Part Nine

Whipping and Seizing

There are many ways to prevent the end of a rope from unraveling (see Preventing Fraying), but whipping is by far the most effective. Whipping involves binding the rope’s strands or yarns with a tight wrapping of heavy thread or light twine. This seemingly imposing task is actually quite easy, and after doing it once or twice, you’ll find it second nature. Seizing is a similar procedure to permanently join two lengths of rope or sections of the same rope. A seized eye in the end of a rope is stronger, more secure, and more compact than any loop knot.

Uses: prevent fraying; mark positions on rope

Pros: easy, quick, and effective

Cons: whipping will unravel if the thread breaks

Uses: prevent fraying; mark positions on rope; as service to prevent abrasion

Pros: resists unraveling if cut

Cons: more time-consuming than Common Whipping

Uses: eyes; joining ropes for length or doubling; fastening rope to a shaft

Pros: stronger, more secure, uses less rope, and less bulky than knots

Cons: more difficult and time-consuming than knots; cannot be untied

Materials and General Methods

Few tools and materials are required for the whippings and seizing that follow. Here’s what you’ll need:

Whipping Thread

Also known as whipping twine, this heavy thread is sold by boat chandlers and rigging supply vendors. It is waxed, which helps it stay in position while you’re winding it around the rope. For needle-and-thread whipping methods, the wax also helps it pass smoothly through the rope’s fibers.

Traditionally (or as far back as synthetic ropes go), one used natural fiber twine for natural fiber rope, and synthetic twine for synthetic rope. Nowadays, most of the thread that is sold for whipping is nylon, and it works well for ropes of either natural or synthetic fiber. It is immensely strong for its diameter so it can be pulled very tight. Nylon also stretches, and if it is pulled tight around the rope while whipping, it will grip tenaciously.

If proper whipping thread is not available, carpet thread or other very heavy synthetic threads will do. These substitutes, however, will not be waxed, and even for the non-needle whipping methods shown here, it is helpful to wax the thread first by drawing it across a block of beeswax or canning wax.

Seizing Twine

Whipping thread is often used for seizing, but tarred marline, which is heavier, is recommended. Seizings are subjected to greater stress than whipping, and when pulled tight enough for a seizing, narrower thread might bite into and cut some of the rope’s fibers. Marline is expensive and hard to come by, but braided nylon mason’s twine is a good alternative. Available at any builder’s supply store, it is very strong and quite inexpensive. Make sure you get the braided stuff, not twisted.

Knife

Any type will do, as long as it’s sharp and straight-bladed, not serrated.

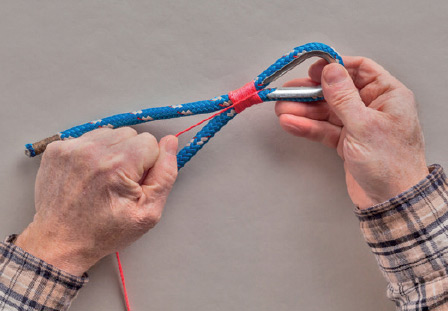

Marlinespike

Whippings and seizings must be pulled so tight that you can’t do it bare-handed; the twine will bite you! By tying a Marlinespike Hitch around a proper marlinespike, screwdriver, ice pick, or similar object, you can exert all the tension you need.

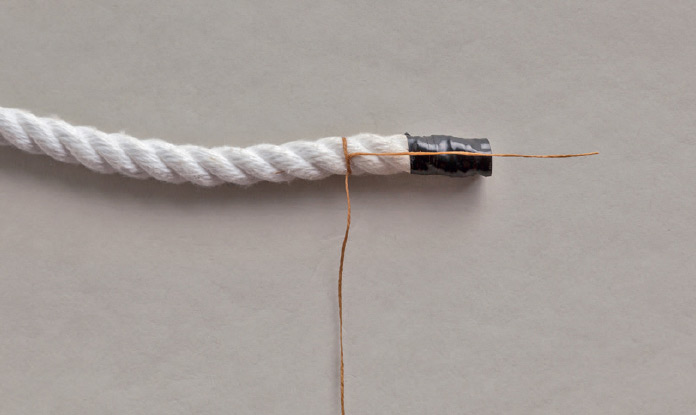

Electrician’s Tape

Tape works better than cordage for temporarily holding the strands together while you whip the end. It’s easier to wrap the whipping right up to the edge of the tape. Masking or painter’s tape will work in a pinch, but neither can be stretched tight like plastic electrician’s tape.

Cutting Board

You’ll want something to cut the whipped end against. A scrap of plywood or dimensional lumber will do the job.

Common Whipping

Also known as: Plain Whipping, Ordinary Whipping

This is the easiest whipping to apply, and it is reliable in most applications. Its drawback is that if a single wrap of the thread is worn through or cut, the entire whipping will unravel.

