate methods for communicating with and responding to others

The information chain therefore includes a myriad of people as discussed previously when defining how roles are formed within both construction and the electrical team and how senior people within each element tie in with the client. It is vital therefore that Information is kept current when initial plans or work schedules are changed, and irrespective of the justification, circumstance or reasons behind such change, the details of which must be made available to the relevant people. For instance, there are many examples of those working on site being driven by working drawings, but they have not been made aware that the drawings they are using have been updated, they have been superseded by a later version, since that information has not been passed down to them.

Such matters can cause friction since what has taken place is a waste of materials and labour. Friction can also take place when different trades are at loggerheads since both parties require access to a specific area. During such times a meeting must take place in order to find a way forward.

Assessment criteria 4.5

Specify procedures for re-scheduling work to coordinate with changing conditions in the workplace and to coincide with other trades

Assessment criteria 4.6

Clarify organizational procedures for completing the documentation that is required during work operations

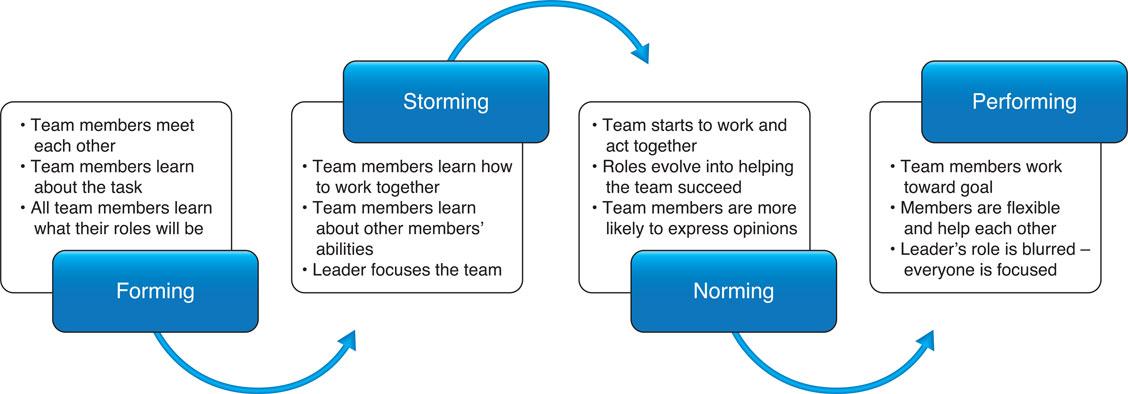

One strategy used in building relationships and formulating roles and responsibility is shown below.

Stages of team development

• Forming: Individuals will gather together in order to discuss an ongoing issue or concern and share different ideas or strategies.

Figure 2.23 Forming, Storming, Norming and Performing involves defining how an individual meets their responsibilities within a team environment.

• Storming: The process when a trade-off of thoughts takes place and also individuals define their role within the team.

• Norming: Moving forward the individuals involved agree certain roles and responsibilities within the team and especially define key processes such as how best to perform a task.

• Performing: Individual responsibilities have now been defined and especially how they fit in with others.

What is important here is that everyone understands their role and this includes cooperation in a wider context. For instance, there is always going to be tension when resources are required to be shared but an element of understanding can disarm such situations. Other examples of site tension can be caused through a lack of support from supervisors or management, and it is well worth reminding those in authority that the Electricity at Work Act 1989 lays down clear requirements in ensuring that through an onus of care, apprentices are given appropriate guidance and supervision based on their skills and experience.

In some cases where disputes cannot be settled in-house then some form of mediation is required through the involvement of a union representative who will negotiate on a member’s behalf. Their aim will be to instil the fundamentals of fair working practices. If all relationships are harmonious then it will make for a happier workforce, which in turn will ensure:

• the efficient use of resources;

• customer satisfaction;

• increased efficiency and productivity;

• wastage reduction;

• increased profitability.

Top tip

Top tip

Although you will be given an induction programme to help you gain familiarity of site processes and procedures there is still a lot of information to remember. Don’t be a mushroom if you are being kept in the dark – make it your business to find out!

There is a lot to learn for any new employee, therefore it is worth stressing that if a problem does occur that is outside of your authority or comprehension then contact your supervisor for professional help and guidance. It is not unreasonable for a young member of the company’s team to seek help and guidance from those employees with more experience. This approach would be preferred by most companies rather than having to meet the cost of an expensive blunder.

