three

Pitch, Turpentine and Rosin

Pines exude resin that is sticky, aromatic and honey-like. It is a mixture of solid rosin and liquid turpentine. Produced by the trees to seal wounds and eject foreign matter, it is viscous and highly flammable. On the trees it appears in drips and flows; on cones it oozes in flecks or shows as tear-like drips. When fresh it is glisteningly transparent; as it ages, it becomes milky, looking a little like candle wax. Resin exposed to the air hardens through evaporation and oxidation. Other conifers also produce resin, but pines are an especially rich source. Small amounts can be scraped from naturally occurring flows, but at some point in the distant past, probably repeatedly in different times and places, the idea of deliberately wounding the trees to increase the flow began.

In China, from an early date, physicians held complex beliefs about pine resin, sung chih, and its relationship to a fungus, fu ling (Polyporus cocos), which grows on the roots of pines. The fungus was thought to be the result of pine resin flowing into the ground and remaining there for a thousand years, and was considered to be an elixir of immortality.1 In ancient Greece the pitys pine was sacred to both Poseidon, god of the sea, and Dionysus, god of wine. This was not only because pines produced timber for ships and gave resin or pitch to preserve them and their tackle, but also because their resin was used for sealing porous wine vessels and mixed with the wine itself. There is a hint that resin or pitch may have been more important than timber in relation to pine trees in the ancient Mediterranean world. A treaty of the fourth century BC between the Macedonian king and the cities of Chalcidice grants the latter the rights for products from Macedonian forests, mentioning pitch before timber.2 Pitch is recorded in Old English as pic, in Middle English as picche or pisch, and in continental Europe as pic, pi, pek or peh in Germanic languages on the North Sea littoral. Well away from the European mainland, the Old Icelandic word was bik, and in Eastern Europe related words were recorded in Slavonic languages. Pitch was evidently both sought after and widely travelled.

Woodcut illustration for Sebastian Münster’s Cosmographia (1544–52) showing a pine tree with a collecting box for resin at the roots. |

|

The early link between pine trees and maritime travel is still apparent in the English expression ‘naval stores’ to describe the industry that extracts pine products. The phrase originally included cordage (ropes), wood for masts, spars and planks, and pine tar or pitch, but by the nineteenth century it meant pine resin from living trees, the turpentine and rosin distilled from it, and pitch or tar extracted from dead pinewood.3

As in all things to do with pine trees, the English vocabulary is fluid. Resin is sometimes called turpentine, gum (especially in the USA) and pitch. Pitch can indicate resin extracted from cut or dead pinewood by heat, also called tar. Rosin, in early texts, is sometimes used to indicate resin. Usage is hopelessly confused, reflecting the great utility of these items in a world without the fossil fuel products now used instead.

Resin, technically oleoresin, is defined as ‘a non-aqueous solution of resin acids dissolved in a terpene hydrocarbon oil’.4 It has excellent adhesive qualities, as anyone who has had to remove it knows (it can be removed from the skin by rubbing in a little fat or oil). In the nineteenth-century turpentine industry of North Carolina, the men working with resin got so much of it on their overalls that the cloth became stiff; unable to fold the overalls, they left them standing in the corner of the cabin at night.5 Although the word gum is often used in the USA for pine resin, this is inaccurate (gum is water soluble).

Pitch, anciently associated with pine trees, is defined in the Oxford English Dictionary as

a sticky, resinous, black or dark brown substance, hard when cold and semiliquid when hot, that is obtained as a residue from the distillation of wood tar or turpentine and is used for caulking the seams of ships, protecting wood from moisture, etc.

This substance was also referred to as tar, a word traced back to ad 700 in Anglo-Saxon sources, where teru or teoru were equated with Latin resina. Like the word pitch, tar seems to have had an Indo-European root (this source from the Oxford English Dictionary). Pitch and tar are confusing, the words sometimes being used interchangeably, and pitch could refer to a product that had received further heat treatment by boiling. From the earliest records onwards, the word tar was also applied to mineral pitch or bitumen, the sense in which it is now more commonly used. Pine pitch and pine tar have an aroma that is slightly astringent, woody and chemical, but not unpleasant. They have left a lingering smell along quaysides and in sail lofts all along the Western European coast, and the extreme darkness of these products has given English the expression ‘pitch-black’ for moonless nights and lightless cellars.

Crude resin tapped from living trees was also called turpentine. When distilled it became known as oil of turpentine, and according to the Oxford English Dictionary this was

a volatile oil, contained in the wood, bark, leaves and other parts of coniferous trees, and usually prepared by distilling crude turpentine. There are many varieties according to the source, which, although all having the same formula, C10H16, vary in their physical and more especially their optical properties.

Unless otherwise indicated, in this chapter the word ‘turpentine’ is used to indicate the distilled product. Often abbreviated to ‘turps’ in English, it combines with linseed oil to produce the characteristic odour of an oil painter’s studio – an evocative, never-to-be-forgotten smell. Mineral-derived white spirit is frequently substituted for lessexalted purposes.

