T

Tank Heaters

The term “tank heaters” does not appear in the Subject Index of Patents, including all patents to 1873. Research during the course of this book does not find tank heaters prior to the 1890s. By that time, several companies were making tank heaters, with many more to follow. Additional examples will be found under the earlier heading of Farmstead Tools & Equipment.

Brown Bros. Manufacturing Co., Nappanee, Ind.

A 1904 advertisement illustrates the Nappanee, which was adapted for either steel or wood tanks, said to be able to burn anything and included a cement bottom to sink it in the tank. Many such companies arose, but little information is now available.

Challenge Wind Mill & Feed Mill Co., Batavia, Ill.

Challenge had become a major windmill and feed mill manufacturer by the time this 1895 advertisement appeared. The Challenge tank heater differed from most in its use of a side connection to provide draft and permit cleaning of ashes from the heater.

Hunt, Helm & Ferris, Harvard, Ill.

Its 1894 advertising read, “Hitch your wagon to a Star Tank Heater.” This interesting design was one of many appearing in the 1890s. Farmers welcomed the coming of tank heaters instead of having to chop ice on almost a daily basis through the winter months.

U.S. Wind Engine & Pump Co., Batavia, Ill.

The 1890s spawned some interesting tank heater designs, including this IXL from U.S. Wind Engine & Pump Co. Although fed from the top, this one included a separate bottom draft and clean-out, bolted into the side of the tank. The entire unit was made of cast iron.

Threshing Machines

In the May 1887 issue of Farm Machinery Magazine, an editorial of old-time threshing methods states, “Agriculture is the acknowledged basis upon which all other works rest and upon its successful development depends all substantial progress. The rise in agriculture is readily traced in the improvement of agricultural implements and appliances, of which none present a more interesting study than the thrasher.”

Of all aspects of farm life, one that was always held in high regard was threshing time. Few things inspired more enthusiasm than the sight of the steam threshing rig coming down the road or the plaintive whistle, sometimes heard for miles. The joy of the harvest also included farm wives who put together glorious feasts at threshing time. Even though the work was heavy, sweaty and dusty—not necessarily in that order—threshing time continues to inspire people to preserve a bit of our past. In the 1950s, “thresher reunions” began. These were mainly demonstrations of threshing as in days gone by. Eventually, the thresher reunions grew to the point that hundreds of these expositions are held every year.

The world’s first successful threshing machine was built by Andrew Meikle in Scotland back in 1786. However, it simply threshed the grain; the thresher combined with a cleaner or separator did not come until much later. Hiram A. and John A. Pitts of Winthrop, Maine, are credited with building the first American threshing machine in 1830. (In the early days they were called “thrashing machines” as compared to the later term of “threshing machines.”) As will be noted under the Buffalo-Pitts Co. heading below, the Pitts machines were indeed crude by later standards, but they marked the end of the flail and the beginning of a mechanical threshing machine.

About the same time as the Pitts Brothers were working out their design, Jacob A.V. Wemple in New York worked out a somewhat different design. In 1840, he went into partnership with George Westinghouse to build the machine and this was the beginning of the Westinghouse threshers. Wemple later went to Chicago, setting up a thresher factory there; it operated under the title of Wemple & Kline until 1857. Cyrus Roberts at Belleville, Ill., was the first to develop a vibrating separator about 1852. Subsequently, the Cox &Roberts machines were built; a manufacturing license was also issued to Kingsland & Ferguson at St. Louis for these machines. Cox eventually sold out his interests and Roberts moved to Three Rivers, Mich., where the Roberts, Throp Co. operated for some years.

Nichols & Shepard at Battle Creek, Mich., were the first to build threshers on the vibrating principle established in the Roberts patents. Its first Vibrator machines were built in 1858. Cornelius Aultman and H.H. Taylor organized the Aultman & Taylor Machinery Co., Mansfield, Ohio in 1867; this company manufactured machines under the Roberts patents.

Many other designs appeared, with some, like J.I. Case and Meinrad Rumely becoming quite famous. Unfortunately, the constraints of time and space do not permit a comprehensive review of the history associated with the thresher. To help this situation, many of the historic kernels are embedded within the captions that follow. Let it be noted, however, that the glory days of steam threshing only lasted about 40 years, beginning about 1890 and coming to a rapid close by 1930. Threshing remained on the scene for another 20 years. After 1930, the tractor replaced the steam engine; in the 1950s, the combine replaced the thresher.

Since so few threshing machines remain, especially the early wooden designs, they have now acquired collector status. Late model, all-steel machines of the 1920s and later, often bring $500 or more in good condition and some of the earliest wooden designs have acquired museum status. Hopefully, the remaining examples will survive for the enjoyment of future generations.

This section is presented in alphabetical order by manufacturers, rather than attempting to use a chronological sequence.

For centuries, the flail was used to beat the grain from the straw. In a day’s time, the average worker could thresh from five to seven bushels of wheat using a flail. After this came the job of winnowing to separate the grain from the chaff. It is an interesting phenomenon that the flail continued to be used in certain areas of the country into the early 1900s.

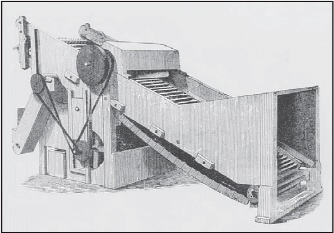

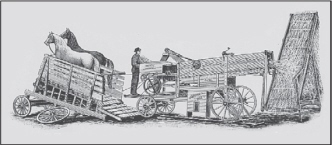

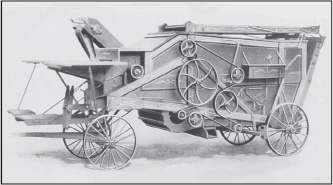

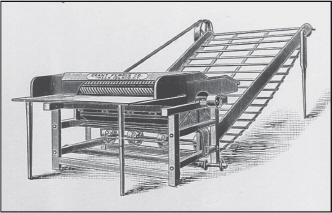

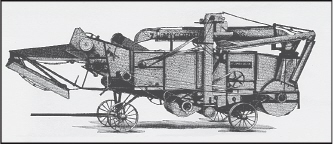

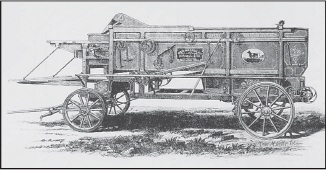

By 1850, threshing machines had improved over the original designs. Shown here is an unnamed design in which the cut grain was fed into the machine where the grain was threshed from the stems and cleaned after a fashion. Despite the crude appearance of these early machines, they represented a substantial improvement over the earlier methods.

Threshing machines of the 1840s were commonly known as “ground hog threshers” or “chaff pilers.” These machines simply eliminated the flail, but did not winnow or clean the grain from the chaff. J.T. and E. Warren in New York received several patents for their “thrashing machine” in the 1830s and 1840s, an example of which is shown here. It could thresh as much as 120 bushels of wheat in a single day. One man with a flail would have been a month doing this much threshing.

Advance-Rumely Thresher Co., LaPorte, Ind.

An 1895 issue of Farm Machinery Magazine published an engraving of Meinrad Rumely, the founder of this company. He began building grain threshers at LaPorte in 1852, continuing in the business until his death in 1904. The company remained under the title of M. Rumely Co., until a reorganization of 1915, after which time the firm was known as Advance-Rumely Thresher Co. This firm remained in operation until selling out to Allis-Chalmers Manufacturing Co. in 1931.

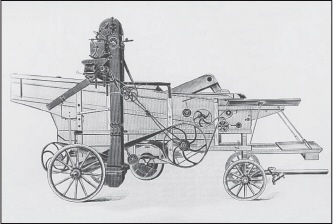

An extensive history of M. Rumely Co. and Advance-Rumely Thresher Co. is contained in the author’s The Allis-Chalmers Story (Crestline/Motorbooks: 1988). It details many of the early thresher designs by Rumely. However, the firm progressed until this basic design appeared about 1880. The New Rumely thresher continued on the market until replaced with the Rumely Ideal in 1904. Shown here is a 1903 version of the New Rumely.

