Kit Assembly

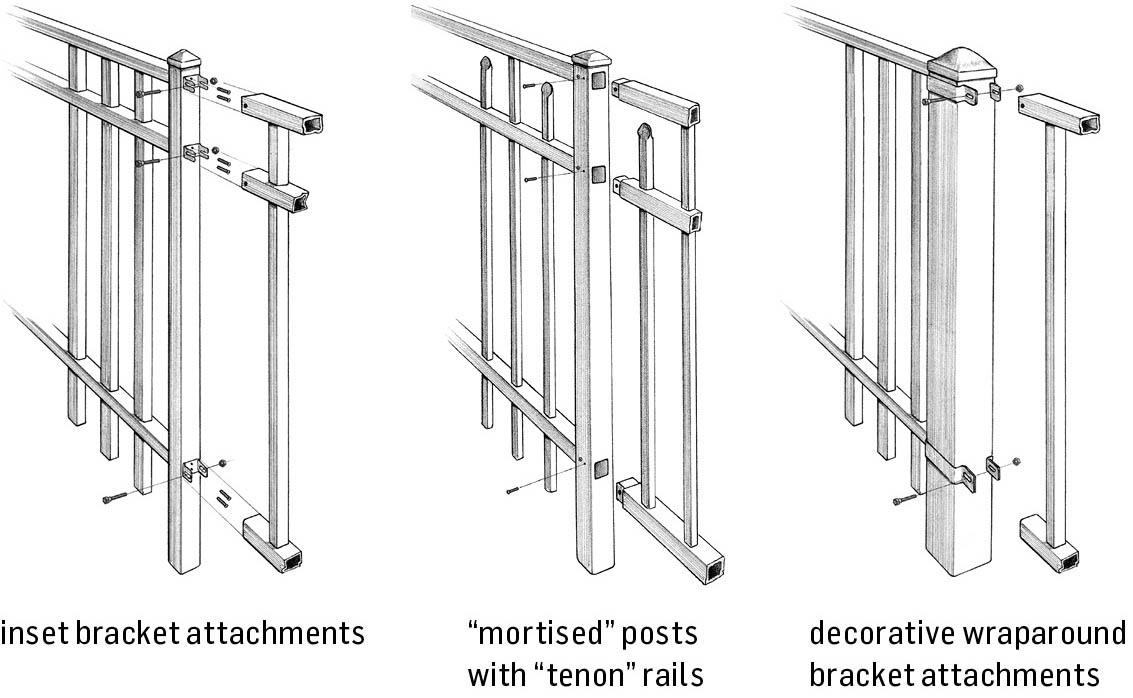

Ornamental fence kits typically use bolts and screws to attach rails to posts, but the exact mechanism can differ from manufacturer to manufacturer.

Metal is adaptable to almost any fencing need, from high-end residential to remote, rural applications. Most types of metal fence can be constructed quickly and require little upkeep and maintenance. This chapter focuses on the two most common types of metal fencing: ornamental metal (the modern answer to traditional wrought iron) and chain link. If all you need is an effective barrier to corral pets or keep critters out of your garden, a simple mesh fence should do the trick.

It is hard to think of any fencing material that offers a better combination of security, beauty, strength, durability, and see-through visibility than wrought iron. But building an authentic wrought-iron fence requires a great deal of labor. Each piece of iron must be heated and shaped or twisted, then joined to the main structure. Cast iron has largely replaced wrought iron for fencing because single molds can be used to create endless quantities of identical metal pieces.

Most of what passes for wrought iron these days is really a much lighter and less expensive imitation that is made out of aluminum, steel, or (the new, nonmetallic kid on the block) composite or polymer materials. All of these are available in styles that mimic traditional wrought iron, at least from a distance. Many contemporary styles are also available. Ornamental metal fences are sold in kits that can be easily transported and assembled by do-it-yourselfers.

DIY-friendly ornamental fencing is sold in kit form, and it’s a good idea to buy all of the materials from the same manufacturer. Each product has its own style and methods of assembly. Welded steel tends to be somewhat stronger than aluminum, but the latter offers the great advantage of being rust-resistant and, therefore, requires less long-term maintenance. Steel fence sections often are welded on site by contractors. Alternatively, steel fencing can be purchased in preassembled sections, which the do-it-yourselfer can complete on-site. Aluminum fencing is more likely to be put together with screws, nuts, and brackets.