Distilling turpentine leaves a clear, solid, pale gold residue in the still. This became known as rosin, a word ultimately derived from Latin rēsina, resin (according to the Oxford English Dictionary), making the discussion about pine products somewhat circular. Rosin was used to indicate resin by some early modern authors, who used an alternative, now-archaic term, colophony (from Colophon, an Ionian island), for this residue. Such a tangle of vocabulary can only indicate that these substances were enormously useful and sought after by people often remote from the area of production. Perhaps for those who lived far from their origin, they had mysterious and slightly magical associations as natural products of forests in distant lands.

As part of his Enquiry into Plants, Theophrastus recorded two methods of extraction. Resin could be obtained by tapping living trees such as silver fir and Aleppo pine, a process that, he noted, eventually weakened them. Quality varied according to the aspect of the tree, the finest and purest resin coming from trees growing in a sunny position and facing north. They yielded less in dry weather. Resin was ‘carried about in baskets, and so acquires the more solid form which we know’.6 The second extraction method recorded how the Macedonians and Syrians made pitch by fire using cut or dead wood. A piece of ground was levelled, making a slope for the pitch to run towards the middle. Then cloven logs were placed ‘in an arrangement like that used by the charcoal-burners’, upright in a pile 180 cubits round by 50 or 60 high (more if the wood was very resinous). The pile was covered with timber, then earth, and fire was kindled through a gap, which was then closed. The smouldering pile was kept covered with earth ‘and a conduit is prepared for the pitch right through the pile, so that it may flow off into a hole at about fifteen cubits off’. It burned for two days and nights, after which the pitch stopped flowing. ‘All this time they keep watch and do not go to rest, in case the fire should come through; and they offer sacrifice and keep holiday, praying that the pitch my be abundant and good.’7 This method of extracting pine pitch or tar was later called ‘dry distillation’, and became widely known. Pomet recorded that pine tar ‘is generally brought to us [in France] from Denmark, Norway, Finland and Swedeland; but there is much of it made in New-England, Virginia, Carolina and other Parts of Florida’,8 and that ‘black pitch’ was a mixture of tar and resin, the best coming from Stockholm. In New England in the eighteenth century, North Carolina became known as the ‘Tar Heel’ State because of its association with pitch production. Around the end of the seventeenth century, John Evelyn described laying knots from decayed wood on hearths ‘after the very same manner as our colliers do their wood for charcoal’ in a ‘kind of rude distillation’.9 The method was simple but tedious. It could also be hazardous, as vents made in the cover of the heap – intentionally or otherwise – sometimes needed sealing, with the chance that a worker (or slave in the North American colonies) might suffer burns or even fall into the kiln.

Sweden produced the best pitch. In the early twentieth century, a ‘dale’, a pitch-producing kiln as used in Sweden, was funnel-shaped and built on a slope, with a spout at the lower end and the interior lined with clay, iron or thick cardboard. The Swedes prepared the trees by barking them from the ground to a height of about 2.5 m, leaving only a narrow strip on the north side that kept the tree alive until the next year. Then they felled them, and the bases, now full of resin, were dried over the summer. The resinous stumps were stacked on the dale and the whole was covered with brushwood and peat. The burning brushwood was carefully controlled so that the pinewood did not flare up, but merely yielded a pitch that was high in turpentine and much in demand. Dry distillation was inefficient but gave a good product; it was still used to a limited extent to produce high-quality pitch in Sweden in the early twentieth century.10

Pitch was a variable product. Anciently, Theophrastus recorded that the people of Mount Ida considered pitch (resin) from their local pine to be ‘more abundant, blacker, sweeter and generally more fragrant’ when raw than that of ‘the fir of the seashore’, but it contained more ‘watery matter’, so the amount reduced more when it was boiled down.

Pliny the Elder (ad 23–79) also described pitch produced in various places from different kinds of tree, including a ‘spruce’ found in Bruttium (southern Italy; possibly a pine formerly known as Pinus brutia, now considered a variant of Aleppo pine). He recorded that the early flow of pitch was collected separately, and in Syria was known as cedar oil. Subsequent, thicker pitch was collected in bronze cauldrons and mixed with vinegar to coagulate it. Known as Bruttium pitch, it had a reddish colour and was more viscous and greasier. Pitch could be heated in oak barrels using hot stones; it was evidently solid, as it could be ground up like flour. Cooked gently with water and clarified, it took on a red colour and was known as distilled pitch, although this was usually made from inferior resin. Pliny also mentions a special ‘intoxication resin’, rarely found except in a few places in the foothills of the Italian Alps. It was made of the ‘untreated flower of resin’ and thin, short chips of wood, crushed and steeped in boiling water until melted. This somewhat mysterious product apparently had medicinal applications.11

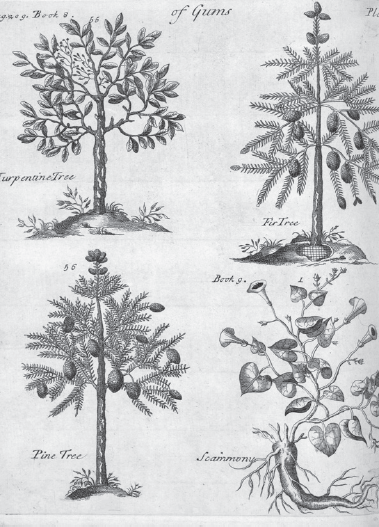

Pine tree, fir tree, turpentine tree: an illustration to Pierre Pomet’s A Compleat History of Druggs (1737).

