Chapter 9

Soil Management

Proper soil management is an important part of any operation that involves crop production or natural resource management. The goal of soil management for crop production is to establish and maintain the correct combination of all soil factors necessary to optimize and maintain production efficiency. Effective soil management will ensure that food and fiber production are maximized and sustained over the years while leaving the soil in a productive state.

In agriculture, soil management is closely related to crop management. It includes (1) maintaining the soil in a good physical condition; (2) keeping the chemical characteristics of the soil in the proper balance, such as maintaining soil fertility and the correct pH; and (3) influencing the biological or organic portion of the soil so that maximum benefits result.

Physical Condition

Soil with good physical condition is important to plant growth. The physical condition of soil as it relates to ease of tillage, quality of the seedbed, and resistance to seedling emergence or root growth is referred to as soil tilth. Good tilth helps the water infiltration rate, water-holding capacity, soil−air interchange, and root development. It also aids in reducing erosion. Soil tilth can be maintained by continuing to return plant residues and organic materials to the soil and by using tillage practices that do not compact soil. Physical condition deteriorates if the soil is compacted by tilling when it is too wet or by using heavy machinery too often.

Residue Management

Crop residues influence the soil's physical condition. A soil that is loose and friable is generally considered to have good tilth. Managing the residues on the soil surface is important to maintaining the tilth. Often the old crop residues are incorporated (buried) into the soil during tillage. The first residue management step is deciding if and when crop residue incorporation is needed. The time to incorporate residue will depend on the cropping system. Options for residue management range from complete incorporation of residue—often referred to as clean till—to using no-till where all the old crop residues are left on the soil surface.

Residue may be incorporated any time from immediately after harvest to just before planting of the next crop. If the field is to be planted the following year, it is sometimes desirable to incorporate residue soon after harvest to start the decomposition process. This helps to ensure that a smooth seedbed can be prepared and that the soil is free of excessive residue for planting. If a crop is not going to be planted the following spring, the residue can be left on the soil surface to act as a cover. This would greatly reduce erosion by both wind and water and conserve soil water.

Where wind or water erosion is a problem, partial incorporation of residue into the soil may be desirable, with a portion left on the surface (stubble mulching). Some farmers never incorporate plant residues into the soil and plant the subsequent crops with the residue still on the surface (minimum tillage).

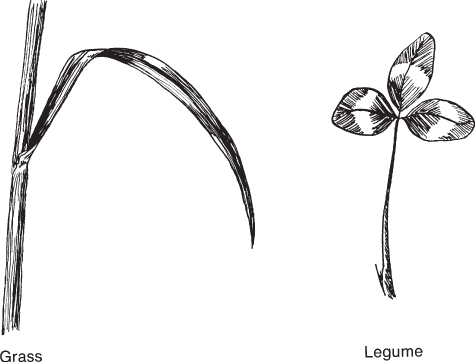

As discussed in Chapter 4, bacteria decompose (break down or change) crop residue after it has been incorporated into the soil. Bacteria break down corn, wheat, and grain sorghum (all in the grass family) residues quite slowly, whereas alfalfa, soybean, and clover (all in the legume family) residues decompose more rapidly. The principal reason for the difference in decomposition between the two groups is the amount of nitrogen (in protein form) in the residue (Fig. 9.1). Legumes are high in nitrogen, whereas grasses are low in nitrogen. If it is ever desirable to speed up the decomposition or breakdown of a low-nitrogen residue, adding nitrogen fertilizer should help.

Figure 9.1 Grasses are low in nitrogen at maturity and are more slowly decomposed than legumes, which contain much more nitrogen.

Tillage Practices

Tillage practices used to manage soil vary widely. The type of crop grown, type of soil, erosion hazards, the use (or not) of irrigation, and cost of the tillage practice are all considered in determining which practices to use.