Black is the traditional standard for most metal fencing, but color options are improving all the time. You can find powder-coated steel and aluminum ornamental fencing in a range of lighter colors, which is a popular option for pool enclosures.

Most manufacturers offer several options of strength and security with metal fence gates. Popular upgrades include self-closing and self-latching gates with keyed deadbolts — all included in a package and easy to install.

Ornamental fence kits typically use bolts and screws to attach rails to posts, but the exact mechanism can differ from manufacturer to manufacturer.

Ornamental metal has several “faux” versions. Some iterations are manufactured from a mixture of polypropylene and fiberglass, while others are all fiberglass and are made through a process called pultrusion. Pultruded fiberglass is commonly used for making high-strength floor grates for industrial and commercial applications. Polypropylene is the primary material used to make composite decking boards (and fencing). Manufacturers claim that nonmetal fencing is fade resistant, durable, and virtually maintenance-free. Regardless of these claims, a fence made from this material will not rust and will never need to be painted or stained.

One composite system I’ve seen comes in 6-foot-long sections at 4 to 5 feet in height. The sections are joined by concealed fasteners, which is a nice improvement over aluminum fences. The gates are steel-reinforced and feature self-closing hinges and latches.

First produced in Europe in the 1850s, chain link became a fixture of the American landscape through the twentieth century. It offers a great combination of security with visibility, and is strong, long-lasting, and affordable. It stands up well to regular use and is relatively easy to install.

Standard galvanized chain link will not win any beauty contests (and therefore is not the best choice for front yards), but a few options can make the material more attractive. Color-coated chain link — in green, brown, or black — can blend in nicely with many environments. Colored chain-link fencing with square posts has a nicer look than the same fence with standard round posts, if for no other reason than because it is different. Weaving colored slats through the chain-link mesh is another way to improve the look. Slats are available in a wide range of colors and often are used to add privacy. Alternatively, tall plants or vines that climb up and through the mesh can help to obscure the fence.

Chain link comes in heights of 3 feet to 12 feet. The most common height is 4 feet, which is an easy height for do-it-yourselfers to install. Taller fences can be tricky to install and probably should be left to fencing contractors.

There are many manufacturers of chain link, and although the parts are often interchangeable, I think it’s best to buy everything you need from one supplier. There are quality differences, so it pays to shop around and ask some questions. After deciding on height and surface coating, the key factors to consider are gauge and mesh size. The size of the framework (posts and rails) is typically informed by the height and intended use of the fence.

Gauge is a standard measurement of the diameter of wire: the higher the number, the thinner (and weaker) the metal. You can find chain link in gauges ranging from 6 to 14, but for most residential purposes I would suggest something in the range of 9 to 111⁄2. Wire that is thinner than 111⁄2 gauge stands a much better chance of being damaged over time.

Mesh size. The size of the mesh relates to both visibility and strength. Smaller mesh means that more wire must be used in the fence, which adds to its strength (while reducing visibility). Mesh under 1" is generally found only in high-security installations. Swimming pools and tennis courts are often enclosed with 11⁄4" to 13⁄4" mesh, while standard yard fences rely on mesh of 2" or more. Obviously, thicker-gauge metal and smaller mesh size will translate into greater expense, so you’ll want to choose carefully. One other factor to keep in mind is that kids have a strong preference for bigger mesh, which allows ample room for their toes. This is to say, the bigger the mesh, the easier the fence is to climb.