Assessment criteria 4.2

Describe methods of determining the competence of operatives for whom they are responsible

Employee skills and competencies

Certain skills and understanding of trade related information are maintained through industry driven schemes and are especially important on a construction site, since it is one of the most hazardous workplaces that you can work within.

Consequently, entry on to site is controlled and regulated through the Construction Skills Certification Scheme (CSCS) card. The CSCS is a scheme that assesses an individual’s knowledge of health and safety policies and procedures in order to ensure that personnel that gain entry recognize and understand what is expected of them, including policies and procedures. The scheme will also differ for a labourer (green card) to a skilled individual (gold card) and therefore allow further involvement and engagement on specific operations and tasks. An electrician is normally afforded an ECS card, which proves recognized and current trade based skills and qualifications as well as having been successful in undertaking a health and safety assessment.

Figure 2.24 Instructional communication not only saves time, but it also makes for a safer working environment.

Other industry recognized schemes regarding recognition of trade related skills and experience can be found through JIB membership and being given an electrician’s gold card.

That said, all contractors irrespective of their qualifications are still monitored on site to ensure that safety is maintained at all times. In certain conditions written references from previous employers would be required if, for instance, a prospective contractor had worked abroad for a time or had not been active in the industry. The government has approved schemes to be operated by BRE Certification Ltd, British Standards Institution, ELECSA Ltd, NICEIC Certification Services Ltd, certsure.com, and Napit Certification Services Ltd. All the different bodies will operate the scheme to the same criteria and will be monitored by the Department for Communities and Local Government, formerly called the Office of the Deputy Prime Minister.

Installers of environmental technology systems must also be registered under the scheme. The work of members will then be inspected at least once each year. There will be an initial registration and assessment fee and then an annual membership and inspection fee.

Assessment criteria 5.1

Describe how to plan work allocations etc.

Assessment criteria 5.2

Specify procedures for carrying out work activities that will maintain the safety of the work environment etc.

Organizing and overseeing work programmes

Smaller electrical contracting firms will know where their employees are working and what they are doing from day to day because of the level of personal contact between the employer, employee and customer. As a firm expands and becomes engaged on larger contracts, it becomes less likely that there is anyone in the firm with a complete knowledge of the firm’s operations, and there arises an urgent need for sensible management and planning skills so that men and materials are on site when they are required and a healthy profit margin is maintained. What is paramount, however, is that work operations also tally with the skills and experience of the workforce so that individuals are not put in a position that exceeds their responsibility or ability.

When the electrical contractor is told that he has been successful in tendering for a particular contract they are committed to carrying out the necessary work within the contract period. They must therefore consider:

• by what date the job must be finished;

• when the job must be started if the completion date is not to be delayed;

• how many men will be required to complete the contract including qualifications, skills, authorizations;

• when certain materials will need to be ordered;

• when the supply authorities must be notified that a supply will be required;

• if it is necessary to obtain authorization from a statutory body for any work to commence.

In thinking ahead and planning the best method of completing the contract, the individual activities or jobs must be identified and consideration given to how the various jobs are interrelated. To help in this process a number of management techniques are available. In this chapter we will consider only two: bar charts and network analysis. The very preparation of a bar chart or network analysis forces the contractor to think deeply, carefully and logically about the particular contract, and it is therefore a very useful aid to the successful completion of the work.

Assessment criteria 5.7

Specify methods of producing and illustrating work programmes such as bar charts, spreadsheets and critical path analysis