Mosaic, late 2nd or early 3rd century AD, from St Romain en Gal, showing two farmworkers coating the inside of porous pottery jars with pine pitch.

Columella (AD 4–c. 70), the Roman writer on agriculture, mentions several different kinds of pitch, including Bruttian pitch, Nemeturican pitch from Liguria and pitch of the Allobroges from the Savoy region of the French Alps. Rasis was ‘a kind of crude pitch’, for which he gives no provenance. They clearly had different qualities, but he says nothing about the trees with which they were associated.12

Pitch is an extraordinarily useful substance. It has anti-microbial and insecticidal properties, as well as the ability to set solid and form water-impermeable barriers, and makes a good adhesive. The ancient Egyptians used some form of pitch (possibly from pine trees) in the mummification process. The precise origin of resins used in the process is unknown, but Pliny wrote that the initial flow of pitch ‘has such strength that in Egypt they make use of it for embalming human corpses’.13 Recent research indicates that this is probably true: analysis of resins from Egyptian mummies has shown that tree resins, some of which were probably from pines, were present.

As a barrier to liquids, a preservative and a flavouring, pitch was frequently used in the ancient world during wine production. Columella had much to say on this subject. Ordinary pitch was used for waterproofing wine jars. The jars sunk into the ground were heated with burning iron torches, the old pitch was scraped, and new pitch was poured in and spread with a brush and wooden ladle to coat the insides. Jars that were above ground were cured in the sun for several days before being turned upside down above a fire that heated them until they were too hot to touch. Then hot pitch was poured in and the jars were rolled until every bit of the inside was covered.14

Purified pitch mixed with spices or seawater was for preserving the wine itself. Columella’s instructions for purifying Nemeturican pitch are complex. First it was washed three times with lye (alkali made from wood ash). Then Bruttian pitch and ‘old seawater’ (partially evaporated and stored) were added, and the mixture was left uncovered in the sun ‘during the rising of the dog-star’.15 It was stirred periodically until all the seawater had evaporated. Nemeturican pitch on its own could be used, mixed with warm seawater that had been reduced by boiling. When the pitch had settled the water was poured off, more was mixed in and it was stirred until it became bright red in colour. The pitch was allowed to stand in the sun for fourteen days, then mixed, first with a little fermenting wine must, then into the main body of the wine. Columella also recommended that powdered pitch, sometimes combined with spices, should be mixed into wine as a preservative. Purification may have been an attempt to reduce the distinctive flavor of the pitch. The Romans, it seems, did not want their wine to taste of pitch: Columella says that the flavour of the preservative should not be noticeable, ‘for that drives away the purchaser’.16

Pitch was still recommended as a preservative for wine in Geoponika (a tenth-century book of agricultural instructions compiled in Constantinople), first being washed with lye and then mixed with other resins, perfumes and spices. Wine jars were still pitched inside. Some people added wax to the pitch, but others counselled against this ‘because the wine will be astringent, and thus more readily turn vinegary’.17 Retsina, flavoured with pine resin, is still produced in Greece when all practical necessity for it has ceased. Reactions are mixed among those unused to it, with many regarding it as an acquired taste.

Pitch-coated or pitch-sealed jars were also used for preserving fresh fruit for winter; bunches of grapes (any overripe ones carefully snipped off), pears and apples are all mentioned in this context. Geoponika also contains instructions for this. Fruit should be stored in pitched wooden boxes filled with dry pine or fir sawdust. The stems of pears should be tipped with pitch before they are hung up to keep (pears with their stems dipped in a red sealing compound are still sold in Italian markets); in a jar of dried figs, a few dipped in pitch and interspersed among the rest would prevent them from going mouldy.

Numerous other minor uses were recorded. Pitch mixed with bull’s bile or amorge (the bitter, watery by-product of olive pressing) was used to deter ants; mixed with the juice of squirting cucumber, it killed bedbugs. Medicinal uses often related to treating skin lesions, sometimes in humans, but especially in animals. Geoponika mentions pitch mixed with sulphur as a treatment for mange in oxen, with olive oil and ash for treating cuts, or with salt as a poultice for suppurating wounds on oxen. For humans, a recipe for a mixture of honey, liquid pitch, oil, butter and pig fat against the cough is listed.18 Pitch was used to coat bronze and other metals to prevent tarnishing. It was used as a dressing for minor wounds on sheep incurred during shearing. For vain men it made a useful depilatory, and for artists it was a source of pigment. Such uses are also apparent in Chinese literature. From antiquity, the resin of Masson pine (P. massoniana) was known as a treatment for skin problems caused by parasites, and later Chinese works also listed the twigs, leaves, flowers, cones, bark and root as useful for their insecticidal properties.19