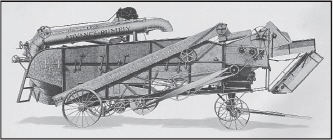

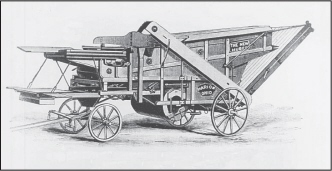

Rumely’s Ideal separator first appeared in 1904 and remained in production for 20 years. More than 20,000 Ideals of various sizes were built during that time. This one is equipped with a pneumatic stacker, also known as a wind stacker, but the slat stacker was also available.

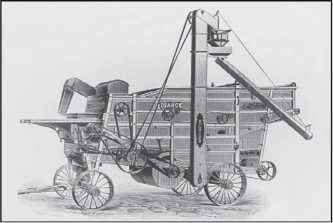

Built in the 1909-1918 period, the Rumely Ideal Jr. was a small machine built in a 28 x 46 inch size. Thresher sizes refer first to the width of the cylinder, with the latter number referring to the width of the separator. This machine is illustrated with a slat stacker, a simple conveyor to carry the straw to the stack.

The discussion of threshing would be incomplete without showing what it was like in those days. In this photo, the grain is all being sacked, a common practice in some areas. Two men are pitching bundles into the machine, while the “separator tender” keeps an eye on things from a high vantage point.

In 1918, Advance-Rumely began building all-steel threshers, but also continued to offer the Rumely Ideal all-wood design. These machines were built in several sizes and remained in production until the Allis-Chalmers buy-out of 1931. The latter continued to offer Allis-Chalmers-Rumely threshers for a couple of years, mainly to use up the remaining parts inventory.

During the 1920s, Advance-Rumely introduced its small 22 x 36 inch All-Steel Thresher. This machine was intended for the farmer wishing to do his own threshing. With its easy running ball bearing design, it could even be pulled by the then-popular Fordson tractor. Small machines like this one were very popular in the 1920s and 1930s.

During the 1920s, Advance-Rumely offered a pea and bean thresher. Apparently, it was built for only a few years and probably in small numbers. A likely scenario is that this machine was a takeoff from the Aultman-Taylor pea and bean huller, since Rumely bought out Aultman & Taylor in 1924.

Advance Thresher Co., Battle Creek, Mich.

Advance opened its doors in 1881; 10 years later its thresher took this form. Known as the Advance No. 2 outfit, this separator was a hand-feed model but was equipped with a Washington grain weigher. Note the interesting construction of the weigher— even the delivery spout is made of wood.

Sattley stackers were widely known and used; this simple device was really no more than a conveyor to carry straw to the stack. Sattley was famous for its farm equipment line; among threshermen the Sattley stacker was equally famous. The Advance thresher shown here is of 1903; its machines stayed in essentially this same form until the company was bought out by M. Rumely Co. in 1911.

C. Aultman & Co., Canton, Ohio

Cornelius Aultman began building farm equipment in 1851. Subsequently, the firm began making threshing machines, with its Sweepstakes thresher gaining a great reputation. This was an early apron machine that antedated the vibrator threshers. The grain passed through the cylinder and over an endless open belt, permitting the grain to fall into the cleaning apparatus, then known as the “fan mill.”

In the 1880s, the Aultman line included the New Model and Star separators. This one is equipped with a Perfection weigher made by Selby, Starr & Co., Peoria, Ill. The term “separator” became synonymous with the longer term, “threshing machine.” Even the Aultman title calls this thresher a “separator.”

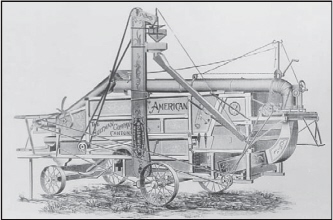

By 1900, C. Aultman & Co. had developed its American thresher; this one is equipped with a Washington grain weigher made by Daniel Wilde & Son, Washington, Iowa. Numerous companies made grain weighers. Curiously, very few thresher manufacturers built their own feeders, stackers or weighers. In most instances, these items were extra-cost equipment supplied by specialty manufacturers.

Aultman & Taylor Machinery Co., Mansfield, Ohio

In 1866, Cornelius Aultman and H.H. Taylor formed a partnership to build threshers under the Cox & Roberts patents. Its new vibrator thresher evolved into the Globe thresher, shown here in its 1890 version. The smaller size was available in a geared model for use with a horse power, while the two largest sizes were only available as belted machines.

Reflecting the new advances in thresher design, the Aultman-Taylor took this form by 1893. After passing through the cylinder, the grain and straw traveled over vibrating straw racks with the grain falling to a grain pan beneath and the straw continuing to the back of the machine.

By 1915, the Aultman & Taylor New Century separator had already been on the market for about 15 years. Most separators used a feeder, stacker and weigher built by specialty houses; in this instance, a Ruth feeder, Peoria Double-Tube Weigher and a Farmer’s Friend Wind Stacker were included.

During the early 1900s, Aultman & Taylor developed a bean and pea huller, continuing with these machines until being bought out by Advance-Rumely Thresher Co. in 1924. The latter then continued making these machines for a short time.

Avery Co., Peoria, Ill.

Avery had its beginnings in farm equipment at Galesburg, Ill., establishing a small factory there in 1877. Seven years later, the company moved to Peoria, Ill.; in 1891 it began building grain threshers, first under the title of Avery & Rouse Steam Thresher Co. Shown here is its 1898 model of the Yellow Fellow Thresher, distinctive because of its deep yellow color and fancy red decoration.

An early Avery catalog illustrates and describes many of the salient features of the Yellow Fellow separators. In those days the catalog was the main sales tool available to farm equipment dealers, aside from state and local fairs. The company’s Yellow Fellow trademark was widely known, perhaps because it was so distinctive.

Avery Co. was incorporated in 1907. By that time, the Yellow Fellows were in use all over the United States, as well as in many foreign countries. The company also built steam-traction engines and other farm equipment, even including wagons. This catalog illustration typifies the usual cleanup at the end of the day or when finishing the job.

While the Avery Yellow Fellow was built in many sizes, even the smallest machine was too large for small farm tractors. Thus the company introduced its Yellow Kid machine about 1912; this one was specially set up for threshing rice.

By the early 1920s, Avery had come out with an all-steel thresher design; the smallest model was the Avery Yellow Baby. Unfortunately, the company went into bankruptcy, but recovered as Avery Farm Machinery Co. and continued to operate for a few more years.

Avery came out with a “Header-Thresher” in 1923. It was designed to be used in conjunction with a grain header for harvesting grain directly in the field. The thresher was powered by a mounted Avery engine. This unique alternative to the combine was only marketed for a short time.

Avery Farm Machinery Co. continued building threshers into the 1930s but few, if any, were built after World War II. The company continued to supply repair parts for a time and eventually disappeared from the farm equipment business.

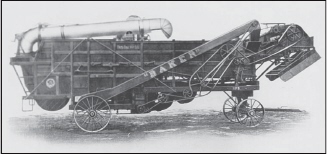

A.D. Baker & Co., Swanton, Ohio

A.D. Baker & Co. was organized to build steam-traction engines, with threshing machines also coming about the same time. By 1911, the company was building three different sizes of these machines. Advertising of the day notes that “our frame is made of carefully selected and thoroughly seasoned hard maple.”

By the 1920s, Baker was offering an all-steel thresher in several sizes. This company was famous for its Baker Locomotive Valve Gear, used on steam locomotives all over the world. In later years, the company built some farm tractors, but production of threshers and tractors ended during World War II.

Banting Manufacturing Co., Toledo, Ohio

Research for this book details nothing concerning Banting Manufacturing Co. prior to 1919. At that time, its Greyhound Grain Thresher appears in five sizes, from a small 22 x 36 inch model up to a large 36 x 58 inch machine. By the 1930s, parts for the Greyhound threshers were available from A.D. Baker & Co.

A 1919 Banting catalog illustrates the Greyhound Bean Thresher, a special design for hulling beans and peas. As with its grain threshers, little has been found in the present research concerning the history of the firm, although it entered the tractor business about this same time, and remained in this business for some years. However, its tractors appear to have been contracted from Allis-Chalmers. Curiously, the company remains in the trade directories into the late 1940s, offering repair parts for its steam-traction engines.

Belle City Manufacturing Co., Racine, Wisc.

Although our current research has not determined the origins of this company, an 1894 engraving shows its small Columbia thresher. The company specialized in small threshers and also built feed cutters and other farm equipment.

