P

Peanut Machinery

Various kinds of equipment has been developed specific to the culture and harvesting of peanuts. Since this crop is regional in nature, few advertisements or other information reached the general agricultural press. Within this section are a number of items located in our research. It is to be assumed that there are numerous other items suitable for this heading.

Ferguson Manufacturing Co., Suffolk, Va.

A 1917 advertisement illustrates the New Ferguson Peanut Picker. This machine was designed to pick and stem the crop. Of all-wood construction, it typifies the construction of many farm machines of the day. No additional information has been found on this firm.

Williams Mill Manufacturing Co., Texarkana, Tex.

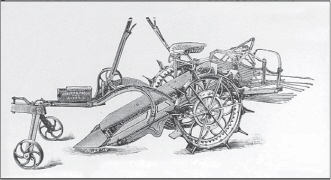

From about 1920 comes this illustration of the Williams peanut digger. This unit appears to be a modified form of the potato digger; the latter had been well developed by this time. A noticeable difference was the steel tines to the rear of the machine which left the vines in a windrow to the side of the furrow.

Williams offered its peanut thresher for some years, although little information has been found regarding this company. Once the peanuts were separated from the vines, the hay was conveyed to a stack. This peanut thresher was designed to “leave the hay in the best possible feeding condition.”

Plows

From ancient times, the plow has been considered to be a primary tillage implement. Until recent years, the disc harrow and various other tillage devices have all been considered to be secondary tillage implements. With today’s emphasis on minimum tillage or no-tillage farming, the plow has lost its dominant role, one that it held for centuries. Yet, without the plow, the vast plains of the United States and Canada would not have become productive farmland.

Until the 1820s, most plows used a wooden moldboard. About this time, the cast-iron plow appeared; by 1840, the majority of plows were made of cast iron. These plows were quite satisfactory in the Eastern states, but the heavy black soil of the Midwest was another matter. Cast-iron plows would not scour in these soils—this led to the development of the steel plow.

John Deere built his first steel plow in 1837. It proved to be very popular from the beginning. Within a few years, the John Deere plow was well known in the Midwestern and Southern states. Who actually built the first steel plow is a matter of conjecture, but, in 1833, John Lane of Chicago built a steel plow. His invention did not gain the attention that followed the Deere plow, but it was John Lane who conceived the idea of a three-layered moldboard, hard on its outer surfaces, but with a soft center. Eventually, the soft-center moldboard was built by virtually every steel plow manufacturer.

Other important developers of the steel plow were Major Andrus, Deere’s early partner in the plow business. Andrus went on to form the Grand Detour Plow Co. Another important figure in the plow business was William Parlin, Canton, Ill. The firm of Parlin & Orendorff emerged as a major plow maker.

Recognizing the deficiencies of the cast-iron plow, many inventors attempted to devise a method of building one of chilled iron. In foundry parlance, a chill is a device—often of iron and sometimes water cooled—that is placed near the mold cavity. When iron is poured into the mold, the chill quickly absorbs heat from the iron, causing the outer surfaces to cool more quickly than the inner parts. This hardens or chills the outer surface, making it very hard and also capable of acquiring the “land polish” required for scouring in black, sticky soil. Several inventors achieved some degree of success, but James Oliver was by far the predominant force in the development of the chilled-iron plows. Thus came the Oliver Chilled Plow Works; this company was a leader in manufacturing plows of this type.

Already in the 1840s, there were thoughts of building a sulky plow, a design that carried the beam and moldboard on wheels. These made little progress into the 1860s, with some designs appearing at that time, but farmers were not flocking to buy them. For one thing, many farmers thought that the horses had enough work pulling the plow itself, without carrying along still more mechanism. Many others were barely able to afford a simple walking plow, much less the more expensive sulky plow. At this point, the idea of a riding sulky plow met with even less favor.

Numerous sulky plow designs came onto the market in the 1870s, but the Gilpin Moore Patent of 1875 finally brought a truly successful sulky plow to the market; this plow was manufactured by Deere & Co. A year later, W.L. Casa-day received a patent on a sulky plow; this design was subsequently marketed by Oliver Chilled Plow Works. Moline Plow Co., began making sulky plows based on the patents of G.W. Hunt in 1884 and numerous others followed suit.

By definition, a sulky plow is a wheeled plow with one moldboard. A gang plow was usually considered to be a two-bottom wheeled plow, but this definition was later broadened to any plow with two or more moldboards. Jones Malone, a farmer near Orena, Ill., claimed to have made the first gang plow and also claimed that the patent was stolen from him. However, once the sulky plow came to success in the 1870s, the gang plow soon followed. Usually, farmers would pull a sulky plow with three horses and a gang plow with four or even five horses.

Sharpening the plow lays was an annual process. Most farmers kept an extra set of plow lays on hand in case one should be spoiled in an encounter with a rock. If the damage was not too severe, the local blacksmith could put it in the forge and draw the metal to a sharp edge once again. Every farmer had his favorite blacksmith. Undoubtedly, some were better at plow work than others. For those who were skilled in the art, a good income was assured, since the need to sharpen plow shares never ended.

By the 1890s, some attempts were being made to build large plows for use with steam-traction engines. These early attempts were largely unsuccessful, partially because the traction engines were not yet developed for the heavy work of plowing. By 1900, special engine gang plows were a reality and these were built and sold in limited numbers for about 20 years. By that time, the smaller tractor plows had been developed, having two, three or more bottoms. As a result, the huge engine gang plows faded from the scene. In addition, disc plows were coming into use in some areas, so the moldboard plow was not needed in those regions.

With the coming of minimum tillage and no-tillage farming, the time-honored moldboard plow faded from the scene in the 1960s and today is used only to a limited extent in most regions. However, it is of interest that in Great Britain and many other parts of the world, plowing still remains as the primary tillage method.

Allis-Chalmers Manufacturing Co., Milwaukee, Wisc.

(See LaCrosse Plow Co.)

American Plow Co., Madison, Wisc.

Aside from this 1905 advertisement, no information has come to light on the American Plow Co., or its line of plows, cultivators and other implements. Its interesting trademark leaves the impression that these plows were sold all over North and South America.

Ames Plow Co., Boston, Mass.

An article in the Feb. 17, 1872, issue of Boston Cultivator, delves at length into the success of Ames Plow Co. and illustrates its huge warehouse at the Faneuil Hall Market. At the time, Ames Plow Co. was a major supplier of almost every kind of farm implement on the market, but it eventually faded into obscurity.

B.F. Avery & Sons, Louisville, Kty.

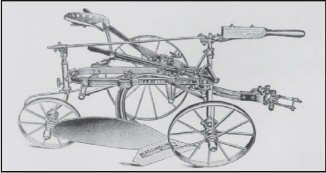

B.F. Avery & Sons Co., was incorporated in 1877 for $1.5 million. Benjamin Franklin Avery had founded the company in 1825 with $400 in capital. Over the years, the company built countless models of plows; this is a sulky model of 1917.

B.F. Avery offered this Mixed Land Plow in its 1916 catalog. It was designed to work well in varying soil conditions, thus the trade name. Avery was a long-standing builder of plows, beginning in the days of the cast-iron plow with a small factory in Clarksville, Va.

By 1916, B.F. Avery was offering a series of tractor plows. The continuing popularity of the Avery line prompted further expansion, including the acquisition of the Champion line of hay and harvest tools from International Harvester Co. After a long career in the farm equipment business, Avery merged into the Minneapolis-Moline Co., in 1951.

Boggs Manufacturing Co., Atlanta, N.Y.

Nothing at all is known of this firm aside from this 1928 illustration of its Neufang two-way tractor plow. The company had previously gained attention with its line of potato warehouse machinery, including graders, sorters and other equipment.

David Bradley Manufacturing Co., Bradley, Ill.

David Bradley had family roots in America traceable back to the 1630s. The family moved to Chicago in 1849, becoming involved in the retail seed and implement business in the 1860s. Through a series of events, the company eventually became David Bradley Manufacturing Co., in 1882. Shown here is the David Bradley X Rays Sulky Plow of 1897.

An 1897 advertisement calls this model the XX Rays Gang Plow. This model featured an improved hitch system. One of the major difficulties with sulky and gang plows was to achieve the correct hitch so that the plow would run easy and perform as it should. Some farmers achieved this skill. For others, setting up the hitch correctly was always a problem.