As a sticky substance that catches fire easily, pitch was useful in warfare. There are records of its use both in the classical European world and in ancient China, where it was recorded that a primitive but probably deadly weapon in the form of a flame-thrower was composed of gunpowder, pitch and various noxious substances. Flame-throwers became known later in medieval Europe, and were called fire lances in English.20

In North America native peoples used pine pitch as an adhesive. One of the most striking and spectacular examples of this use appears in the exquisite turquoise mosaics made by the Aztecs in the time just before the Spanish conquest. Shaped over wood carved into discs, animals and knives, and over other forms, including masks in which a human skull was sometimes used as a base, the turquoise was glued to the base material with resin. Another use was to glue stone arrowheads to wooden shafts. Pine pitch was used for waterproofing baskets and porous pottery.

Pears on sale in an Italian market in 2009. Their stems are sealed in the manner recommended 1,000 years ago.

In the seventeenth century, John Evelyn still recorded rosins, liquid pitch and tar as having uses for ‘Arthritic and Pulmonic Infections’, and for plasters after surgery. Mechanics (tradesmen generally) had ‘innumerable uses’ for them.21 Pomet said that pitch

cures all Sorts of Scabs, Itch, Tettars, Ringworms and other Vices of the Skin. Tar is better than pitch because in boiling the Pitch loses the more subtle and firey parts, and therefore it is proper for Coughs, Phthysicks, Hoarseness, and other Humours that fall upon the Lungs.22

|

Extraordinarily useful: pine pitch and tar were a major Swedish export, travelling the world for many purposes: here it is packaged for sheep-shearers in Australia. |

Tar and beeswax made a plaster good against the gout and old aches and pains. Minor uses of pitch continued to display an eclectic nature down almost to the present day: as stiffening and waterproofing for both tarpaulins and nineteenth-century miners’ felt hats; as a foaming agent that helped separate tin ore from rock in tin mines; and as sizing for the wooden boards used by oil painters, a method favoured by the eighteenth-century English artist George Stubbs. Even now, a pot of pine pitch under the name ‘Stockholm Tar’ is part of every farmer’s medical armoury for treating wounds and minor infections among livestock, and for grooms and farriers in the care of horses.

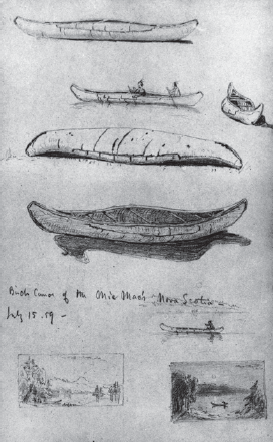

Pine products, especially pitch and tar, had an enormous part to play in seafaring and the politics of naval supremacy. Perhaps the earliest reference to their use in this context is biblical: ‘Make thee an ark of gopher wood; rooms thou shalt make in the ark, and shalt pitch it within and without with pitch’ (King James Bible, Genesis 6:14). The story of Noah’s Ark is only slightly spoiled by the possibility that bitumen was intended (Noah being closer to sources of this than the translators of the King James Bible were), but pine pitch was obviously known from early times. Prehistoric boats and ships built of wood leave few physical traces – and allowance has to be made for the possibility of even more fragile craft of withies and animal skins, or birch bark, perhaps waterproofed with pitch, now represented by Irish curraghs of canvas and bitumen, and Welsh coracles. Native North Americans certainly knew its value. David Douglas recorded canoes made of birch bark, with seams ‘neatly gummed with the resin of pine’.23

Pliny records that the first flow, the liquid pitch, was used for treating ship’s tackle, but the wooden ships of the classical world were constructed in a way that meant they did not need caulking. Pitch was still applied to their hulls as a preservative. This gave rise to a product known to the Greeks as ‘live pitch’, which was scraped off sea-going ships and mixed with wax. Considered much more efficacious for all applications in which pitch was normally used,24 it went by a curious name transmitted to the early modern world as zopissa, still evidently sought after in some form in the seventeenth century. Pomet said:

There is another black Pitch, which the Ancients call Zopissa, and is properly what the Mariners call Pitch and Tar, and which serves them to pitch their Vessels with. This Zopissa is a Composition of black Pitch, Rosin, Suet and Tar, melted together; and this is what is sold for true Ship Pitch, and us’d as such by the Apothecaries in their Compositions where this is required.25

Whatever its role in seafaring in the ancient world, pitch became increasingly important in late medieval and early modern Europe, as sea travel in ships caulked and sealed with pitch extended. Two kinds, one called ‘schippe picche’, were mentioned by the late thirteenth-century English monk Bartholomaeus Anglicus in his compendium On the Properties of Things (De Proprietatibus Rerum). Ships were treated to ‘kepe yat water schal nought come in to ye schippe’ (Oxford English Dictionary). He also said that there was much pitch to be found in Greece. Pitch sealed the caulked seams and preserved the timbers and rope work of ships. In the Royal Naval Museum at Portsmouth there is an undistinguished length of rope, frayed at one end, dark brown in colour and partially coated with a slightly greasy black substance. From the time when Henry VIII’s favourite warship, Mary Rose, sank in 1545 until her wreck was excavated in the 1980s, this lay anaerobically sealed under sediment on the seabed, preserving, remarkably, both the pitch and a smell of pine tar.