Bar charts

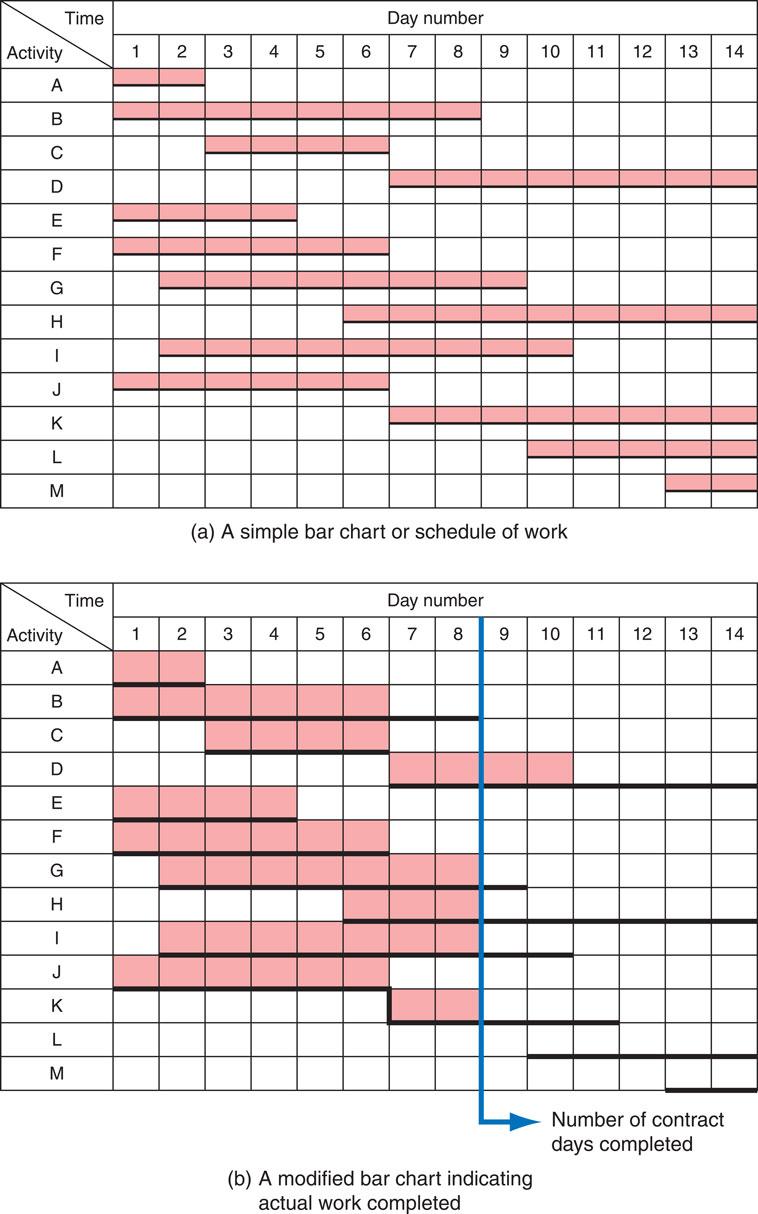

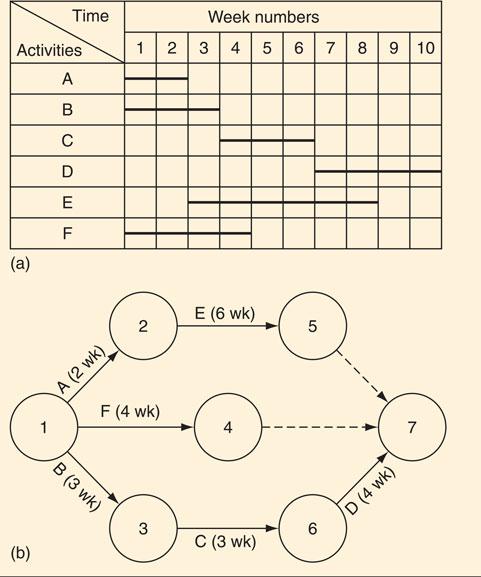

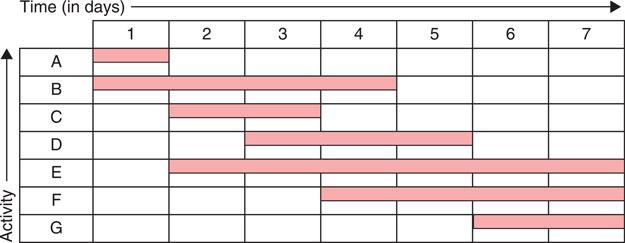

There are many different types of bar chart used by companies but the objective of any bar chart is to establish the sequence and timing of the various activities involved in the contract as a whole. They are a visual aid in the process of communication. In order to be useful they must be clearly understood by the people involved in the management of a contract. The chart is constructed on a rectangular basis, as shown in Fig. 2.25.

Definition

Definition

There are many different types of bar chart used by companies but the objective of any bar chart is to establish the sequence and timing of the various activities involved in the contract as a whole.