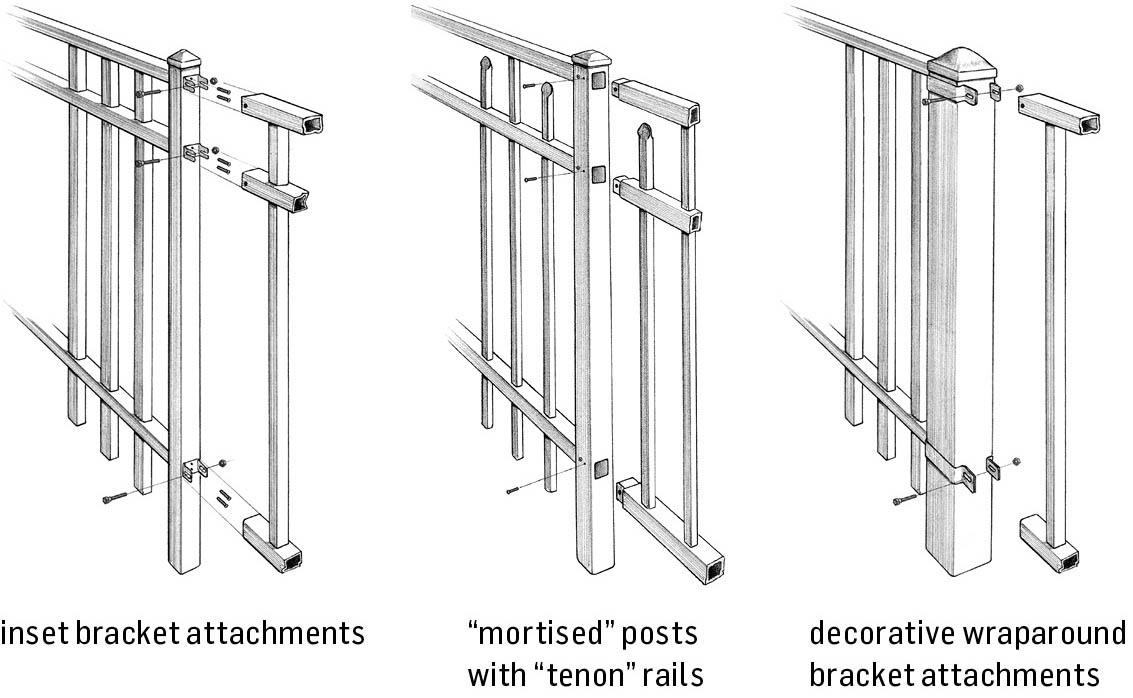

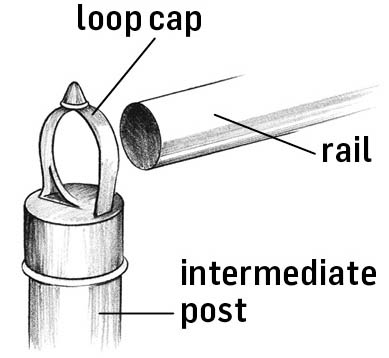

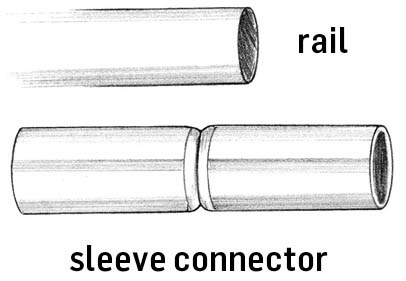

Framework. The chain-link mesh material itself (often called “fabric” in the trade) is not the only component that affects strength and durability of a finished fence. The posts and rails that constitute the fence frame are also critical to the lasting quality of a chain-link fence. Posts and rails are offered in different strengths and sizes. Manufacturers tend to break down the choices into categories based on the height of the fence and the degree of use it will get (light, medium, or heavy). Terminal posts (those used at ends, corners, and gate openings) are the largest, followed in size by the intermediate posts and then the top rail. Sleeve connectors are used to join sections of top rail.