Hot pine tar being used to seal oakum-caulked seams on the wooden deck of the flagship Niagara.

In the human history of pine trees, the period of colonial expansion from the fifteenth-century voyages of discovery through to the development of steam power and iron ships emerges as a time when pine trees and their products played an essential part in economics and politics, especially in a period of shifting alliances between maritime countries during the eighteenth and nineteenth centuries. Pine pitch or tar, and turpentine and rosin, all essential for wooden ships, increased in importance as the naval power of the Western European trading nations grew, to the extent that they became both an important source of revenue for producer areas and a political bargaining point. In early modern Europe, barrels of Swedish pitch were traded around the North Sea to countries such as the Netherlands and England, whose depleted native pine forests could no longer supply their own. It was a cash crop, and each type was named for the district of northern Sweden from which it originated. Pitch became a trading monopoly of the Wood Tar Company of North Sweden, founded in 1648, the sole export privileges granted by the Swedish crown.26 Because of this, high-quality pitch became known as Stockholm Tar (in contrast to pitch of lesser quality produced in Finland and Russia). This monopoly increased the price of pine tar, doubling it between 1689 and 1699.27 Alliances between countries, cost and tax regimes influenced the use of Swedish pitch in Europe between the seventeenth and nineteenth centuries, as did new sources of naval stores.

The English marked out North American forests as a source of naval stores from the start, and the 1704 Act for Encouraging the Importation of Naval Stores from America allowed the Navy to pay bounties on tar, pitch, turpentine, rosin, hemp and wood for masts and spars. In time, this allowed the British to become exporters of naval stores to other European countries and drove down the price of Swedish products.28 During the eighteenth century the vast stands of longleaf pine growing on land unsuited to agriculture in North Carolina became a valuable source of resin products, replacing Sweden and its neighbours. Later in the century, politics in the form of the American Revolution intervened, and the British were forced back to Baltic supplies at a time when they were involved in the Napoleonic Wars, much of which were fought at sea.

James Gillray, Retribution; Tarring & Feathering; or The Patriots Revenge, hand-coloured etching, 1795. William Pitt, Prime Minister and chief agent of the war against Revolutionary France, is being tarred and feathered by radical sympathizers Charles James Fox (with tar on a mop) and the playwright turned MP Richard Brinsley Sheridan (tipping feathers out of a French Revolutionary ‘Liberty cap’). This was a highly visible, and possibly very ancient means of showing disgrace.

Detail of standing rigging from HMS Victory. All such rope work on sailing ships was protected against seawater with pine tar.

The demand for pine tar must have been immense. HMS Victory, Nelson’s flagship at the Battle of Trafalgar in 1805, carried 42 km of rigging. Of this, about 10 per cent was ‘standing rigging’ treated with pine tar as a preservative. Victory was one of the largest ships of the time, but pine products were a necessity for all ships, whether men o’ war, the merchant fleets of East and West Indiamen, or innumerable smaller trading and fishing craft, not only in Britain but in all the maritime nations of northern Europe, the Mediterranean and the Americas.

Control of supply through production or trade was a source of political power. Pitch was essential for waterproofing and preserving wood and rope, and all ships carried a pitch kettle among their gear. Sailors boiled pine tar to condense it further before coating the rigging and using it to seal caulked seams between the planks of a ship’s hull (giving British sailors their nickname of Jack Tars), and waterproofed canvas sheets to make tarpaulins. The demand for pitch and tar only eased when gradually, through the nineteenth century, the development of iron-hulled, steam-driven ships to replace wooden sailing ships resulted in less need for it, and tar from coal provided competition. At the same time, new markets developed for pine products, especially turpentine and rosin.

The resin for turpentine was always extracted from living trees in pre-industrial times. Originally appearing in English as terebentine, the word turpentine derives from terebinth (genus Pistacia), a tree unrelated to pine and native to the eastern Mediterranean, whose highly valued resin it originally denoted. This is still available as Cyprian or Chian turpentine, from the island of Chios. By the seventeenth century, turpentine was also a name given to products from conifers including pines, firs and larches. Like pitch and tar, turpentine was a variable product whose qualities to some extent depended on area and producer. Pomet listed turpentine of Chio (terebinth) and

the Turpentine from the Pine Wood and the Bordeaux Turpentine. There are several others besides these to be met with in the Shops, which are nothing else but false Names given to them, according to their Adulterations.29