A 1903 advertisement of the X Rays sulky plow illustrates its unique lift system whereby “a little girl six years old can raise the X Rays with 10,000 lbs. weight on the front end.” David Bradley implements were marketed through Sears, Roebuck & Co. for some years, with the latter finally gaining control of the company.

Bryan Plow Company, Bryan, Ohio

It appears that in 1905, Bryan Plow Company specialized in walking plows and disc harrows. The company’s 1905 steel-beam version is shown here. Little is known of this firm.

Bucher & Gibbs Plow Co., Canton, Ohio

Established in 1864, Bucher & Gibbs Plow Co., had its line of Imperial plows on the market during the 1880s. Shown here is the Imperial Prairie Plow, a wood-beam version designed especially for the black prairie land. It was also built in a steel-beam style.

During the 1880s, the Imperial Gang Plow from Bucher & Gibbs took this form, using two wheels instead of the three-wheeled model made famous by Gilpin Moore. Note the four-horse even-er on this plow. Every company had a different method of assuring that the plow moved forward in a straight line, crowding in neither direction. To achieve this desirable goal, many kinds of eveners and hitches were designed, some by companies specializing in this business.

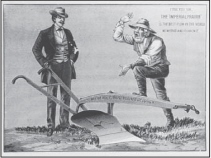

Probably as comic humor, Bucher & Gibbs ran this 1900 advertisement of the Imperial Mobiliser, an auto-plow that existed only in the mind of the engraver. However, many readers took the ad seriously, deluging the factory with inquiries. Red-faced officials then had to reply that the whole thing was a joke. Ironically, the concept would become a reality in only a few more years.

At some point in its history, Bucher & Gibbs Plow Co. came under control of the Myer’s interests at Ashland, Ohio. For some years, the company was actually owned by principals of F.E. My-ers Co., the famous pump manufacturers. For 1903, Bucher &Gibbs offered this unusual Imperial Two Furrow Plow that would turn a furrow from 8 to 10 inches deep and 24 to 26 inches wide. Trade directories list the company into the late 1950s.

J.I. Case Co., Racine, Wisc.

I. Case Co., Racine, Wisc.

(See Grand Detour Plow Co.)

J.I. Case Plow Works, Racine, Wisc.

This company was formed by J.I. Case of threshing machine fame in 1878, when Case took over the firm of Case, Whiting &Co. This company was an entirely separate entity from J.I. Case Threshing Machine Co. After Case’s death in 1892, a bitter rivalry ensued between the two companies, finally ending when the Plow Works was sold to Massey-Harris in 1928. The latter then sold all rights to the “Case” name back to the Threshing Machine company. Shown here is the 1897 version of the Case Sod and Stubble Plow.

In 1890, Case introduced its Racine Sub-Soil Plow, a design not often seen in contemporary catalogs. It was built specifically to break up hardpan that occurs naturally in some soils. This provided a much better seed bed and crop growing conditions.

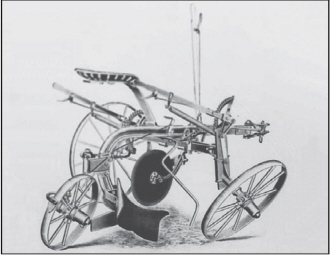

J.I. Case owned a famous race horse called Jay-Eye-See. His fame led to the introduction of numerous Jay-Eye-See implements, including the Jay-Eye-See Sulky Plow of the 1890s. This small two-wheeled design was quite popular.

Already in the 1890s, Case had introduced its Triumph line of plows, with its Triumph Gang Plow being illustrated here. This was a foot-lift plow that was easy to raise and lower by foot pedals.

An 1895 advertisement from J.I. Case Plow Works illustrates its Triumph Sulky Plow, noting that it “Triumphs over all hard ground.” Since many plows would not penetrate hard ground, any company having such a plow would immediately gain the attention of interested farmers.

J.I. Case Plow Works often made claims for the lightness of draft in its plows. To prove the point they often conducted live demonstrations as shown here from April 1895. This test, done at Wyoming, Ill., shows one of the J.I. Case representatives “playing horse.”

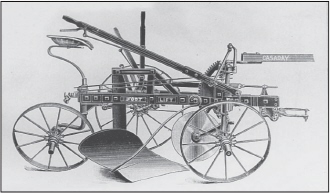

From 1906 comes this illustration of the J.I. Case Spinner Sulky Plow. The company built literally dozens of different plows during its long career, ending in 1928. At that time, Massey-Harris Co. bought out J.I. Case Plow Works.

Chattanooga Plow Works, Chattanooga, Tenn.

International Harvester Co. bought out Chattanooga in 1919. The latter had developed a considerable business, particularly in the Southern states. Shown here is an example of its No. 95 chilled-iron walking plow, one of many different models from this company.

Cockshutt Farm Equipment Ltd.,Brantford, Ontario

(See Frost & Wood)

Coffeyville Implement & Manufacturing Co.,Coffeyville, Kan.

By the turn of the century, a few companies were building sulky attachments to convert the walking plow with a riding attachment. Shown here is a $15 set-up that consisted of axle and wheels, plus the suitable levers for leveling the plow and the raising device.

Reflecting the objection of some farmers to a riding plow, the Banner riding attachment was designed so that “it can be adjusted so there will be no more draft with the rider on the seat than there is to a walking plow.” Since the Banner riding attachment was clamped to the plow beam, there was no need to drill any holes. All that was needed was a wrench that was supplied with the attachment kit.

Dayton Plow Co., Dayton, Ohio

Numerous plow companies were in operation during the 1880s, including Dayton with its Perfected Perfection Plow of 1887. Like many plow companies, its products were not widely distributed, it did little advertising and was not in business for more than a few years. Thus for Dayton and many others, little information now exists.

Deere & Co., Moline, Ill.

John Deere built his first plow in 1837, with many more in 1838. From then on, the story is well known of how John Deere built up a huge industry, beginning with a steel plow. A 1912 advertisement commemorates this achievement, illustrating an early example of the famous John Deere trademark.

Deere perfected its breaking plow with the Prairie Queen model shown here; this one even included a rolling coulter, a definite improvement over the earlier knife coulter. Production of the Deere breaking plows continued at least into the 1920s; by then, most of the virgin prairie had come under the plow.

The John Deere Red Jacket Plow was a well-known walking plow built for decades. For reasons now unknown, some farmers referred to these plows as “stirring plows.” Whatever they were called, plows were an essential part of frontier life. If tough conditions forced a wagon train to leave part of its load behind, seldom was the plow one of the victims. It was as necessary to the new life on the frontier as the ax and the hoe.

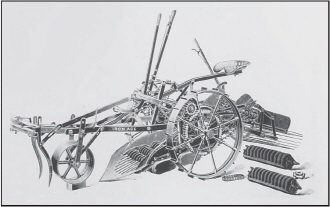

In 1875, Gilpin Moore patented a new sulky plow design, immediately put into production as the Gilpin Sulky Plow. This new design immediately launched Deere into a new era of the plow business, with the Gilpin and its successors continuing into the Deere line for decades to come.

For 1889, Deere illustrated its Gazelle Sulky Plow as part of the line. It was an improved style of the Gilpin sulky, pioneered several years earlier. New developments continued apace, with Deere & Co., remaining as a leader in the manufacture of steel plows.

A 1908 Deere catalog illustrates the company’s Southern Sulky Middlebreaker. This style was developed especially for certain regions of the United States, particularly where semi-arid conditions were prevalent. Various kinds of Deere middlebreakers were offered in the following decades.

Certain conditions called for the two-way sulky plow. With this design, it was possible to start at one side of a field and plow to the other with no back furrows and no dead furrows. Two-way plows were particularly adapted to hilly ground and small, irregular-shaped fields.

In the early 1900s, Deere & Co. came forth with its New Deere Gang Plow, an improved design that remained in the Deere catalogs for years to come. Immensely popular, the New Deere plows were marketed everywhere, including many foreign countries.

Recognizing the coming of motive power, whether from a steam traction engine or a tractor, Deere developed an engine gang plow in the early 1900s. This four-bottom engine gang of 1908 was but one of several early John Deere designs; the company built styles as large as a huge 14-bottom model designed for use with the largest steam-traction engines or tractors.