All the individual jobs or activities which make up the contract are identified and listed separately down the vertical axis on the left-hand side, and time flows from left to right along the horizontal axis. The unit of time can be chosen to suit the length of the particular contract, but for most practical purposes either days or weeks are used.

The simple bar chart shown in Fig. 2.25(a) shows a particular activity A, which is estimated to last two days, while activity B lasts eight days. Activity C lasts four days and should be started on day three. The remaining activities can be interpreted in the same way.

With the aid of colours, codes, symbols and a little imagination, much additional information can be included on this basic chart. For example, the actual work completed can be indicated by shading above the activity line as shown in Fig. 2.25(b) with a vertical line indicating the number of contract days completed; the activities that are on time, ahead of or behind time can easily be identified. Activity B in Fig. 2.25(b) is two days behind schedule, while activity D is two days ahead of schedule. All other activities are on time. Some activities must be completed before others can start. For example, all conduit work must be completely erected before the cables are drawn in. This is shown in Fig. 2.25(b) by activities J and K. The short vertical line between the two activities indicates that activity J must be completed before K can commence.

Useful and informative as the bar chart is, there is one aspect of the contract that it cannot display. It cannot indicate clearly the interdependence of the various activities upon each other, and it is unable to identify those activities that must strictly adhere to the time schedule if the overall contract is to be completed on time, and those activities in which some flexibility is acceptable. To overcome this limitation, in 1959 the Central Electricity Generating Board (CEGB) developed the critical path network diagram, which we will now consider.

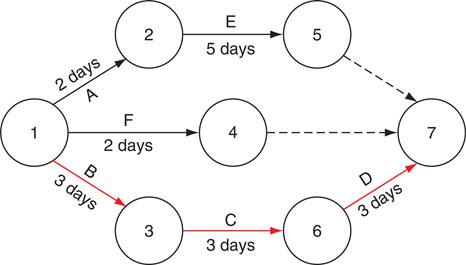

Network analysis

In large or complex contracts there are a large number of separate jobs or activities to be performed. Some can be completed at the same time, while others cannot be started until others are completed. A network diagram can be used to coordinate all the interrelated activities of the most complex project in such a way that all sequential relationships between the various activities, and the restraints imposed by one job on another, are allowed for. It also provides a method of calculating the time required to complete an individual activity and will identify those activities that are the key to meeting the completion date, called the critical path. Before considering the method of constructing a network diagram, let us define some of the terms and conventions we shall be using.

Definition

Definition

A network diagram can be used to coordinate all the interrelated activities of the most complex project.

Figure 2.25 Bar charts: (a) a simple bar chart or schedule of work; (b) a modified bar chart indicating actual work completed.

Critical path

Critical path is the path taken from the start event to the end event which takes the longest time. This path denotes the time required for completion of the whole contract.

Definition

Definition

Critical path is the path taken from the start event to the end event which takes the longest time.

Float time

Float time, slack time or time in hand is the time remaining to complete the contract after completion of a particular activity.

The total float time for any activity is the total leeway available for all activities in the particular path of activities in which it appears. If the float time is used up by one of the early activities in the path, there will be no float left for the remaining activities and they will become critical.

Definition

Definition

Float time, slack time or time in hand is the time remaining to complete the contract after completion of a particular activity.

Float time = Critical path time – Activity time

Activities

Activities are represented by an arrow, the tail of which indicates the commencement, and the head the completion of the activity. The length and direction of the arrows have no significance: they are not vectors or phasors. Activities require time, manpower and facilities. They lead up to or emerge from events.

Definition

Definition

Activities are represented by an arrow, the tail of which indicates the commencement, and the head the completion of the activity.

Dummy activities

Dummy activities are represented by an arrow with a dashed line. They signify a logical link only, require no time and denote no specific action or work.

Definition

Definition

Dummy activities are represented by an arrow with a dashed line.