By the 1920s, Belle City had come out with a small all-steel separator; this 1925 style was hailed as “Fordson’s Partner,” an obvious suggestion to couple it to a Fordson tractor. Belle City continued to offer threshing machines at least until the late 1940s.

Did You Know?

Feed cutters, rare as they are today, have a limited value to vintage machinery collectors—often less than $50.

C.H. Bidwell Thresher Co., Batavia, N.Y.

The origins of Bidwell Thresher Co. are unknown; in 1908, the company announced its Bidwell Compound Grain Separator. This advertisement also notes that the company was offering traction engines, but no details are available. Apparently, this machine was built for only a short time.

The Bidwell trade name was well known in the specialty business of bean and pea threshers. By 1918, the Bidwell was being built by Batavia Machine Co., also of Batavia. By the 1930s, repair parts were available from Climax Corporation of the same city.

E.M. Birdsall Co., Auburn, N.Y.

This company had its beginnings with a small thresher factory at Penn Yan, N.Y., in 1860. By 1881, the firm was relocated to Auburn where it continued to build threshers and other machinery. Shown here is an 1893 example of its separator with a Perfection weigher. The company slips from view in the early 1900s.

Buffalo Pitts Co., Buffalo, N.Y.

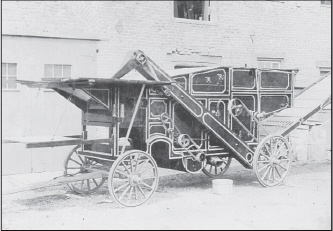

To Hiram and John Pitts go the credit for the beginning of the American threshing machine. In 1831, they built a “ground hog” thresher with their own improvement. This consisted of the open wood raddle chain which carried the threshed grain from the cylinder, permitting the grain and chaff to fall to the ground while elevating the straw to a pile.

In the 1831-34 period the Pitts brothers experimented with various designs, eventually coming out with the first thresher having a built-in grain separator. This design was patented by the Pitts brothers in 1834. John A. Pitts eventually came to Buffalo, N.Y.; subsequently, his machines got the Buffalo Pitts name. Hiram A. Pitts went to Illinois in 1847 and built threshers in Chicago after 1851. His machines were known as the Chicago Pitts design.

By the 1850s, the Pitts mounted thresher appeared. This was a great forward step, since now the machine was portable and could be moved from farm to farm with relative ease. This was a so-called apron machine because the threshed grain was separated from the straw by traveling over an open wood apron. The straw went to the stack and the grain dropped below to the “fan mill” or separator. Eventually, threshers or threshing machines were simply referred to as separators.

For the 1890s, Buffalo Pitts offered a variety of threshers, including its Rival design. This was an improved version of the early apron machine and was made in five different sizes.

An 1895 offering of Pitts Agricultural Works—as the company was then known—included its California Thresher, built in several sizes and designed specifically for the Western states. By this time, the California and other Pitts designs could be equipped with a self-feeder at extra cost.

Research has not determined when Pitts first built a vibrator thresher, that is, a thresher using shakers instead of the apron design. Its Niagara model of 1895 was a vibrator separator, shown here as a hand-fed machine with a slat stacker, also known to threshermen as a “common stacker.”

By 1901, Buffalo Pitts had designed and built a special Bean, Pea and Cow Pea Thresher. Little is known of this design, aside from a few advertisements of the time. It would be an accurate assessment that few were built, even though they appear in Buffalo-Pitts catalogs as late as 1910.

The Buffalo Pitts catalog of 1910 illustrates the company’s Rice Thresher. This crop had its own special requirements and most ordinary threshers could thresh and clean the crop only with difficulty. Thus some companies built special machines designed specifically for this crop.

By 1910, Buffalo Pitts had introduced its Niagara Second threshers. They were available in a steel-frame design, using wood to enclose the machine. For a time, these threshers were sold by International Harvester Co. to complement its vast implement line.

Buffalo Pitts Niagara Second threshers were available in steel-frame and wood-frame designs, with the latter being shown here. Although a few companies were building all-steel machines by 1910, the majority were still using wood construction, since this was preferred by many threshermen.

Buffalo Pitts went into receivership in 1914, but reorganized and continued for a few more years. However, by the early 1930s and perhaps sooner, repair parts only were available for these machines. Sometime during the 1930s, the repairs for the Buffalo Pitts separators could be secured from Wagner-Langemo Co., Minneapolis. The latter was then secured by Deere & Co., who began building threshing machines for several years.

Butterworth Universal Thresher Co., Trenton, N.J.

Aside from this 1905 advertisement, little is known of Butter-worth. Its Patent Universal Thresher had apparently been on the market for a time, but subsequently was offered by New Jersey Agricultural Works, also in Trenton.

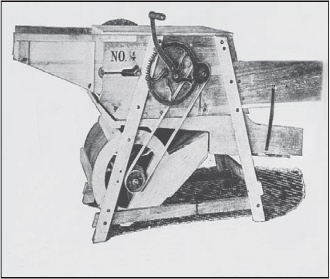

S.K. Campbell Co., Ltd., Central Bridge, N.Y.

Already in 1867, this company began building threshers. From the beginning, it built vibrator threshers. However, little information is now available beyond their descriptions from a 1920 catalog. Its small Thresher No. 2 shown here, had apparently been built in this form for many years.

Did You Know?

Old bucket sprayers were sometimes rather ornate and today are a conversation piece, although their collector value has generally not become more than $10 to $30.

The Campbell catalog of 1920 illustrates its Undershot Thresher No. 1-1/2, commenting that it was being offered in response to numerous demands. It was a small machine, having a cylinder width of 26 inches and a separating width of 36 inches.

The S.K.C. thresher line also included a straw-preserving rye thresher, designed for preserving the straw straight, as required for various industries. The company’s 1920 catalog lists this special thresher—complete with the binding attachment—for $600.

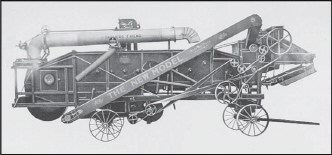

Cape Manufacturing Co., Cape Girardeau, Mo.

In 1906, the first Cape separators appeared; this model was among the first to use a revolving rake instead of the time-honored vibrating straw racks. A 1920 catalog notes that the Cape design was made possible by “breaking away from the moss-grown principles” of the past.

Did You Know?

Today, hay knives might sell from $15 to $35.

For 1920, the Cape New Model Separators were built in six different sizes, ranging from a small 24 x 40 inch machine to a big 32 x 56 inch model. The rotary picker and raker system of the Cape New Model was unique; despite the advantages of this machine, it disappears from view by 1930.

J.I. Case Plow Works, Racine, Wisc.

In 1920, Case plow works announced its Wallis Thresher. This machine appears in an initial announcement, but subsequently disappears altogether. It is unknown if the Wallis was actually built at the Plow Works or contracted from another thresher manufacturer.

J.I. Case Threshing Machine Co., Racine, Wisc.

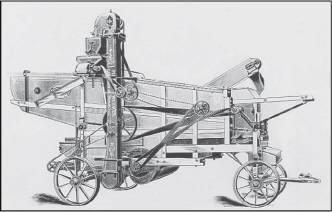

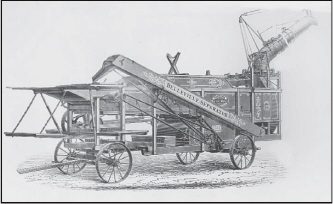

J.I. Case came to Wisconsin in 1842 and began building threshers. By the 1850s, the Case Sweepstakes threshers were on the market. Shown here is one of the earliest advertisements for the machine. At the time, Case built an apron machine like virtually everyone else; the agitator or vibrator design was not yet developed.

Case continued to promote its apron machines for some years after the vibrator designs had come to the market. Into the 1870s, Case built its Eclipse thresher, which was a continuing development over the earliest designs of the 1850s. The development of the Case threshers are detailed extensively in the author’s 150 Years of J.I. Case (Crestline/Motorbooks: 1991).

In 1880, J.I. Case introduced its famous Ironsides Agitator, an entirely new vibrator design. This machine was available with a belt pulley for steam power or it could be furnished as shown, with the necessary gearing to run the separator with a horse power.