Deere & Co. pioneered the development of the tractor plow, beginning with its engine gangs in the early 1900s. By 1919, the small farm tractor had arrived. With its coming, Deere offered a series of tractor plows to meet the demand. The company continued to build plows until the changing tillage methods of recent years brought them to an end.

Economist Plow Co., South Bend, Ind.

In the 1880s, Economist Plow Co. offered its Solid Comfort Sulky Plow, a new design with a steel frame, but still using a wooden plow beam. Little is known of the company; by the early 1900s, the Solid Comfort was being built by Syracuse Chilled Plow Co., Syracuse, N.Y.

Emerson-Brantingham Co., Rockford, Ill.

Emerson Manufacturing Co. had a long career in the plow business, reaching back at least to the 1880s. One of its popular early designs was its Prairie Breaker, offered in 12-, 14- and 16-inch sizes. Made only in a wooden-beam design, this plow used the familiar prairie breaker moldboard designed to completely cover all the vegetation it turned over.

Like many other companies, Emerson-Brantingham offered a two-way plow, with this one having a built-in power-lift system. With this design it was only necessary to push a foot lever to raise the plow, with power from the wheel taking care of the mechanical duties.

Emerson-Brantingham was a pioneer in the farm tractor business and likewise was early to offer a tractor plow with a self-lift attachment. With this device, the operator pulled a rope to engage the lifting mechanism. Pulling it again dropped the plow into the ground once more.

The E-B No. 90 Tractor Plow was one of many different designs offered over the years. This plow was of independent-beam design, meaning that each plow standard was on its own individual beam and the depth of each plow was controlled by a plowman on the large platform seen here. Individual gauge wheels controlled the depth of the plows.

A.C. Evans Co., Springfield, Ohio

This company was one of the partners forming American Seeding Machine Co., in 1903. Prior to the merger, Evans built grain drills and numerous tillage implements. The wing shovel plow pictured here was for hilling potatoes and similar work. The steel wings were adjustable by means of spread rods.

A.B. Farquhar Co. Ltd., York, Pa.

By the 1870s, Farquhar was building the Reese Combination Plow, probably under license from its inventor. This tool is shown here with the beam alone, plus various kinds of plows to be attached to the plow stock.

Farquhar’s Chilled Plow was offered in various styles and sizes into the early 1900s. Although the company remained in operation until the 1950s, there is no indication that it built sulky plows, gang plows or tractor plows.

Frost & Wood Co. Ltd., Smiths Falls, Ontario

Little is known of Frost & Wood, but, from all appearances, much of its line was acquired from other companies. For instance, this 1910 illustration of the Kangaroo Gang Plow is actually one from Cockshutt Farm Equipment Ltd., of Brantford, Ontario, Canada. Cockshutt was a pioneer Canadian plow maker.

The 1910 Frost & Wood plow line was actually the Cockshutt plow line. The latter became widely known for its plows, particularly in Canada. Eventually, Cockshutt, Oliver and others were merged into White Farm Equipment Co.

Fuller & Johnson Manufacturing Co., Madison, Wisc.

Fuller & Johnson had its roots in the plow business, going back to the 1840s. During the 1880s and 1890s, the company was especially active, with its New Eclipse Riding Plow appearing about 1900. In 1911, the company sold out its entire implement business, opting to concentrate all its efforts on manufacturing gasoline engines.

Gale Manufacturing Co., Albion, Mich.

By the 1870s, Gale Manufacturing Co., was offering many kinds of plows, including the rod-beam plow shown here. This unusual design replaced the usual wooden beam for three heavy steel rods. Also of interest is the unusual knife coulter.

Being able to turn a square corner was always a desirable feature for plows and Gale Manufacturing Co. offered just such a plow in 1887. Known as the Big Injun, this plow had a rather unusual design, since the tongue or pole was mounted a couple of feet behind the evener, pivoting on the furrow wheel standard. Little is known of Gale Manufacturing Co., aside from a few illustrations.

Globe Plow Works, Davenport, Iowa

An 1888 advertisement illustrates the Hercules Tricycle Sulky Plow from Globe Plow Works. This unusual design lifted the moldboard vertically through a slide mounted to the rigid frame. Globe was a successor to Davenport Plow Co.; no information can be found on the latter entity.

Grand Detour Plow Co., Dixon, Ill.

In 1837, this company was founded at nearby Grand Detour, Ill., but moved to Dixon in 1869. In 1879, the firm was incorporated as Grand Detour Plow Co.; by 1890, the company was building more than 100 styles and sizes of plows. Shown here is its Little Yankee sulky plow of 1887. The company was originally founded at Grand Detour by Major Andrus and John Deere. After a few years, however, the two parted company. J.I. Case Threshing Machine Co. bought Grand Detour in 1919.

Hackney Manufacturing Co., St. Paul, Minn.

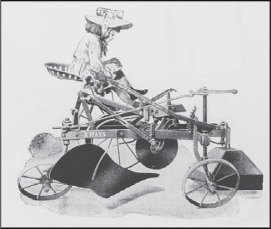

By the early 1900s, a few farmers were looking for a plow that could be run with gasoline power rather than horse power. About 1910, Hackney came out with its Auto-Plow; a unique design that carried the plows beneath the tractor while the farmer sat in a seat with leather upholstery. Priced at $1,500 to $1,800, the Hackney was ahead of its time and soon left the scene.

Hapgood Plow Co., Alton, Ill.

Hapgood was one of numerous small plow companies; small at least, when compared to Deere, P&O, Grand Detour and a few others. However, the company had developed an extensive line by the time this Hapgood-Hancock Disc Sulky appeared in 1902. Available in one-, two-, three- and four-gang models, it was designed especially for hard ground that the moldboard plow could scarcely penetrate.

A 1906 offering was the Piasa Bird Double Lift Gang Plow from Hapgood Plow Co. Current research has not determined the origins of Hapgood Plow Co., but repairs for its plows were available into the late 1930s. However, during World War II, the company disappears from the trade directories.

Heilman Plow Company, Evansville, Ind.

Hundreds, perhaps thousands, of different makes and models of walking plows were made in the century following 1830. Included was the 1892 Vulcan Chilled Plow. As manufacturing and transportation both developed, most of the smaller companies ceased to exist. The development of wheeled plows in the 1870s left little need for the walking variety.

Independent Harvester Co., Milwaukee, Wisc.

Almost nothing is known of the plows built by Independent Harvester Co., or if they were built by Independent or bought under contract from another plow maker. However, parts were available from Independent as late as 1944, after which time the firm disappears from the implement trade directories.

International Harvester Co., Chicago, Ill.

In 1909, IHC contracted with P&O (Parlin & Orendorff) to sell its plows. This helped IHC broaden its product line and gave a great boost to the fortunes of P&O. Over the next 10 years, P&O made many developments, including its Little Chief sulky plow shown here. When IHC bought out P&O in 1919, the Little Chief remained in the IHC product line for several years to come.

P&O plows included its No. 2 Diamond gang plow, developed in the early 1900s and remaining as part of the IHC plow line for several years after IHC bought out P&O in 1919. Despite the popularity of the recently designed tractor plows, horse-drawn plows remained with most manufacturers up to World War II.

To drain low-lying areas, the farmer could sometimes achieve the goal with a ditching plow, such as this one developed by P&O. IHC sold this style for many years. Although it never sold in large numbers, this plow was an essential implement in some areas.

In the period around World War I, tractor plows gained new importance, especially since many of the nation’s young men were off to war and every possible means had to be used for tilling the soil and planting the crop. This urgency greatly hastened the development of tractor plows, with the P&O Little Genius being one of the results. IHC continued to sell Little Genius plows in various models, but retained the Little Genius trade name into the 1950s.

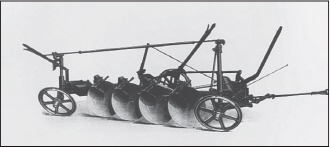

Before 1920, IHC was offering the P&O power-lift tractor disk plow in various sizes, with this four-furrow model typifying the line. While Midwestern farmers had no need for the disk plow, it was essential in many crop-growing regions and remained an important part of the tillage arsenal until minimum tillage practices emerged.