Event

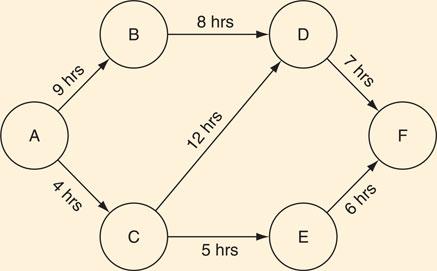

An event is a point in time, a milestone or stage in the contract when the preceding activities are finished. Each activity begins and ends in an event. An event has no time duration and is represented by a circle, which sometimes includes an identifying number or letter. Time may be recorded to a horizontal scale or shown on the activity arrows. For example, the activity from event A to B takes nine hours in the network diagram shown in Fig. 2.26.

Definition

Definition

An event is a point in time, a milestone or stage in the contract when the preceding activities are finished.

Example 1

Identify the three possible paths from the start event A to the finish event F for the contract shown by the network diagram in Fig. 2.26. Identify the critical path and the float time in each path.

The three possible paths are:

1 event A – B – D – F

2 event A – C – D – F

3 event A – C – E – F

Figure 2.26 A network diagram for Example 1.

The times taken to complete these activities are:

1 path A – B – D – F = 9 + 8 + 7 + 24 hours

2 path A – C – D – F = 4 + 12 + 7 + 23 hours

3 path A – C – E – F = 4 + 5 + 6 + 15 hours

The longest time from the start event to the finish event is 24 hours, and therefore the critical path is A – B – D – F.

The float time is given by:

For path 1, A – B – D – F,

There can be no float time in any of the activities which form a part of the critical path, since a delay on any of these activities would delay completion of the contract. On the other two paths some delay could occur without affecting the overall contract time.

For path 2, A – C – D – F,

For path 3, A – C – E – F,

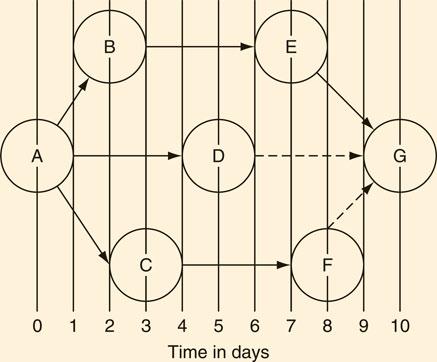

Example 2

Identify the time taken to complete each activity in the network diagram shown in Fig. 2.27. Identify the three possible paths from the start event A to the final event G and state which path is the critical path.

The time taken to complete each activity using the horizontal scale is:

activity A – B = 2 days

activity A – C = 3 days

activity A – D = 5 days

activity B – E = 5 days

activity C – F = 5 days

activity E – G = 3 days

activity D – G = 0 days

activity F – G = 0 days

Activities D – G and F – G are dummy activities which take no time to complete but indicate a logical link only. This means that in this case, once the activities preceding events D and F have been completed, the contract will not be held up by work associated with these particular paths and they will progress naturally to the finish event.

Figure 2.27 A network diagram for Example 2.

The three possible paths are:

1 A – B – E – G

2 A – D – G

3 A – C – F – G

The times taken to complete the activities in each of the three paths are:

The critical path is path 1, A – B – E – G.

Constructing a network

The first step in constructing a network diagram is to identify and draw up a list of all the individual jobs, or activities, that require time for their completion and which must be completed to advance the contract from start to completion. The next step is to build up the arrow network showing schematically the precise relationship of the various activities between the start and end event. The designer of the network must ask these questions:

1 Which activities must be completed before others can commence? These activities are then drawn in a similar way to a series circuit but with event circles instead of resistor symbols.

2 Which activities can proceed at the same time? These can be drawn in a similar way to parallel circuits but with event circles instead of resistor symbols.

Commencing with the start event at the left-hand side of a sheet of paper, the arrows representing the various activities are built up step by step until the final event is reached. A number of attempts may be necessary to achieve a well balanced and symmetrical network diagram showing the best possible flow of work and information, but this time is well spent when it produces a diagram that can be easily understood by those involved in the management of the particular contract.