Tillage of soil may vary from farms on which there is no tillage (except planting)—called no-till or minimum till systems—to farms where the soil may be tilled 8−10 times a year. Because of excessive erosion and high costs, the trend for most producers is to reduce the number of tillage operations. Many farmers now use a reduced or conservation tillage system, where some crop residue is left on the surface and the soil is only moderately disturbed. These systems can be thought of as a compromise between the extremes of tillage, moldboard plowing, and no-till. Reduced tillage was initially adopted mostly by farmers in the higher rainfall areas of the eastern and midwestern parts of the United States.

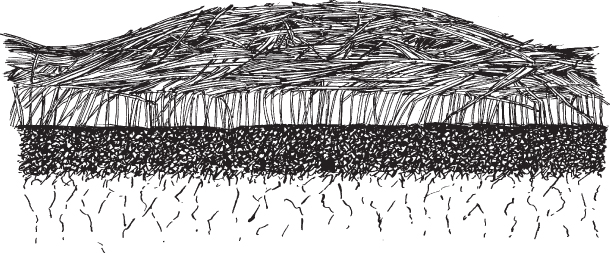

In a no-till system, all the crop residue is left on the surface and seeds are planted with as little disturbance of the residue and soil as possible. An example of no-till planting is illustrated in Figure 9.2. In addition to cost savings, minimum tillage also decreases soil erosion and normally increases the water infiltration rate. Minimum tillage may require a modification of certain practices, including planting, fertilization, and application of pesticides. Fertilization rates, particularly for nitrogen, may need to be increased because soil temperatures tend to be lower as a result of the surface residues. Surface residue could also harbor insects, thereby resulting in an increased need for insect control.

Figure 9.2 Minimum tillage or no-till often means planting while residue from the previous crop is still in the field.

Soil erosion by water and wind has been a problem since soils have been tilled. Conservation tillage practices were developed to reduce the loss of valuable topsoil by erosion; thus, they often involve leaving a portion of crop residues on the surface of the soil. By definition, conservation tillage is in effect when 30% of the soil surface is covered with crop residue. Conservation tillage has been practiced for many years in the areas of limited rainfall and potential wind erosion in the western United States. Crop residue is left on the surface of the soil not only to decrease erosion but also to conserve water (stubble mulching).

Reasons for Tillage

Tillage refers to the moving, turning, or stirring of the soil. The soil is tilled to accomplish a number of things:

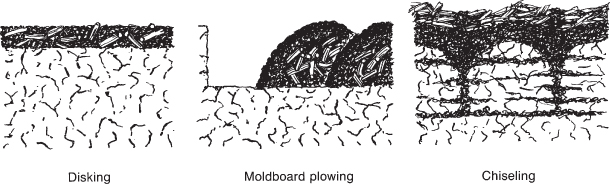

- 1. Incorporate residue. Incorporation of some crop residue into the soil hastens its decomposition. Without the decay of crop residues, it could become difficult to prepare a good seedbed and plant the seed. Different degrees of residue incorporation are illustrated in Figure 9.3; the implements employed are discussed in the next section.

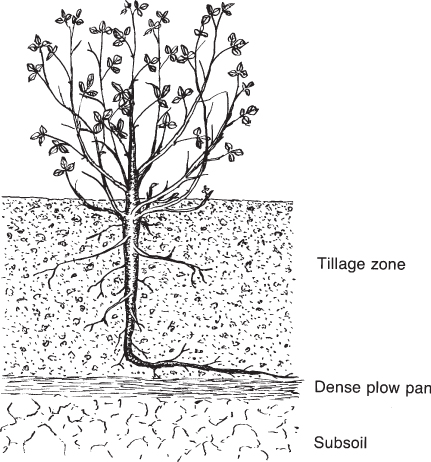

- 2. Improve physical condition. Too often soils are worked or crops are harvested when the soil is too wet, causing the soil to compact or form a plow pan (Fig. 9.4). Some soils have naturally compact layers; deep plowing or chiseling can be done to break up the compacted soil or plow pan.