LaCrosse Plow Co., LaCrosse, Wisc.

When Allis-Chalmers bought out LaCrosse in 1929, A-C had its first line of tillage equipment. For a time after the purchase, the new line was advertised as Allis-Chalmers LaCrosse or A-C LaCrosse; it was simply a continuation of the old established LaCrosse line. One such item was the LaCrosse walking plow, offered in numerous styles and a design that the company had been marketing for years.

The origins of LaCrosse have not been made manifest during the present research; however, into the 1920s, the company was offering its LaCrosse Hustler Sulky Plow, advertised as an up-to-date and modern plow. As noted elsewhere in this section, tractor plows were becoming quite popular by the 1920s, but there were still many farms of this time using horse power almost exclusively for field work.

By 1915, LaCrosse was building this big tractor plow with a power-lift system. It could be operated entirely from the tractor, with no need for a plowman to raise and lower the independent beams. By the 1930s, this style was seldom sold. New designs were just as big and just as efficient, but with much less iron and much less weight than before.

Tractor plows were developed by LaCrosse during World War I. At this point, there were many small tractors coming onto the market, with a consequent demand for tractor plows. One lever was used to control the plowing depth, another lever on the furrow wheel kept the plow level and a trip rope raised and lowered the plow at will. This plow was the foundation of the A-C line of plows manufactured after the 1929 buyout of LaCrosse.

Larimer Manufacturing Co., Eola, Ill.

As noted elsewhere in this section, the ditching plow was an essential implement for farmers in many areas. Crops yielded poorly in wet ground and some system of drainage was essential. The Larimer Ditching Plow pictured here is equipped with a subsoil attachment and tile-bed shovel so that underground drainage was possible, even though the operation had to be repeated occasionally. This design is from 1909.

H.H. Lovejoy & Son, Cambridge, N.Y.

A small and indistinct illustration is the only clue found in the present research for this company. Shown here is its Cambridge Reversible Plow of 1906, one of more than 40 different styles available at the time. Reversible plows gained slight popularity in some areas, but the two-way sulky plows available by this time were probably better received by most farmers.

Lowell Steam Plow Co., Des Moines, Iowa

In 1905, the Lowell Steam Plow was announced. This huge plow was designed for use with steam-traction engines; the lift system used steam from the boiler for fully automatic operation. Little is known of the company or its plows; apparently the company didn’t remain in business for more than a few years; it does however, appear until about 1910.

Madison Plow Co., Madison, Wisc.

Fuller & Johnson in Madison was in the plow business until 1911 when it sold out to private investors; the company then being known as Madison Plow Co. Shown here is its Madison New Eclipse Sulky Plow; this one is equipped with a breaker moldboard. Madison Plow Co. appears in the trade listings into the late 1940s.

Massey-Harris Co. Ltd., Toronto, Ontario

Although Massey-Harris was a well-known Canadian manufacturer, its career in the U.S. plow business was launched with the 1928 purchase of J.I. Case Plow Works at Racine, Wis. The latter was a well-known American manufacturer with many designs for almost every plowing application. By 1940, Massey-Harris had launched its new No. 28 tractor plow; it was built in two- and three-bottom sizes.

Mittendorf Manufacturing Co., Hermann, Mo.

An advertisement of about 1909 is the only evidence to surface thus far on the Mittendorf Plow Sulky. This device was attached to almost any walking plow, giving the farmer a continued use for the plow and providing a chance to ride instead of walk.

Moline Plow Co., Moline, Ill.

Established in 1865, Moline Plow Co. quickly grew into a major plow manufacturing enterprise. In 1906, the firm began expanding with acquisitions of other product lines. An engraving of the 1890s illustrates the plant facilities, dwarfed by the locomotive heading to the countryside with another load of Moline plows.

During the 1890s, Moline Plow Co. launched its Flying Dutchman sulky, a design that proved to be very popular. The Flying Dutchman trademark continued until the days of World War I when anti-German sentiment prompted the company to withdraw the slogan for fear of unsavory connotations. This design was marketed for almost 40 years.

Moline Plow Co. offered its first foot-lift gang plow in 1897, as part of its Flying Dutchman line. Moline claimed to have revolutionized many aspects of plow manufacturing. Indeed, the company was among the most innovative of its time.

Yet another popular part of the 1900 Moline line was its Bismarck Sulky Plow. As part of the Flying Dutchman line, the Bismarck trade name had obvious German connotations and with many areas of the Midwestern states being dominated by farmers of German descent, the association was a beneficial one.

By the early 1900s, Moline Plow Co. had developed a disc plow for very hard ground and for use in certain areas where the moldboard plow was unsuccessful. Through the following years, Moline continued developing new designs, including a series of very successful tractor plows. Moline Plow Co. merged with others in 1929 to form Minneapolis-Moline Co.

Monmouth Plow Co., Monmouth, Ill.

An advertisement of the early 1900s illustrates the Monmouth walking plows; at the time these sold from $8 to $10. By this time, most walking plows had taken the same general form, with the steel beam being the prevalent design. Few companies were now manufacturing plows with wooden beams.

The New I.D. plows of 1906 “are noted for their lightness of draft, simplicity of construction and satisfactory working qualities.” By the mid-1940s, repairs for the Monmouth plows were available from Brown, Lynch, Scott Co., also of Monmouth. The latter firm fades from the trade directories by the late 1940s.

Morrison Manufacturing Co., Fort Madison, Iowa

Although the origins of Morrison Manufacturing Co. are unknown, the company was offering the Lenhart Sulky Plow as shown here in 1897. This interesting design used an exceptionally large tail wheel. The linkage between the furrow wheel and the tail wheel permitted square turns.

For 1903, Morrison offered a series of plows to its customers, including the New Morrison shown here. With great pride, the company pointed to the fact that when cutting 6 inches deep, a draft of only 338 pounds was required. By 1909, the company was known as Fort Madison Plow Co. The latter disappeared by 1918.

North River Agricultural Works, New York, N.Y.

In 1866, North River Agricultural Works offered several different plows, among them being this Mohawk Valley Clipper No. 1. It featured a steel moldboard and point; the latter being of an interesting design. The knife jointer is also of interest, but, at the time, rolling coulters were not yet a popular alternative.

Known as Fisher’s Patent First Premium Lever Plow, this 1866 offering from North River Agricultural Works demonstrates one of the first sulky plows. It was invented by Samuel Fisher of West Windsor, N.J. He acquired Patent No. 30,727 on this design in 1860.

Norwegian Plow Co., Dubuque, Iowa

For 1887, Norwegian Plow Co. offered its Honest Abe Sulky Plow. This design has several interesting points, including the unusual design of the tail wheel. This was a foot-lift plow, operated by a lever attached to the rear of the plow beam. The Norwegian was built for only a few years before disappearing from the scene.

Oliver Chilled Plow Works, South Bend, Ind.

Through great adversity, James Oliver built a successful chilled plow. Instead of the soft-center plow steel used by many, the Oliver design was a special alloy of iron with an exceedingly hard surface that would scour and would last for years of work. Shown here is an early example of the Oliver Chilled Plow. James Oliver acquired a great many patents for plows during a long career in the business.

Through the years, the Oliver plows rose to the top of the market, being very popular in all parts of the United States and in many foreign countries. In 1929, Oliver was a partner in the formation of Oliver Farm Equipment Co. An extensive coverage of the Oliver plows can be found in the author’s Oliver Hart-Parr (Motorbooks: 1993). Shown here is an Oliver one-way plow of 1929.

Parlin & Orendorff Co., Canton, Ill.

In 1842, William Parlin began building plows at Canton, Ill. The company operated under various titles until incorporating under the Parlin & Orendorff title in 1880. By this time, the Canton Clipper plows were well known; P&O was now known all over the United States and in many other parts of the world.

The P&O Clipper Tricycle Plow appeared in the 1880s; it is shown here being pulled by a team, although in heavy sod or certain other conditions, three horses were used. P&O built this style for a number of years, but followed it with many improved designs before the company was bought out by International Harvester in 1919.

An unusual style was this walking gang plow, offered by Parlin & Orendorff Co., in 1887. Sulky plows were then in vogue, so it seems unusual that the company would offer a walking gang plow rather than one on which the farmer could ride. William Parlin remained active in the business until his death in 1891.