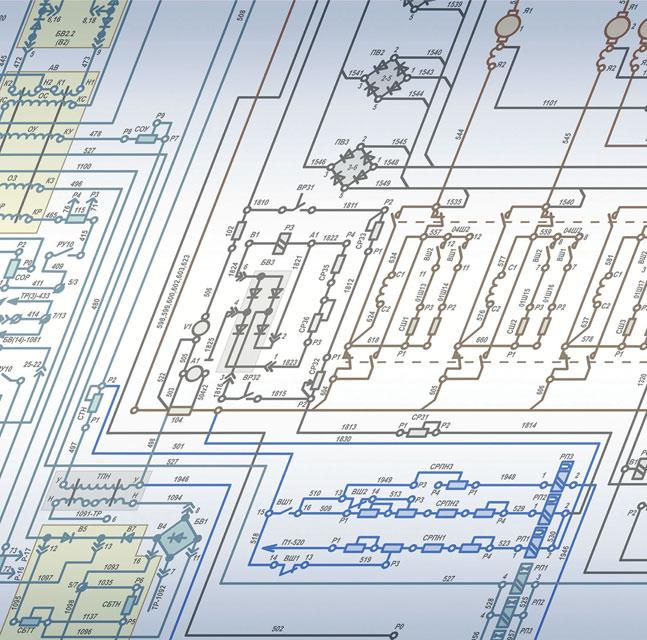

Figure 2.28 Part of an electrical network diagram.

Example 3

A particular electrical contract is made up of activities A – F as described below:

Certain constraints are placed on some activities because of the availability of men and materials and because some work must be completed before other work can commence as follows:

(a) Produce a simple bar chart to display the activities of this particular contract.

(b) Produce a network diagram of the programme and describe each event.

(c) Identify the critical path and the total contract time.

(d) State the maximum delay which would be possible on activity E without delaying the completion of the contract.

(e) State the float time in activity F.

Figure 2.29 (a) Bar chart and (b) network diagram for Example 3.

(a) A simple bar chart for this contract is shown in Fig. 2.29(a).

(b) The network diagram is shown in Fig. 2.29(b). The events may be described as follows:

Event 1 = the commencement of the contract

Event 2 = the completion of activity A and the commencement of activity E

Event 3 = the completion of activity B and the commencement of activity C

Event 4 = the completion of activity F

Event 5 = the completion of activity E

Event 6 = the completion of activity C

Event 7 = the completion of activity D and the whole contract.

(c) There are three possible paths:

1 via events 1 – 2 – 5 – 7

2 via events 1 – 4 – 7

3 via events 1 – 3 – 6 – 7.

The time taken for each path is:

The critical path is therefore path 3, via events 1 – 3 – 6 – 7, and the total contract time is 10 weeks.

(d) We have that:

Activity E is on path 1 via events 1 – 2 – 5 – 7 having a total activity time of 8 weeks

Activity E could be delayed for a maximum of 2 weeks without delaying the completion date of the whole contract.

(e) Activity F is on path 2 via events 1 – 4 – 7 having a total activity time of 4 weeks

Assessment criteria 5.5

Identify how to determine the estimated time required for the completion of the work required taking into account influential factors such as the deployment and availability of suitable personnel etc.

Assessment criteria 5.6

State the possible consequences of not completing work within the estimated time etc.

Another type of chart is known as a Gantt chart and it enables various stages of an installation to be controlled and tracked against a critical and optimum time frame. Disruptions and delays inevitably happen and can occur due to a variety of reasons such as:

• unavailability of suitable personnel;

• unavailability of suitable materials;

• equipment failure;

• latent (hidden) faults;

• inclement weather;

• scheduling additional requirements or additional specifications.

Key fact

Key fact

Re-scheduling work due to delay must include all the trades involved.

It is therefore vital that team meetings are held on a regular basis to track progress and discuss any related issues as mentioned above. This will allow certain contingencies to be made available or brought about in order to maintain certain milestones and target dates. Inevitably, certain outdates might have to be changed to accommodate circumstances that are not retrievable, which could lead to a breach of contract and in some circumstances where such matters have been formalized will bring about a heavy fine.

Assessment criteria 5.3

Identify the industry standards that are relevant to activities carried out during the installation of electrotechnical systems and equipment, including the current editions of Management of Health and Safety Regulations etc.

Within the electrical installation industry there are relevant elements and statutory regulations that impact work activities. They include the Health and Safety Act 1974, which is the main umbrella act that other statutory regulations are drawn from such as:

Management of Health and Safety at Work Regulations (MHSWR) 1999

This regulation makes sure that managers ensure that they:

• make arrangements for implementing the health and safety measures to reduce risk;

• appoint competent people to help you implement the arrangements;

• set up emergency procedures;

• provide clear information and training to employees and ensure that policy and procedures are adopted by employees;