Various improvements were introduced on the Case Agitator following its 1880 introduction. For instance, this 1898 model shows the unique tubular return elevator that Case had introduced 10 years earlier. Production of the Agitator continued into the earlier 1900s.

In 1904, J.I. Case Threshing Machine Co. was the first to come out with an all-steel thresher. Many improvements were made to these all-steel machines in subsequent years, but the same basic design remained intact until J.I. Case finally suspended production of threshing machines in 1953.

Caswell Bros., Cherokee, Iowa

In 1908, Caswell Bros. announced its new Gasoline Traction Thresher. This was a self-contained unit, complete with its own engine. When finished with one job, the traction gears could be engaged for moving to the next. Since nothing more is heard of this machine beyond its 1908 announcement, it is presumed that production ended almost before it began. Unfortunately, this very poor illustration is the only one that could be located; even this one is an improvement over the original.

Champion Thresher Co., Orrville, Ohio

For 1903, Champion offered this machine in 24 x 40 and 33 x 52 inch sizes. This was a combined separator and clover huller, with the separate hulling cylinder noted behind the front wheels of the machine. Little is known of this firm aside from the advertisement shown here.

Did You Know?

B.F. Avery & Sons Co. was incorporated in 1877 for $1.5 million. Benjamin Franklin Avery founded the company in 1825 with $400 in capital.

Clark Machine Co., St. Johnsville, N.Y.

This company was building threshers in the early 1900s, but its origins are unknown. In the 1909-11 period, the company advertised its new line of gasoline engines extensively, but they disappear after that time. Shown here is the company’s 1914 version of the Clark thresher.

Herman Cook, Sioux City, Iowa

From the May 1908 issue of American Thresherman comes an illustration of Cook’s Auto-Thresher. It was intended to be a self-contained unit, complete with its own engine and traction wheels. Several different “auto-threshers” appeared about this time, but none of them achieved popularity.

Cripple’s Revenge Thresher Co., LaCrosse, Wisc.

In a 1901 issue of American Thresherman is this drawing of Cripple’s Revenge Thresher, but no other information has been located.

Deere & Co., Moline, Ill.

About 1930, Deere acquired Wagner-Langemo Co. of Minneapolis. From this purchase came the John Deere threshing machines, marketed for some years afterwards. This machine was built in 24 x 40 and 28 x 52 inch sizes, suitable for small- and medium-sized farms.

Dugan Manufacturing Co., Wichita, Kan.

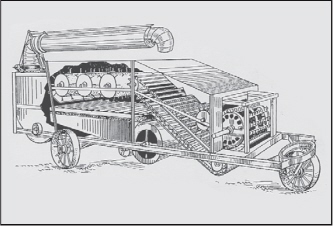

The Dugan Rotary Separator first appeared in a number of 1909 advertisements, then quietly disappears from the various trade directories and product journals. This machine used a rotary separating system instead of the conventional straw racks, as shown in the sectional drawing.

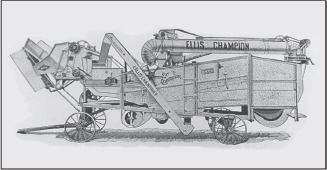

Ellis Keystone Agricultural Works, Pottstown, Pa.

By the 1890s, Ellis Keystone was offering its Champion threshers in many styles, including this No. 3 Thresher and Cleaner, along with a two-horse railway or tread power. Probably responding to demand, this style remained available at least into the 1920s.

An 1898 engraving shows the No. 3 Ellis Keystone Champion thresher mounted on wheels and set up for operation by a steam-traction engine. This was a simple apron machine and the company continued to build it into the 1920s, long after most firms had opted for all-steel machines.

The Ellis Champion remained on the market at least into the 1940s. Trade directories of the late 1950s still show Ellis Keystone Co. as supplying parts for these machines. This small outfit had a 24-inch cylinder and was capable of threshing 35 to 60 bushels of wheat per hour.

By the 1920s, the Ellis Champion Steel Thresher had arrived; it was a 28 x 46 inch machine capable of handling the work on small- to mid-sized farms. This machine weighed some 5,800 pounds (as shown). Very little is known of the company aside from various trade advertisements.

Emerson-Brantingham Co., Rockford, Ill.

Emerson-Brantingham Co. purchased Geiser Manufacturing Co. in 1912. For some years after, the company continued to build Geiser threshers, with this example coming from its 1919 catalog. E-B also marketed the Reeves threshers, having also bought this firm in 1912. In 1924, the company offered its remaining stock at bargain prices, as it phased out the sale of threshing machines.

Farmers’ Independent Thresher Co., Springfield, Ill.

In 1917, this interesting machine appeared. It used two sets of corrugated rolls ahead of the cylinder to rub as much grain as possible from the heads prior to entering a conventional cylinder. The remainder of the machine was built along conventional lines. Aside from a 1917 catalog, little else is known of this firm.

A.B. Farquhar Co., Ltd., York, Pa.

An 1887 article in Implement & Hardware Magazine illustrated one of Farquhar’s early threshers, called the Excelsior. Little is known of this model. Farquhar began a partnership with W.W. Dingee; after its factory burned in 1859, Dingee went to Racine and the J.I. Case Threshing Machine Co., while Farquhar remained to build his own fortune.

By the 1870s, Farquhar had developed his own apron thresher. Like other apron machines of the time, it carried the straw across an open wooden raddle chain to separate the grain. For many years, the cleaning mechanism was known as a separator or fan mill. The term “separator” eventually became synonymous with threshing machine or thresher, referring to the complete machine rather than one of its components.

Plain threshers—consisting of a cylinder, feed table and open riddle—were probably among the first of the A.B. Farquhar’s developments. This simple machine was fed by hand. The shaker table behind the cylinder served to separate grain and straw, leaving the grain on the floor to be winnowed and sacked as a separate operation. Farquhar continued to manufacture Plain Threshers well into the 1900s.

Farquhar’s introduction of the Rake Separator is unknown, but presumably it was on the market by the 1880s, perhaps earlier. This machine was widely sold, primarily because of its simplicity and ease of operation. Farquhar continued to build these machines into the early 1900s; it appears that the company would continue to build them on order so long as the company remained in operation.

As with many other Farquhar machines, the year when this Vibrator Separator was introduced is now unknown, but probably by the 1880s. Although some farmers and threshermen were determined to hang onto their plain threshers or the simple rake separator, others were just as convinced that the vibrator design was faster and did a better job than the older designs.

By 1900, Farquhar had introduced its New Farquhar Separator No. 26. It was an updated version of the earlier Vibrator Separator. Like others of its time, it used a massive wooden frame made of the best materials.

Recognizing the special needs of the rice crop, Farquhar introduced this special Rice Separator sometime prior to 1900. While it was similar to the standard machines in many respects, it was designed especially for the needs of this special crop. Originally Farquhar’s firm was known as Pennsylvania Agricultural Works. In 1889, the official title was changed to A.B. Farquhar Co., Ltd., but the former title also remained in company advertising into the early 1900s.

In 1910, Farquhar offered this Pea Vine Thresher and Shredder, a machine designed to shed peas from their vines, then shred the vines for use as livestock feed. Presumably the production of this very specialized machine was rather low. Few details are available concerning the No. 1 Pea Huller.

Farquhar introduced its all-steel threshers by the 1920s; a decade later, it was still offering them in 22 x 36 and 28 x 48 inch sizes. The company continued in the business until being bought out by Oliver Corp. in 1952.

Frick Co., Waynesboro, Pa.

George Frick began building threshing machines in the 1840s, but virtually nothing is known of his early designs. By 1884, the company was offering the Vibrating Thresher shown here. It was of simple design and is shown with the common stacker folded over the machine, ready for the road.

By 1900, the company had launched its Landis Eclipse Thresher, an improved design with a distinctive appearance. This one is equipped with a sacking elevator, shown in the foreground. At the time, much of the grain was sacked for storage, rather than being stored in large open bins.

A smaller version of the Landis Eclipse was the Light Eclipse. This machine embodied all the design features of the larger machines but was smaller in size, making it ideal for the small farmer or the small “threshing ring.” These groups were frequently formed to pool labor resources among farmers. Thus there was sufficient help to make quick work of the harvest as the separator moved from farm to farm.

About 1913, Frick introduced its Waynesboro Eclipse, a small thresher designed specifically for the farmer wanting to do his own threshing. This machine apparently was a successor to the Light Eclipse introduced some years earlier.