By 1898, the Canton Disc Plow was available from Parlin &Orendorff. This design was especially suited to hard ground and certain areas outside of the Midwestern prairies. P&O also built the first lister in the 1860s.

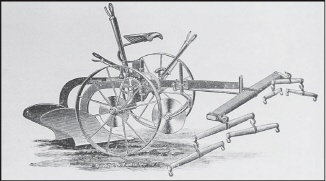

In 1909, International Harvester began marketing the P&O line, continuing in this manner until buying out the company in 1919. Already in 1910, P&O had developed its P&O Mogul Engine Gang Plow, a large and heavy design with individual beams. The plowman’s platform was needed to raise and lower the individual plow beams.

P&O was offering this modern sulky plow for the 1912 market. It featured its 3-in-1 X.X. adjustable moldboard. In fact, the latter design was furnished on all its Diamond and Success sulky and gang plows. When IHC bought out P&O in 1919, it purchased an established and respected member of the plow-making fraternity.

Plymouth Foundry & Machine Co., Plymouth, Wisc.

This company made feed cutters and other farm machines, but almost nothing can be found of its activities in the plow business except for this illustration. Pictured is Plymouth’s Hero steel beam plow, available in a 12- or a 15-inch cut.

David Prouty & Co., Boston, Mass.

An 1861 issue of the Boston Cultivator illustrates the Michigan Double Plough, as built at the time by Prouty. Apparently, a few other companies had attempted building a “double plough” but none had been eminently successful. In demonstrations of the Prouty, it proved successful, even in the hands of a relatively inexperienced plowman.

Racine-Sattley Co., Springfield, Ill.

Marshall Sattley began building plows in 1851. The success of the early plows caused him to locate at Taylorville, Ill., in 1858. Sattley was a self-made plow mechanic, having learned the trade from a local blacksmith who he later brought with him and continued in the plow business.

Sattley built his first successful gang plow already in 1863. From these beginnings, the Sattley line gained fame far and wide. Shown here is the company’s 1899 Hummer plow, a sulky design which its makers said “will plow anything anywhere.”

By the early 1900s, Sattley Manufacturing Co. reorganized as Racine-Sattley Co. One of its 1903 offerings was the Royal Blue Sulky shown here. This plow was arranged so that it could handle 12-, 14-, 16- or 18-inch bottoms simply by moving the beam to the appropriate position.

About 1915, Sattley was building the Wonder Gang Plow pictured here. It was a two-wheel walking plow, made especially for farmers who preferred this design to the three-wheeled sulky. Marshall Sattley died in 1907. Racine-Sattley continued into the 1920s. For some years after, the Sattley plows were built by Hummer Plow Works of Springfield, Ill.

Rock Island Plow Co., Rock Island, Ill.

With roots going back to the 1850s, Rock Island Plow Co. emerged as a major U.S. plow builder. When it is considered that the modern steel or chilled-iron plow did not appear until about 1840 and that there were thousands of farms needing a plow, it is a small miracle that American manufacturing capacity could fill the need. Most companies found their niche in the business and Rock Island found theirs with this New Model Walking Sulky of 1887.

Rock Island offered its New Rock Island Sulky to the market in 1903. Its “High-Low” design gained great popularity, along with the company’s extensive line of farm tillage equipment. In addition, Rock Island built hay tools and many other items, even venturing into the tractor market.

An unusual offering was the Rock Island No. 10 Triple Gang Plow. This three-bottom plow was horse-drawn, probably requiring six or seven horses for easy operation. Very few companies built a three-bottom horse-drawn gang plow. Rock Island Plow Co., was purchased by J.I. Case Co. in 1937.

Ruggles, Nourse & Mason Co., Boston, Mass.

Famous by the 1860s, this company has now been almost forgotten. The company was an early manufacturer of the old cast-iron plows. After the introduction of the steel plow, it came out with its own design by the 1850s. Shown here is its plow of the early 1860s. In 1866, Ruggles, Nourse & Mason was bought out by Ames Plow Co., also of Boston.

M. Rumely Co., LaPorte, Ind.

From all appearances, Rumely built its own plows for a time in the early 1900s. While the specialty was in engine gang plows, the Rumely Hercules Brush Breaker shown here was a design intended for use with tractor power. The heavy design of this plow made it nearly indestructible. Aside from a brief entry into the plow business, Rumely laid claim to the famous OilPull tractors.

St. Paul Plow Works, St. Paul, Minn.

An 1897 illustration shows the newly designed St. Paul Sulky Plow. Among its other features, this plow claimed to be ideal for turning a square corner when plowing; this was achieved largely through the linkage from the furrow-wheel standard to the tail wheel. Little is known about this company or its duration in the plow business.

Scientific Farming Machinery Co., Minneapolis, Minn.

In 1917, Guy E. Lincoln designed the Once-Over Tiller as being the ideal approach to creating a seed bed. This design used a steel-tooth rotor powered by a gasoline engine; in this illustration, a Cushman 8-horsepower two-cylinder model is attached. The Once-Over Tiller could be attached to almost any sulky plow. The company disappears after 1924.

Skandia Plow Co., Rockford, Ill.

A unique feature of the Skandia plow was that it could easily be converted back and forth from a breaking plow to an ordinary design with relative ease. For farmers having some of their land broken to the plow, with others remaining unbroken, this was cited as a distinct advantage. However, by the early 1900s, no further trace of the company has been found. The model shown here was illustrated in 1887.

South Bend Chilled Plow Co., South Bend, Ind.

This company goes back to the 1870s and the sulky plow designed by W.L. Casaday. Apparently, Casaday was associated with James Oliver for a time, but eventually formed his own company or at least associated himself with a company building his designs. Shown here is the Garland Riding Plow of 1890. Like many others of the time, it was designed to turn a square corner. As shown, the farmer is plowing from the center of the field outward, always turning the soil to the center. This left no dead furrows or back furrows.

By 1905, the Casaday High Lift Gang Plow was a reality, this being another of the Casaday designs. The Casaday was one of the first to eliminate the landside, thus reducing the draft of the plow.

From 1910 comes this illustration of the Casaday Foot-Lift Sulky, a rather modern plow for its time. By this time, plow makers had approached most of the problems in design and this plow even included a special adjustment for the pole or tongue so that the center of draft was correct. Apparently, this firm came under control of Vulcan Plow Co. in the 1920s, with the latter joining in the 1930 merger that created Farm Tools, Inc.

Alexander Speer & Sons, Pittsburgh, Penn.

For 1878, Speer offered this unique hillside plow that could be operated as either a right-hand plow or a left-hand plow. With this plow, a farmer could begin at one side of the field and plow to the other side, never having to make a back furrow or leave a dead furrow. Dozens of small companies like this one were in the plow business into the early 1900s.

Syracuse Chilled Plow Co., Syracuse, N.Y.

Shown here is the Syracuse Reversible Sulky Plow, also known as a two-way plow. With this design, it was possible to plow from one side of a field to the other without the need for back furrows or dead furrows. In 1912, this firm came under control of Deere & Co.

Did You Know?

In 1905, New Process offered its Long Knife Cultivator for $8.

J. Thompson & Sons, Beloit, Wisc.

In 1887, Thompson offered its Ole Olson Sulky Plow, the trade name being an obvious reference to immigrants of Scandinavian extraction. This plow remained on the market for some years, with parts being available from Thompson Plow & Engine Works at least into the late 1940s. After that time, the company slips into obscurity.

Universal Plow Co., Canton, Ohio

Advertised in the 1880s and 1890s, the Universal plow could be purchased with a steel moldboard or one of chilled iron. An 1887 advertisement lists the company at Canton, Ohio; by 1894, the firm is shown at Wooster, Ohio. After the 1890s, no further trace of Universal Plow Co. can be found.

Vulcan Plow Co., Evansville, Ind.

Vulcan had a long history in the plow business, with much of its trade being in the Southern states. One of its late catalogs illustrates the Vulcan Chilled Plow with a wood beam, noting that many farmers still preferred this style to the steel beam design. At some point in the 1920s, it appears that Vulcan came into control of the South Bend Chilled Plow Works.