Then there were ‘true Venice turpentine’, Cyprus and Pisa turpentine, and Strasbourg turpentine, which was frequently sold in Holland. Turpentine from southwest France was apparently not of the highest quality; it was ‘the common Turpentine, to which some give the name of Bayonne, or Bordeaux Turpentine. This is white, and thick as Honey, and comes most from Bordeaux, Nantz or Rouen.’ It was made from galipot, a ‘white hard rosin [resin]’ exuded from pines and came from Guyenne, a loosely defined province of southwest France in pre-revolutionary times.30

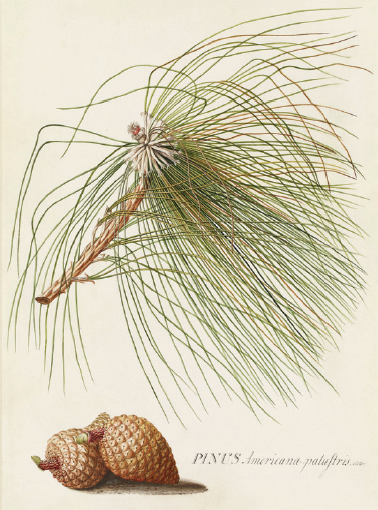

In 1831, John Davies recorded numerous types of turpentine – common turpentine from P. sylvestris, Bordeaux turpentine from P. maritima, Strasbourg turpentine from ‘P. picea . . . silver fir tree’ and Venice turpentine from larches. He also recorded two varieties probably unavailable when Pomet was writing 150 years earlier: one he called Terebintha canadensis (from American silver fir), and ‘American turpentine, furnished abundantly by the Pinus palustris, Lin, P. australis, Michaux, a tree growing principally in the southern states’.31

Georg Dionysius Ehret, Study of a Marsh Pine with Two Cones, 1725–70, watercolour and body colour on vellum.

Conifer turpentine was produced by true distillation, a colourless, aromatic liquid much used as a solvent, technically known as oil of turpentine. Pomet said that it

should be clear and white as Water, of a strong penetrating Smell; yet this is a mischievous Commodity, and great Cheats in it, besides the risque of Fire, and the little Profit there is got by it, which is the Reason why so many People will not deal in it.32

Nicholas Mirov, whose work involved much analysis of the chemistry of the volatile components of pine resin, commented that in the twentieth century the word turpentine was rather loosely applied to the distillate and that the concentrations varied according to the producer. Turpentine was, and remains, expensive.

The point at which resin from living trees was first distilled to make turpentine is unknown. The origins of distillation for alcohol lie in the ritual uses of wine by Dionysian cults in the late centuries BC,33 but the development of the pot still and worm (for cooling, both essential in the distillation of turpentine and many other substances) were essentially products of the alchemical investigations of the early Middle Ages. The search for the elixir of life led to many discoveries. It seems reasonable to assume that tree resins, like numerous other organic and inorganic substances, were used in these experiments.

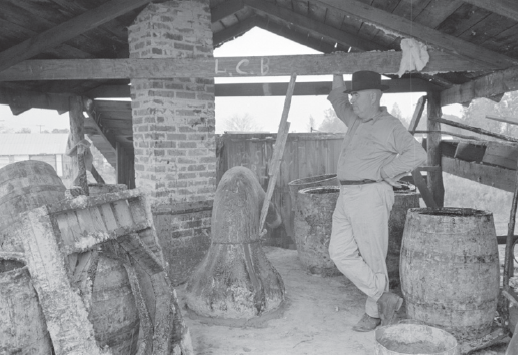

Pot stills remained in use into the nineteenth century, and using them was dangerous. Temperature control was crucial; the distiller had a narrow band between 363°F and 392°F (184–200°C) that gave optimum results. If the mass cooled during distilling, vapour trapped in it resulted in a danger of it boiling over; heating too fast created too much vapour. Both could lead to disastrous fires. The process depended on the skill and experience of the distiller, who assessed quality by looking at the distillate, and listened to the sounds at the end of the worm to estimate how the resin was boiling.34 Adding water to resin improved the process. Turpentine distillation moved into the industrial age in the mid-nineteenth century with introductions such as thermometers for use in the stills, agreed standards and the design of a continuous process still.

Jan van Vianen after Jan van der Heyden, Ruins of a turpentine-oil distillery on the Passeerdersgracht in Amsterdam, 17th December 1683, c. 1690, etching and engraving. Fire and explosion were ever-present hazards for the owners of turpentine distilleries.

The turpentine industry led to a remarkable exploitation of the native pine forests of the southeastern USA in the nineteenth century, starting with the long-leaf pine forests of North Carolina. Since the eighteenth century the ‘piney woods’ had been exploited for wood, pitch and tar. By the 1830s oil of turpentine was more profitable, and the industry expanded with improvements in both transport and technology. It was pursued in a manner destructive to the forests:35 tapping the trees by ‘boxing’. This involved removing some of the bark and sapwood where a prominent root left the tree to make a hollow in which the resin collected. Above this, the bark and sapwood were partially removed in a distinctive pattern of downward-pointing chevrons extending up the trunk for a few centimetres. Down this ‘cat’s face’, with its downward-pointing, shallow ‘V’ cuts, the resin oozed from the damaged wood and collected in the box. The gum, as it was called locally, was scooped into barrels, taken to local centres and distilled for turpentine. Dried resin scraped from the face of the trees was also sold, but ‘scrape’ was lower quality than liquid resin.