- 3. Reduce erosion by wind or water. Some tillage practices are used to reduce erosion (see Chapter 10). They include plowing on the contour, terracing, furrow diking, stubble mulching, and creating ridges to roughen the soil surface.

- 4. Prepare the soil for planting. This may consist of cultivating beds in rows in which to plant seed. Or it may involve a light disking or harrowing to break up a surface crust and at the same time destroy small weeds.

- 5. Incorporate pesticides, fertilizers, and animal manures. Some pesticides and fertilizers may be left on the soil surface and still be effective. Most pesticides, however, are incorporated either with a light disking or by using a rotary hoe. Fertilizers and manures are often incorporated into the soil by either disking or plowing.

- 6. Control pests, including weeds, insects, and diseases. Even though many types of weeds are controlled by chemicals, tillage practices are also used. A light disking before (or during) planting may be used to kill early-emerging weeds. Deep moldboard plowing is occasionally used to turn up roots of hard-to-kill weeds such as Johnsongrass so that they will be killed by freezing. Shallow tillage may be used on fallow land to control weeds. Tillage is also used to incorporate residues or host plants that might harbor insects and diseases.

- 7. Increase water infiltration. In areas where moisture is often limiting or where irrigation is practiced, certain tillage methods are used so that water, particularly rainfall, can move into the soil more rapidly or stay on the surface until it does so. Tillage that breaks up a surface crust can increase the infiltration rate. Forming rows on the contour and terracing as well as furrow diking (see Chapter 10) helps soil hold water longer.

Figure 9.3 Disking incorporates crop residue to a shallow depth, a moldboard plow covers the residue, and a chisel plow goes deep but leaves no residue on the surface.

Figure 9.4 Plow pans can form at the depth of tillage and inhibit root penetration because of their increased density. Chiseling or periodic deep plowing can prevent this effect.

Tillage Implements

Several types of farm implements are used to accomplish the tasks listed above. The degree of soil disturbance varies by the type of implement, how deep it is placed in the soil, and how fast it passes through the soil. Primary tillage implements refer to those that disturb the soil a great deal and incorporate significant amounts of crop residue (moldboard plow, chisel plow, and disk), while secondary tillage implements (disk, field cultivator, and harrow) generally till the soil to a shallower depth and often follow primary tillage operations.

A moldboard plow (Fig. 9.5A) is used to lift the soil and completely or partially turn it over. This can be done at any depth, but in most areas, it is 6-10 in. (15-25 cm). Development of a moldboard plow with steel shares (the “share” is at the base of the plow; it cuts and lifts the soil onto the “moldboard” which inverts the soil) was one of the key factors that enabled development of the Midwest and Great Plains of the United States as major crop-producing areas in the nineteenth century.

Figure 9.5 Implements used for farming.

Moldboard plowing is often done to incorporate residue and break up dense soil. When followed by some secondary tillage, moldboard plowing helps create a fine seedbed for planting. Moldboard plowing incorporates most of the crop residues, which may be good for residue decomposition and seedbed preparation but can also leave the soil vulnerable to erosion. It was once the most common type of primary tillage but its use has decreased significantly due to the high cost of fuel to pull the plow and concern regarding excessive erosion.

Deep plowing to a depth of 18−36 in. (46−92 cm) is done in certain areas. This is usually used on a soil that has a sandy surface and a clay subsoil, with clay being brought to the surface to mix with the sandy portion. In some regions, it is also used to incorporate underlying mineral soil into a surface layer of thick muck (high organic material).

A disk (Fig. 9.5B) can be used for both primary and secondary tillage by varying the depth of the implement. It is often used to incorporate materials into the surface of the soil, usually the top 4−6 in. (10−15 cm). This often includes chemicals for weed control, fertilizers or other soil amendments, or crop residues. A light disking is also used to control weeds. Disking or shredding of crop residues with an implement called a flail chopper sometimes precedes moldboard plowing to improve residue incorporation and prevent clogging of the plow. One disadvantage of disking is that it tends to compact the soil just below the depth being tilled.