By 1913, Frick came out with its Improved Frick Thresher. This one is shown with a pneumatic stacker presumably, it could also be fitted with a self-feeder. Wind stackers, self-feeders and grain weighers were almost always supplied by specialty manufacturers. About 1930, the company moved toward its growing refrigerating machine business, eventually leaving the farm equipment trade entirely.

Gaar, Scott & Co., Richmond, Ind.

The firm of A. Gaar & Co. was organized in 1849 to build threshers and other items. After continuing success, the firm was incorporated as Gaar, Scott & Co. in 1870. By the 1890s, the firm was offering this attractive machine; it is fitted with a Perfection weigher from Selby, Starr & Co., Peoria, Ill.

By 1900, the company was offering a wide range of separators in the following sizes: 28 x 49, 31 x 52, 33 x 56, 36 x 60 and 40 x 64 inches. The company also built special Rice Separators. This model is equipped with a self-feeder, grain weigher and wind stacker.

M. Rumely Co., LaPorte, Ind., bought out the Gaar-Scott line in 1911. The latter continued to offer the Gaar-Scott line along with its own Rumely Ideal machines until about 1914. At that time, all thresher lines were combined under the Rumely title and Gaar-Scott disappeared from the scene. Shown here is a Gaar-Scott Junior Separator; this model was built in 20 x 40 and 24 x 44 inch sizes.

Garden City Feeder Co., Pella, Iowa

During the early 1900s, numerous companies specialized in making self-feeders for grain threshers. The Garden City is one such example. As the threshing machine industry developed, few thresher manufacturers developed their own feeder, for reasons now unknown. This firm was eventually bought out by Hart-Carter Co., Peoria, Ill.

Geiser Manufacturing Co., Waynesboro, Pa.

Peter Geiser began building threshing machines already in 1850, setting up a factory at Waynesboro 10 years later. Billed as “The Original Geiser” this machine appears in catalogs of the early 1900s, but no information has surfaced as to when the machine was first introduced. This small machine could be operated with a 6-horsepower steam engine.

By the early 1900s, Geiser had an extensive line of threshers, including this small machine, designed especially for stack threshing or barn threshing. However, many barn threshers were furnished without wheels and were mounted within the barn. Unthreshed grain was stored in the barn and threshed in the winter months when other farm work was slack.

The No. 4 and No. 5 Geiser separators were built in 24 x 32 and 27 x 39 inch sizes. While this machine had a telescoping wind-stacker pipe, some of the smaller sizes would oscillate, but the blower pipe could not be extended beyond its fixed length. These small separators were very popular with the small farmer and with threshermen whose territory included many small farms.

While most Geiser separators were of the vibrator type, the company also built a raddle machine that dispensed with the shaking straw racks. Thus the company called this its New Peerless Sieveless Separator. A minority of threshermen preferred this style, objecting to the “shaking” of vibrator machines. In reality, well-designed vibrator threshers “shook” very little.

In the early 1900s, Geiser introduced its Peerless Rice Thresher, a machine especially designed for the peculiarities encountered in threshing and cleaning this crop. By this time, Geiser had adopted steel axles for its larger machines; they were less expensive and stronger than wood axles. However, many threshermen still insisted upon wooden construction wherever possible.

Geiser’s time in the thresher business lasted until the 1912 buyout by Emerson-Brantingham Co., Rockford, Ill. The latter continued building the Geiser separators into the 1920s, apparently ending production about 1924. Shown here is the Class A and AA New Peerless separator of 1912.

A.L. Gill Agricultural Works, Trenton, N.J.

Peerless Rye Threshers apparently had their beginnings in the 1860s, being built under patents of A.L. Gill. The machine shown here was for threshing rye without injuring the straw. The 66-inch cylinder was wide enough to accommodate the tallest rye. This engraving is from the 1880s.

Gill Straight Straw Preserving Threshers included the large Peerless model shown here. To the left is shown the binding attachment; it was a conventional grain binder mechanism that put the straw in neat bundles after threshing. The latter was achieved with a tubular steel cylinder using wooden concaves covered with sheet steel. The straight straw was used for everything from thatched roofs to various industrial applications.

The Peerless grain thresher was a conventional separator, as compared to the company’s straw-preserving models. This machine appears to have come onto the market at least by the 1890s, but no history of the firm—of its beginnings or its demise— have appeared.

John Goodison Thresher Co., Sarnia, Ontario, Canada

While the beginnings of this company are unknown, it appears that thresher production ended in the early 1920s. Perhaps as a testimony of its quality, a number of Goodison threshers were sold in the United States, despite the great number of American manufacturers. The machine illustrated here is of 1918 vintage.

Gopher Machine Co., New Prague, Minn.

In the 1920s, the Gopher thresher appeared for a few years— its designers, like many others, probably hoped for success in the very competitive business of building threshing machines. Since the company operated for only a few years, very little is known of its origins. By the late 1920s, the company was out of business and no repairs were available for these machines.

Grant-Ferris Co., Troy, N.Y.

This firm had its beginnings in 1822, it was incorporated under Grant-Ferris Co. in 1894. Virtually nothing is known of the company’s history; in the 1890s, the company was still manufacturing this straw-preserving thresher, which it called its Plain Beater.

An 1897 issue of the Grant-Ferris catalog notes that its grain threshers were the inventive result of John G. Snyder of Rens-selaer County, N.Y. One of the machines available at the time was this straw-preserving rye thresher, complete with cleaner and binder.

For 1897, Grant-Ferris offered this Combined Oat and Rye Thresher, claiming its Snyder design to be the only successful combination machine on the market. The company was also building grain drills and other farm equipment at the time. Apparently, the firm either sold out or ceased business in the early 1900s; a 1909 issue of the Farm Implement News Buyer’s Guide lists no farm equipment manufacturers at Troy, N.Y.

Harrison Machine Works, Belleville, Ill.

This company was originally founded in 1848. Although no direct evidence has been found, it appears that the firm was actually that of John Cox and Cyrus Roberts. The firm began building ground hog threshers at Belleville in 1848; the following year, it added a “vibrating pan” to separate grain from straw. These events are retold in an early Harrison catalog, although the Cox and Roberts names do not appear. The company continued building threshers, eventually organizing under the Harrison name in 1878. Shown here is its Belleville Separator of 1903.

The Belleville line of the early 1900s included many models, including this one with an attached grain weigher and wind stacker. A hand-feed table was furnished as standard equipment; by this time, however, the self-feeder was coming into use.

Topping the Belleville line of the early 1900s was The Great Western Separator, shown here with an attached Farmers’ Friend Wind Stacker. Many of the early windstackers were mounted as shown, with the open bevel-gear drive being obvious. This machine was built in 32 x 53 and 36 x 57 inch sizes.

By the 1920s, Harrison Machine Works had redesigned the Great Western as the New Great Western. This machine was much the same as the original design, but embodied many improvements. A Langdon self-feeder is shown, but the plain feed table could still be furnished; instead of the wind stacker, this machine could be furnished with a common stacker if so desired.

Harrison promoted its threshers into the 1940s and continued to offer repair parts at least into the late 1940s. Its designs changed but little over the years and this 1924 catalog illustration shows its Belleville separator of which it commented, “It has been built continuously by us since 1848.”

Hart Grain Weigher Co., Peoria, Ill.

In the early 1900s, Hart Grain Weigher rose to prominence as a leading manufacturer of self-feeders and grain weighers for threshing machines. Its equipment could be fitted to virtually any thresher. The company eventually came to a point of dominance, with numerous other product lines being absorbed into the Hart line. Shown here is its Langdon self-feeder of the 1920s.

Heebner & Sons, Lansdale, Pa.

David S. Heebner began making various farm implements in 1840. Within a year or so, the company was also making threshers; by the 1890s, Heebner’s Little Giant took the form shown here. These small machines were very popular in some regions; the company remained in business until 1926.

Heilman Machine Works, Evansville, Ind.

This company was in the thresher business in the early 1900s, but its origins are unknown. For 1905, the Heilman threshers took the form shown here, as extracted from an advertisement of the period. In the early 1920s, the firm apparently ceased making separators, although repair parts were available from the company into the late 1940s.

Heineke & Co., Springfield, Ill.