The work was poorly paid and only those who controlled large areas of trees made much money from it. ‘Turpentining’ in the thinly populated pine woods initially depended on slave labour. Frederick Law Olmsted (1822–1903), a journalist who worked in North Carolina, remarked that

Negroes employed in this branch of industry seemed to me unusually intelligent and cheerful. Decidedly they are superior in every moral and intellectual respect to the great mass of people inhabiting the turpentine forest.36

They did much collecting and transporting of resin, a sticky, dirty task, as well as a lonely one. Poor whites also worked in turpentining – some were squatters who valued the isolation and opportunities for small-scale cropping the woods offered.

Quantities involved were vast, turpentine was relatively valuable and the industry had a huge impact as transport improved. The pine trees were worked to exhaustion by the late nineteenth century. Less destructive systems of extraction were trialled unsuccessfully, and extracting pitch and turpentine from stumps became futile when the stumps themselves were all consumed. Lumbermen began to compete with naval stores producers for the trees. The industry depleted the basis for its own existence and migrated south into vast tracts of untapped pines that still flourished in Alabama, Mississippi and Florida. In North Carolina today, only about 3,900 ha of old-growth longleaf pine remain from an original range of 37 million.37

A ‘cat’s face’ chevron pattern as a partially healed wound on a pine trunk, showing that the tree was once tapped for resin. |

|

A less destructive method of turpentine extraction developed in nineteenth-century France. Here, forests of maritime pine had been planted to stabilize sand dunes in Les Landes, southwest of Bordeaux, in the eighteenth century, a policy encouraged by Napoleon and subsequent administrators. The resin was collected by making a small incision at the base of a tree, and a gutter guided the flow into metal or clay collecting vessels. More expensive and labour-intensive, but less damaging to the trees, this method produced a higher-grade product. Eventually, the system was adopted in the eastern USA, but by the early twentieth century France dominated production of naval stores using resin from Les Landes and pitch from Aleppo pine forests in its colony of Algeria. European countries including the USSR, Greece, Spain and Portugal also developed as sources of supply. Tapping pines for resin is labour intensive. By the 1990s, production had moved to South American countries using introduced pine species such as slash pine. Increasing costs there led to a move to Southeast Asia using Sumatran pine, and China, where several species are tapped, most importantly Masson pine. Chir pine is also used in India. Of the ‘traditional’ Western producer countries, only Portugal remained important in the world markets, although some countries, such as Russia, were producers that consumed almost all production domestically.38

Turpentine was almost as useful as pitch. Historically, it was much employed as a medicine despite being poisonous. ‘All the Turpentines,’ said Pomet,

yield a great deal of Oil, and volatile acid, or essential Salt. They are very aperitive, proper for the Stone, and for Colicks, Ulcers of the Kidney and Bladder, Retention of Urine and Gonorrhoea . . . It gives the Urine a Violet Smell, and creates sometimes a Pain in the Head.39

Samuel Pepys, who suffered from kidney stones, was one person who found turpentine a useful medicine. On 1 January 1664, he recorded that he talked at dinner with a doctor ‘whose discourse did please me very well, about the disease of the stone, above all things extolling Turpentine, which he told me how it may be taken in pills with great ease. There was brought to table a hot pie made of a swan.’40

Turpentine also had dangers. John Davies warned that,

Adminstered internally in large doses, it produces, in the first instance, nausea, vomiting and abundant alvine evacuations; afterwards, it is absorbed, and it produces a lively excitement throughout the whole economy, as is evinced by the frequency of the pulse, the heat and redness of the skin, cephelagia, vertigoe, &c.

A pot still for turpentine in Florida, 1930s.The owner is facing the ‘gooseneck’, the tube leading the distillate from the top of the still out through the wall into a coiled condensing tube.

Like others before him, Davies recommended turpentine for urinary tract problems, among other things:

It is employed with great advantage in the last period of chronic catarrhs of the bladder . . . it is frequently applied externally to cleanse wounds and ulcers, and it enters into the composition of numerous salves and irritating plasters.41

Another important use of turpentine was as a solvent. House painters, artists, carriage makers and furniture makers were among those who had cause to use it. It helped to thin oil-based paint and to clean brushes that had been used with it. For those needing varnish – such as makers of musical instruments, furniture and artists – turpentine and pine resin were both part of an armoury of ingredients including many gums, solvents and waxes. The exact nature of these and the quantities in which they were combined were often kept secret and could give significant differences, for instance, in the sound of violins treated with them. Common turpentine (resin) was used to make printer’s ink, and resin and oil of turpentine melted together was used by farriers to make coarse varnish, ‘but this is a Composition they are forced to make in private or bye Places, for fear of Fire’, noted Pomet.42 In the mid-nineteenth century, turpentine found new uses as an ingredient of a North American lamp fuel known as palm oil, and as a solvent in the nascent rubber industry.