A chisel plow is another type of implement used in primary tillage (Fig. 9.5C). It is an implement pulled through the soil usually at depths of 10−14 in. (25−35 cm) and used primarily to break up a hardpan or plow sole (a dense, compacted layer of soil usually caused by farm implements such as the moldboard plow). Some chisel plows are made so that the chisel vibrates, causing the soil to shatter or loosen. Recently, several companies have produced implements that combine a disk, chisel plow, and harrow. These implements are quite popular because the depth, spacing, and size of the individual elements can be customized or adjusted to suit the farmer's needs and the field conditions. Such implements allow farmers to use a single implement for most of their tillage operations.

A spring chisel or Graham-Hoeme plow is a tillage instrument used in the low-rainfall areas of the United States (Fig. 9.5D). Its principal advantage is that the soil is tilled to control weeds (and partially incorporate residue) while minimally disturbing the surface soil and thereby reducing loss of soil water by evaporation.

A lister may also be used for tillage (Fig. 9.5E). It forms the soil into beds or rows 6−8 in. (15−20 cm) high where the seeds may be planted or the bed may be lowered 3−4 in. (7.5−10 cm) before planting.

A planter (Fig. 9.5F) and a cultivator (Fig. 9.5G) may also be used to till the soil. Even though the principal function of the planter is to place the seed in the soil, the furrow openers and other attachments are capable of cutting through crop residues so fertilizers and pesticides can be applied during planting. Cultivating was usually done in the past to control weeds that germinated after planting. However, modern herbicides have replaced much of the requirement for cultivation. Cultivation is still used in some areas when chemical weed control fails and to break up crusts to improve infiltration.

Chemical Characteristics

It is also desirable to keep the chemical characteristics of the soil in proper balance or condition. This includes maintaining soil pH in an optimal range, providing a sufficient and balanced supply of nutrients, preventing or alleviating saline–sodic soil conditions, and avoiding soil degradation from toxic pollutants.

Soil pH

Soil pH (see Chapter 5) is important in crop production and is an indicator of the acidity or alkalinity of a soil as well as an indicator of levels of certain nutrients and their availability. It also influences biological activities in the soil.

If a soil is too acid (below pH 5.0), phosphorus, iron, and certain other nutrients have limited availability, and levels of calcium, magnesium, and potassium will be low. If a soil is too alkaline (above pH 7.8), phosphorus, iron, zinc, manganese, and other micronutrients will have reduced availability but there will be an ample supply of calcium, magnesium, and potassium.

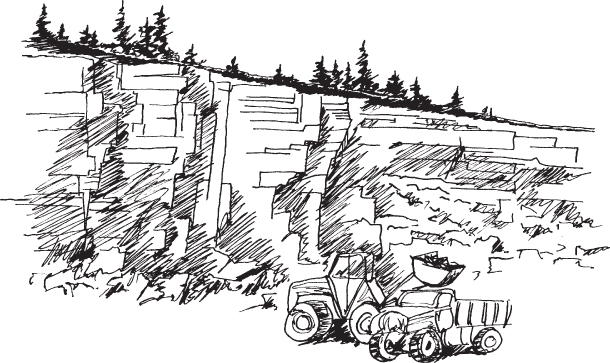

Soils in the eastern United States and in many of the high-rainfall areas worldwide are more likely to be acid. If soils in these areas are in crop production, the pH usually ranges from 5.0 to around 7.0. A soil test is the best method for determining whether pH needs to be adjusted. Most soils are not adversely affected by acidity if they are in the pH range of 6.0–7.0. If the soil pH is 6.0 or below, it may be necessary to raise the pH (make it less acid) by the use of limestone (calcium and/or magnesium carbonate). Limestone for application to soil (also called aglime) is relatively inexpensive because it can be quarried from abundant deposits (Fig. 9.6).