Many companies were manufacturing self-feeders for threshing machines in the ealry 1900s, including the Heineke designs. This firm also manufactured the Langdon self-feeder of the Lang-don Feeder Co., Kansas City. Eventually, the Langdon came under control of Hart Grain Weigher Co., noted above. Heineke sold more than 3,500 self-feeders in 1919. The company continued in operation into the early 1940s.

Herrgott Co., Mildmay, Ontario

The origins of the Lion thresher are now unknown, although it continued building threshers into the 1940s. Subsequently, the company was taken over by Lobsinger Bros., which continued to build separators at least into the 1950s.

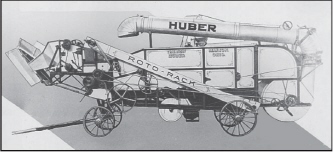

Huber Manufacturing Co., Marion, Ohio

Edward Huber began manufacturing hay rakes in 1865, followed by other machinery in the following years. Threshing machines came along in 1880, with the New Huber of the 1890s being illustrated here.

By 1900, the New Huber separator had been improved over earlier versions, with this model featuring the hand-feed table and a common stacker. This simple conveyor for the straw required little power but was unable to make the large stacks possible with the windstacker. Thus, it required resetting the machine once the straw stack had reached its maximum size.

Into the 1900s, Huber came with its larger machines; this one being of about 1912 vintage. At some point, the design changed to the Huber Supreme and these machines were popular in many regions.

By the 1920s, Huber had developed a new all-steel thresher; this one had the new Huber Roto-Rack design. The company continued to build separators into the 1940s, but production was largely suspended because of World War II and never resumed afterward.

In the early 1900s, Huber designed a rice thresher, especially for this crop. A notable difference was that this was a combination machine that could also be converted back to a grain thresher. The backward conversion was relatively simple, but it was not nearly so easy to convert a grain thresher into one suitable for rice.

Built until about 1920, the Huber Bean and Pea Thresher was a special design intended only for this purpose; it was unsuitable for use as a grain thresher. This one is shown with a three-way stacker for the vines; it could be swung to the left, straight back or to the right for three separate stacks before having to reset the machine.

Illinois Thresher Co., Sycamore, Ill.

Wm. N. Rumely was a son of Meinrad Rumely, founder of M. Rumely Co. (see Advance-Rumely Thresher Co.). In 1911, he severed his interests in the company; by 1915, he formed the Illinois Thresher Co. The latter built threshers and traction engines for a number of years, but by the late 1920s, production had ended, although the firm continued to supply repair parts for a few more years.

Indiana Manufacturing Co., Indianapolis, Ind.

In 1891, Indiana Manufacturing Co., began selling wind-stackers and apparently built these, or contracted for them to be built, for direct sale to farmers. The company soon began buying up new windstacker patents and then sold manufacturing rights to various thresher manufacturers. Shown here is the Uncle Tom’s Farmer’s Friend stacker of 1895. Thousands of threshing machines were adorned with the famous Farmer’s Friend trademark.

International Harvester Co., Chicago, Ill.

International Harvester began marketing threshing machines as early as 1909. These were not built by IHC, but by Belle City Manufacturing Co. About 1913, IHC contracted with Buffalo Pitts Co. for its Niagara Second threshers, selling these also for a time. Shown here is a New Racine thresher of 1911, made for IHC by Belle City.

In 1925, IHC began building its own all-steel threshing machines. These were available in 22 x 38 and 28 x 46 inch sizes. The latter size was large enough for medium sized farms and for small threshing rings. (A “threshing ring” was a group of farmers who banded together for the harvest, pooling their labor, bundle wagons and horses to bring the grain to the separator. They traveled from one farm to another until the harvest was completed). Production of this popular thresher ended in 1956.

Keck-Gonnerman Co., Mt. Vernon, Ind.

Established in 1873, Keck-Gonnerman built a variety of steam-traction engines, tractors, sawmills and threshing machines. Shown here is the K-G Steel Thresher of the late 1920s. This style remained in production into the late 1950s. It was one of the last companies to cease production of threshing machines.

O.S. Kelly Western Manufacturing Co., Iowa City, Iowa

O.S. Kelly was a partner in the firm of Whiteley, Fassler & Kelly already in the late 1850s. This famous company developed the Champion line of harvesting machinery. Kelly got into the threshing machine business in 1882 with the Springfield Engine & Thresher Co.; the latter was eventually known as O.S. Kelly Co. In the late 1890s, Kelly established a factory at Iowa City, Iowa, building the Iowa Separator there for a few years.

Kingsland & Ferguson Manufacturing Co., St. Louis, Mo.

In the 1850s, Kingsland & Ferguson adopted the vibrator separator designs of Cox & Roberts (see Harrison Machine Works above) and commenced building separators in the following years. This 1884 example shows the state-of-the-art at that time, with this machine being set up for operation by steam power. Geared machines for use with a horse power were also available. By 1900, the company disappeared from the scene.

LaCrosse Threshing Machine Co., LaCrosse, Wisc.

Aside from a photograph found at a collector’s fair, no information has been located concerning this company or the separator illustrated here. It appears to be a machine of the 1910-1920 period. The unique belting arrangement for driving the wind-stacker is evident, with two idler pulleys being used to keep the belt away from the left rear wheel of the machine.

McOsker Thresher Co., Turon, Kan.

In 1911, Frank McOsker determined to build a thresher suitable to his needs and one that would be the ultimate design. Accordingly, this machine was developed by 1912 in hopes of developing a company to manufacture it. Apparently, this did not materialize, since nothing else can be located in addition to this 1912 illustration from the American Thresherman Magazine.

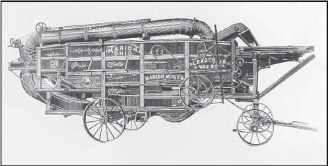

Marion Manufacturing Co., Marion, Ohio

Marion Manufacturing Co. began building Leader engines and threshers in 1886. By 1900, its line included the Leader Northeastern Special shown here; it was equipped with the Leader self-feeder and a Farmer’s Friend wind stacker. Like most threshers of its time, the Leader was of all-wood construction.

From all indications, Leader Manufacturing Co. left the thresher business about 1908 for reasons not shown in the present research. By this time, the threshing machine business was very competitive with many different companies trying for a portion of the market and the larger companies trampling the smaller ones with better prices and sometimes a better machine. For whatever reasons, the company does not appear in the trade directories after 1907.

Minneapolis Threshing Machine Co., Minneapolis, Minn.

This company was originally organized in 1874 at Fond du lac, Wis., as Fond du lac Threshing Machine Co. The firm failed. In 1887, it came back to life in Minneapolis under the heading shown here. By 1890, its Victory Separator was well on its way to fame, along with the company’s newly designed steam-traction engines.

By the early 1900s, Minneapolis Threshing Machine Co. had become a major manufacturer of grain threshers, offering this model about 1913. Its design included large cylinder teeth—larger than those of any other manufacturer. The company continued in the grain thresher and tractor business until merging with others in 1929 to form Minneapolis-Moline Farm Machinery Co.

Morley Self Feeder Co., Sioux City, Iowa

In 1904, Morley announced its new self-feeder to the thresher-man. At the time, this was the only self-feeder with a built-in automatic governor. Its purpose was to stop the feeder if the speed dropped below a certain level, to prevent slugging the separator. After a few 1904 advertisements, Morley Self Feeder Co. left the scene.

Morningstar Manufacturing Co., Napoleon, Ohio

For a short time, Morningstar advertised its new Napoleon separator, shown here in a cross-sectional view. Aside from a few advertisements, no information concerning this company has appeared. The illustration given here is from a 1903 issue of American Thresherman Magazine.

National Machine Co., Columbus, Ind.

A 1903 advertisement in American Thresherman Magazine provides an illustration of the National Self-Feeder. As shown, the bundles of grain were pitched into the side conveyors and carried sideways to the feeder for their journey to the threshing cylinder. Little is known of the company except for a few advertisements.

Nichols & Shepard Co., Battle Creek, Mich.

This company had its beginnings in 1848 building small threshers. In 1858, the company began building vibrator threshers, more or less following the earlier Cox & Roberts designs. Its Vibrator Separator was an immediate success and probably did more to revolutionize thresher design than any feature of its time. Shown here is the 1893 model of the Nichols & Shepard New Flag Separator.