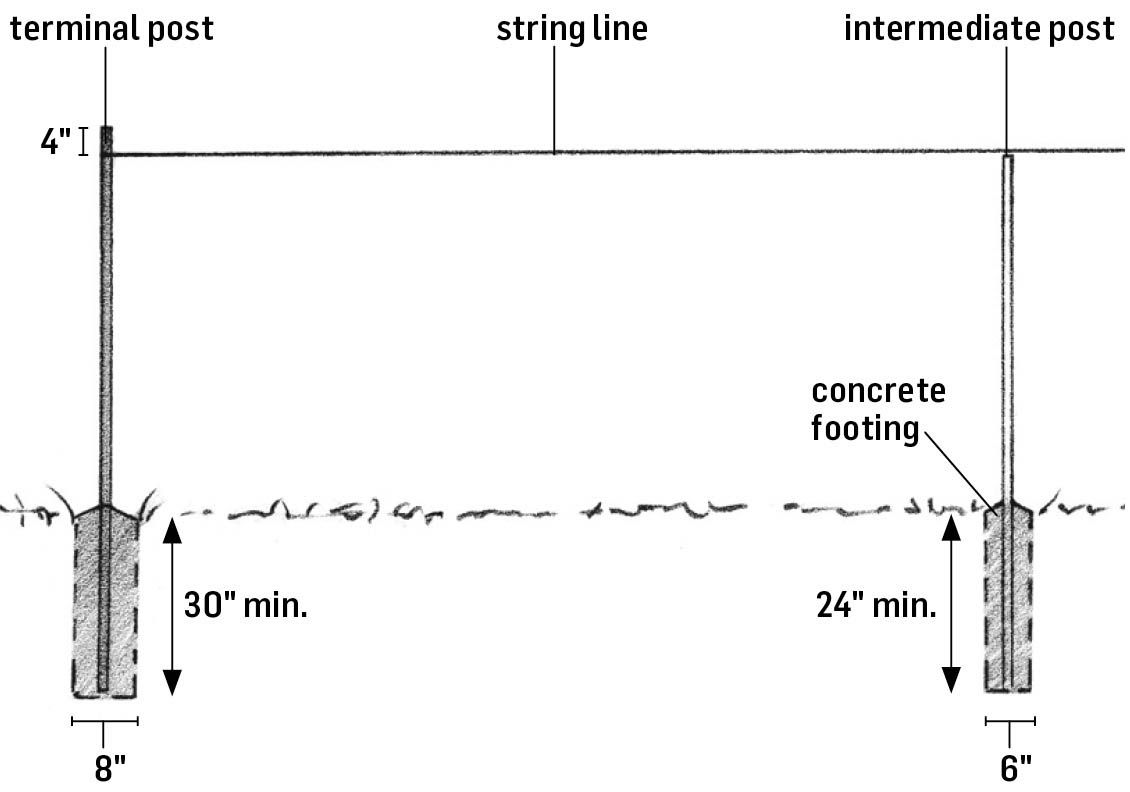

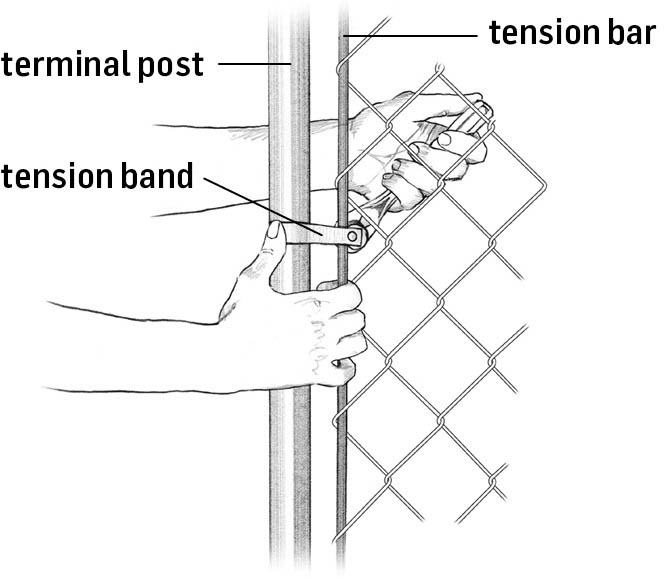

Fittings. The fabric is joined to the frame with a variety of fittings, including bands, rings, nuts, bolts, and gate hinges and latches. The completed fence is only as strong as these fittings, so you should carefully compare the hardware that accompanies different product lines. Make sure that any warranty that comes with the fencing covers all components.

The installation of a chain-link fence is pretty straightforward. Your fencing may or may not come with detailed instructions. The following guidelines should help you through a typical installation. However, this guidance should not be treated as a substitute for any instructions from the manufacturer.

On a gradual slope, you can set all the posts at the same height above ground so the fencing follows the slope perfectly, as in Sloped framing. More pronounced slopes may require a terraced pattern similar to Stepped framing. For more complex sites, consult your supplier or the manufacturer for recommendations.

This step is easier to accomplish with a helper who holds up the fencing while you make the connections.

Use tension bands to tie the terminal post to the tension bar. Fasten the nuts to the bolts tightly with a socket wrench.