Figure 9.6 Agricultural lime is produced from limestone quarried from bedrock.

The amount of limestone needed per acre (hectare) depends on the cation exchange capacity (CEC) of the soil (see Chapter 5). The CEC is dependent on texture, type of clay mineral, and organic matter content. At a pH of 5.5, a soil with a high CEC might need 3 tons of limestone per acre (6.72 Mg/ha [mega-grams/hectare]) every 2–3 years, whereas a soil with a low CEC may need only 1 ton per acre (2.24 Mg/ha) to raise the pH to a desired level (Fig. 9.7). The application rates and amount of time between applications depend on the crops being grown, the amount of rainfall and leaching, and the CEC.

Figure 9.7 Many humid-region soils need regular applications of lime to combat acidity.

Limestone increases pH (decreases the acidity) by providing calcium, and in some cases magnesium, which in turn replaces hydrogen or other acidic ions on the exchange complex. With more calcium and magnesium, which are bases, and less hydrogen on the exchange complex, pH increases.

In the western United States and other limited rainfall areas of the world, soils tend to be neutral to alkaline. If the soil pH needs to be decreased (made less alkaline) and the soil is not sodic (to be discussed later), elemental sulfur (S) may be applied. Using sulfur to decrease the pH of the entire soil mass would be quite costly; hence, the economic benefits usually would be less than the returns. Where high pH due to calcium is a problem, the common practice is to apply sulfur or an acid-forming sulfur product into a small band or limited soil area.

The sulfur forms an acidic microenvironment in which nutrient availability may be greatly increased. In this way, a small amount of sulfur at a low cost can be beneficial for one season in counteracting the undesirable effects of high pH. The amount of sulfur required to effect this change in a microenvironment may range from 20 to 100 lb of sulfur per acre (22–110 kg/ha) if properly applied. Sulfur products most commonly used for this purpose are prilled sulfur (80–90% elemental S), ammonium thiosulfate (26% S), and ammonium polysulfide (45% S).

Nutrient Supply

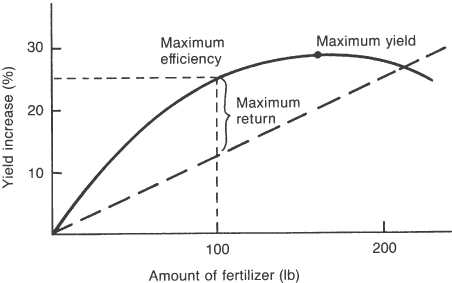

Keeping plant nutrients at adequate levels is important and proper nutrient balances need to be maintained to ensure that nutrient levels are adequate but not too high. Next to irrigation, this is probably the single most important soil management factor that can influence yield over which the producer has control. If too much of a nutrient is applied, not only is it an inefficient use of resources (Fig. 9.8) but it also may alter the balance of nutrients, adversely affect plant growth, and create a potential source of pollution. For a thorough discussion of nutrients and their application, see Chapter 8.

Figure 9.8 An illustration of how profit from fertilizer is maximized. In this hypothetical example, the most profitable rate of fertilization is 100 pounds per acre (about 110 kg/ha). Note that the maximum yield does not correspond to the most efficient rate of application.

Saline and Sodic Soils

Another important management practice is to reduce the effect of saline and sodic soils on plant growth. A saline soil is one in which soluble salts have accumulated in sufficient quantity to adversely affect growth. A sodic soil is one that contains too much sodium, which adversely affects yields. Remediation of saline and sodic soils may involve a combination of soil management practices.

Saline and sodic conditions may occur naturally, but most arise when irrigation water is applied that is too high in salt and/or sodium. Areas in the United States where these situations occur are mainly in the Southwest, from Texas to California. It is a potential hazard in any irrigated area in the world.