About 1906, Nichols & Shepard introduced its entirely new threshing machine called the Red River Special. The name stuck and these machines became immensely popular. This was an all-wood machine and these remained in the line until about 1922, even though its all-steel machine had been introduced a few years earlier.

Responding to the coming of small tractors, Nichols & Shepard introduced its Junior Red River Special by 1914. It was built in 22 x 36 and 28 x 46 inch sizes. This one is equipped with self-feeder, wind stacker and grain weigher, but all of these accessories could be substituted for hand-feed parts and a common stacker.

By 1920, Nichols & Shepard had introduced its all-steel version of the Red River Special. This machine was continued after the 1929 merger that formed Oliver Farm Equipment Co. A detailed history of the Nichols & Shepard line may be found in the Author’s Oliver Hart-Parr (Motorbooks: 1993).

Northwest Thresher Co., Stillwater, Minn.

This company began building threshers in 1874; prior to that, it had functioned as Minnesota Thresher Manufacturing Co. Northwest threshers took the form shown here by 1903 when this engraving appeared in the pages of American Thresherman Magazine. In 1912, Northwest Thresher was taken over by M. Rumely Co., LaPorte, Ind.

J.L. Owens Co., Minneapolis, Minn.

While the origins of this company are presently unknown, a 1901 advertisement shows the Owens Bean Sheller, a hand-operated machine designed specifically for the purpose. Subsequently, the company specialized in this business, remaining active at least into the late 1940s.

In addition to its small hand-operated models, Owens also built various sizes and styles of belt-powered bean and pea threshers. Shown here is the 28 x 44 inch double-cylinder style with plain feed table and a common stacker.

Parsons, Rich & Co., Newton, Iowa

One of the earliest self-feeder attachments was the Hawkeye, shown here in operating position. Subsequently, there were many models and company changes, including the famous Ruth feeders from Parsons Band Cutter & Self-Feeder Co., also at Newton. Few farmers and fewer threshermen were sorry to see the hand feeder become obsolete.

Pioneer Thresher Co., Shortsville, N.Y.

Pioneer Thresher Co. was a successor to the Westinghouse threshers of George Westinghouse. This company was still listed as a thresher manufacturer in the late 1950s. Pioneer threshers of the 1930s took the form shown here and were offered in various sizes and styles.

Port Huron Engine & Thresher Co., Port Huron, Mich.

An 1893 engraving of the Port Huron Rusher separator also illustrates one of the earliest examples of the Farmers’ Friend Wind Stacker. Initially, it was a huge rectangular metal chute; in a short time, the latter was changed to the commonly known cylindrical design. Port Huron had its beginnings in 1851, taking its final name in 1890.

By 1900, the Port Huron Rusher had been upgraded from earlier years, but still retained the same essential design. This machine of that period is equipped with a web stacker, also known as a slat stacker or a common stacker; all three names mean the same thing.

In the early 1900s, Port Huron built a new machine. Although it was of all-wood design, this model of 1910 was offered in several sizes and featured the Port Huron Razor-Back cylinder teeth, guaranteed by the company to save up to $200 a season in grain that would otherwise be lost in the straw pile.

The Port Huron line included a small 20 x 34 inch “Tractor Special” thresher by the 1920s. This small machine was designed to thresh all kinds of grain in addition to its normal fare of wheat and oats. The company continued to build threshers into the 1940s.

Quick & Thomas Co., Auburn, N.Y.

The origins of Quick & Thomas are unknown, but the firm continued building Wide Awake threshers into the 1920s and had parts available for its machines for some years after. Numerous firms built small threshers for those regions in which small farms predominated. Few were sold in the large grain-growing regions.

Randolph Manufacturing Co., Newton, Iowa

In 1904, Randolph announced its new windstacker for grain separators. This unique design used the Randolph “Twin-Fan” system, actually employing two separate fans and discharge spouts as shown. Little else is known of the company aside from the 1904 illustration from American Thresherman Magazine.

Reeves & Co., Columbus, Ind.

Reeves began building threshers in 1874, coming up through the ranks to a dominant position by 1900. Its 1905 Reeves Compound Thresher took the form shown here, complete with wind stacker, self-feeder and weigher (it was also available without these accessories). The company functioned until 1912 when taken over by Emerson-Brantingham Co., Rockford, Ill. The latter continued building Reeves separators until 1924.

Roberts & Cox, Belleville, Ill.

Cyrus Robert and John Cox began building plain threshers at Belleville in 1848. The following year they adapted a vibrating pan behind the cylinder to separate grain from straw. This was the beginning of the vibrator thresher. About 1856, Cox sold his interest in the company; a year or so later, Roberts also sold out and moved to Three Rivers, Mich. At this location, he became involved again in the thresher business under the title of Roberts, Throp & Co.

Roberts, Throp & Co., Three Rivers, Mich.

As noted under Roberts & Cox above, Cyrus Roberts moved to Three Rivers about 1857. Subsequently, he became involved in the thresher business. Roberts was the originator of the vibrator system of grain separation and this cross-sectional view of the Three Rivers Invincible Thresher of 1884 illustrates how the straw and grain were separated.

An 1884 engraving shows the Three Rivers Invincible Separator in operating position. The feeder, usually also the owner and the thresherman, is shown standing on the feeder’s platform. In the early days of grain binders (when wire was used to tie the band), bits of wire often went through the machine, to the later detriment of livestock. After twine came into use, thresherman held a sharp cutter in one hand; sometimes these were attached with small leather straps to the hand. The bundle was then spread out and fed evenly into the cylinder.

Robinson & Co., Richmond, Ind.

This company had its beginnings in 1842 as a machine shop and later as a farm equipment manufacturer. The company began building threshers in its early days and by 1893 the Bonanza Separator took the form shown here. This one is equipped with a Perfection weigher from Selby, Starr & Co., Peoria, Ill.

For many years, the company operated under the title of Swayne, Robinson & Co. This illustration of about 1915 shows its Money Maker Separator. Hart-Parr Co., Charles City, Iowa, sold the same machine for a time as the Hart-Parr Money Maker. The company continued building threshers into the 1920s and supplying repair parts into the 1940s.

Russell & Co., Massillon, Ohio

In the 1840s, this company began making simple threshers and building on its early success, the company remained in this business until being sold at auction in March 1927. By 1883, the company was offering the New Massillon shown here with its Patent Lateral Moving Stacker. Russell & Co. had introduced this machine already in 1863 and sold 150 separators the first year.

An 1887 article in Farm Machinery Magazine regarding “Modern Threshing Machinery” illustrates the New Massillon thresher of that time. It was a simple and sturdy machine. Eventually, the company would refer to itself as building “the old reliable Russell line.”

By 1900, Russell had come out with several new thresher designs, including the Massillon Cyclone shown here. It was built in various sizes and was available with the usual attachments, although this one is shown with a hand-feed table and a common stacker.

Toward the end of its career in the separator business, the company came out with its New Russell, equipped here with the Massillon Farmers’ Friend Stacker, Boss Feeder and Peoria Grain Weigher. When this 1921 model came out, the company was not much longer in business, being sold at auction in 1927. However, parts were available until 1942.

Sageng Threshing Machine Co., St. Paul, Minn.

In 1908, the Sageng Combination Gasoline Thresher appeared. A company was organized to raise $1 million in capital to build the new machine, but the entire plan failed. Sageng had been a missionary in Madagascar for about six years and had developed his ideas for the machine during that time. The Sageng machine was equipped with a 40-horsepower engine.

Did You Know?

Challenge’s Daisy Hog Waterers had a 1910 price of $3.

St. Albans Foundry Co., St. Albans, Vt.

This interesting company was building an extensive line of farm equipment by 1880. An engraving of the time shows its “One Horse Power and Thresher.” This small outfit with the drive belt sold for $232 a handsome price for the early 1880s. The one-horsepower was also known as a railway power.

Snyder Combined Thresher Co., Troy, N.Y.

Calling it “the two best threshing machines produced,” the Snyder Combined was an oat and rye thresher, as well as being a straight straw rye thresher. A small folder in the Author’s files gives no indication as to whether this company preceded Grant-Ferris Co. with the Snyder design or whether the firm appeared after Grant-Ferris went out of business. Regardless, John G. Snyder was involved with both companies.