In 1930, Vulcan Plow Co., merged with Roderick Lean, Hayes Pump & Planter Co., and the Peoria Drill Co., to form Farm Tools, Inc. This bolstered the four companies by giving them better marketing power, as well as helping them weather the disastrous Great Depression. Shown here is the Vulcan Zephyr Tractor Plow of the 1930s. Vulcan had developed this plow prior to the merger and Farm Tools, Inc. continued to manufacture it for some years to come.

Weir Plow Co., Monmouth, Ill.

By 1887, Weir had come out with its “three-wheel plow,” a new design with some unique features. Malleable iron chain transferred movement of the tongue to the furrow wheel, while the tail wheel was free to caster on its own. Weir continued in the plow business for some years; a well-known model was its Wild Irishman Sulky of the 1890s. By the 1920s, parts for Weir plows were available from Martin & Kennedy at Kansas City.

Wiard Plow Co., Batavia, N.Y.

George Wiard, who died in 1913, was the founder of Wiard Plow Co. His father before him was a plow maker. Shown here is a Wiard steel beam walking plow of the early 1900s. The company also built many different tillage implements and farm machines.

Parts for the Wiard plows were available at least into the late 1940s, after which time the company disappears from view. Shown here is the Wiard reversible sulky plow of the early 1900s. Curiously, George Wiard’s nephew, Harry Wiard, was also in the plow business, being one of the organizers of the Syracuse Chilled Plow Co., noted previously in this section. In the 1870-1920 period, hundreds of plow makers built thousands of plow models; only a few are illustrated in this section.

Trade Names

Potato Machinery

Specialized equipment for planting and harvesting the potato crop came onto the market in the 1860s; by 1910, there were more than 50 different companies making various kinds of potato plows or potato digging machines. Unfortunately, many of these companies advertised only to a specialty market, so illustrations of their equipment are difficult to find. Even so, this heading offers a cross-section of the equipment used to plant and harvest potatoes.

Today, vintage potato harvesting equipment is still found in use quite often; sometimes a potato planter or potato digger has been within the same family or the same locality for 60, 70 or even 80 years. Thus this equipment often has a greater utilitarian value than an antique value. Under these circumstances, the $50-$100 a vintage machinery enthusiast might pay for a planter or digger will be exceeded several times by family or friends wishing to keep one of these machines within its locality where it can continue its annual task of planting or harvesting the crop.

R.L. Allen & Co., New York, N.Y.

An 1869 issue of the Boston Cultivator illustrates the newly developed Empire Potato Harvester from R.L. Allen & Co., New York. The revolving tines separated the soil from the potatoes, leaving them on top of the row.

American Seeding Machine Co., Springfield, Ohio

For 1924, American offered this version of the Superior potato planter. By comparison, hand methods of planting were slow and laborious. However, some farmers lessened the work by using a cultivator to make large furrows for planting the crop. It was then planted and covered by hand. In 1929, American merged with others to form Oliver Farm Equipment Co.; the latter then produced potato machinery for several years.

Aspinwall Manufacturing Co., Jackson, Mich.

L.A. Aspinwall began development of a potato planter in 1861. After 20 years of work, a few were sold. With this encouragement, Aspinwall opened a factory at Three Rivers, Mich., in 1884, selling 50 planters the first year. Business continued at Three Rivers until 1891 when the company moved to Jackson. Shown here is an Aspinwall model of 1889.

By the 1890s, the Aspinwall potato planter had gained a considerable reputation. This 1894 engraving illustrates the planter at work. The Aspinwall pioneered the concept of a machine that would furrow, plant and cover the seed potatoes in one operation.

By 1900, Aspinwall had the most complete line of potato machinery anywhere in the world. Other companies entered the business, but Aspinwall seemed to be the leader. The company augmented its line with other items from sprayers to barrel churns to lawn swings by 1900, but potato machinery was the specialty of the company.

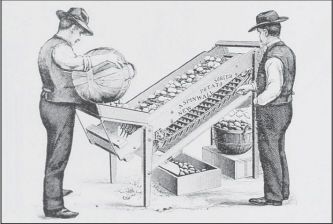

In 1900, Aspinwall began marketing its potato sorter. This was intended primarily for the commercial grower who found it necessary to sort potatoes by size before marketing. The new machine also helped clean the potatoes of dirt; as they made their journey across the sorter, an attendant could spot any spoiled or inferior product.

Aspinwall introduced this engine-powered potato digging machine in 1919. It is powered by a New-Way engine. In the early 1920s, Aspinwall went out of business. For a few years after, parts were available from John A. Watson Co., Houlton, Maine. L.A. Aspinwall moved on to McKenzie Manufacturing Co., La-Crosse, Wis. In 1925, at the age of 83, Aspinwall was busy developing new potato machinery.

Associated Manufacturers, Waterloo, Iowa

For 1917, Associated offered its potato sorter, powered of course, by an Associated gasoline engine. Numerous companies built similar machines; their primary role was to sort out the small potatoes from the larger, more marketable sizes. This one was available in three different sizes, ranging in price from $98 to $150, complete with engine.

Bateman Manufacturing Co., Grenloch, N.J.

In 1906, Bateman announced its Iron Age potato diggers in two different styles. The company also built potato planters along with other farm equipment. Bateman continued in business until being bought out by A.B. Farquhar Co., York, Pa., in 1930.

Champion Potato Machinery Co., Hammond, Ind.

For 1903, Champion offered a potato planter, as well as a two-horse digging machine. The potatoes and the soil were both carried up the open raddle chain, with the dirt falling through the chain and the potatoes landing on top of the ground to be picked up by hand. By the 1920s, Champion potato equipment was being offered from Messinger Manufacturing Co., Tatamy, Pa.

C.J. Cummings, Tully, N.Y.

An 1895 advertisement by Cummings notes that “over seventy-five different potato diggers have been built by me in the last twelve years.” Little more is known of this venture; in the 1920s, the Cummings-Otsego potato diggers were being built by Babcock Manufacturing Co., Leonardsville, N.Y.

Davenport & Prince, Downer’s Grove, Ill.

Potato machinery development flourished in the 1890s, with Davenport’s Automatic Potato Cutter and Planter appearing in 1895. This machine was designed to mark, furrow, cut, drop and cover the potatoes in one operation. Davenport planters remained on the market for some years, being offered by Davenport Planter Co., Wheaton, Ill., into the 1920s; parts for these planters were available at least into the late 1940s from this firm.

Deere & Co., Moline, Ill.

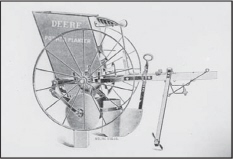

In 1896, Deere introduced the potato planter shown here, selling it through Deere & Mansur Co. Curiously, very little information can be found regarding this planter, aside from some announcements of 1896 for the new design, nor does it appear in the trade directories after 1907.

The John Deere Plow Co., catalog for 1908 illustrates the Deere potato digger. Potato plows like this one were common. These plows lifted the potatoes and, with the aid of a rake or a fork, the potatoes could be sacked for winter storage. Eventually, Deere got into the potato machinery business with its 1926 purchase of Hoover Manufacturing Co. Deere had sold the Hoover line for some years prior to the takeover.

Dowden Manufacturing Co., Prairie City, Iowa

In the 1890s, Dowden offered its potato cutter. It was designed to cut seed potatoes into a uniform size to work in any potato planter. The design of many planters was such that if the seed potatoes were too large, they lodged in the mechanism. A mechanical cutter was preferable to cutting by hand.

During the 1890s, Dowden began manufacturing its famous potato diggers. As shown, the machine straddled the row, actually taking dirt, potatoes and all and carrying everything over an open chain. The soil fell back through the chain, leaving the potatoes on top of the row. Dowden potato diggers remained on the market for decades; the company is listed in implement directories into the 1950s.

Emerson-Brantingham Co., Rockford, Ill.

Exactly when E-B entered the potato machinery business is unknown, but this attractive planter was available in its 1919 catalog. Among its many features, the E-B No. 1 planter also included an optional fertilizer attachment.

Emerson-Brantingham offered its E-B No. 2 potato digger in its 1919 catalog. As shown, it was furnished with the company’s own Type N gas engine. The latter had been designed as a power for grain binders. Another feature was the use of steel over-tires, as portrayed in this illustration. For road transportation, the overtires were easier to install than removing the lugs from the wheels.