Irrigation waters can be chemically analyzed to determine whether salt and/or sodium are high enough to create problems if used. Chemical tests are highly desirable for any new irrigation project or in areas where the salinity of water might tend to change.

Soils that become saline show irregular growth of crops in a field and usually have a whitish cast from salt accumulation, with the greatest amount being in the tops of the beds (Fig. 9.9A). Saline soils are often called “white alkali” because they are light in color and have an alkaline soil reaction.

Figure 9.9 Saline soils (A) usually have “white caps” of salt in the tops of the beds. Growth of crops normally is spotted. Sodic soils (B) are usually dark colored (often called “black alkali”) and are gummy and slick when wet and cracked with a powdery surface when dry.

If saline conditions develop, leaching the soil with water with less salt is a common practice. The downward movement of water in the soil that occurs during leaching carries the salts below the root zone, where they cause less of a problem.

If a soil becomes sodic, it is highly dispersed and in very poor physical condition (see Soil Aggregation in Chapter 5). The soil feels slick and gummy when wet. When dry, the soil is dark, appears to be highly dispersed, and has cracks. Sodic soils are called “black alkali” because of their dark color and alkaline soil reaction (Fig. 9.9B). Sodic soils usually range in pH from 8.5 to 10.0.

To correct a sodic soil condition, a calcium-containing compound— specifically gypsum, which is calcium sulfate (CaSO4·2H2O)—would need to be applied. The calcium would replace the sodium which combines with the sulfate. Leaching with high-quality water is required to move the sodium sulfate downward and out of the root zone. The calcium then helps the soil to reaggregate and improve in physical condition. In some sodic soils, calcium may be present as calcium carbonate and, if so, only sulfur (an acid-forming type) is needed to correct the sodic situation. The general pH management considerations for the soils of the United States are summarized in Figure 9.10.

Figure 9.10 The generalized pH management considerations for soils of the United States. Region A soils are generally above pH 7.0-soils may be saline or sodic. In region B the acid-base relationships are commonly favorable, and in region C the bases have been leached so that lime and fertilizer are needed in high amounts.

Biological Characteristics

Life in the soil, or soil biology, was discussed in Chapter 4. One of the principal practices related to the biology of the soil is crop residue management. Crop residue decomposes to replenish soil organic matter, a process that has important and generally beneficial effects on soil biological activity. Other management practices affecting soil biology include the application of animal manure or other organic materials such as biosolids (wastewater treatment residuals) and cannery or processing plant byproducts. Physical or chemical conditions in the soil that adversely affect soil organisms (poor aeration or toxic levels of chemicals) should also be avoided.

Plant residue also serves as a source of energy for organisms that live in the soil. As crop residue decomposes, nutrients that plants require are released. Organic acids are formed that in turn may enhance the availability of certain plant nutrients and also aid in the breakdown of minerals in the soil.

After humus is formed, additional cation exchange capacity is present. Organic matter helps a soil retain more water. Water infiltration rates often increase with additional organic matter as a result of an improved aggregation of soil and enhanced structure. Soil temperature may also tend to be slightly higher because increased organic matter generally causes a soil to darken. Other benefits of increased organic matter include (1) reduced toxicity of certain pesticides, (2) increased buffering in the soil, and (3) a decreased effect of saline–sodic soil conditions.

Crop residue on the surface decreases the detrimental impact of raindrops and thereby decreases erosion caused by runoff water. Residue cover also decreases erosion by wind by slowing the wind near the soil surface. In winter, crop residue can trap and hold snow. As the snow melts, the water moves into the soil where it can be stored and absorbed by the crop later.

In areas of limited rainfall, this extra moisture may be critical for crop production. Surface residue also conserves moisture by keeping soil temperatures lower and decreasing the loss of water by evaporation.