With the fencing attached to one terminal post, use a pulling bar or stretcher and a come-along to pull the slack out of the fencing before fastening it to the other terminal post.

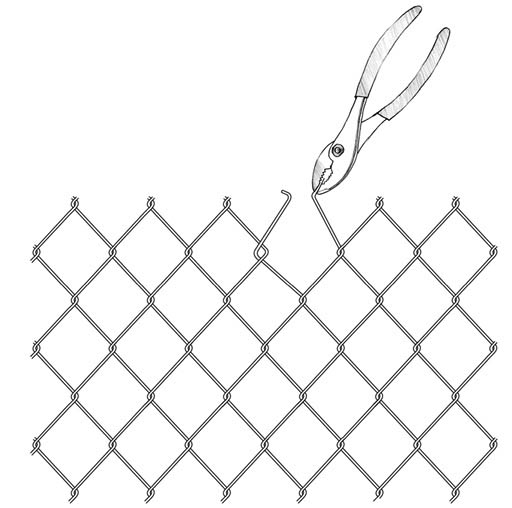

Remove excess fencing by loosening the loops of the same wire at the top and bottom of the fence and then unwinding the wire.

Using pliers, attach the fencing to the top rails and intermediate posts with tie wire.

Most chain-link fences have matching gates (again, buy the gates from the same supplier/manufacturer as the fencing). Adding a gate is all about attaching hardware. First decide which way you want the gate to swing, then attach the two gatepost hinges to the appropriate gatepost, about 8" from the top and bottom (a tall gate may require more hinges). The pins on the hinges should point toward each other, as shown in the accompanying illustration. Next, attach the gate frame hinges to the gate frame, and then hang the gate in place. With the bottom of the gate about 2" above ground, tighten all the nuts and bolts on the hinges. Finally, fasten the latch to the other side of the gate at a comfortable height.

Metal mesh is fencing stripped down to its most elementary, functional essence. Determine exactly what you want the fencing to keep in or out, then choose the appropriate fence construction and mesh material.

Mesh fencing can be knotted, welded, or woven, depending on the function of the fence and the gauge of the metal used. Welded and woven fencing is most common, but knotted mesh offers flexibility that’s appropriate for rolling terrain (some types of knotted mesh have sharp edges and so aren’t suitable for animals or kids).

The gauge, or thickness, of mesh wire ranges from very thin 20- or 24-gauge wire used on netting to thick 9- or 10-gauge wire used for heavy-animal enclosures. The size of the mesh openings ranges from 1⁄4" squares to 2" × 4" rectangles or diamonds. Fencing height starts at 12" and goes up to 72". Terminology may vary by manufacturer or supplier, but here are the basic types:

Hardware cloth. Thin (19- to 23-gauge) wire produced with small mesh sizes (1⁄4" or 1⁄2" square). For light-duty fencing, such as for small rabbit cages.

Poultry netting. Typically 20- or 22-gauge wire woven into hexagonal shapes. Mesh sizes range from 5/8" to 2". Lightweight and easy to handle; often used for low-cost garden fencing.

Small-animal fencing. Often used to keep rabbits and rodents out of gardens. Mesh openings at the bottom of the fence are smaller than those at the top. Heights range from 28" to 40".

Apron fencing. Includes a preformed apron on the bottom, which is laid horizontally a few inches below ground to prevent animals from burrowing under the fence. You can provide similar protection with standard fencing by bending and burying a portion of the bottom edge of the mesh.

General-purpose mesh fencing. Also called utility, garden, or kennel fencing, this type is typically welded wire fencing with uniform, rectangular mesh. Used for garden and small-animal enclosures. Mesh sizes include 1⁄2" × 1" to 2" × 4", in heights up to 72". Heavy-duty 2" mesh makes a less expensive but suitable alternative to chain link. Green vinyl-coated 3" × 2" mesh is popular for garden enclosures.

To build a permanent mesh fence, use 4×4 wood posts set in the footing of your choice (see chapter 2). Attach the mesh to the posts with galvanized fence staples (U-shaped nails). For a temporary or seasonal barrier, metal T-posts go in quickly and stay put without a footing. Attach mesh to metal posts with wire or wire clips designed for this purpose, or use posts with small hooks that you cinch over the mesh wires with a hammer.