A.B. Farquhar Co. Ltd., York, Pa.

Farquhar bought out the Iron Age line from Bateman Manufacturing Co., in 1930. Prior to that time, Farquhar had sold the Iron Age line for several years. Included was this No. 220 Iron Age potato digger. Machines like this included a four-horse hitch, but engine-powered diggers required only two horses.

Hist Manufacturing Co., Barberton, Ohio

For 1907, Hist offered this potato digger, advertising it as “strictly a two-horse machine.” At the time, many machines similar to the Hist required four horses for successful operation. By the 1920s, Hist potato diggers were being manufactured by Akron Cultivator & Manufacturing Co., Akron, Ohio.

Hoover Manufacturing Co., Avery, Ohio

In 1889, Hoover & Prout offered its potato sorter and sprouter. The revolving wooden reel permitted small potatoes to drop through, while the larger ones emerged from the end of the machine. In the process, any emerging sprouts were broken off so as to retard spoilage. Eventually, the company became known as Hoover Manufacturing Co.

During the 1880s, the Hoover potato digger assumed the form shown here; it remained essentially in this form for many years. The Hoover became quite popular, especially because John Deere began selling the Hoover in the early 1900s. Deere bought out Hoover in 1926.

International Harvester Co., Chicago, Ill.

During the 1920s, IHC began developing various kinds of potato machinery. Included was this two-row potato digger of the 1920s. It was pulled by the company’s new Farmall Row-Crop tractor, shown here in a large field with a large crop of potatoes coming off the chains.

LeRoy Plow Co., LeRoy, N.Y.

Little is known of the Boss Potato Digger aside from this illustration of the early 1900s. The company was active into the late 1940s, but it appears that B.F. Avery Co. may have acquired the Boss potato digger at some point. In the late 1950s, parts for the Avery-LeRoy potato diggers were available from the Minneapolis-Moline Co.

Oakfield Agricultural Works, Oakfield, N.Y.

An interesting design is shown with the Oakfield potato digger of 1895. This outfit lifted the potatoes after which they passed over a series of shaker bars to sift out the dirt, leaving the potatoes on top of the row. Aside from this illustration, no information has surfaced regarding the company.

Oliver Farm Equipment Co., Chicago, Ill.

From 1939 comes this photograph of an Oliver tractor hitched to an Oliver two-row potato digger. Not only was this a two-row machine, it was operated from the tractor PTO and rode on rubber tires. Eventually, the commercial potato harvest changed to include large self-contained units that would dig the potatoes, clean them and load them in a single operation.

S.H. Peek, East Aurora, N.Y.

For 1906, Peek offered the Reuther potato digger, a machine that became quite popular in many regions. By the 1920s, the Reuther digger was being built by U.S. Wind Engine & Pump Co., Batavia, Ill. Later, it was made by LeRoy Plow Co. noted above.

A.J. Platt, Sterling, Ill.

About 1910, the Keystone Hand-Drop Potato Planter appeared. This was a simple, but very popular design owned by many farmers for the household crop, as well as for commercial purposes. Seated above the press wheel, the farmer picked seed from the storage box, placing it in the chain slots shown beneath the hopper. The company remained active into the 1930s.

Alexander Speer & Sons, Pittsburgh, Pa.

By the 1870s, there were many plow makers offering some type of potato digger. One of these was the Speer & Sons digger exhibited at the Paris Exposition of 1878. This design typified the plow-type potato digger; thousands were built by many different companies in the following years.

Stearns Manufacturing & Foundry Co., Decatur, Ill.

In 1912, Stearns offered its Light-Draft Potato Digger. Instead of the usual open chain, this machine lifted the potatoes to the side of the row using revolving steel tines. Very little is known of this machine; the company disappears from the trade directories in the 1920s.

Trade Names

Pumps

In 1924, there were more than 50 companies making wind mill pumps in more than 150 different models. In the previous 50 years, there were numerous companies that emerged and disappeared through merger or by simply going out of business. Considerable research would be required to determine even a rough estimate of the total numbers, but there is no doubt that it would be surprising. Many small firms sold their pumps locally, probably within a couple of counties in any direction. Most never made it as far as trade listings and probably had no great interest in a business which was already big enough to make a comfortable living. For this reason and due to the space constraints, the author has selected various kinds of pumps from many different manufacturers. This has been done to present a cross-section of pumps.

Today, an old pump standard will often sell from $60 to $100. Ornate or unusual designs will bring far more, but surprisingly few of the fancy and ornate pumps are seen today. After about 1900, the vast majority of pumps were rather simple in design; the extra costs involved in ornate iron castings gave way to maintaining a competitive edge in a very competitive business.

Aermotor Co., Chicago, Ill.

Aermotor Co. was the developer of the steel windmill, bringing it to the market in 1888. With it, the firm also built a variety of pump standards in various sizes and styles. A typical model is this one from the 1920s. As pictured here, it was priced at $10.

About 1909, Aermotor pioneered a small pumping engine, complete with pump jack. It was attached to the pump standard and took over when there wasn’t enough wind for the windmill. Into the 1930s, Aermotor continued with various designs, including this “Heavy Back-Geared Pumping Engine” of 1930. Equipped with a magneto, this one sold for $142.

Appleton Manufacturing Co., Batavia, Ill.

Windmills were wonderful when there was a wind, but on those still summer days when not a leaf moved, the water supply disappeared. Virtually no one wanted to return to the days of pumping water by hand, so there was a great need for pump jacks to mechanize the process. They came in all sizes and styles imaginable, with this one from Appleton being pictured in its 1917 catalog. It was priced at $15.

Associated Manufacturers, Waterloo, Iowa

Associated engines had become very popular by the time this 1917 combination appeared. It consisted of the company’s Jack Boy engine to which was fitted its pumping attachment. The $52 list price did not include the pump standard.

Baker Manufacturing Co., Evansville, Wisc.

Baker Manufacturing Co. began business in 1872, with windmills and pumps being the main product lines within a couple of years. By 1900, the Monitor line had grown to a huge industry, remaining so to the present time. Shown here are two examples of literally hundreds of different Monitor pump standards.

Monitor pumps were offered in almost every conceivable design to suit individual needs. Three styles of hand pumps are illustrated here; these were popular for pumping from cisterns or shallow wells.

Pump jacks were another important part of the Monitor line. Over the years, the variety included this style from the 1920s. Since the pump jack clamped to the pump standard, the jack could be used on almost any windmill pump. Hand pumps were not fitted with the necessary guides for use with a pump jack.

By 1905, Baker had added gasoline engines to its thriving Monitor pump and windmill line. Eventually, the Little Monitor pumping engine appeared, becoming one of the most popular of all pumpers. Production of this style apparently ended in the 1930s.

Butler Manufacturing Co., Kansas City, Kan.

A catalog of the 1920s illustrates the E-Z Roller Bearing Bucket Pump from Butler Manufacturing Co. As was sometimes the custom in those days, the pump came to the dealer with a place where the dealer’s name could be stenciled on the unit for a constant reminder to anyone coming for a cool drink of water.

Cedar Rapids Pump Co., Cedar Rapids, Iowa

In the 1890s, this company was offering its new Cedar Rapids Pump, a wooden pump with a brass cylinder. At the time, there were many folks who preferred a wooden pump instead of cast iron, but the latter eventually won out. Cedar Rapids Pump Co. continued making these pumps into the 1940s or later.

Challenge Co., Batavia, Ill.

This company went back to 1867 as Challenge Windmill & Feed-mill Co. When these 1910 pump-jacks appeared, Challenge had been in business for more than 40 years. The coming of small gasoline engines by 1910 prompted the development of pump jacks so that farmers no longer had to pump water by hand when there wasn’t enough wind for the windmill.

Challenge offered a variety of pump stands or pump standards, including this windmill standard of 1910. The handle was essential— when there wasn’t enough wind for the windmill, the latter was disconnected and water had to be pumped by hand. This was no small task, even for a relatively shallow well.

By the 1920s, the Challenge line included this heavy-duty double-geared pump jack. Like most others, it clamped to the pump standard and was also bolted to the pump platform. By the late 1940s, the company had become U.S.-Challenge and subsequently disappears from the trade listings.