Rosin, the residue from turpentine distilling, is clear and sets to a hard, brittle, amorphous mass that melts easily at relatively low temperatures. Its colour varies from dark brown and quite opaque to pale yellow and clear, the finest grade. For many centuries it had fewer applications than turpentine and its value fluctuated. The most often quoted use is as a lubricant for the bows of stringed instruments, a practice that helps the bow grip the strings more easily and gives a better sound. The larger the instrument, the softer the rosin should be. Another, less visible nineteenth-century use was as an ingredient of composition, a chalk-based mixture pressed into wooden forms for decorative mouldings.

In the early years of turpentine distilling in North Carolina, the value of rosin was often so low that it was simply discharged onto waste ground or into lakes. Uses were found for rosin in the making of varnishes and soaps, but a new and important use evolved in the 1820s. At this time papermakers began to use rosin to size paper and make it less absorbent, a use that grew as their industry expanded. It became more valuable and eventually was exported too. Discarded rosin was exploited for profit from around the end of the American Civil War well into the twentieth century.43

Although pine products still find many of their traditional uses, for instance as remedies for coughs, other uses have been superseded by synthetic products developed from oil during the twentieth century. Some new markets also developed: rosin yielded a product that was used in vinyl discs for the music industry until they were displaced by compact discs in the 1980s.

Experiments, scientific and otherwise, revealed that the chemistry of pine resin varies widely according to the species. It was a major focus of study for Nicolas Mirov, who told of unexpected hazards when resin distilling started in California during the American Civil War. Correct identification of tree species was essential. Ponderosa pine was a species whose resin was safe to distil, but Jeffrey pine, which is very similar in appearance, contains heptane, a highly inflammable hydrocarbon. It is a constituent of petrol, the substance that makes petrol engines ‘knock’. The two species were sometimes confused by distillers, and heating a pot still loaded with Jeffrey pine resin was like ‘building a fire underneath a gasoline tank’. Mirov provided heptane extracted from Jeffrey pine resin, which was sometimes called the ‘gasoline tree’, for the development of the octane scale for petrol.44

Authors constantly mention the hazards of naval stores. They must have caused many fires, and were perhaps instrumental in one of the most famous conflagrations of all time. In the seventeenth century, London, a major port, contained many chandlers’ shops packed with naval stores, which worried John Evelyn. On 5 September 1666, he felt vindicated, writing in his diary:

The coal and wood-wharfs, and magazines of oil, rosin, &c, did infinite mischief, so as the invective which little before I had dedicated to his Majesty and published, giving warning what might probably be the issue of suffering those shops to be in the City, was looked on as a prophecy.

The Great Fire of London had finally burned itself out, but not before it had consumed, among other things, vast quantities of naval stores.45

Methods for extracting pitch, turpentine and other pine derivatives underwent great changes in the late nineteenth century, partly as new papermaking processes developed. Products were first distilled directly from cut wood, but then became by-products of the pulpwood and paper industries. ‘Sulphate naval stores’ is the name given to pitch and turpentine extracted from tall oil, an anglicized version of Swedish tall olja, pine oil. This is skimmed off during papermaking by the Kraft process (a method of making paper using sodium hydroxide and sodium sulphide). Tall oil is ‘a mixture of resin acids and fatty acids (mostly unsaturated), together with unsaponifiables’,46 which can be further processed. Pine oil is, among other things, ‘a good emulsifier, an excellent solvent, an effective germicide . . . an effective frothing agent for floating off impurities’.47 Many benefits are claimed for the Kraft process, including the fact that by-products can be burned to generate power, but it generates a most noxious smell as gaseous sulphur compounds are also produced.

Pouring rosin into containers to set, France, 1950s.

Until recently, gum naval stores produced from resin tapped from living trees were considered better than tall oil products, which often suffered from odour problems and had a tendency to crystallize. Coal-tar distillation, developed in Germany by the mid-seventeenth century, also expanded rapidly after 1845, its derivatives replacing pine products.

Traditional uses of rosin and turpentine – in soap, paper size, paint and varnish – are still important in developing countries, but both products are now also hugely important as raw materials for the chemical industry. They are chemically complex and can be broken down into many constituents. Modern industrial applications of rosin still include sizing paper, and it is also an ingredient in adhesives, printing ink, fluxes, surface coatings on pharmaceutical tablets, chewing gum, synthetic rubber, detergents and chewing gum. Alpha-and beta-pinene extracted from turpentine are used in the synthesis of fragrances, flavours, vitamins and resins. Turpentine is further processed by fractional distillation; components such as citronellol and menthol are used in flavours and fragrances,48 but it is synthetic pine oil, another derivative, which lends the characteristic pine smell to disinfectant.