Crop residue can have some potentially detrimental effects. It may harbor diseases that would appear the following year. Weed seeds may also be present and thus may germinate the next year. If the residue is low in nitrogen, which is normally the case with crops like corn and wheat, temporary nitrogen shortages may occur for the next crop to be grown in that soil.

Residue is often burned to avoid one or more of the above-perceived problems. It is undesirable to burn residue because certain nutrients contained in the residue will be lost to the atmosphere and must be replaced through increased fertilization. Burning crop residue is a common practice with rice (Fig. 9.11). In California, some rice straw is baled and injected with ammonia for animal feed.

Figure 9.11 For some crops such as rice, the straw remaining after harvest is so thick that burning may be the only practical way to manage it.

Crop Production Factors

Crop production is influenced by many factors; some can be controlled by the farmer and some cannot. These factors can be classified as (1) soil, (2) crop, (3) environmental practices, and (4) cultural practices.

The many facets of the soil are discussed throughout this book. Its physical, chemical, and biological characteristics should be maintained under optimum conditions for best crop growth.

The crop to be grown involves many management decisions. A crop needs to be adapted to the soil as well as to climatic conditions. Markets must also be considered. Choice of cropping system (whether to grow one crop continuously or to use a particular cropping sequence) is important. A cropping system may involve continuous corn in the Midwestern United States or a sequence of corn/soybeans every 2 years. In the Southwest, a cropping system may be continuous cotton or a sequence of cotton and some other crop such as grain sorghum or wheat.

Other management decisions on crops include which variety to plant. Some varieties are adapted for high-yielding potentials where fertility and moisture are adequate, whereas others are better adapted to low potential yield situations such as in dryland production areas. The plant population of most crops is important and needs to be maintained at an optimum level.

The environment is generally the most important aspect of crop production and often cannot be controlled or influenced. Length of growing season, altitude, day length, light energy, and rainfall are among conditions over which the farmer has no control. Even though rainfall cannot be changed, certain management practices can be used to conserve water. Contour rows, crop residue cover, furrow diking, and similar practices can be used to increase rainfall retention.

As one moves from the southern to the northern United States, the growing season shortens. Farmers need to plant annual row crops (corn and various bean types) as early as possible to get the highest yield. Therefore, it is very important that the soil temperature is warm enough for seed germination and growth. One way to manage this factor is to move the crop residue from within the row to the inter-row areas of the field. Row cleaners are wheels that travel at an angle to the planting direction and they gently move the residue from the row area to the inter-rows. Having bare soil in the row area allows the sunlight to dry (dry soil warms more quickly than wet soil) and warm the soil which greatly improves early season plant growth.

For some specialty crops, management practices can be used to modify the plant growth environment. For example, additional lighting can be used to control the growing season, day length, and light energy for greenhouse plants, but little can be done for most field-crop production. An exception would be tobacco grown under cheesecloth, for example, where the amount of light reaching the plant is reduced.

Using the right cultural practices at the right time (management) is important. Such decisions start after harvest and could include (1) whether to incorporate residue or leave it on the soil surface; (2) what tillage practices to use; (3) when to plant and how deep to plant; (4) the type and rate of fertilizer and how and when to apply; (5) the rate, time, and method of application of herbicides, insecticides, or fungicides for pest control; (6) when to apply irrigation water if it is available; (7) when to harvest; and (8) what marketing strategy to use. And the alternatives could go on and on. A producer makes many management decisions each year, with almost every decision being a critical one for yield and profit.

Conditions that could limit yield are numerous. A few are cited here as a checklist to determine why yields are less than the potential: (1) biological hazards such as weeds, diseases, or insects; (2) nonbiological hazards such as hail, excessive or insufficient rainfall, early or late frosts, or extreme temperatures; (3) inadequate plant populations; (4) imbalance of plant nutrients or improper nutrient application; (5) poor physical condition of soil; (6) soil pH that is too high or too low; or (7) improper variety (cultivar).