Chandler Pump Co., Cedar Rapids, Iowa

By the 1890s, Chandler was offering this wooden pump as part of its already extensive line. The company specialized in pumps for many years, broadening its product line to include various plumbing specialties. Production of wooden pumps slowed considerably after 1900, although this Chandler model was available at least into the 1920s.

Typical of the time, these Chandler hand pumps were designed for shallow wells or cisterns. In many regions, a driven well was used; it consisted of a sand-point driven down to water. Sometimes, this was 10 feet or less.

Pitcher pumps were an entirely separate category from the ordinary pump standard. These small pumps were used mainly for drawing water from cisterns or other applications with a small lift andwere commonly seen at the kitchen sink or a laundry sink. Some were quite ornate.

About 1910, many farms were enjoying the benefits of running water piped to various places on the farm. Within the farm home, a pressurized water system was now a possibility. Chandler, among others, offered a geared pump, ostensibly powered by a gasoline engine through a small line-shaft hung on the basement ceiling. Thousands of these pumps were placed into service, many of them operating for 30 or 40 years with little attention.

By the 1920s, electricity was available to many city dwellers and most farms could now have their own electric plant. One of the first electrified home water systems was the Hawkeye motor pump from Chandler Pump Co. First offered in the 1920s, these small pumps were installed by the thousands; some of them were in operation for 20 or 30 years before succumbing to newer designs.

Chase Pump Co., Canton, Ohio

Especially during the 1880s and 1890s, pump standards were often a very ornate affair. One of these was the Chase Pneumatic Double-Acting Anti-Freezing Force Pump shown here. An important part of pump design was to prevent it from freezing in winter; this was usually accomplished by a device that permitted the stand-pipe to drain back to the well when the pump was not in use.

Cincinnati Pump Co., Cincinnati, Ohio

While the bucket pump or water elevator goes back to antiquity, it gained new status during the 1880s with numerous ornate designs coming to the market. For dug wells, this device was especially popular. The principles of operation are evident from the engravings.

Deming Co., Salem, Ohio

Deming became a well-known pump manufacturer by the early 1900s, with a unique product being its hydraulic ram pictured here. This simple device used low water pressure to force a smaller quantity of water to a greater height. While this device wasted water, it required no other form of energy, except for the head pressure of the supply. Hydraulic rams were very popular in some areas; many of them were also used in foreign countries.

Duplex Manufacturing Co., Superior, Wisc.

Another of the well-known pump manufacturers was Duplex with its Superior hand and windmill pumps. A 1904 catalog lists dozens of different styles, with the four models shown here being especially interesting. Duplex remained active until the 1950s, but then the firm disappears from the trade directories.

Elgin Windmill Co., Elgin, Ill.

Elgin remained active until the 1940s; but, as with many of the firms in this book, its precise history is unknown. In 1930, the company offered this interesting motor-powered pump jack, reflecting the coming of electrical power to the farm. This eliminated the gas engine. Farm electrification spelled the end of the small gasoline engines for farm power purposes.

Fairbanks, Morse & Co., Chicago, Ill.

One of the earliest windmill manufacturers was Fairbanks-Morse. Its efforts were confined primarily to building windmills and pump jacks; well equipment and well pumps were not a major enterprise, at least for farm use. During the 1920s, the company offered its No. 3 Handy Pump Jack as a simple means of pumping water; this one clamped to the pump standard and could be operated with a small gasoline engine. It weighed 90 pounds and retailed at $6.20.

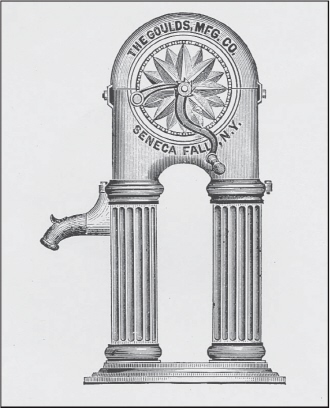

Goulds Manufacturing Co., Seneca Falls, N.Y.

This company was established in 1848. Its 1875 catalog illustrates this chain pump made of cast iron. Chain pumps or bucket pumps were a popular method of raising water from a dug well at the time and remained fairly popular into the 1920s. This one had an 1875 price of $9.

The 1875 Goulds pump line included a variety of pumps, including this small cistern pump. By the 1870s, the idea of building a cistern for storage of rain water was becoming quite popular. Underground cisterns and overhead water tanks were commonplace until the widespread use of pressurized water systems came along in the 1950s.

Drilled wells were becoming a reality by the 1870s. The 1875 Goulds catalog illustrates one in use as it attempts to save the house from fire. Graphic portrayals like this one were often used to make a point—in a time when fire protection was virtually non-existent, this represented

Hydraulic rams had come into use by the 1870s, with this 1875 engraving illustrating how the ram was set up and used. Usually the ram was set at least 25 to 50 feet from the water supply, giving sufficient “drive pipe” for successful operation. A fall of 10 feet from the brook or spring was sufficient to raise water to a considerable height. To demonstrate the power of the ram, with a 10-foot fall, one gallon of every 14 could be raised to a height of 100 feet. These unique devices have become prized collector’s items.

Driven wells were a reality by the 1870s and this engraving illustrates how they worked. The “point” seen at the bottom of the pipe was threaded to the pipe, a suitable cap was placed on top and the pipe was driven into the ground. Once it hit water, there was nothing left except to install the pump and secure water for the house and for the livestock.

F.E. Myers & Bro. Co., Ashland, Ohio

Frank E. Myers began manufacturing pumps in 1875, along with his brother, Philip A. Myers. The latter was largely responsible for the design of the pumps, while F.E. Myers was a director of the Bucher & Gibbs Plow Co. at Canton, Ohio. Shown here is a sampling of the Myers pump line for 1903. Included are various pitcher pumps, hand pumps and well pumps. To the left of this illustration is a Myers thresher tank pump and at the bottom are two examples of Myers spray pumps.

A 1910 style was the Myers Regulating Pump shown here. This pump used an ornate standard, along with a cog-tooth lifting device for the handle. Today, ornate pump standards are hard to find and command an excellent price as a collector’s item.

Along with its extensive line of pumps, Myers offered many styles of pump jacks, with this 1924 model being somewhat ahead of many competitors. This model operated in a completely enclosed gear case to keep out dust and moisture, all the while bathing the gears in oil. Also illustrated is a Myers windmill standard of the period.

In 1927, Myers offered its self-oiling Bulldozer pump. This design could be furnished with an electric motor as shown and the latter could be controlled with a pressure switch for fully automatic operation. The company also made an early reputation for its haying equipment.

N.O. Nelson Manufacturing Co., St. Louis, Mo.

This illustration from 1884 demonstrates the operation of the bucket pump. One of the advantages claimed for these pumps was the constant aeration of the water. This was achieved by the entrapped air from each bucket as it descended into the well. These wells were dug out by hand, sometimes going down 20 feet or more.

Nelson Manufacturing Co. offered a wide range of pumps and well supplies by 1884, with two of its pumps shown here. To the left is a bucket pump using small buckets to carry water to the spout. On the right is a curb pump or chain pump of wooden design. A lifting link of the chain pump is partially shown at the right.

Red Jacket Manufacturing Co., Davenport, Iowa

Red Jacket emerged as a major pump manufacturer in the early 1900s. Shown above in this illustration is its hand-powered pump. This design was intended to pressurize a large tank, giving sufficient pressure for the house for a day or two. Then it was time to work the pump for 20 or 30 minutes again. Below is a Red Jacket pump jack designed for use with a gasoline engine. Thousands of these pumps were installed in farm basements and a surprising number still survive.

O.P. Schriver & Co., Cincinnati, Ohio

For decades, the IXL and GEM steel curb chain pumps were available from Schriver and later from Butler Manufacturing Co., Kansas City. While the bucket pump has been illustrated elsewhere in this section, the chain pump is shown with its rubber cups descending into the water, trapping it within the vertical tube and discharging it from the spout.

Stover Manufacturing & Engine Co., Freeport, Ill.

D.C. Stover was an early windmill designer; the Stover Ideal windmills were built until the company closed its doors in 1942. By the 1920s, Stover had developed a number of pump jacks, with the No. 18 and the No. 18-1/2 shown here. The No. 18 was for use with a gasoline engine, while the No. 18-1/2 was for use with an electric motor.