Instructions

1. Apply electrical tape around the rope just above where you intend to whip it. If the rope is already frayed, apply the tape on a part that is still intact. Cut through the tape to remove the frayed end or excess length of rope.

2. Make a bight near the working end of the whipping thread. This whipping will be easier if you pay the thread directly from the spool, as shown, rather than cutting off the length you will need.

3. Lay the bight in the thread against the rope, with the bight overlapping the tape. The bottom of the bight should be one to two times the rope’s diameter back from the tape, and you should leave a few inches of working end beyond that—enough to pull on later. (Leave a little more than is shown in the photo.) Wrap the thread directly from the spool around the working end of the bight, making a Single Hitch around the rope in the same direction as the lay of the rope.

4. Take a round turn around the rope and the bight, laying it right against the Single Hitch. Take a second round turn, laying it against the first, working toward the end of the rope. Holding the spool, pull the thread really tight.

5. Continue making round turns, pulling the thread tight and laying each one right against the previous turn. Stop when the wraps cover a length of rope that is between one and two times its diameter. The end of the bight should still be visible, and there should be enough rope exposed between the wraps and the tape to cut through safely.

6. Holding the wraps tight against the rope, cut the thread from the spool, leaving an end longer than the whipping.

7. Pass the newly cut end all the way through the bight.

8. Tie a Marlinespike Hitch around a spike in the working end of the bight at the bottom of the whipping. Pull on that end, to bring the eye of the bight under the wraps. It will pull the opposite end of the thread along with it. Stop pulling when the bight is well buried under the wraps. Trim the ends at the top and bottom of the whipping.

9. Cut the rope between the whipping and the tape.

French Whipping

French Whipping is a little more difficult to tie than Common Whipping, but it is more secure, because each wrap is tied as a Half Hitch. Should any single wrap be worn through or cut, the rest of the whipping will remain intact. Half Hitches cannot be tied readily from the spool, so the whipping thread must be cut first, allowing a goodly length for pulling and tying the final knots tight.

Instructions

1. Allowing one to two times the rope’s diameter for the whipping, tie a Half Knot around the rope with both ends of the whipping thread facing the rope’s end. If you are whipping laid rope, the long working end of the thread should face the same direction as the twist toward the end.

2. Align the short standing part of the thread toward the rope’s end.

3. Tie a Half Hitch in the working end of the thread adjacent to the Half Knot, capturing the short end against the rope.

4. Pull the first Half Hitch tight up against the Half Knot. Trim the short end of the thread so that it is a little shorter than the intended length of the whipping.

5. Continue tying Half Hitches, pulling each one very tight right up against the previous one and continuing to bury the thread’s short end against the rope.

6. When the wraps cover a length of rope at least equal to its diameter (1.5 times the diameter is better), tie a doubled Half Hitch by making two wraps around the rope before passing the end through both. Pull the knot tight. Make a second doubled Half Hitch and pull it tight.

7. Trim the long end of the thread, trim the short end if any remains exposed, then cut the rope between the whipping and the tape.

8. The stacked Half Hitches confer a spiral pattern to the finished French Whipping.

Flat Seizing

A flat seizing is an extremely effective way to make a loop in the end of a rope, to join two ropes together to extend their length, to double ropes for strength, or to fasten a rope in line with a shaft or pole. The seizing is extremely secure, uses less rope than a knot, and is less bulky and apt to catch on obstructions.

Instructions

1. Leaving the twine on the spool, tie a Constrictor Knot around the two pieces of rope to be joined or both legs of a bight (as shown). Position the Constrictor Knot so as to allow the length of the completed seizing to be twice that of the diameter of the rope.

2. Align the short end of the twine between the legs of the bight. Using the spool to pull the twine, begin wrapping round turns around both legs of the rope and the short end of the twine.

3. Place each round turn right up against the previous one, and pull each one as tight as possible.

4. Trim the short end of the twine so that it will be completely covered by the seizing. Keep wrapping until the seizing is twice as long as the rope’s diameter.

5. Make a final turn through one leg of the bight, then pull the twine down over the wrappings.

6. Bring the end between the legs of the bight and pull it up tight on the other side. Pull the end through the eye, completing the first frapping turn. Then go around again to make another frapping turn.

7. Bring the twine through the eye to complete the second frapping turn. Pass the end under the first frapping turn. A pointed tool can be used to lift this tight frapping turn slightly so that the end can be passed through.

8 Complete a round turn around the first frapping turn, then pass the twine under both frapping turns.

9. Bring the end of the twine through the eye and pull it tight to bring the final knot between the legs of the bight at the base of the eye. Trim the end close.

10. The finished seizing. A second seizing should be added to secure the bitter end to the standing part as shown below.