Springfield Engine & Thresher Co., Springfield, Ohio

Organized in 1882, this firm was offering its Improved Springfield Pitts Over-Blast Separator in 1885. This was one of the company’s first designs and reflects the use of the Pitts design. The overblast or overshot cleaning fan was designed to direct its blast beneath the riddle, blowing through the grain without blowing it over into the stacker.

One of the finest engravings found in our research for this entire book is represented with this rendering of the New Springfield Vibrating Separator of 1885. This machine was quite modern for its time and brought immediate success for its makers.

To build a large straw stack, the swinging stacker was a necessity. It attached to the back of the separator and received its power from a small belt. After leaving the common stacker, straw was carried to the stack for leveling by men with pitchforks. Eventually, the name of the company was changed to O.S. Kelly Co., reflecting the name of its principal owner.

A.W. Stevens Co., Marinette, Wisc.

This firm began building threshers at Genoa, N.Y., in 1842, moving to Auburn, N.Y., in 1878. For 1893, the company offered the Stevens Apron Thresher shown here. It was built to the preferences of some threshermen who disliked the vibrator machines, although the latter had become the dominant form by this time.

The Stevens New Vibrating Separator of 1893 was essentially the same as the firm had been building for several years. The design was attractive, especially when embellished with extensive decoration. The company moved to Marinette in 1898.

After moving to Marinette, the company emerged with the New Stevens, a machine much like the same model built in Auburn. However, the company designated it thus so as to set it apart from the Stevens Apron Thresher, an older design that still remained with the company in 1903. The firm continued for a few years, but disappears from the farm equipment directories after 1909.

Twin City Co., Minneapolis, Minn.

The Twin City Jr. wood frame thresher was announced in 1922. This design was made in 22 x 36, 24 x 42 and 28 x 46 inch sizes. The Twin City Co. was actually a division of Minneapolis Steel & Machinery Co., builders of the Twin City tractors. Current research has not determined its activity in the threshing machine business prior to this 1922 announcement. In 1929, the firm joined with others to form Minneapolis-Moline.

Waterloo Threshing Machine Co., Waterloo, Iowa

In 1905, Waterloo Threshing Machine Co. advertised its Win-nishiek separator, an impressive design shown here with self-feeder, wind stacker and grain weigher. Virtually nothing is known of the firm except that by about 1909, the same machine was being offered by Cascaden Manufacturing Co., also of Waterloo. After that, the Winnishiek disappears from the scene.

Weber Implement Co., St. Louis, Mo.

A few advertisements about 1905 illustrate the Illinois Special Separator, noting that Weber Implement had exclusive sales for this machine. Nothing has surfaced in the present research to indicate the manufacturer of the machine; obviously it was not Weber. After a short time, the Illinois Special disappeared and various trade directories make no mention of it in subsequent years.

Westinghouse Co., Schenectady, N.Y.

About 1835, George Westinghouse began building threshing machines at Central Bridge, N.Y., moving to Schenectady in 1856. By 1893, the firm had a machine with the appearance shown here from a catalog of Selby, Starr & Co., Peoria, Ill. The latter was illustrating how its Perfection grain weigher could be attached to the Westinghouse machines.

By 1912, the Westinghouse Improved Grain Thresher had already made its name in the marketplace. This 1912 catalog illustration comments that its threshers at the time had steel wheels instead of the wooden ones shown. The company continued into the 1920s, with Pioneer Thresher Co. continuing to supply parts for the Westinghouse machines, as well as building its own designs.

George White & Sons Co., Ltd., London, Ontario

Although this company began building steam-traction engines in the 1870s, the firm did not enter the threshing machine business until 1898. Subsequently, the George White separators became very popular, particularly in the Canadian provinces. The company ended production of traction engines in 1924, but it is unknown when separator production came to a close.

Wood Bros. Thresher Co., Des Moines, Iowa

In the 1890s, F.J. and R.L. Wood began building harvesting machinery, moving their plant to Des Moines in 1899. At this time, the company was incorporated as Wood Bros. Steel Self Feeder Co., reflecting its invention of a self-feeder for separators. Shortly after, the firm began building the Humming Bird separators in various sizes. This one is of 1905 vintage.

In 1911, Wood Bros. Thresher Co. was incorporated as a successor to the Self-Feeder Co. Its line of threshers and steam-traction engines remained very popular. By the 1930s, the firm was offering an all-steel machine; it continued on the market for some time, with production apparently coming to a close with the onset of World War II. As often noted in this book, World War II can be likened to a great curtain in the history of farm implements. After its end, many of the time-honored farming methods ended, to be replaced with new and innovative ideas.

Trade Names

Transplanters

By the early 1900s, various companies approached the mechanization of planting small seedlings. Until that time, small plants such as tobacco, cabbage, tomatoes and similar truck crops were planted by hand. Transplanters saved many hours of hard work compared to hand methods. They became fairly popular with large growers. During the research for this book, we came across several different makes, although there surely are more that we were unable to access.

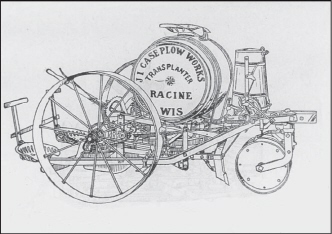

J.I. Case Plow Works, Racine, Wis.

In the 1920s, the J.I. Case Transplanter appeared; it has a great similarity to the Bemis transplanter from Madison Plow Co. The water tank was provided to give the seedlings an extra drink of water upon landing in their new home.

A.B. Farquhar Co., Ltd., York, Pa.

Farquhar bought out Bateman Manufacturing Co., of Grenloch, N.J., in 1930. The latter had developed a transplanter some years earlier. Farquhar sold them for at least a decade prior to buying the company.

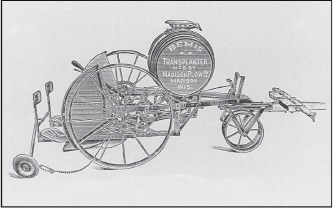

Madison Plow Co., Madison, Wisc.

A 1912 catalog of Madison Plow Co., illustrates its Bemis Transplanter. The Bemis had previously been built by Fuller &Johnson Manufacturing Co., but when it opted out of the farm machinery business, Madison took over the line, including the Bemis Transplanter.

New Idea Inc., Coldwater, Ohio

By 1940, perhaps earlier, New Idea was offering a transplanter for truck gardeners of the style shown here. It differed from most others because the laborers were seated forward instead of at the back of the machine. The transplanter became especially valuable when labor was scarce during World War II.

J.L. Owens Co., Minneapolis, Minn.

By the 1920s, this firm was offering the Owens Transplanter as an automatic and self-setting machine, somewhat more advanced than some of its competitors. The company continued to make these machines for a few years; by the late 1930s, it was out of production, although the company continued to supply repair parts.

Tread Powers

Under the heading of Horse Powers will be found a number of tread powers, also called tread mills or railway powers. The latter name is a reference to the wheel and track arrangement similar to a train. The tread power was fairly well developed by the 1830s and was one of the first means of rotary power available to the average farmer. A fortunate few were near a stream where water power could be secured and wind power was entirely dependent on windy days to accomplish any work.

J.S. Brubaker, Freeport, Ill.

From about 1885, comes this engraving of a small dog power, suitable for turning a sausage grinder or other light duties. At the time, the centrifugal cream separator was not a reality, nor were there any power washing machines, so the applications for a small power were quite limited.

S.S. Messinger & Son, Tatamy, Pa.

From the 1880s comes this illustration of Messinger’s railway power, complete with a separator. The advertisement notes that the power could be furnished for one, two or three horses. This early manufacturer was offering an extensive line of farm equipment by 1885.

Search Manufacturing Co., Sheboygan Falls, Wisc.

Most railway powers were inclined, although some were built in a horizontal pattern as shown. Search Manufacturing Co. also built threshersand other farm machines, but current research has not found any illustrations aside from this Horizontal Tread Power.

Whitman Agricultural Co., St. Louis, Mo.

By the 1880s, Whitman was manufacturing a large number of farm machines, including the Whitman Tread Power. This one was of the usual inclined design. As is obvious in this engraving, the movement of the tread turned a pair of large gears meshing with pinions on the pulley shaft. This greatly increased the belt speed and it was further enhanced by the use of a large band wheel.

Trade Names